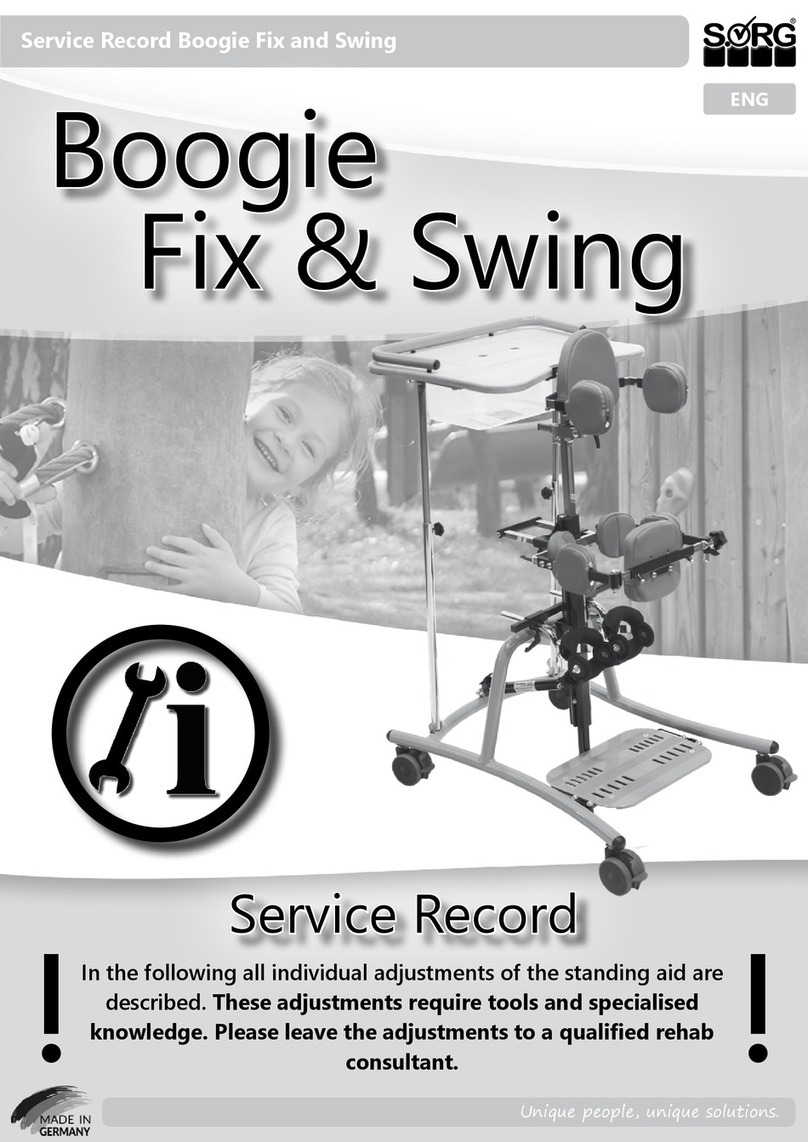

Service Record

3

TABLE OF CONTENT

IMPRINT 2

REVISION STATUS 2

TECHNICAL STATUS 2

REHAKIND 2

COPYRIGHT 2

CERTIFICATION 2

OVERVIEW MOBILE STANDING DEVICE 4

1 PREAMBLE 5

1.1 GENERAL INFORMATION 5

1.2 SIGN EXPLANATION 5

1.3 RECEPTION 5

1.4 SERVICE AND MAINTENANCE 5

1.5 DOCUMENTATION 6

1.6 BASICS TO ALL ADJUSTMENT WORK

ON THE MOBILE STANDING DEVICE 6

1.7 TIGHTENING TORQUE

AND TOOLS 6

1.8 GENERAL SAFETY INSTRUCTIONS 7

1.9 LOADING AND TRANSPORTING 7

2 ADJUSTMENTS 8

2.1 ASSEMBLY GROUP WHEELS 8

2.1.1 Wheel position 8

2.1.2 Camber 9

2.1.3 Sprung back casters 10

2.2 ASSEMBLY GROUP CENTRE COLUMN11

2.2.1 Height adjustment of the centre column

with frame size 1 11

2.2.2 Setting the angle of the centre column

by telescope and clamp lever 11

2.2.3 Angle adjustment of the centre column

by gas pressure spring 11

2.3 ASSEMBLY GROUP STANDARD

FOOT PLATES 12

2.3.1 Setting the height of the foot plate

holder 12

2.3.2 Positioning the standard foot plates 12

2.3.3 Abducting the standard foot plates 12

2.3.4 Turning the standard foot plates

horizontally

12

2.4 ASSEMBLY GROUP 3D FOOT PLATES

WITH ANGLE ADJUSTMENT 13

2.4.1 Setting the angle of the 3D foot plates 13

2.4.2 Abducting the 3D foot plates 13

2.4.3 Setting the height of the 3D foot plates 13

2.4.4 Setting the depth of the 3D foot plates 13

2.5 FOOT SHELLS 13

2.6 ASSEMBLY GROUP CHEST

TRUSS PAD 14

2.6.1 Height of the chest truss pad 14

2.6.2

Angle of the chest truss pad 14

2.6.3

Side chest truss pad 14

2.7 ASSEMBLY GROUP PELVIC TRUSS

PADS 15

2.7.1 Adjusting the height 15

2.7.2 Adjusting the width 15

2.7.3 Adjusting the depth 15

2.8 ASSEMBLY GROUP POSTERIOR

TRUSS PAD PLUGGABLE 16

2.8.1 Crotch cushion 16

2.8.2 Posterior cushion 16

2.8.3 Side posterior truss pads 16

2.8.4

Back truss pads 16

2.9 ASSEMBLY GROUP POSTERIOR

TRUSS PAD WITH CRANK AND

SWIVEL BRACKET 17

2.9.1 Adjusting the height 17

2.9.2 Adjusting the depth 17

2.9.3 Adjusting the width 17

2.10 ASSEMBLY GROUP STANDARD

KNEE TRUSS PADS 18

2.10.1 Adjusting the truss pad width size 1 18

2.10.2 Adjusting the truss pad width size 2 18

2.10.3 Adjusting the height 18

2.10.4 Adjusting the depth 18

2.10.5 Adjusting the distance 18

2.11 ASSEMBLY GROUP KNEE TRUSS

PADS WITH RESTING BRACKETS 19

2.11.1 Adjusting the truss pad width 19

2.11.2 Adjusting the shear angle 19

2.11.3 Adjusting the height 19

2.11.4 Adjusting the depth 19

2.11.5 Adjusting the distance 19

2.12 ASSEMBLY GROUP THERAPY TABLE 20

2.12.1 Standard mounting 20

2.12.2 Mounting on the chest truss pad holder 20

2.13 ASSEMBLY GROUP FRAME 21

2.13.1 Frame size 1 and 2 (gas pressure spring

or telescope) 21

2.13.2 Frame size 3 (gas pressure spring) 21

2.13.3 Frame size 3 (telescope) 21

2.14 ASSEMBLY GROUP BELTS 21

3 TECHNICAL DATA 22

3.1 MEASURMENTS AND DIMENSIONS 22

3.2 MEANING OF LABELS 23

3.3 DECLARATION OF CONFORMITY 23

3.4 RETAILER VERIFICATION 24