3

TABLE OF CONTENTS

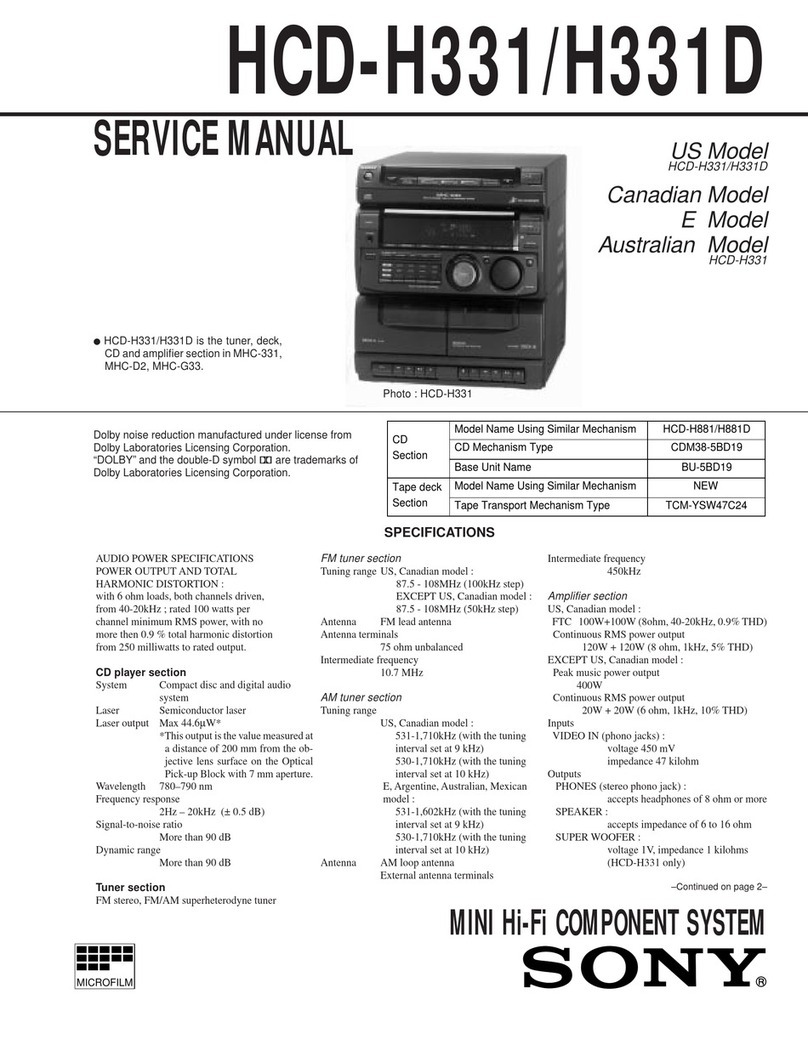

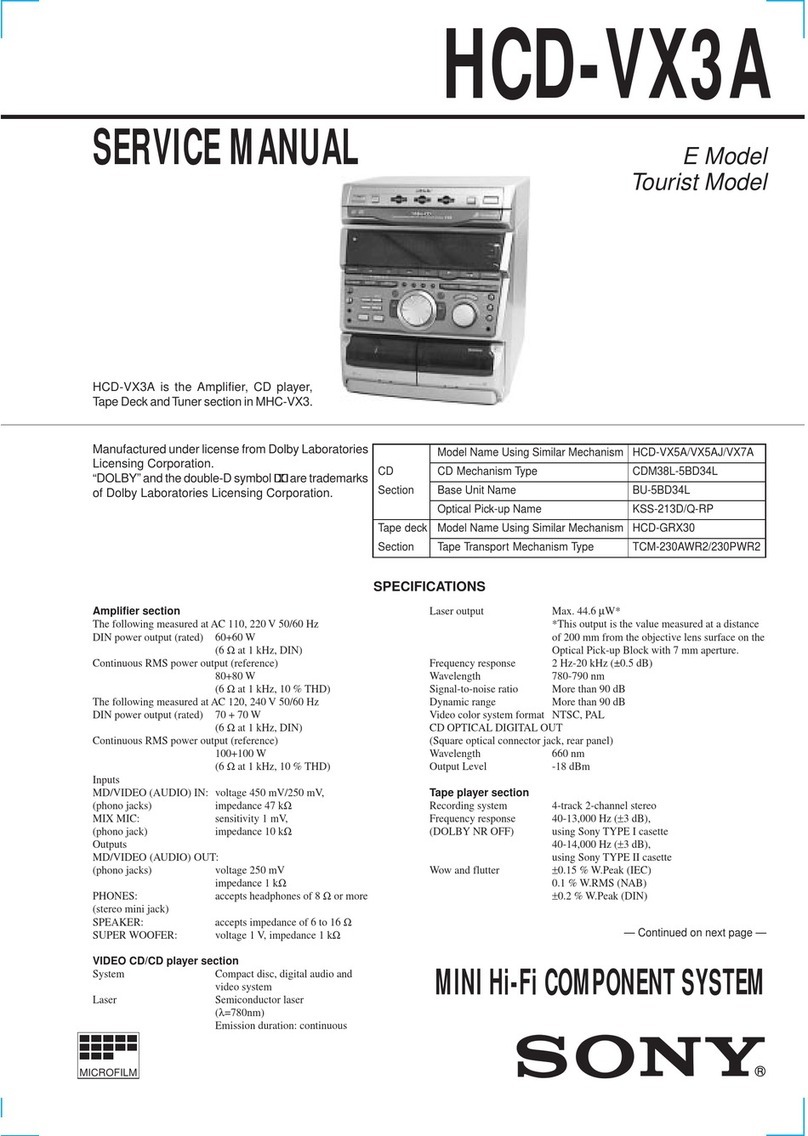

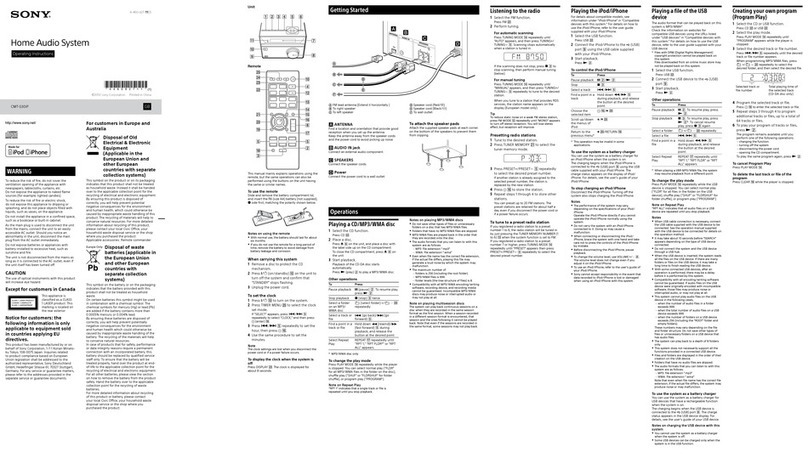

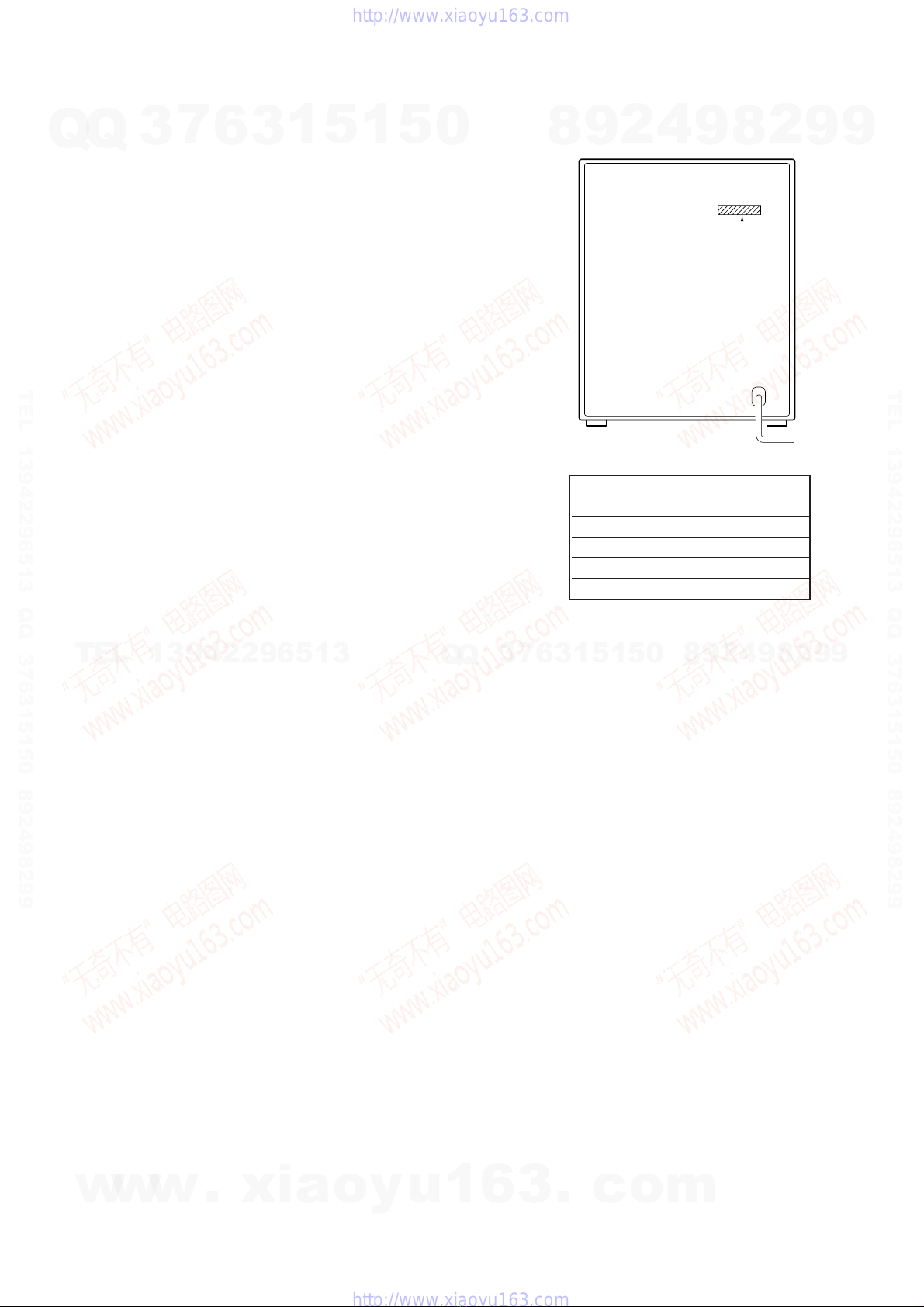

MODEL IDENTIFICATION

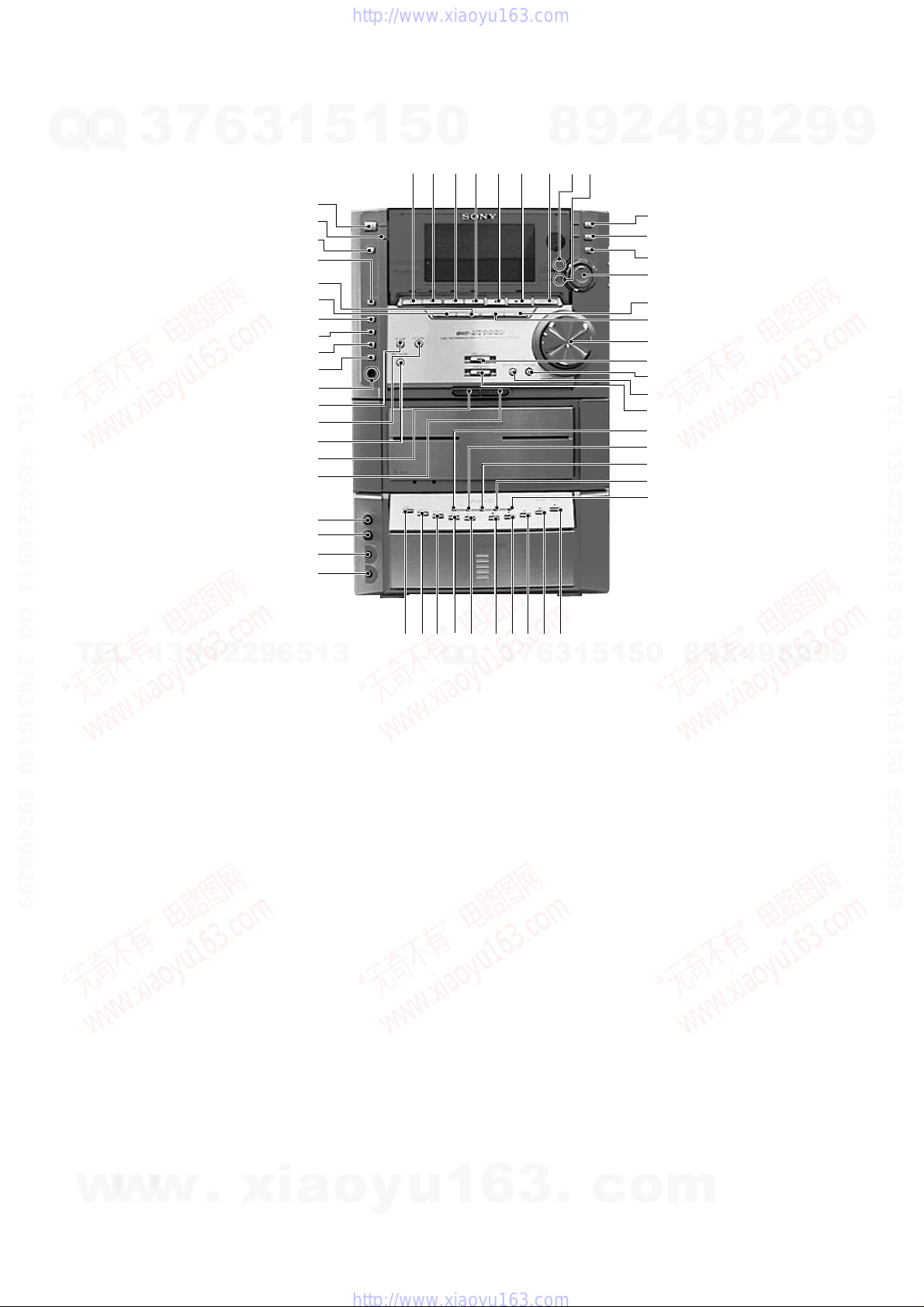

— BACK PANEL —

Parts No.

•Abbreviation

EA : Saudi Arabia model.

SP : Singapore model.

MY : Malaysia model.

TH : Thai model.

HK : Hong Kong model.

CH : Chinese model.

PARTS No.

4-227-555-0s

4-227-555-1s

4-227-555-2s

4-227-555-3s

4-227-555-4s

MODEL

EA

MY, SP

HK

TH

CH

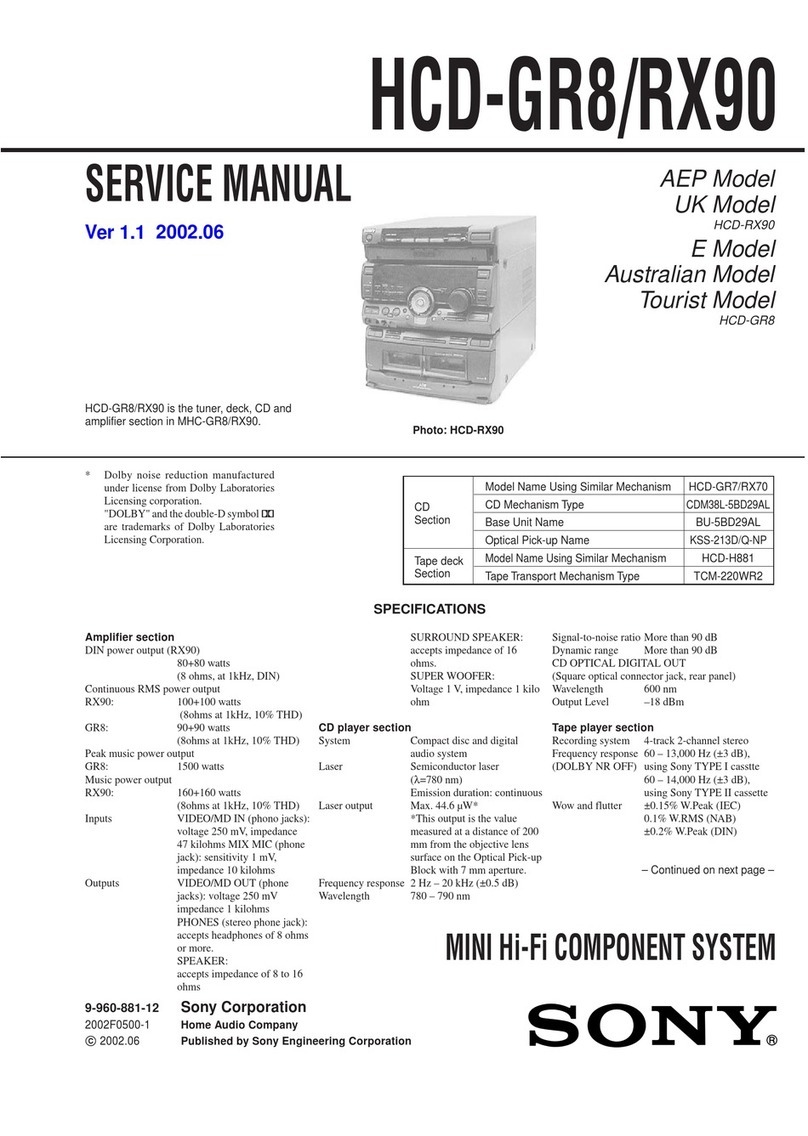

1. GENERAL ·········································································· 5

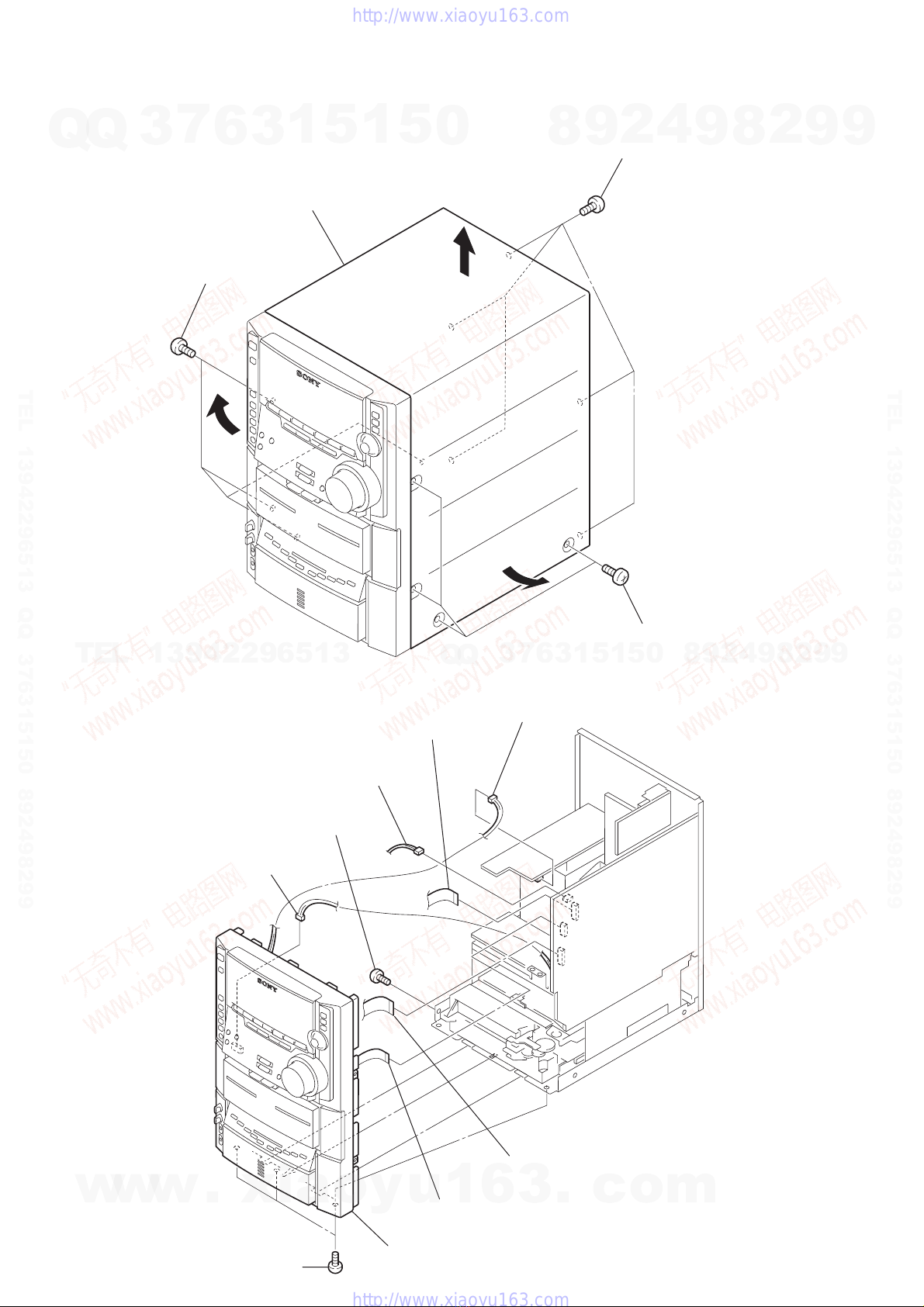

2. DISASSEMBLY ································································ 8

3. SERVICE MODE ···························································· 16

4. MECHANICAL ADJUSTMENTS ····························· 19

5. ELECTRICAL ADJUSTMENTS ······························· 19

6. DIAGRAMS

6-1. Circuit Boards Location ·············································· 24

6-2. Block Diagrams ··························································· 25

6-3. Schematic Diagram Video CD Section (1/2) ·········· 29

6-4. Schematic Diagram Video CD Section (2/2) ·········· 30

6-5. Printed Wiring Board Video CD Section ················ 31

6-6. Printed Wiring Board BD Board ···························· 32

6-7. Schematic Diagram BD Board ······························· 33

6-8. Printed Wiring Boards Sensor/Motor Section ········ 34

6-9. Schematic Diagram Sensor/Motor Section ············ 35

6-10. Printed Wiring Board Audio Board ························ 36

6-11. Schematic Diagram Audio Board ·························· 37

6-12. Printed Wiring Board Leaf SW Board ··················· 38

6-13. Schematic Diagram Leaf SW Board ······················ 38

6-14. Printed Wiring Board Main Board ························· 39

6-15. Schematic Diagram Main Board (1/2) ··················· 40

6-16. Schematic Diagram Main Board (2/2) ··················· 41

6-17. Printed Wiring Board Panel Board ························· 42

6-18. Schematic Diagram Panel Board ···························· 43

6-19. Printed Wiring Board Sub Panel Board ·················· 44

6-20. Schematic Diagram Sub Panel Board ···················· 45

6-21. Waveforms ··································································· 46

6-22. Printed Wiring Board Mic Board ··························· 46

6-23. Schematic Diagram Mic Board ······························ 47

6-24. Printed Wiring Board Front AMP Board ················ 48

6-25. Schematic Diagram Front AMP Board ·················· 49

6-26. Printed Wiring Board Surround AMP Board ········· 50

6-27. Schematic Diagram Surround AMP Board ············ 51

6-28. Printed Wiring Boards Trans Board ······················· 52

6-29. Schematic Diagram Trans Board ···························· 53

6-30. IC Block Diagrams ······················································ 54

6-31. IC Pin Function Description ········································ 56

8. EXPLODED VIEWS ................................................... 61

9. ELECTRICAL PARTS LIST ................................... 68

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety

checks before releasing the set to the customer.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com