SectionTitle Page

1. SAFETY NOTES

1-1. Warningsand Caution………………………………………………………. 5

1-2. Caution Handling of LCD Panel ......…………….................................... 5

1-3. SafetyCheck Out ........................……………......................................... 6

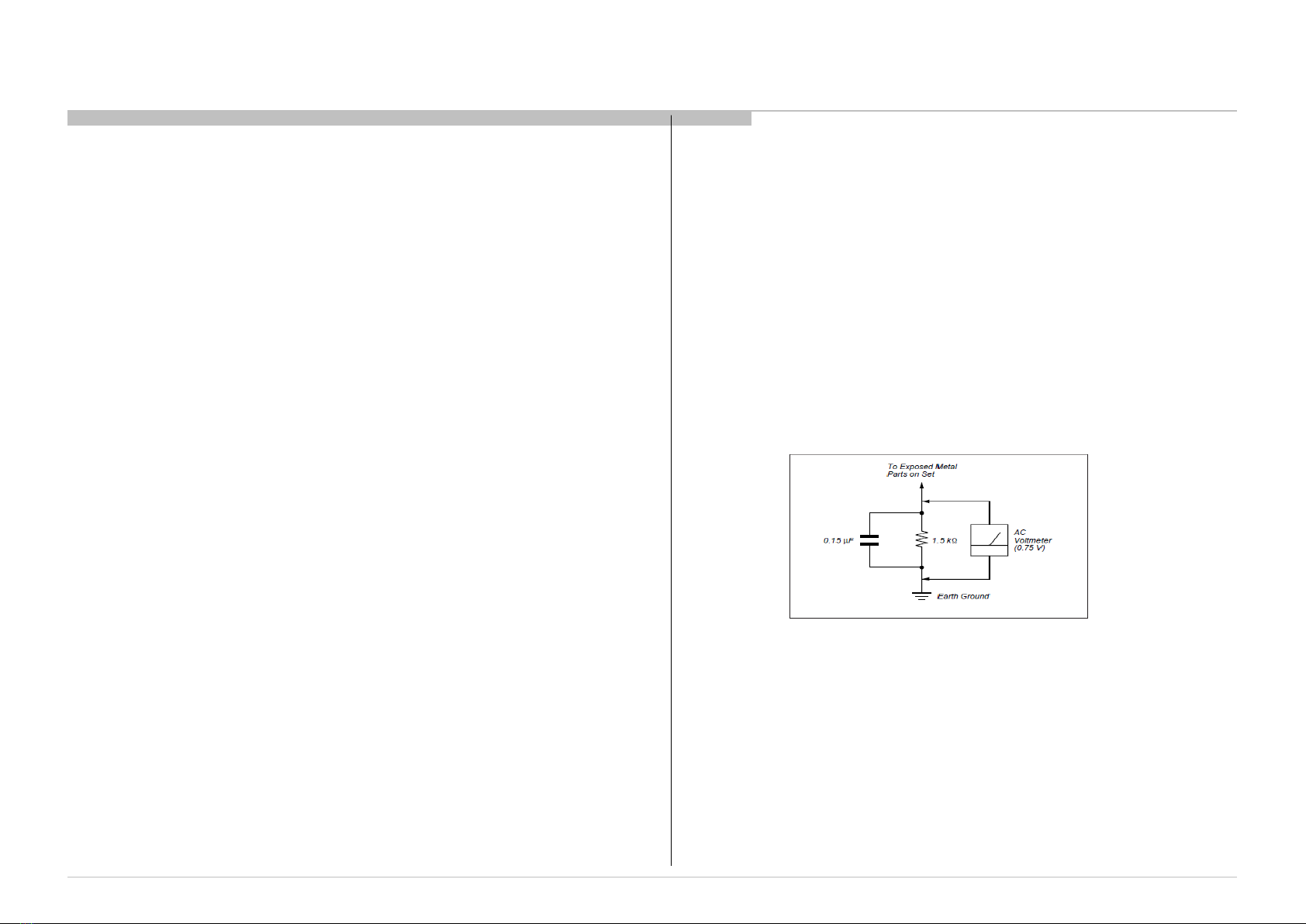

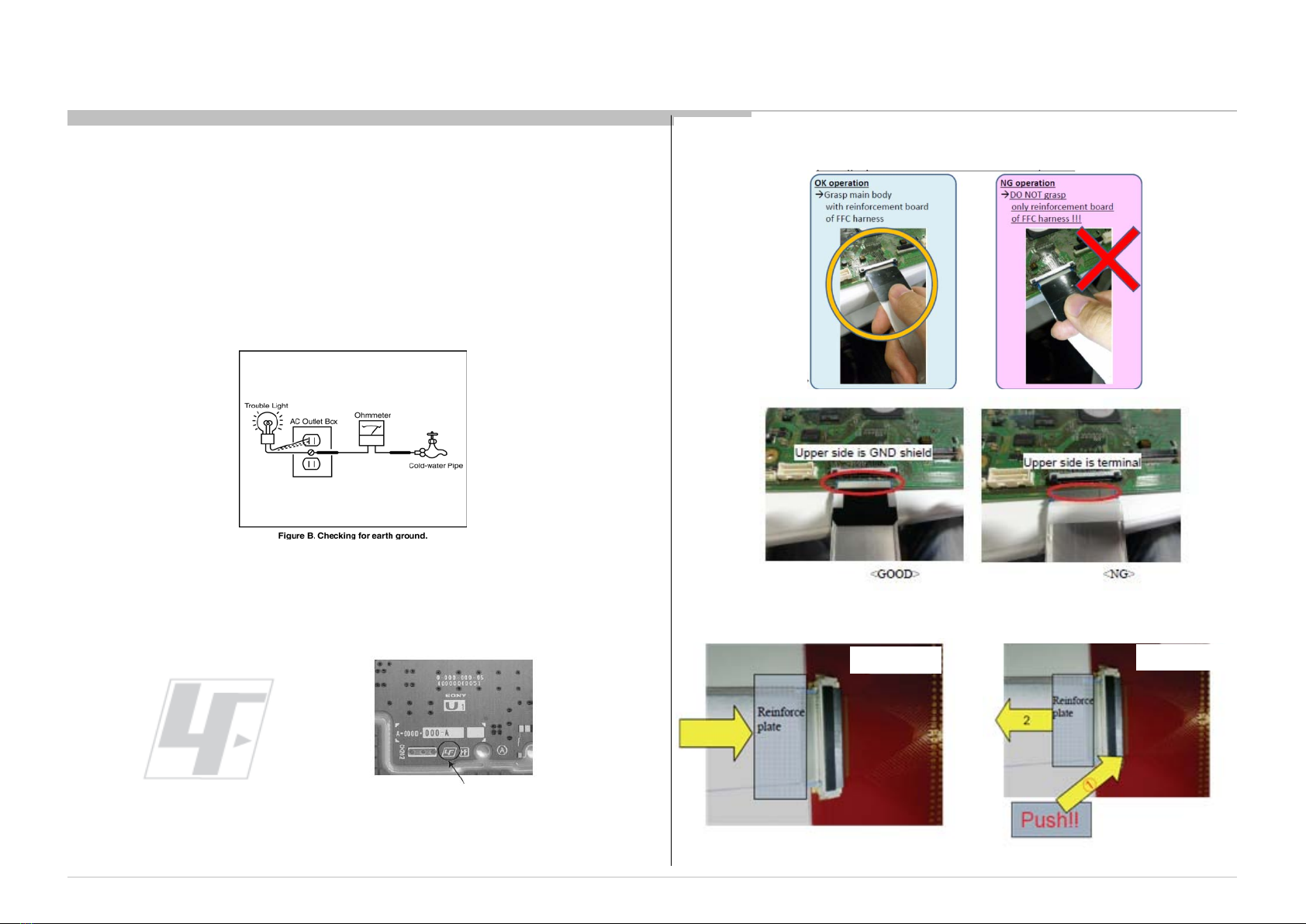

1-4. Leakage Test .......................................................................................... 6

1-5. How to Find a Good Earth Ground………………………………………… 7

1-6. Lead Free Information….…………………………………………………… 7

1-7. Handling the FlexibleFlat Cable (FFC)……………………………………. 7

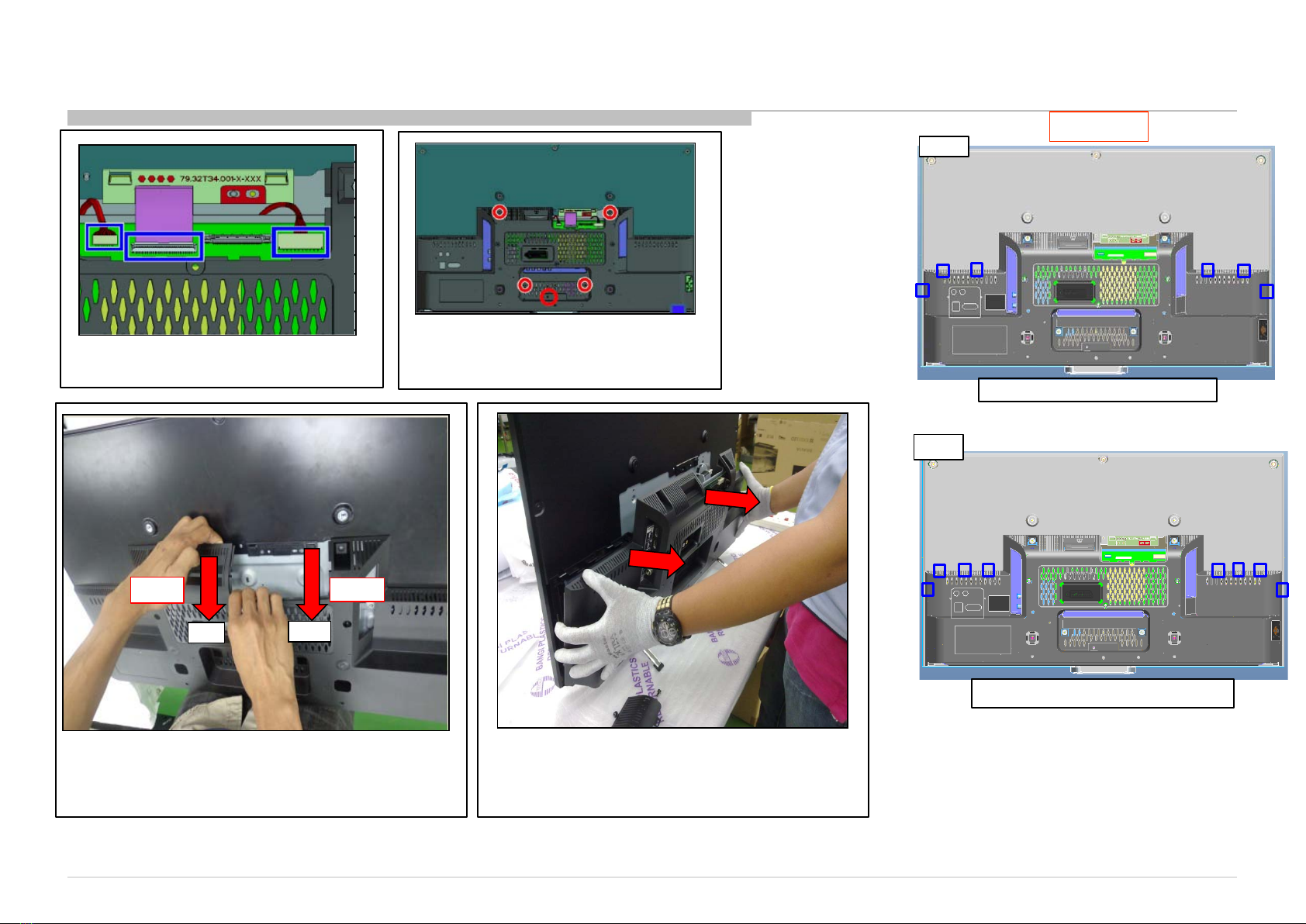

1-8. Method to Disassemble Bracket Top & Chassis Box…………………….. 8

1-9. Method to handle Chassis Box……………………………........................ 10

1-10. Instruction about Disassembling Smart Core……………………………... 11

2. SELF DIAGNOSTICFUNCTION

2-1. Overviewof Control Buttons ................................................................... 14

2-2. LED Display Control ………..................................................................... 15

2-3. LED Pattern………………........................................................................ 15

2-4. Standby LED Error Display…………………………………………………. 15

2-5. Triage Chart ............................................................................................ 16

3. TROUBLE SHOOTING

3-1. No Power…….……………………………………………………………….. 17

3-2. LED Blinking……………….………………………………………............... 33

3-3. No Sound……………………………......................................................... 62

3-4. Analog Signal Path.................................................................................. 116

3-5. No Picture................................................................................................. 117

3-6. Input Skip Function……………………………………………………. 203

3-7. SideButtons Malfunction……………………………………………………. 204

3-8. IR Remote Commander Malfunction………………………………………. 205

3-9. Light Sensor Error…………………………………………………………… 206

3-10. Network Malfunction:Ethernet (Wired)……………………………………. 207

3-11. Wireless Network Malfunction……………………………………………. 211

3-12. BluetoothMalfunction…………………………………………………. 213

3-13. 3D Glasses (Active)Malfunction…………………………………………… 214

3-14. HD Rec Malfunction……………………………………………………….. 215

3-15. Android Application Malfunction…………………………………………… 215

4

TABLE OF CONTENTS

Please refer ServiceManual – Unique for below information:

-SafetyWarnings

-WireDressing

-Circuit Board Location

-Disassembly and ExplodedView.

Section Title Page

4. SERVICE ADJUSTMENTS

4-1. Accessing Service Mode

.....................................................................

216

4-2. Transition of Each Micro’s ServiceMode……….………………………

216

4-3.

Change Data by ServiceMode 1…………………………………..…….

216

4-4. SaveChanging Data by Service Mode 1……………………………… 216

4-5. Change Data by ServiceMode 2……………………………………….. 217

4-6. SaveChanging Data by ServiceMode 2……………………………… 218

4-7. Restore WB/GammaAdj. Data to B Board……………………………..

219

4-8. WB Adjustmentby ServiceMode………………………………………..

219

4-9. VCOM Adjustment (NFR-AUO Panel) ………………………………….

220

4-10. VCOM Adjustment (HFR-SDC Panel) ………………………………….

221

4-11. REC Setting………………………………………...................................

221

4-12. Reset Panel OperationTime……………………………………….........

222

4-13. Set to Shipping Condition………………………………………..............

222

4-14. Summary of Service Control

………………………………………..........

222

4-15. ServiceMenu Tree………………………………………........................

223

4-16. How to Enter Self Diagnosis Display

224

4-17. Updatingthe software……………………………………………………. 226

4-18. Non network function…………………………………………………….. 226

4-17. One Step Touch Key function (not applicable for this model………… 228

5. DIAGRAMS

5-1. Circuit Board Location

.........................................................................

229

5-2. Block Diagram......................................................................................

230

5-3. Connector Diagram ………………………………………......................

237

RB1G CHASSIS

W600A/ W603A/ W605A/ W607A/ W650A/ W651A/ W653A/

W654A/ W655A/ W656A/W657A/ W658A/ W670A/ W674A