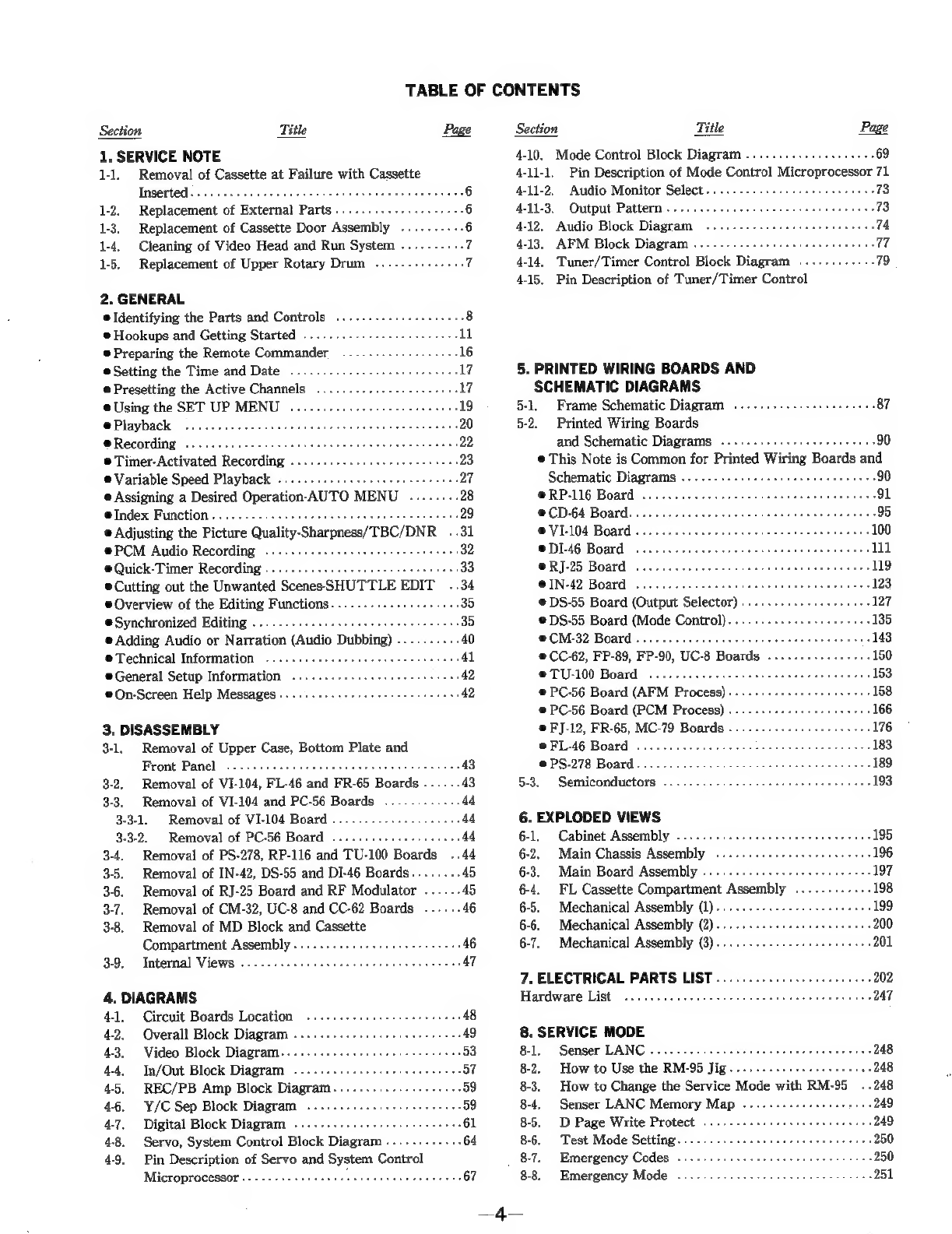

TABLE

OF

CONTENTS

Section

Title

Page

1,

SERVICE

NOTE

1-1.

Removal

of

Cassette

at

Failure

with

Cassette

+6

1-2,

Replacement

of

External

Parts

.

6

1-3.

Replacement

of

Cassette

Door

Assembly

-

6

1-4.

Cleaning

of

Video

Head

and

Run

System

-

7

1-5.

Replacement

of

Upper

Rotary

Drum

.

7

2.

GENERAL

Identifying

the

Parts

and

Controls

8

©

Hookups

and

Getting

Started

...

i

©

Preparing

the

Remote

Commander

16

Setting

the

Time

and

Date

.

Ww

e

Presetting

the

Active

Channels

.

Ww

Using

the

SET

UP

MENU

.

19

@

Playback

20

Recording

-

22

e

Timer-Activated

Recording

.

©

Variable

Speed

Playback

.

©

Assigning

a

Desired

Operation-AUTO

MENU

Index

Function

©

Adjusting

the

Picture

Quality-Sharpness/TBC/DNR

PCM

Audio

Recording

...

©

Quick-Timer

Recording

...

©

Cutting

out

the

Unwanted

ScenesSSHUTTLE

EDIT

©

Overview

of

the

Editing

Functions.

@

Synchronized

Editing

.....-...--

©

Adding

Audio

or

Narration

(Audio

Dubbing)

-

Technical

Information

.....

General

Setup

Information

.

On-Screen

Help

Messages.

.

.

3.

DISASSEMBLY

3-1,

Removal

of

Upper

Case,

Bottom

Plate

and

Front

Panel

...

3-2.

Removal

of

VI-104,

FL-46

and

FR-65

Boards

.

3-3.

Removal

of

VI-104

and

PC-56

Boards

...

3-3-1.

Removal

of

VI-104

Board

..-

3-3-2.

Removal

of

PC-56

Board

...

E

3-4.

Removal

of

PS-278,

RP-116

and

TU-100

Boards

..44

3-5.

Removal

of

IN-42,

DS-55

and

DI-46

Boards...

3-6.

Removal

of

RJ-25

Board

and

RF

Modulator

.

.

3-7,

Removal

of

CM-32,

UC-8

and

CC-62

Boards

......

3-8.

Removal

of

MD

Block

and

Cassette

Compartment

Assembly

.

3-9.

Internal

Views

.

4.

DIAGRAMS

4-1.

Circuit

Boards

Location

4-2,

Overall

Block

Diagram

.

4-3,

Video

Block

Diagram.

4-4.

In/Out

Block

Diagram

.

4.5,

REC/PB

Amp

Block

Diagram.

46.

Y/C

Sep

Block

Diagram

.

4-7.

Digital

Block

Diagram

-

ef

4-8.

Servo,

System

Control

Block

Diagram

...........-

64

4-9.

Pin

Description

of

Servo

and

System

Control

Microprocessor

..-..-.-.0.00cseeeeeeeeeeeeeeenees

67

Section

Title

Page

4-10.

Mode

Control

Block

Diagram

............-+++0055

69

4-11-1.

Pin

Description

of

Mode

Control

Microprocessor

71

4-11-2,

Audio

Monitor

Select

.

ae)

4-11-3,

Output

Pattern

4-12.

Audio

Block

Diagram

4-13.

AFM

Block

Diagram

...

4-14.

Tuner/Timer

Control

Block

Diagram

4-15,

Pin

Description

of

Tuner/Timer

Control

5.

PRINTED

WIRING

BOARDS

AND

SCHEMATIC

DIAGRAMS

5-1,

Frame

Schematic

Diagram

.....-----.-++s++s00e5

87

5-2.

Printed

Wiring

Boards

Schematic

Diagrams

RP-116

Board

-

CD-64

Board.

@

VI-104

Board

..

©

DI-46

Board

..

e@RJ-25

Board

e@IN-42

Board

.

@

DS-55

Board

(Output

Selector)

. .

DS-55

Board

(Mode

Control)

©

CM-32

Board

©

CC-62,

FP-89,

FP-90,

UC-8

Boards

..

e@

TU-100

Board

@

PC-56

Board

(AFM

Process).

.

PC-56

Board

(PCM

Process)

. -

@FJ-12,

FR-65,

MC-79

Boards

@

FL-46

Board

@

PS-278

Board

5-3.

Semiconductors

..

6.

EXPLODED

VIEWS

6-1,

Cabinet

Assembly

6-2,

Main

Chassis

Assembly

..

6-3.

Main

Board

Assembly

6-4.

FL

Cassette

Compartment

Assembly

6-5.

Mechanical

Assembly

(1)

6-6.

Mechanical

Assembly

(2)...

6-7.

Mechanical

Assembly

(3)..

7.

ELECTRICAL

PARTS

LIST

..

Hardware

List

8.

SERVICE

MODE

8-1.

Senser

LANC

8-2,

How

to

Use

the

RM-95

Jig

ae

8-3.

How

to

Change

the

Service

Mode

with

RM-95

.

.248

8-4.

Senser

LANC

Memory

Map

..

"

8-5.

D

Page

Write

Protect

8-6.

Test

Mode

Setting.

.

8-7.

Emergency

Codes

8-8.

Emergency

Mode

..