4

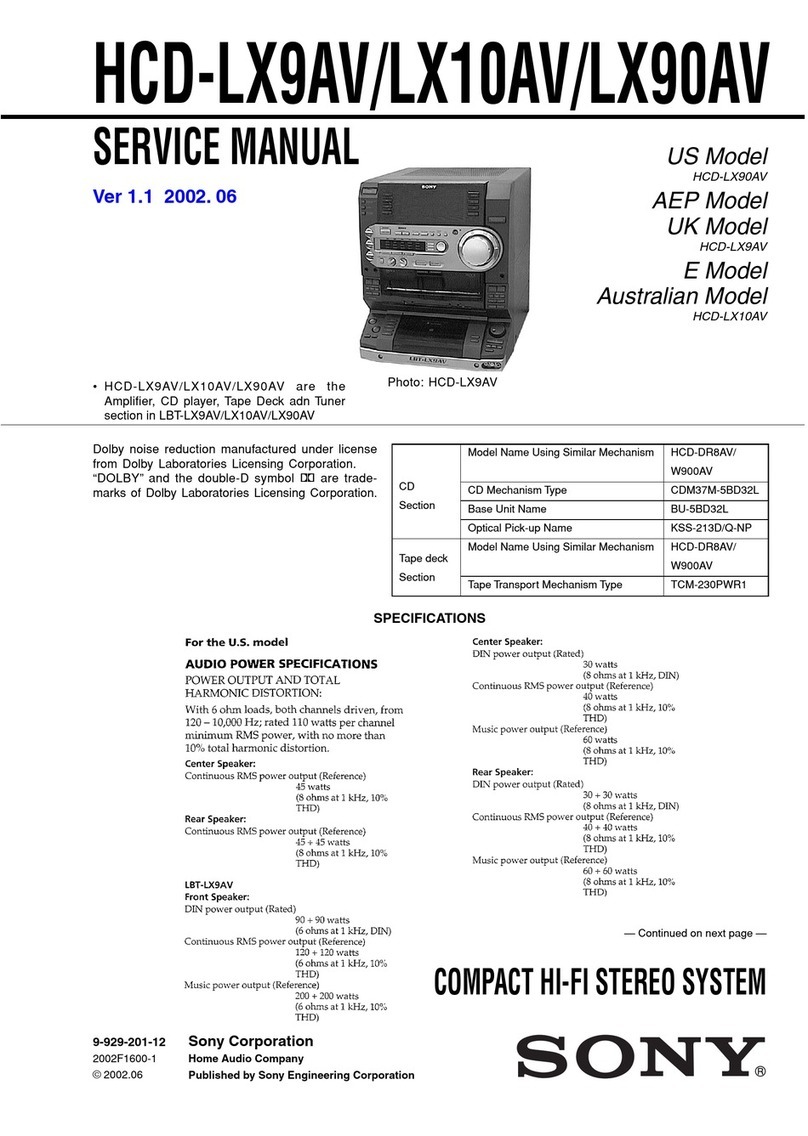

HCD-XGR80

TABLE OF CONTENTS

1. GENERAL ·········································································· 5

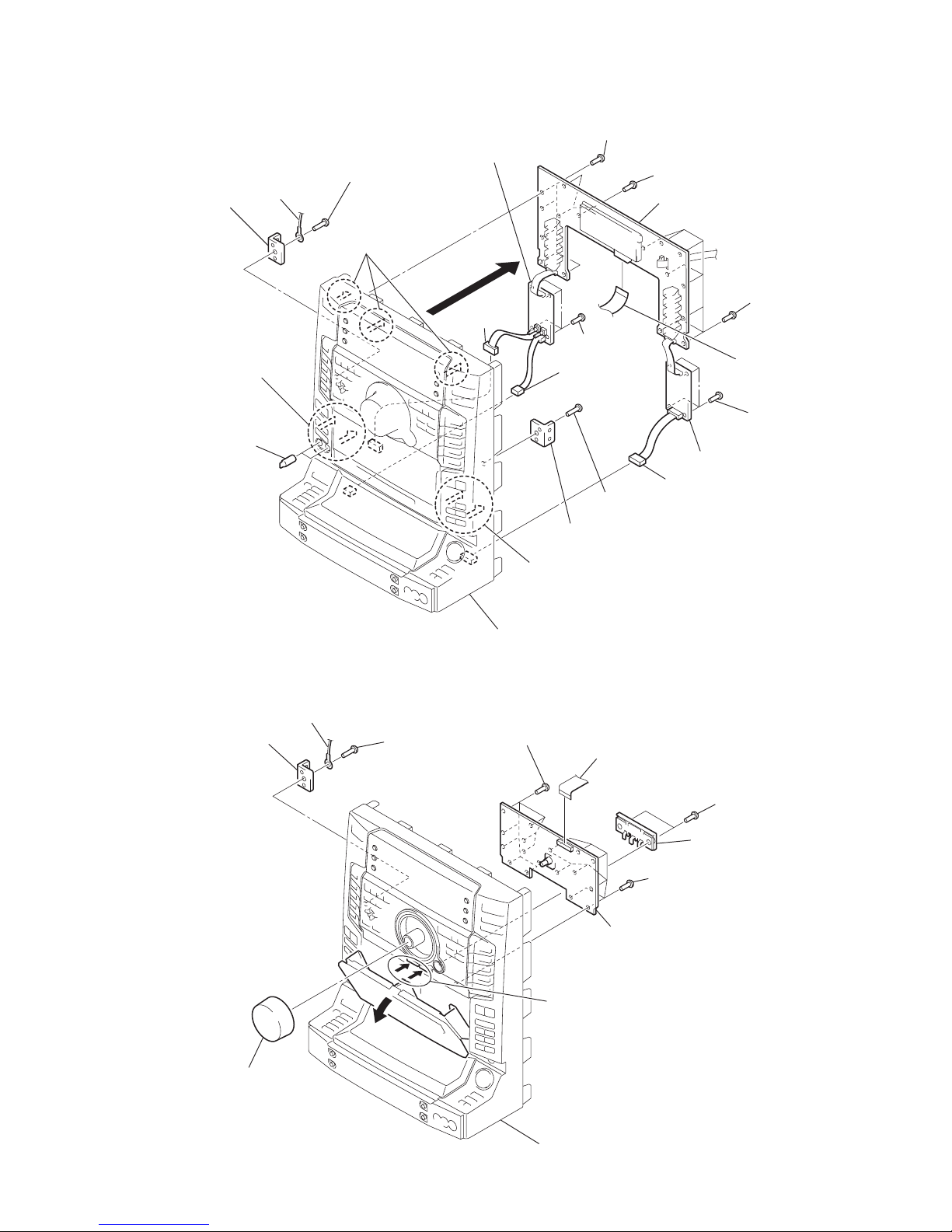

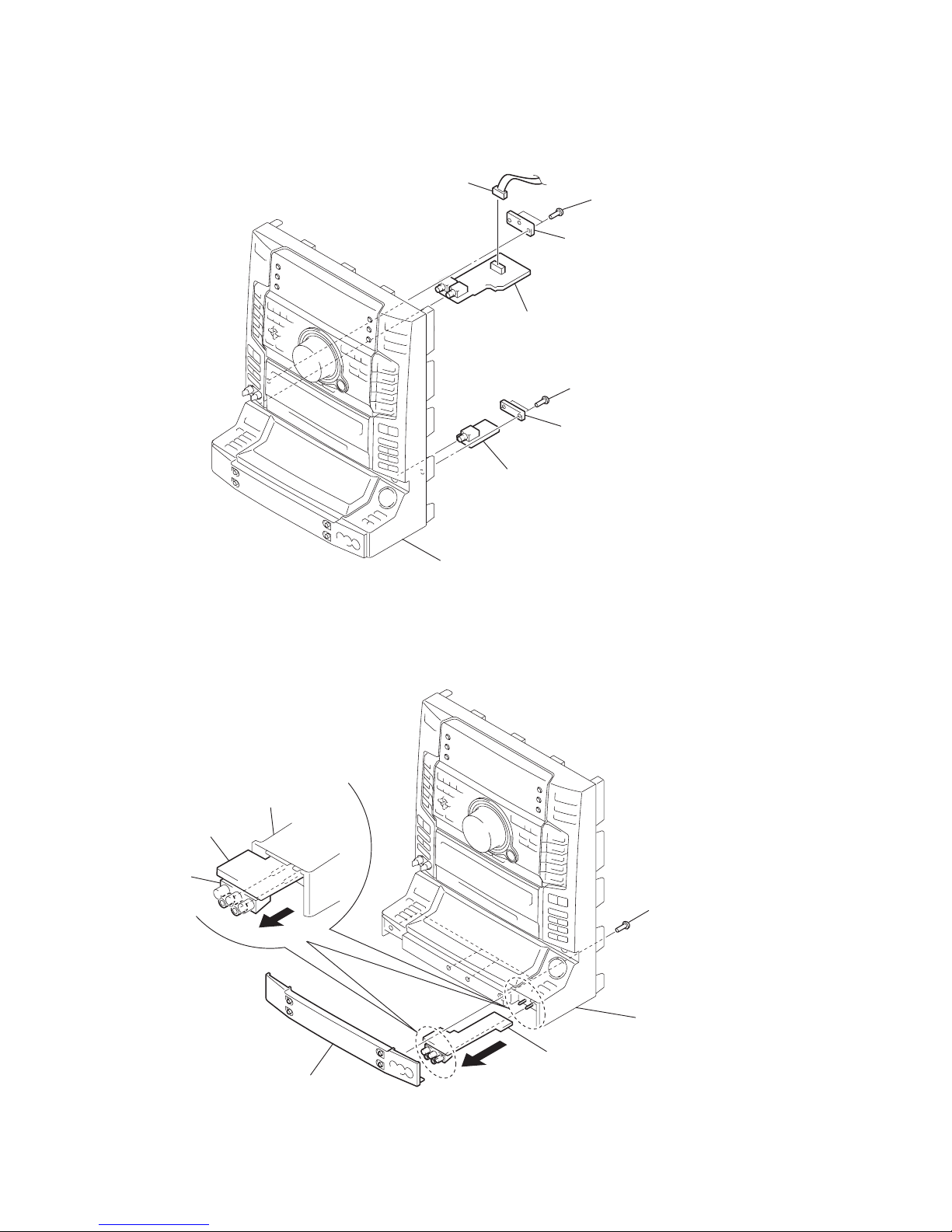

2. DISASSEMBY··································································· 7

3. TEST MODE···································································· 15

4. MECHANICAL ADJUSTMENTS ····························· 17

5. ELECTRICAL ADJUSTMENTS ······························· 17

6. DIAGRAMS

6-1. Circuit Board Location ······················································ 21

6-2. Block Diagram – CD Servo Section –······························· 22

Block Diagram – Tuner/Tape Deck Section – ··················· 23

Block Diagram – Main Section – ······································ 24

Block Diagram

– Display/Key Control/Power Supply Section –·········· 25

6-3. Printed Wiring Board – BD Section – ······························· 26

6-4. Schematic Diagram – BD Section – ·································· 27

6-5. Printed Wiring Board – Motor, LED Section – ················· 28

6-6. Schematic Diagram –Motor, LED Section – ····················· 28

6-7. Schematic Diagram – MIC/Guitar Section –····················· 29

6-8. Printed Wiring Board – MIC/Guitar Section – ·················· 29

6-9. Schematic Diagram – Main (1/3) Section – ······················ 30

6-10.Schematic Diagram – Main (2/3) Section – ······················ 31

6-11.Schematic Diagram – Main (3/3) Section – ······················ 32

6-12.Printed Wiring Board – Main Section – ····························· 33

6-13.Printed Wiring Board

– CD-L,CD-R,Headphone,Front Input,D-SW Section – ·· 34

6-14.Schematic Diagram

– CD-L,CD-R,Headphone,Front Input,D-SW Section – ·· 35

6-15.Printed Wiring Board – Panel VR Section – ······················ 36

6-16.Schematic Diagram – Panel VR Section – ························ 37

6-17.Printed Wiring Board – Panel FL,TC-A,TC-B Section – · 38

6-18.Schematic Diagram – Panel FL,TC-A,TC-B Section –····· 39

6-19.Printed Wiring Board – PA Section – ································ 40

6-20.Schematic Diagram – PA Section – ··································· 41

6-21. Printed Wiring Board – Sub Amp Section – ····················· 42

6-22.Schematic Diagram – Sub Amp Section –························· 43

6-23. Printed Wiring Board – Trans,Sub Trans Section – ·········· 44

6-24.Schematic Diagram – Trans,Sub Trans Section –·············· 44

6-25. IC Pin Function Description ············································· 46

6-26. IC Block Diagram ····························································· 51

7. EXPLODED VIEWS

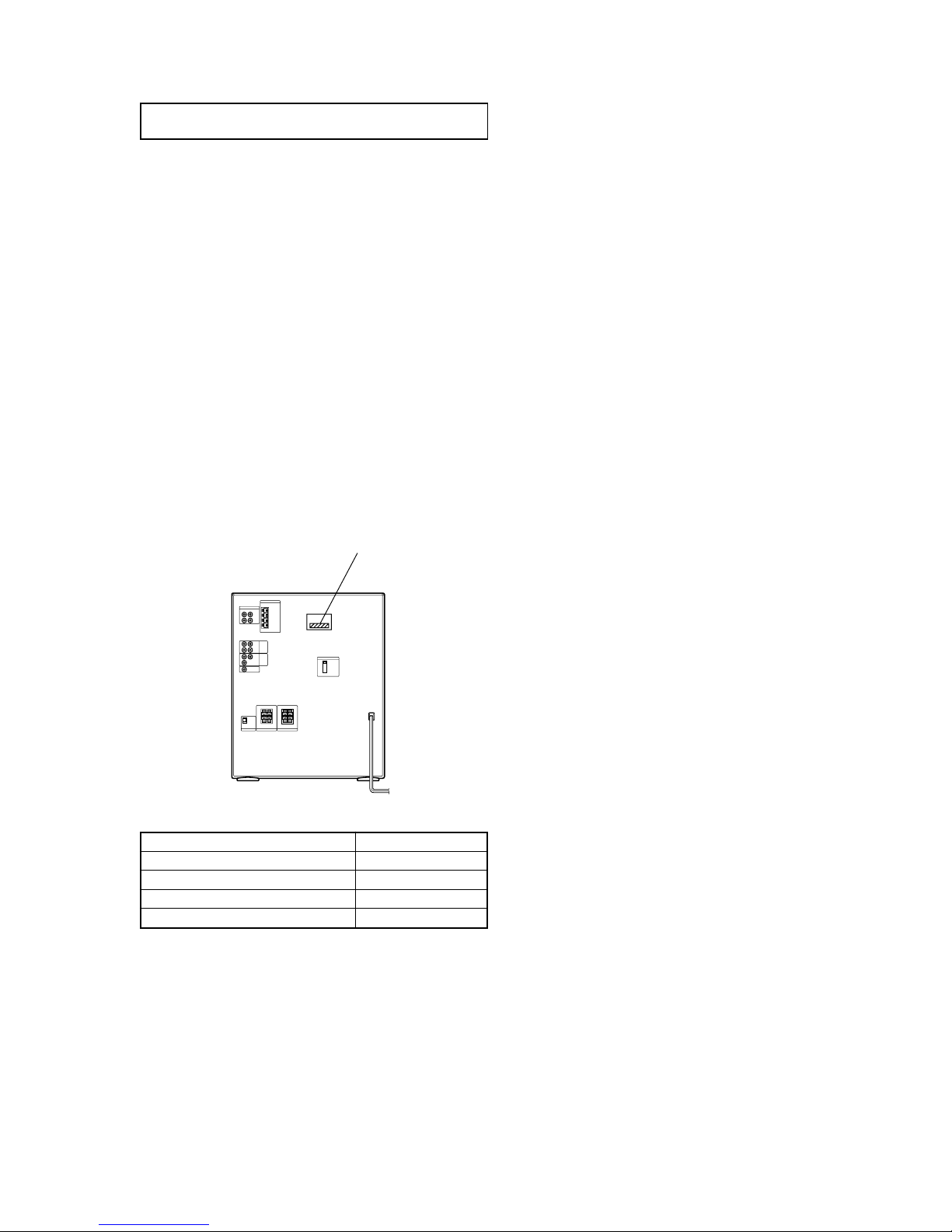

7-1. Case,Back Panel Section ···················································54

7-2. Front Panel Section-1 ························································ 55

7-3. Front Panel Section-2 ························································ 56

7-4. Chassis Section ·································································· 57

7-5. CD Mechanism Deck Section

(CDM-30BD60C)······························································· 58

7-6. Base Unit Section (BU-30BD60C)····································59

8. ELECTRICAL PARTS LIST ······································· 60