SOR 1800PT User manual

Form 1807 (09.22) ©SOR Inc.

1/16

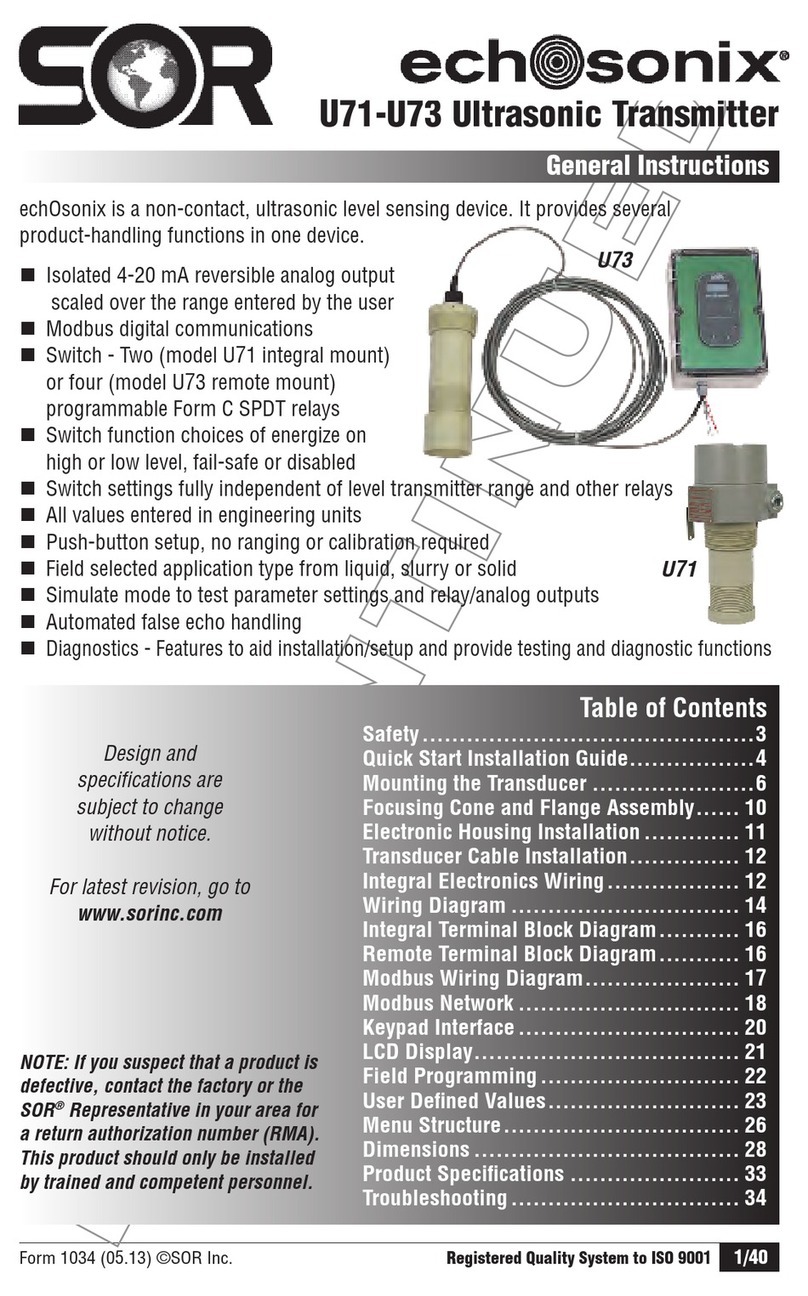

These instructions provide information for installation,

process connection, electrical connection, configuration,

operation and maintenance of the 1800PT and 1800HP

Pressure Transmitters. The 1800 Series Pressure

Transmitters are offered with either a standard over

pressure (model 1800PT) or a high over pressure

(model 1800HP); the information contained

in this document applies to either version.

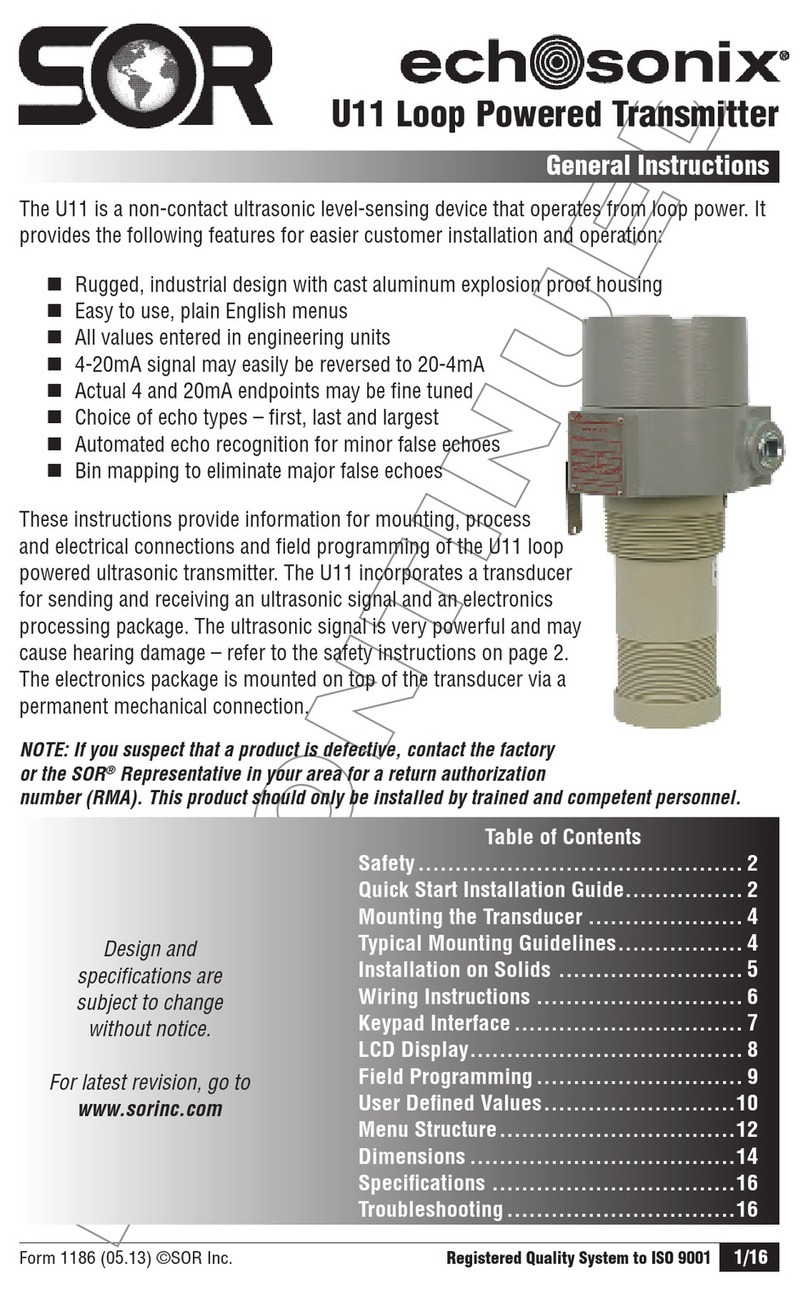

1800PT and 1800HP

Pressure Transmitters

General Instructions

Registered Quality System to ISO 9001

NOTE: If you suspect that a product is defective, contact the

factory or the SOR

®

Representative in your area for a return

material authorization number (RMA). This product should

only be installed by trained and competent personnel. Product

specifications and important information provided on the device

nameplate should be carefully reviewed before installation.

Design and

specifications are

subject to change

without notice.

For latest revision, go to

sorinc.com

Table of Contents

Installation.......................................1

Electrical Connections .........................2

Configuration with Push-Buttons .............2

Factory Settings and Reset....................7

ATEX and IECEx Marking Details .............8

Maintenance.....................................9

Dimensions .................................... 10

Manifolds ...................................... 12

e

1800HP

High Over

Pressure

1800PT

Standard

Over Pressure

Installation

Normally, line mounting provides adequate support for the instrument.

n

The process connection is threaded onto a fitting within an adequately supported

process piping system.

o

Use two open end wrenches when connecting the pressure port to a process piping

system: one wrench to hold the process fitting, the other at the hex flat to tighten the

gauge pressure transmitter.

p

Process connection pipe or tubing may be rigid or flexible.

q

If ordered with the PK accessory, ensure the device is securely fastened to the pipe

mounting bracket.

2/16

Form 1807 (09.22) ©SOR Inc.

Electrical Connections

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

nRemove the housing rear cover.

oPass wiring through the conduit fitting.

pConnect the positive power supply lead to the terminal marked “+”.

qConnect the negative power supply lead to the terminal marked “-“.

Note: The terminals marked “A” and “B” are not used on the 1800 Series.

rReplace the housing rear cover.

sAll housings must be properly “sealed” at the conduit connection to maintain the

NEMA classification.

tApply power to the device. Reference supply voltages are listed below.

Reference Supply Voltages

Standard/Flameproof: 10.5-55VDC

HART Protocol: 16.5-55VDC

Intrinsic Safety: 12-30VDC

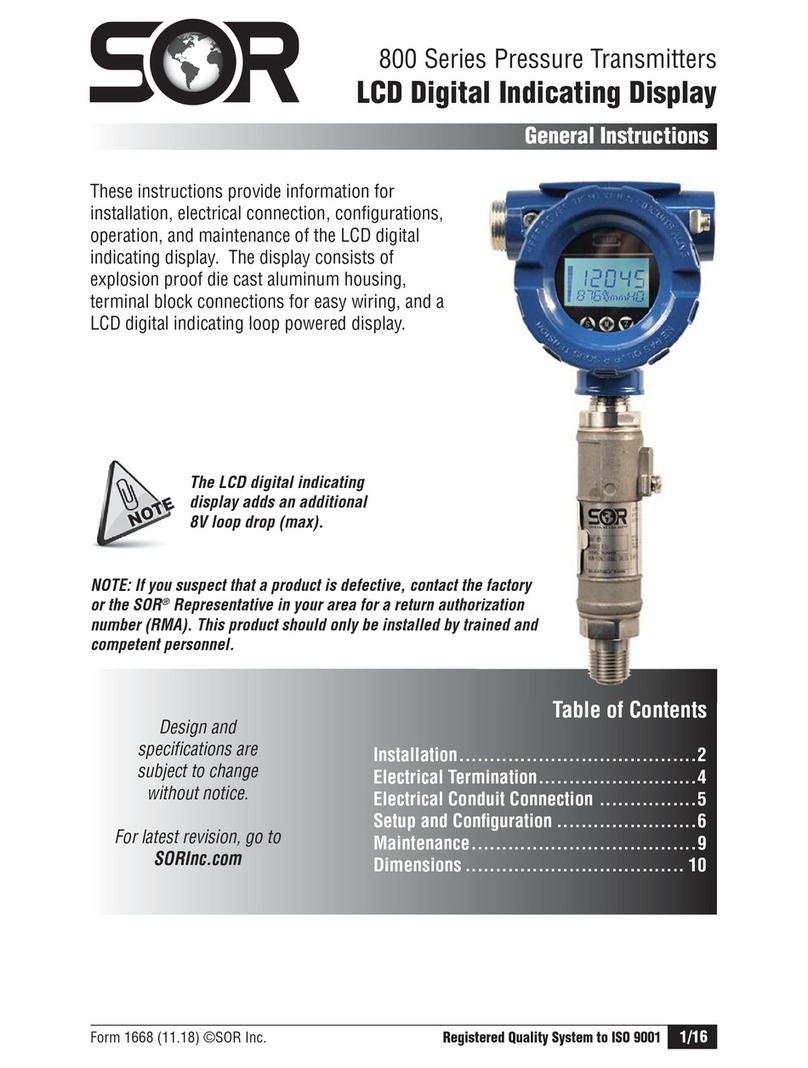

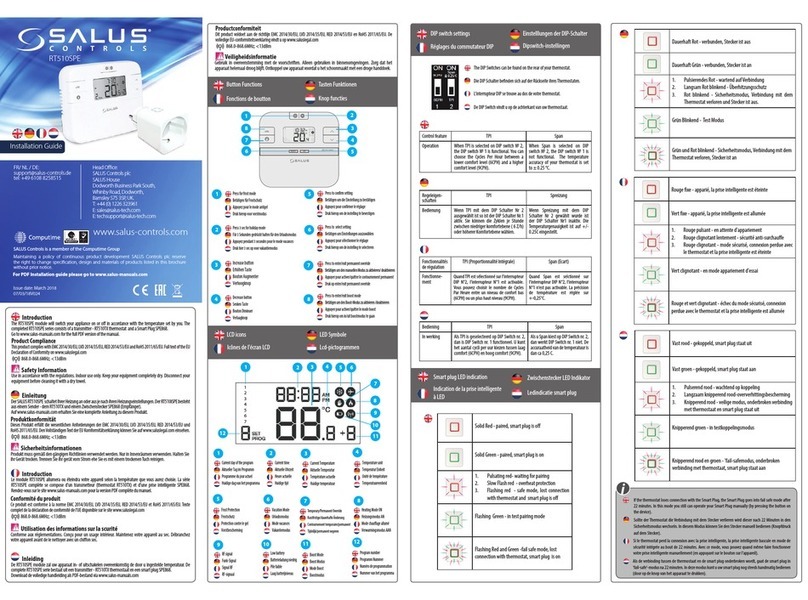

Configuration with Push-Buttons

All 1800 Series Pressure Transmitters include external push-buttons to configure the

device; these push-buttons are located beneath the top nameplate. To access, loosen

the bottom-left nameplate screw until the nameplate can be rotated upward exposing

the external push-buttons. If ordered with an LCD Display, the device will also include

internal push-buttons beneath the housing front cover.

Configuration commands are the same for both

the internal and external push-buttons.

From left to right the

buttons are labeled (S), (M), (Z)

When installed in a hazardous

area only the external push-buttons

should be used to configure the device.

Form 1807 (09.22) ©SOR Inc.

3/16

The following three commands configure the device based on the pressure currently

being applied to the sensor.

Zero Pressure Setting

nMake sure there is no pressure being applied to the sensor.

oPress and hold (S) and (Z) simultaneously for at least five seconds.

pOnce the display reads “PV = 0” the zero pressure has been successfully set.

qRelease (S) and (Z) at the same time.

Note: The zero pressure must be set after installation because it is influenced by the

mounting position. Three weeks after installation, the zero pressure should be set again to

ensure the best accuracy.

4mA Pressure Setting

nApply the desired pressure to the sensor that corresponds to a 4mA output signal.

oPress and hold (Z) and (M) simultaneously for at least five seconds.

pOnce the display reads “4mA OK” the 4mA pressure has been successfully set.

qRelease (Z) and (M) at the same time.

20mA Pressure Setting

nApply the desired pressure to the sensor that corresponds to a 20mA

output signal.

oPress and hold (S) and (M) simultaneously for at least five seconds.

pOnce the display reads “20mA OK” the 20mA pressure has been successfully set.

qRelease (S) and (M) at the same time.

Measuring and Menu Interfaces

The device starts by displaying the Measuring Interface. The measuring interface

can be changed via the Display Mode setting. In all three display modes there will be

a bar on the left side of the display that changes height and follows the spanned

current range.

Pressing (M) once enters the Menu Interface which allows eight different device

settings to be manually configured via the push-buttons. The eight setting menus

follow the same order listed below. If the device is left in a setting menu it will return to

the Measuring Interface after 30 seconds.

Note: If any setting value is changed, (M) must be pressed to confirm the changes or the

setting will revert to the original value.

4/16

Form 1807 (09.22) ©SOR Inc.

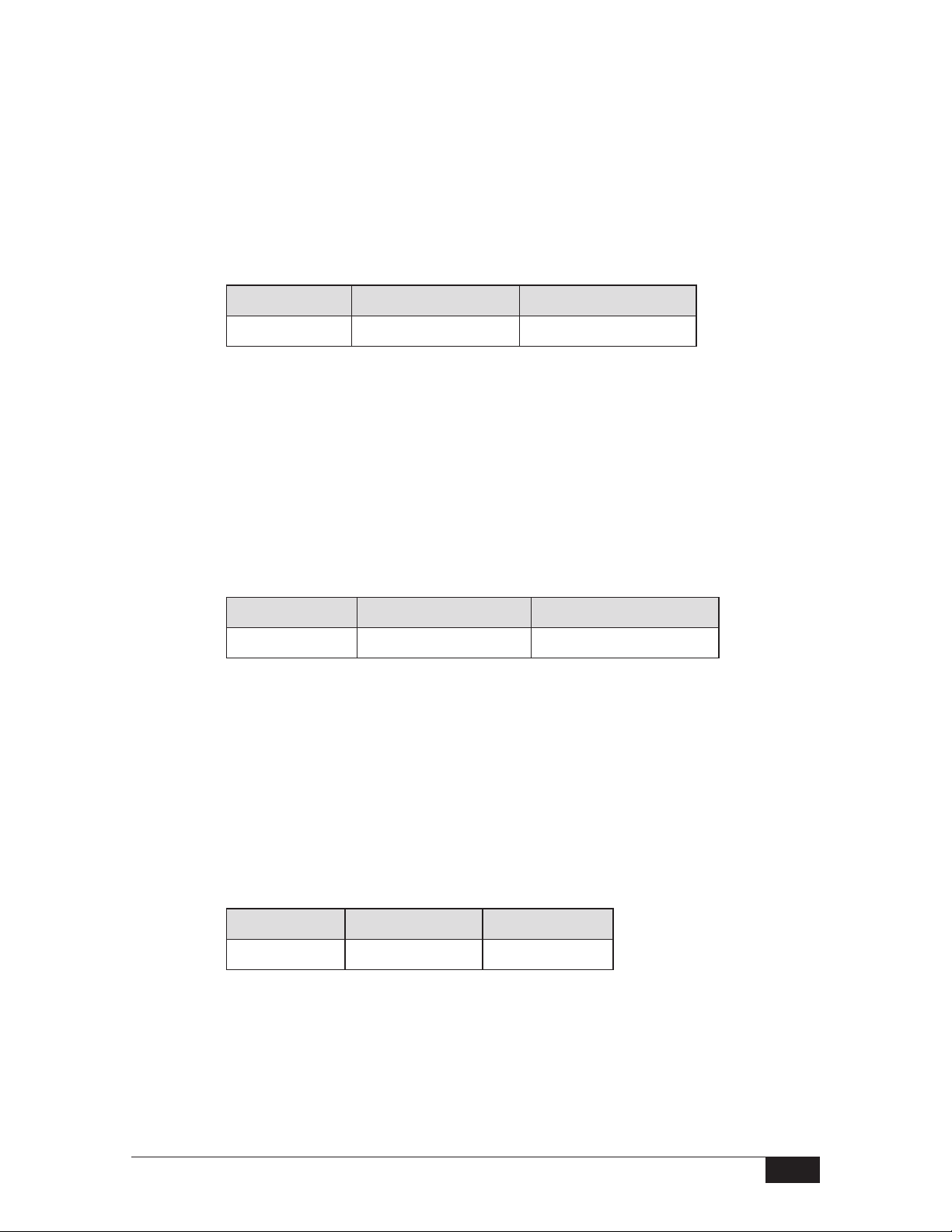

Within each setting menu there is a label displayed below the setting value. The tables

below each setting menu list the menu label and available setting values.

Measuring Interface

n

Press (M) to enter Menu Interface

Menu Interface

n Configure Display Mode

a. Press (M) to skip and proceed to next setting menu

To change setting value

a. Press (Z) to enter setting menu

b. Press (S) to change the setting value

c. Press (M) to confirm the setting value change and proceed

to next setting menu

Menu Label Setting Values Value Details

DISP

PV Process Variable

mA Current

% Percentage (follows spanned current range)

o Configure Unit of Measure

a. Press (M) to skip and proceed to next setting menu

To change setting value

a. Press (Z) to enter setting menu

b. Press (S) to change to next setting value

c. Press (Z) to change to previous setting value

d. Press (M) to confirm the setting value change and proceed

to next setting menu

Menu Label Setting Values

U

kPa inH2O kg/cm2

MPa ftH2O Pa

bar inHg ATM

psi mHg mm*

mmHg TORR m*

mmH2O mbar

mH2O g/cm2

*Unit of measure is for a specific application only and not

recommended for general use.

Form 1807 (09.22) ©SOR Inc.

5/16

p Configure 4mA Pressure Value

a. Press (M) to skip and proceed to next setting menu

To change setting value

a. Press (Z) once to enter setting menu. It will start with the last digit.

b. Press (S) to change the setting value of digit

c. Press (Z) to move one digit to the left

d. Press (M) to confirm the setting value change and proceed

to next setting menu

Menu Label Setting Values Value Details

LRV -19999 to +99999 Lower Range Value

q Configure 20mA Pressure Value

a. Press (M) to skip and proceed to next setting menu

To change setting value

a. Press (Z) once to enter setting menu. It will start with the last digit.

b. Press (S) to change the setting value of digit

c. Press (Z) to move one digit to the left

d. Press (M) to confirm the setting value change and proceed

to next setting menu

Menu Label Setting Values Value Details

URV -19999 to +99999 Upper Range Value

r Configure Damping Time

a. Press (M) to skip and proceed to next setting menu

To change setting value

a. Press (Z) once to enter setting menu. It will start with the last digit.

b. Press (S) to change the setting value of digit

c. Press (Z) to move one digit to the left

d. Press (M) to confirm the setting value change and proceed

to next setting menu

Menu Label Setting Values Value Details

DAMP 0 to 100 Seconds

6/16

Form 1807 (09.22) ©SOR Inc.

s Configure Output Signal Type

a. Press (M) to skip and proceed to next setting menu

To change setting value

a. Press (Z) to enter setting menu

b. Press (S) to change the setting value

c. Press (M) to confirm the setting value change and proceed

to next setting menu

Menu Label Setting Values Value Details

mA LINER Linear

√ Square Root

t Configure Fault Alarm Signal

a. Press (M) to skip and proceed to next setting menu

To change setting value

a. Press (Z) to enter setting menu

b. Press (S) to change the setting value

c. Press (M) to confirm the setting value change and proceed

to next setting menu

Menu Label Setting Values Value Details

ALARM

NO None

H 20.8mA

L 3.8mA

u Configure Fixed Output Current

a. Press (M) to exit Menu Interface and return to Measuring Interface

To change setting value

a. Press (Z) to enter setting menu

b. Press (S) to change the setting value

c. Press (Z) to apply the selected fixed output current

d. Press (M) once finished to return to Measuring Interface

Menu Label Setting Values

FIX\C

NO (None) 12.0000 mA

3.8000 mA 16.0000 mA

4.0000 mA 20.0000 mA

8.0000 mA 20.8000 mA

Form 1807 (09.22) ©SOR Inc.

7/16

Factory Settings and Reset

Setting Menu Label Factory Setting Value

Display Mode DISP PV (Primary Variable)

Unit of Measure U kPa or MPa (Sensor Dependent)

4mA Pressure Value LRV Lower Range Value (Sensor Dependent)

20mA Pressure Value URV Upper Range Value (Sensor Dependent)

Damping Time DAMP 0 Seconds

Output Signal Type mA LINER (Linear)

Fault Alarm Signal ALARM NO (None)

Fixed Output Current FIX\C NO (None)

There are two methods to reset the device to factory settings using the push-buttons.

Method 1

nThe device must be powered on and displaying the Measuring Interface.

oPress (S) and hold for at least five seconds.

pOnce the display reads “RECOVERY” release (S) and press (Z) for at least

two seconds.

qOnce the display reads “OK” release (Z) and the device will begin resetting.

rThe display reads “LOADING” while it is in the process of resetting.

sAfter the display returns to the Measuring Interface the factory reset is complete.

Method 2

nThe device must be powered off before proceeding.

oPress and hold (Z) while simultaneously powering the device on.

pContinue holding (Z) until the display reads “OK”.

qRelease (Z) and the device will begin resetting.

rThe display reads “LOADING” while it is in the process of resetting.

sAfter the display returns to the Measuring Interface the factory reset is complete.

8/16

Form 1807 (09.22) ©SOR Inc.

ATEX and IECEx Marking Details

ATEX Marking IECEx Marking Parameters

II 1 G Ex ia IIC T4 Ga Ui = 28V

Ex ia IIC T4 Ga (-20°C ≤ Ta ≤ +60°C) Ii = 93mA

(-20°C ≤ Ta ≤ +60°C) Pi = 0.65W

Li = 0mH

Ci = 0μF

II 2 GD Ex db IIC T6 Gb

Ex db IIC T6 Gb Ex tb IIIC T80°C Db

Ex tb IIIC T80°C Db (-20°C ≤ Ta ≤ +60°C)

(-20°C ≤ Ta ≤ +60°C)

Certificate Number: IECEx NEP 18.0008X

Standards: IEC 60079-0:2011 Ed 6, IEC 60079-1:2014-06 Ed 7, IEC 60079-11:2011

Ed 6 and IEC 60079-31:2013, Ed 2

Specific Conditions for Use

When equipment is installed in a Zone 0 hazardous area, user shall avoid an

ignition hazard due to impact or friction.

Contact the original manufacturer for information on the dimensions of the

flameproof joints.

Certificate Number: CML 19ATEX1078X

Standards: EN 60079-0:2012+A11:2013, EN 60079-1:2014, EN 60079-11:2012 and

EN 60079-31:2014

Specific Conditions for Use

When the equipment is installed in a Zone 0 hazardous area, the end user shall

protect the equipment from ignition hazards in the form of impact or friction.

The flameproof joints shall not be repaired. Contact the original manufacturer for

information on the dimensions of the flameproof joints.

The intrinsically safe version of the equipment does not satisfy 500 V test of IEC

60079-11 CL 6.3.13. and shall be supplied by an isolated barrier which is suitable

with the internal parameter of the equipment: Ui = 28V, Ii = 93mA, Pi = 0.65W,

Li ≈ 0mH, Ci = 0μF

The user shall ensure that the surface temperature of the sensor connector

shall never exceed +60°C.

Form 1807 (09.22) ©SOR Inc.

9/16

Maintenance

The 1800 Series Pressure Transmitters contain no user serviceable parts and cannot

be repaired on site. Disassembly of the instrument by unauthorized persons will

invalidate the warranty.

If there is a risk of debris accumulating in the pressure port, it should

be cleaned.

Care and caution must be taken when cleaning the pressure port to prevent

damage to the diaphragm.

It is recommended that the device’s Zero Pressure Setting be configured each year.

10/16

Form 1807 (09.22) ©SOR Inc.

#

!"#$ %

$

Dimensions

Model 1800PT (Standard Over Pressure)

Without

Display

(option 00)

Dimensions = mm

Pipe Mounting Kit (accessory PK)

With Integral

LCD Display

(option IN)

Form 1807 (09.22) ©SOR Inc.

11/16

Model 1800HP (High Over Pressure)

Pipe Mounting Kit (accessory PK)

With Integral

LCD Display

(option IN)

!

Without

Display

(option 00)

!

1

#

!

12/16

Form 1807 (09.22) ©SOR Inc.

Manifolds

If ordered with a 2-valve manifold, please

refer to the dimensional connection

drawings and flowpath diagram.

14685 West 105th Street, Lenexa, KS 66215

913-888-2630

800-676-6794 USA

Fax 913-888-0767

Registered Quality System to ISO 9001

Printed in USA sorinc.com

Process Connection

Instrument Connection

Hex Plug

Flowpath

(Dimensions = mm)

+,,

Instrument - 1/2” NPT(F)

Process - 1/2” NPT(F)

Instrument - 1/2” NPT(M)

Process - 1/2” NPT(F)

Instrument - 1/2” NPT(M)

Process - 1/2” NPT(M)

Connections

This manual suits for next models

1

Table of contents

Other SOR Transmitter manuals

Popular Transmitter manuals by other brands

Nautel

Nautel NX50 Preinstallation manual

Extron electronics

Extron electronics XTP T VGA user guide

NIVELCO

NIVELCO EchoTREK SG-300 series Installation and programming manual

Comnet

Comnet FVT4014 Installation and operation manual

R.V.R. Electronica

R.V.R. Electronica TX500SS user manual

Osram

Osram EASY Hybrid Remote Fitting instructions