3

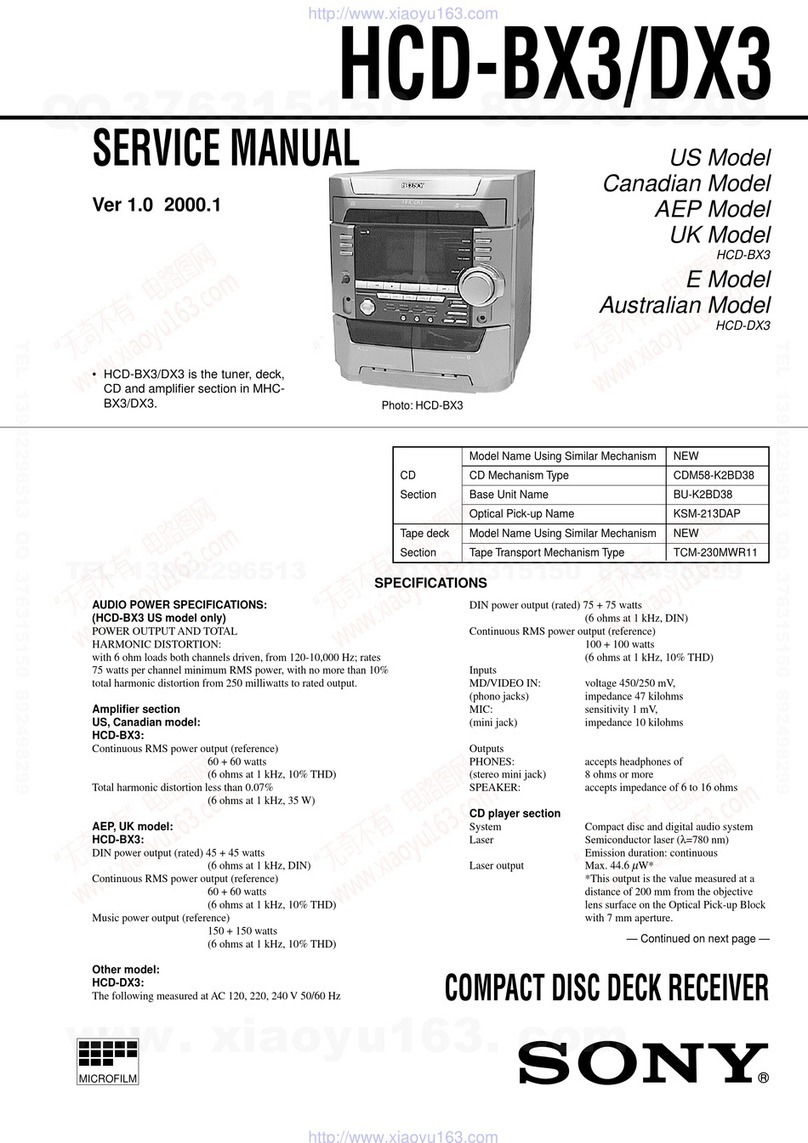

HCD-GX8000/RG77

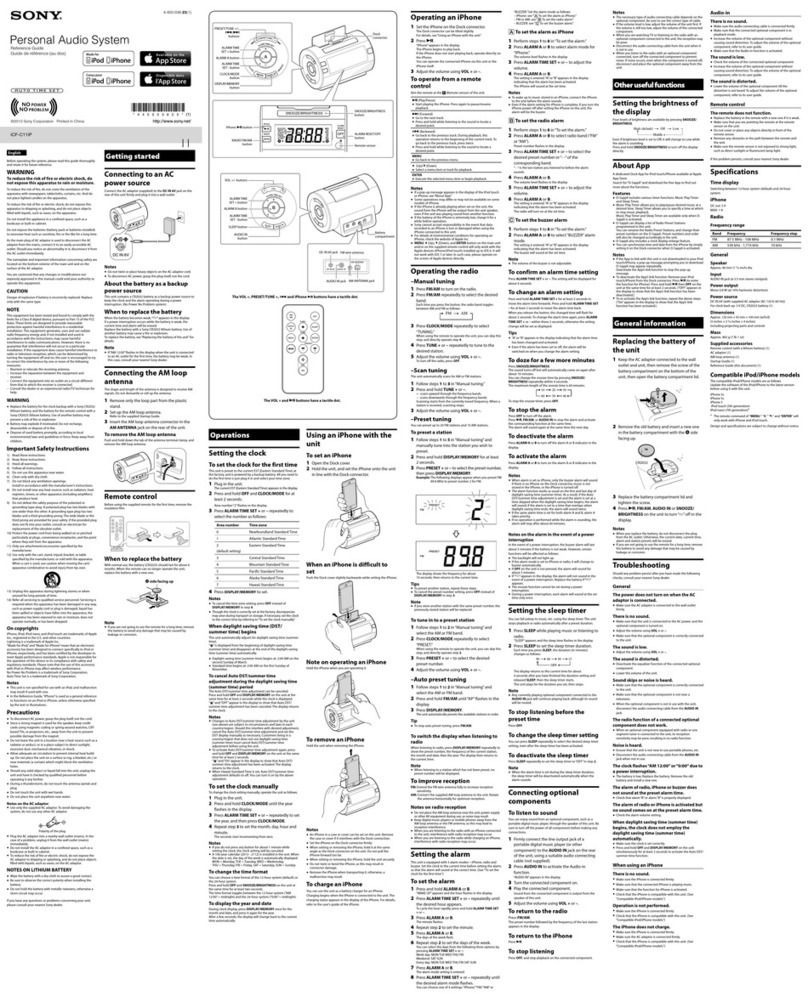

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 4

2. GENERAL

Location of Controls ....................................................... 5

Setting the Clock............................................................. 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Top Case .......................................................................... 8

3-3. Loading Panel.................................................................. 8

3-4. CD Mechanism Deck (CDM58E-30BD60C)................. 9

3-5. Front Panel Section ......................................................... 9

3-6. Back Panel Section.......................................................... 10

3-7. MAIN Board ................................................................... 10

3-8. Base Unit (BU-30BD60C) .............................................. 11

3-9. DRIVER Board, MOTOR Board and

SENSOR (CD) Board ..................................................... 11

3-10. Tape Mechanism Deck (TCM-230AWR41CS).............. 12

3-11. Belt .................................................................................. 12

3-12. SW Board, HEAD (A) Board and HEAD (B) Board..... 13

4. TEST MODE.............................................................. 14

5. MECHANICAL ADJUSTMENTS....................... 18

6. ELECTRICAL ADJUSTMENTS

Deck section .................................................................... 18

CD Section ...................................................................... 21

7. DIAGRAMS

7-1. Block Diagram –CD SERVO Section –....................... 23

7-2. Block Diagram –TUNER/TAPE DECK Section –...... 24

7-3. Block Diagram –MAIN Section –................................ 25

7-4. Block Diagram –DISPLAY/KEY CONTROL/

POWER SUPPLY Section –........................................... 26

7-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 27

7-6. Printed Wiring Board –BD Board –............................. 28

7-7. Schematic Diagram –BD Board –................................ 29

7-8. Printed Wiring Boards

–DRIVER/MOTOR/SENSOR (CD) Boards –.............. 30

7-9. Schematic Diagram

–DRIVER/MOTOR/SENSOR (CD) Boards –.............. 30

7-10. Printed Wiring Boards

–SW/HEAD (A)/HEAD (B) Boards –.......................... 31

7-11. Schematic Diagram –SW Board –................................ 32

7-12. Printed Wiring Board –MAIN Board –........................ 33

7-13. Schematic Diagram –MAIN Board (1/4) –.................. 34

7-14. Schematic Diagram –MAIN Board (2/4) –.................. 35

7-15. Schematic Diagram

–MAIN (3/4)/HEAD (A)/HEAD (B) Boards –............. 36

7-16. Schematic Diagram –MAIN Board (4/4) –.................. 37

7-17. Printed Wiring Board –GAME IN Board –.................. 38

7-18. Schematic Diagram –GAME IN Board –..................... 39

7-19. Printed Wiring Boards

–POWER/SENSOR Boards –........................................ 40

7-20. Schematic Diagram –POWER/SENSOR Boards –..... 41

7-21. Printed Wiring Boards

–PANEL/CD OPEN/CD SWITCH Boards –................ 42

7-22. Schematic Diagram

–PANEL/CD OPEN/CD SWITCH Boards –................ 43

7-23. Printed Wiring Boards

–PAD SWITCH/VOL Boards –..................................... 44

7-24. Schematic Diagram –PAD SWITCH/VOL Boards –... 45

7-25. Printed Wiring Boards

–MAIN TRANS/SUB-TRANS Boards –...................... 46

7-26. Schematic Diagram

–MAIN TRANS/SUB-TRANS Boards –...................... 47

7-27. IC Pin Function Description ........................................... 49

8. EXPLODED VIEWS

8-1. Panel Section ................................................................... 53

8-2. Front Panel Section ......................................................... 54

8-3. Chassis Section ............................................................... 55

8-4. CD Mechanism Deck Section (CDM58E-30BD60C) ... 56

8-5. Base Unit Section (BU-30BD60C)................................. 57

8-6. Tape Mechanism Deck Section

(TCM-230AWR41CS) .................................................... 58

9. ELECTRICAL PARTS LIST ............................... 59

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com