Sony MDR-EX1000 User manual

Other Sony Headphones manuals

Sony

Sony MDR-IF0140 User manual

Sony

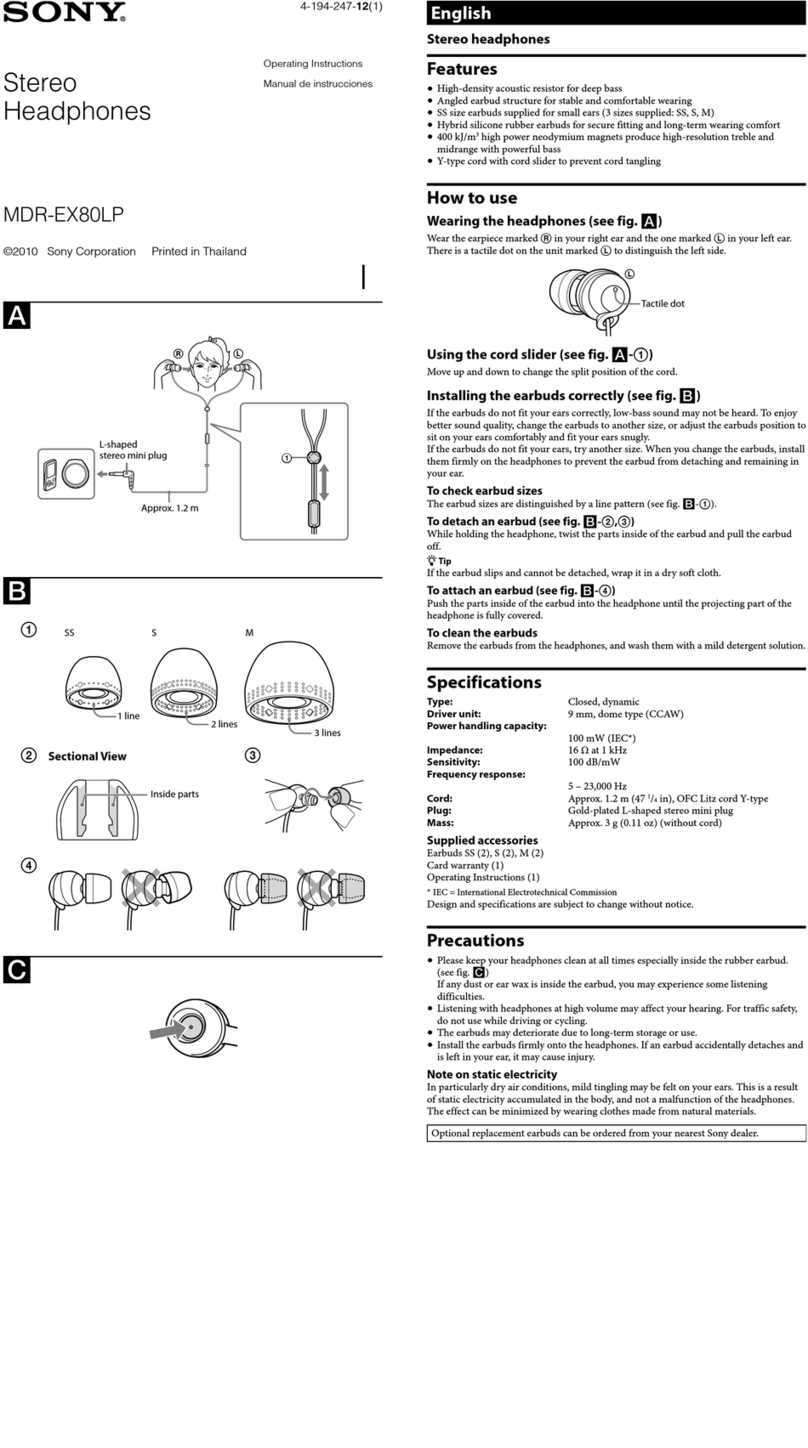

Sony MDR-EX80 User manual

Sony

Sony MDR-E9LP/VLT User manual

Sony

Sony MDR-AS50G Marketing User manual

Sony

Sony MDR-NC05 User manual

Sony

Sony MDR-NC40 Marketing User manual

Sony

Sony DIGITAL NOISE CANCELING HEADPHONES... User manual

Sony

Sony MDR-IF240RK - Headphones - Binaural User manual

Sony

Sony XBA-1VP User manual

Sony

Sony MDR-1ADAC Guide

Sony

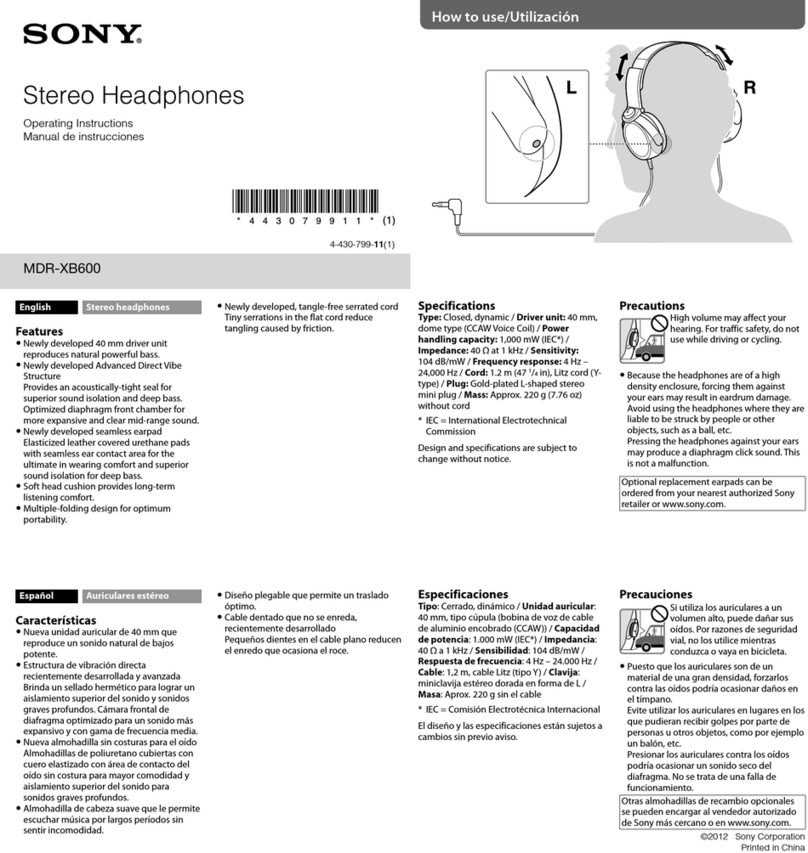

Sony MDR-XB600 User manual

Sony

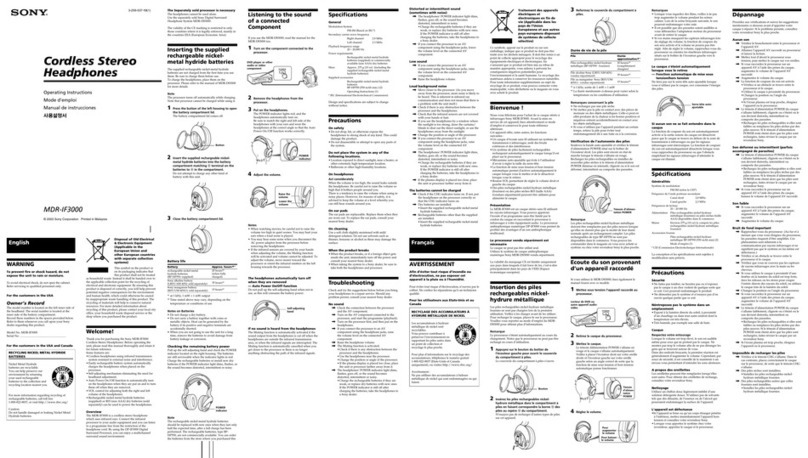

Sony MDR-IF3000 User manual

Sony

Sony MDR-IF120 User manual

Sony

Sony MDR-XB20EX User manual

Sony

Sony Walkman NW-WS623 User manual

Sony

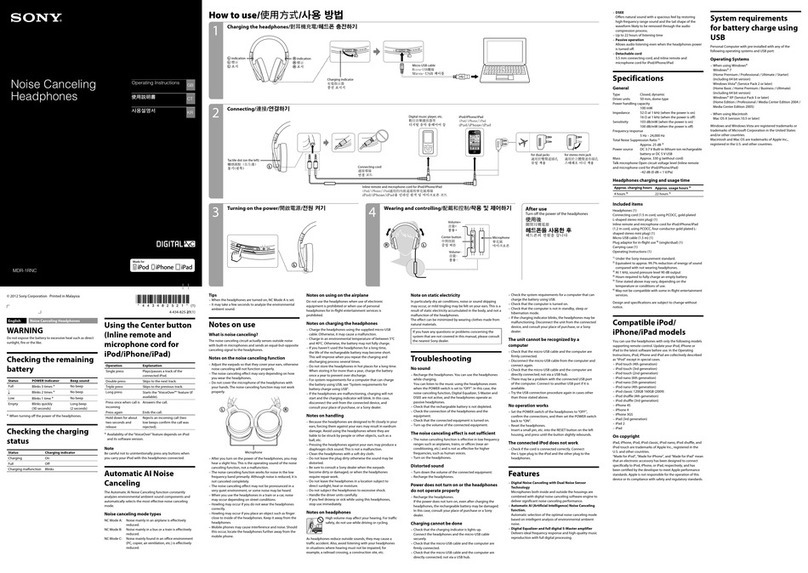

Sony MDR-1RNC User manual

Sony

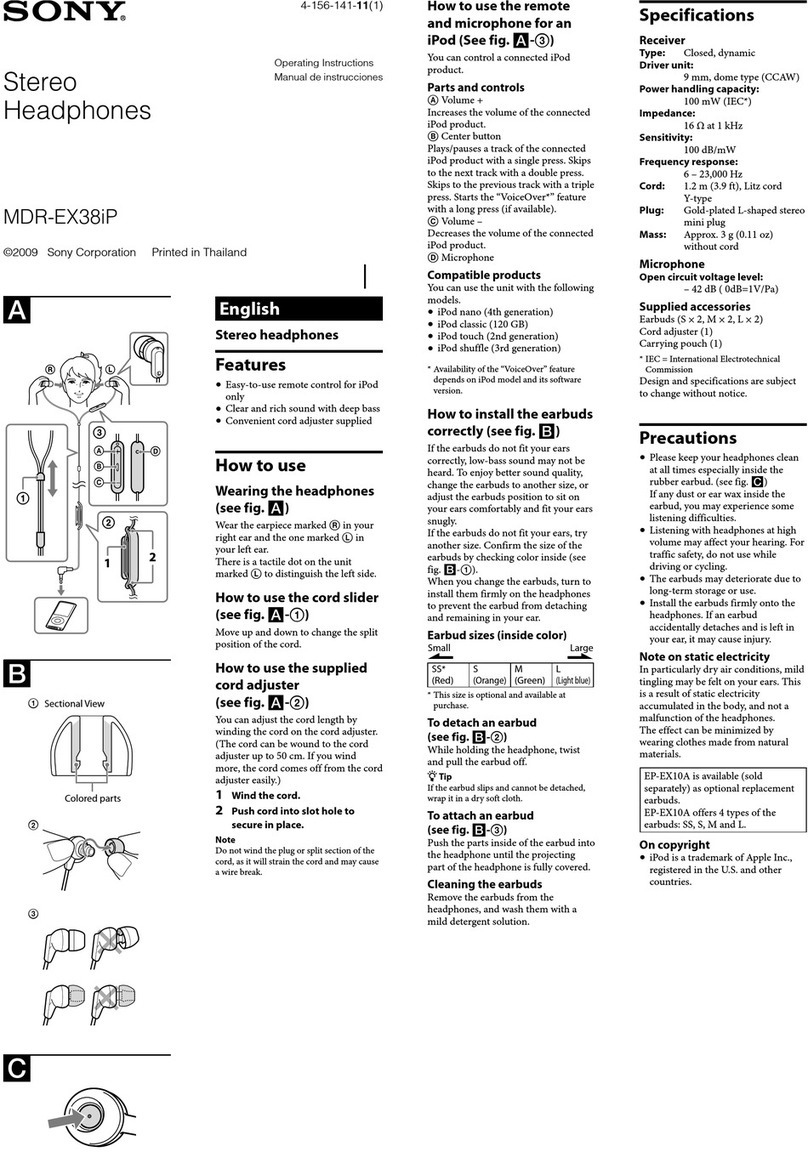

Sony MDR-EX38iP User manual

Sony

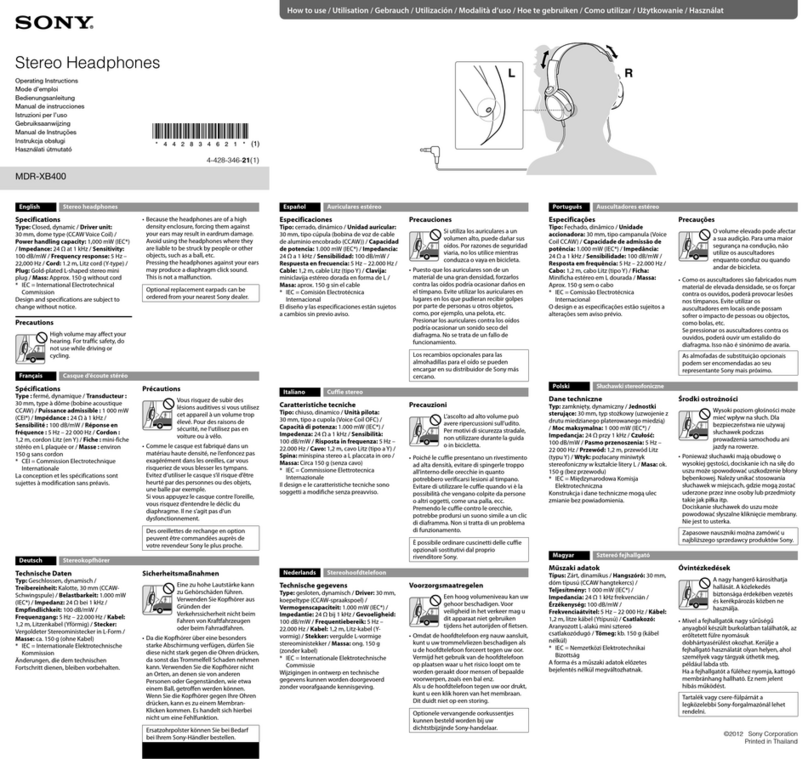

Sony MDR-XB400 User manual

Sony

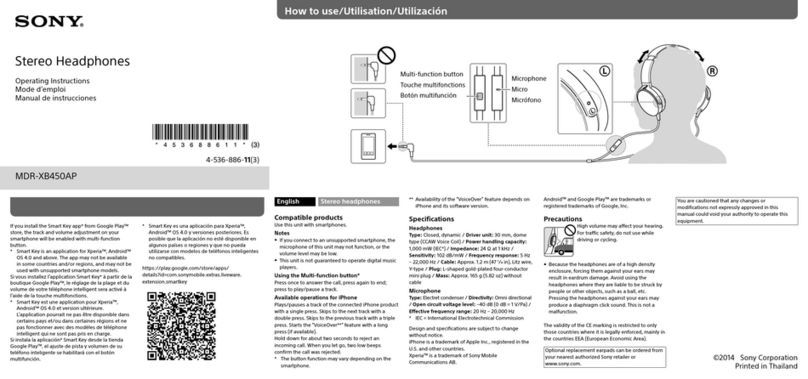

Sony MDR-XB450AP User manual

Sony

Sony MDR-NC7 User manual