Sontay GL-CO-RFG65 Series User manual

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

Gas Leak Alarm Systems

Page 1 of 5

GL-CO-RFG65x

Issue: 5.4

Date Of Issue: 28/10/2008

© 2008 Sontay Limited. All rights reserved.

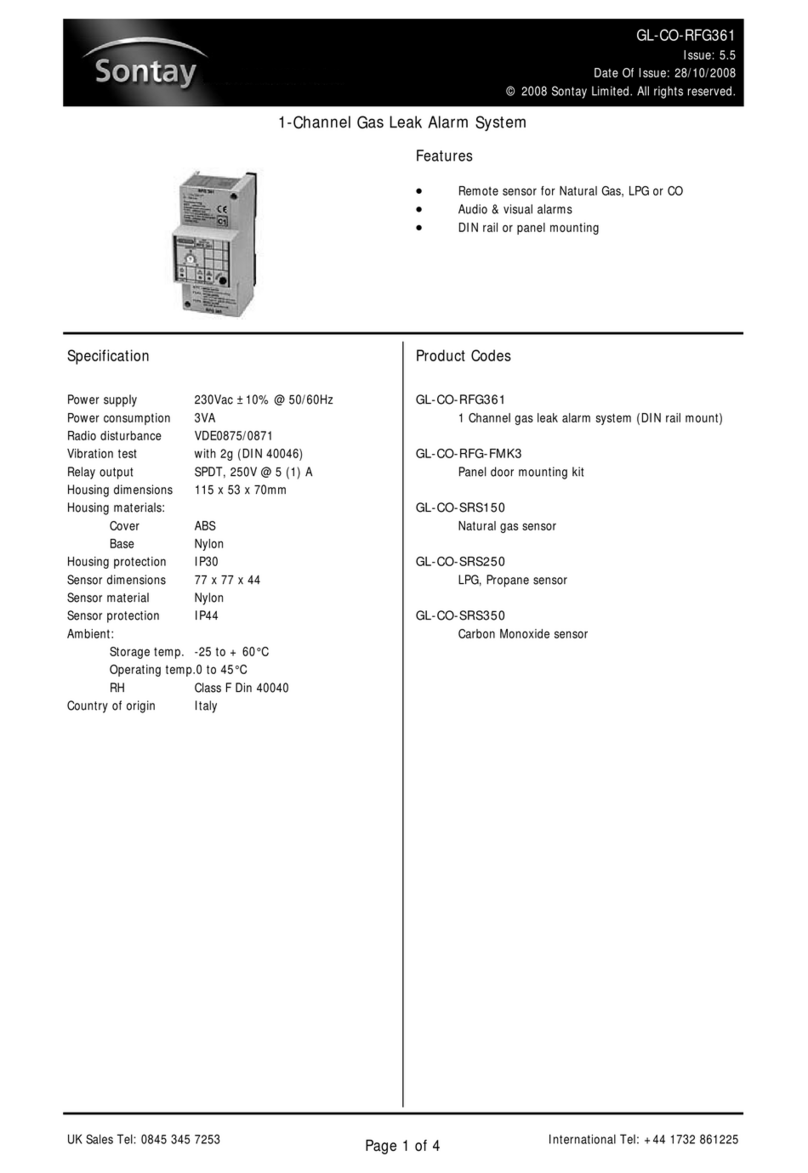

Features

Specification Product Codes

• Remote sensors for Natural Gas, LPG or CO

• Audio & visual alarms

• Adjustable alarm threshold

• Self-diagnosis fault system

• 2 x SPST relay outputs

• DIN rail, panel or wall mounting

Power supply:

230Vac ±10% @ 50/60Hz

12V ±10%

Power consumption 7VA

Radio disturbance VDE0875/0871

Vibration test with 2g (DIN 40046)

Relay outputs 2 x SPDT, 250V @ 5 (1) A

Housing dimensions 105 x 115 x 70mm

Housing materials:

Cover ABS

Base Nylon

Housing protection IP40

Panel mount housing dim.142 x 142 x 125mm

Sensor dimensions 77 x 77 x 44

Sensor material Nylon

Sensor protection IP44

Ambient:

Storage temp. -25 to + 60°C

Operating temp.0 to 45°C

RH Class F Din 40040

Country of origin Italy

GL-CO-RFG651

1 Channel gas leak alarm system (DIN rail mount)

GL-CO-RFG652

2 Channel gas leak alarm system (DIN rail mount)

GL-CO-RFG653

3 Channel gas leak alarm system (DIN rail mount)

GL-CO-WMK6

Wall mounting kit

GL-CO-FMK6

Panel mounting kit

GL-CO-SRS150

Natural gas sensor

GL-CO-SRS250

LPG, Propane sensor

GL-CO-SRS350

Carbon Monoxide sensor

Page 2 of 5

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

GL-CO-RFG65x

Issue: 5.4

Date Of Issue: 28/10/2008

© 2008 Sontay Limited. All rights reserved.

Technical Overview Links

The CL-CO-RFG65x is a series of gas leak alarm systems,

that are designed for the detection of gas leaks in spaces

such as boiler plant rooms, workshops and other industrial

gas installations, to provide safety alarm and shutdown

facilities on detection of gas leakage. 1, 2 or 3 channel ver-

sions are available.

Installation

1. The GL-CO-RFG65x should only be installed by a compe-

tent, suitably trained technician, experienced in installa-

tion with hazardous voltages. (>50Vac & <1000Vac or

>75Vdc & 1500Vdc)

2. Ensure that all power is disconnected before carrying out

any work on the GL-CO-RFG365x.

3. Maximum cable is 2.5mm², care must be taken not to

over tighten terminals.

4. Separate the base from the cover.

5. If DIN rail mounting clip onto the DIN rail.

6. Make connections as required (see page 4 & 5 for

examples) and links as appropriate (see below). NB It is

advised that no more than 2 cables be inserted into a

single terminal. Use external junction boxes if necessary.

7. Replace the cover on the base using the 4 screws pro-

vided, if panel mounting fix to panel door, using the

panel mounting kit.

Panel Mount Cut-Out

Panel cutout: 138 x 138 ±0.5%

Link Functions:

M - F1

No link = Internal buzzer enabled

Linked = Internal buzzer disabled

F2 - F3

No link = Relay normally energised when no gas present

Linked = Relay normally de-energised when no gas present

F3 - F4

No link = Relay with latching alarm

Linked = Relay with non-latching alarm

B2 - H2

Linked = B2 sensor not connected

B3 - H3

Linked = B3 sensor not connected

Operational Relay Output:

When in alarm:

F2 - F3 linked 1 - 3 closes, 2 - 3 opens

F2 - F3 unlinked 1 - 3 opens, 2 - 3 closes

Latching alarm and Reset:

F3 - F4 linked:

Alarm ceases when the gas concentration falls below the

threshold level and the ALARM LED blinks slowly. Press the

RESET button to clear the LED status.

F3 - F4 unlinked:

Alarm continues even when the gas concentration falls be-

low the threshold level. To deactivate press the RESET but-

ton for at least 5 seconds.

Alarm Levels

Alarm thresholds

Natural gas alarm threshold:

0.5% to 1.25% (0.8% with sensitivity =0)

(5000 to 12,500ppm)

LPG alarm threshold:

0.22% to 0.56% (0.35% with sensitivity =0)

(2200 to 5600ppm)

CO alarm threshold:

0.02% to 0.5% (0.03% with sensitivity =0)

(200 to 500ppm)

Page 3 of 5

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

GL-CO-RFG65x

Issue: 5.4

Date Of Issue: 28/10/2008

© 2008 Sontay Limited. All rights reserved.

Alarm Levels (continued) Self Diagnostics

Pre-Alarm thresholds

Natural gas pre-alarm threshold:

0.3% to 0.8% (0.5% with sensitivity =0)

(3000 to 8000ppm)

LPG pre-alarm threshold:

0.14% to 0.35% (0.22% with sensitivity =0)

(1400 to 3500ppm)

CO pre-alarm threshold:

0.012% to 0.03% (0.019% with sensitivity =0)

(120 to 300ppm)

The alarm threshold for Natural Gas is about 16% of the

LEL. This is below the limit set by the manufacturing stan-

dards (20% LEL). The pre-alarm threshold is about 66.6%

of the alarm threshold. Using the SENSITIVITY pot the

thresholds can be adjusted within the limits established the

manufacturing standards. Turning the pot towards + in-

creases the sensitivity and turning towards - decreases the

sensitivity.

Sensor Location

Natural gas 100 to 500mm from the ceiling

LPG 100 to 500mm from the floor

CO 1.5 to 2m from the floor

It is advisable to position sensors at a certain distance from

gas appliances, so as to avoid nuisance triggering.

Boilers & DHW 1 to 2 meters

Gas cookers 2 to 3 meters

Cable types

Power & relay 1.5mm²

Sensor up to 40m 1.5mm²

Sensor up to 60m 2.5mm²

Operation

When the controller is switched on it remains inactive for 1.5

to 2 minutes with the FAULT and ALARM LEDs flashing, to

allow the sensor to stabilise.

When the gas concentration exceeds the pre-alarm thresh-

old the ALARM LED blinks.

When the gas concentration exceeds the alarm threshold,

after a delay of about 20 seconds:

• The internal buzzer will sound (if enabled)

• The ALARM LED switches ON

• Activates the operational control

Self diagnostics

In the event of a fault or incorrect connection of the sensor

the following LED states will occur:

Commissioning

Apply power to controller - POWER LED lights.

Wait 2 minutes for sensor to stabilise.

Set SENSITIVITY pot to ‘0’

Simulate presence of gas (gas from a lighter should work).

When the alarm threshold is reached, after a 20 second

delay the ALARM LED will light, the buzzer will sound (if

enabled) and the relay operate.

Without latching alarm - buzzer ceases, ALARM LED

blinks slowly

With latching alarm - buzzer continues until RESET button

is pressed for at least 5 seconds.

Gas shut off valve

This must be installed on the gas feed pipe, possibly outside

the space controlled, in a place which is easily accessible

and is protected from bad weather.

NB In LPG installations the valve must be installed down-

stream of the pressure reducing valve.

Type of Fault Fault LED Alarm LED

Sensor self-heating element broken ON OFF

No connection to terminal G ON OFF

No connection to terminal B ON OFF

No connection to terminal M OFF ON

Connections G & B reversed ON OFF

Connections G & M reversed OFF ON

Connections B & M reversed OFF ON

Page 4 of 5

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

GL-CO-RFG65x

Issue: 5.4

Date Of Issue: 28/10/2008

© 2008 Sontay Limited. All rights reserved.

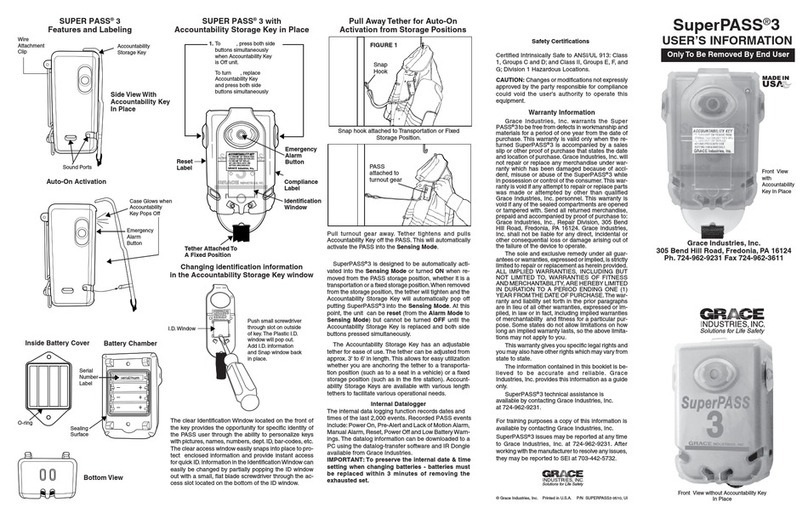

Front Panels Example Connections

1 Sensitivity potentiometer

2 Power supply LED

3 Fault LED

4 Alarm LED

5 Reset button

Dimensions

Basic operation:

GL-CO-RFG652, 230Vac Supply:

Whilst every effort has been made to ensure the accuracy of this specification, Sontay cannot accept responsibility for damage, injury, loss or

expense resulting from errors or omissions. In the interest of technical improvement, this specification may be altered without notice.

Page 5 of 5

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

For the latest information and product updates, register at www.sontay.com

GL-CO-RFG65x

Issue: 5.4

Date Of Issue: 28/10/2008

© 2008 Sontay Limited. All rights reserved.

Example Connections (continued)

GL-CO-RFG653, 230Vac Supply:

GL-CO-RFG653, 12V Supply:

This manual suits for next models

7

Table of contents

Other Sontay Security System manuals

Popular Security System manuals by other brands

M-system

M-system AS4LC instruction manual

Ksenia

Ksenia Imago WLS installation manual

Emerald

Emerald BMW09 Specification & installation guide

Industrial Scientific

Industrial Scientific iAssign Startup guide

Panasonic

Panasonic External Presentation unit 1728 Technical description

Eden

Eden INSIDE SOLO technical information