– 6 –

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

The laser diode in the optical pick-up block may suffer electro-

static break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emis-

sion, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY A !MARK ONTHE SCHEMATIC

DIAGRAMS, EXPLODED VIEWS AND INTHE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESE COMPO-

NENTSWITH SONY PARTS WHOSE PART NUMBERS APPEAR

AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUB-

LISHED BY SONY.

ATTENTION AUX COMPOSANTS RELATIFS ÀLA

SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE !SUR LES

SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES

LISTES DE PIECES

SONT D'UNE IMPORTANCE CRITIQUE POUR LA SÉCURITÉ DU

FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMÉRO DE PIÉCE EST

INDIQUÉ DANS LE PRÉSENT MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

Note:

Be sure to connect all wires (including FFC) in the MD

section before applying power or ICs may be damaged.

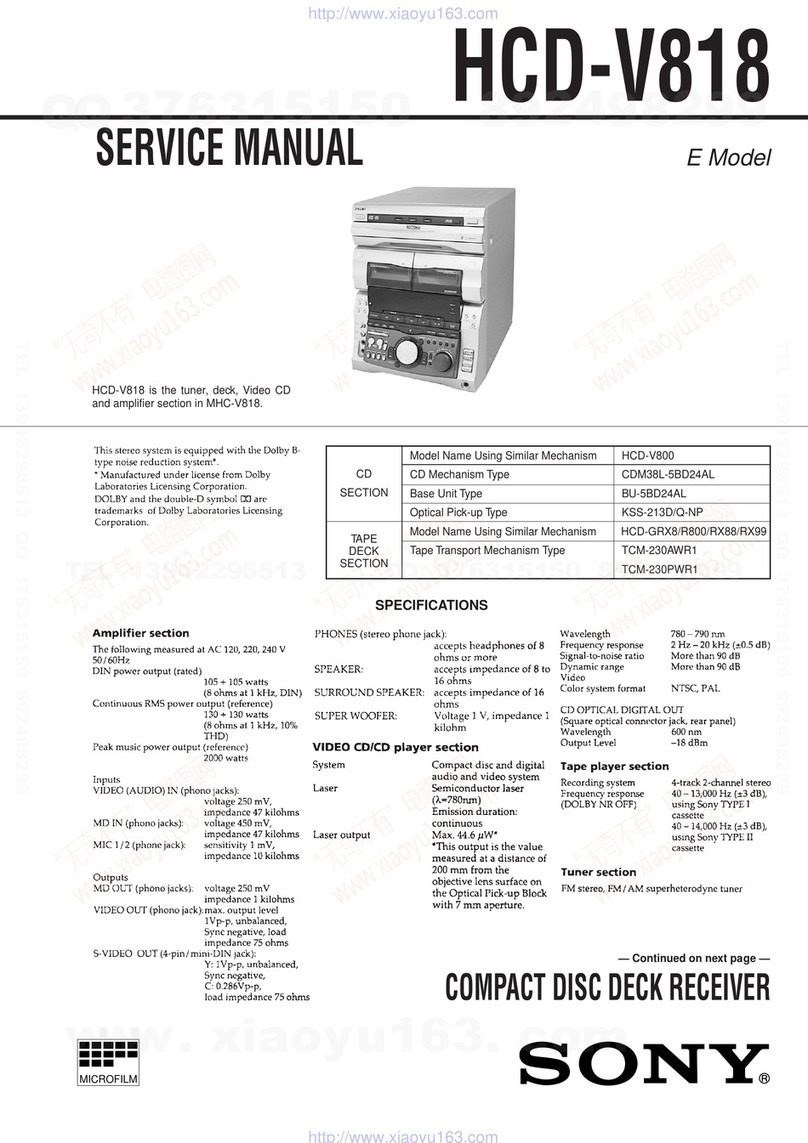

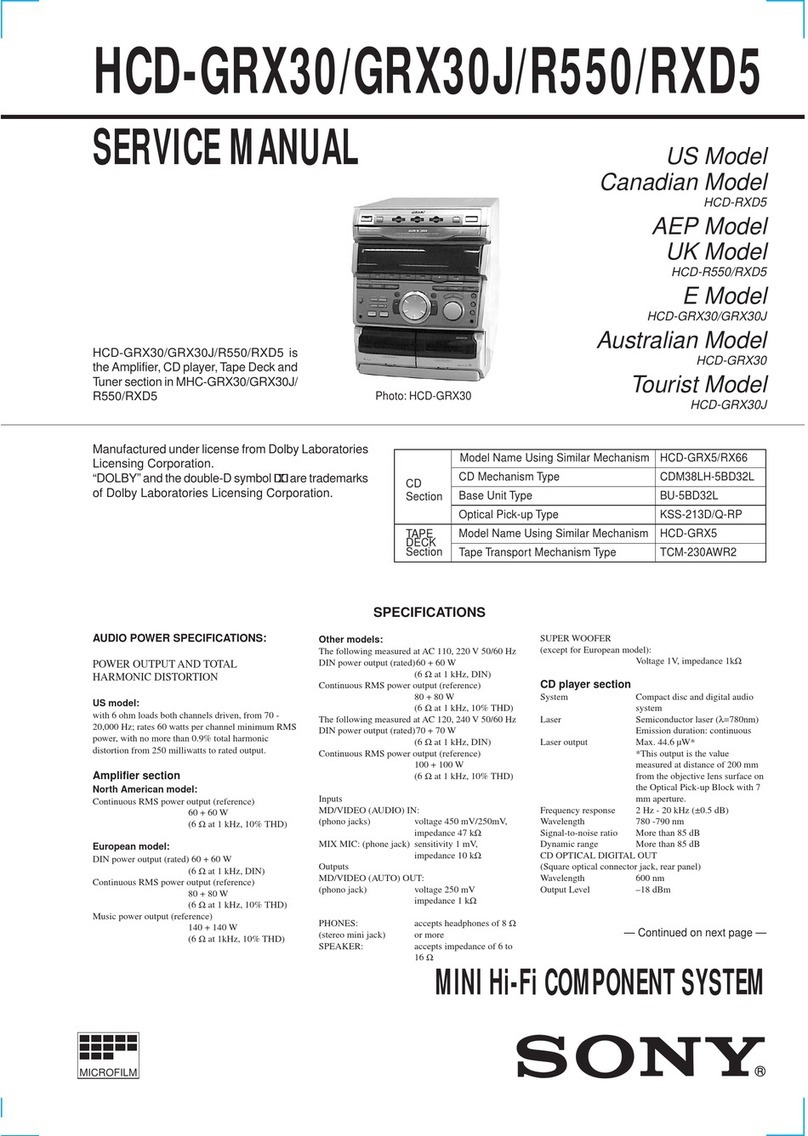

SECTION 1

SERVICING NOTES