Sottoriva SVP 0-E User manual

INSTRUCTIONS MANUAL

Piston type automatic divider

mod.

SVP 0/1/2/3-E

Version:

ENGLISH - Arc. 16

Code: 3529.0091.01

Revision: n° 0 dated 19/06/2001

Costruzioni Meccaniche SOTTORIVA S.p.A.

Via Vittorio Veneto, 63 - 36035 MARANO VICENTINO (VI) ITALY

Phone (+39) 0445.595.111 - Fax (+39) 0445.595.155

Internet: http://www.sottoriva.com - E-mail: sottoriva@sottoriva.com

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

Arc. 16-ig

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

1

7DEOHRI&RQWHQWV

1.

Introduction

.........................................................................................................

3

1.1

Foreword

......................................................................................................

3

1.2

Guarantee: validity and therms

.......................................................................

3

1.3

User instructions and warnings

......................................................................

5

2.

Descriptive manual

.............................................................................................

7

2.1

Foreword

........................................................................................................

7

2.2

Description

......................................................................................................

7

2.3

Overall dimensions and other specifications

..................................................

11

2.4

Machine identification plate

............................................................................

11

3.

Operation and installation manual

....................................................................

13

3.1

Foreword

........................................................................................................

13

3.2

Workplace requirements

.................................................................................

13

3.3

Transporting the machine

...............................................................................

13

3.4

Machine installation

........................................................................................

15

3.4.1

Installation warnings

................................................................................

15

3.4.2

Notes for the electrical installation personnel

........................................

15

3.5

Start up

...........................................................................................................

16

3.6

Operation

........................................................................................................

19

4.

Maintenance manual

..........................................................................................

23

4.1

Foreword

........................................................................................................

23

4.2

Daily maintenance

..........................................................................................

23

4.3

Weekly maintenance

......................................................................................

23

4.4

Three-monthly maintenance

...........................................................................

23

4.5

Fault finding

.................................................................................................

24

4.6

Changing wear parts of the machine

...........................................................

26

4.6.1

Changing the belt ref. 1

Photo 5

.............................................................

26

4.6.2

Changing the belt ref. 1

Photo 6

.............................................................

26

4.6.3

Changing the outfeed belt

.......................................................................

27

4.6.4

Changing the motor ref.6

Photo 5

..........................................................

27

4.6.5

Changing the motor ref. 3

Photo 6

.........................................................

28

4.7

List of parts subject to normal wear

................................................................

31

4.8

Wiring diagrams

..............................................................................................

33

4.8.1

Power wiring diagrams

............................................................................

33

4.8.1.1

230 V 50 Hz VERSION

....................................................................

33

4.8.1.2

400 V 50 Hz VERSION

....................................................................

33

4.8.2

Electrical control diagrams

......................................................................

33

4.8.3

Electrical maintenance

.........................................................................

34

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

2

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

Arc. 16-ig

4.9

Cleaning the machine

.....................................................................................

35

4.9.1

Cleaning the dividing chamber, the main piston ref. 1

Photo 7

and the se-

condary piston ref. 3

Photo 7

....................................................................................

37

5.

Safety and hygiene

.............................................................................................

39

5.1

General notes

.................................................................................................

39

5.2

Mechanical hazards and residual risks

...........................................................

39

5.2.1

Danger zone 1

.........................................................................................

39

5.2.2

Danger zone 2

.........................................................................................

39

5.2.3

Danger zone 3

.........................................................................................

40

5.2.4

Risks of entrapment between transmission components

........................

40

5.3

Electrical danger

.............................................................................................

40

5.4

Safety warning signs

......................................................................................

42

5.5

Noise

..............................................................................................................

43

5.6

Food hygiene requirements

............................................................................

44

5.7

Concluding remarks

........................................................................................

44

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-I

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

3

1. Introduction

1.1 Foreword

1.2 Guarantee: validity and therms

The machine is covered by six months guarantee from the date of delivery

limited to any parts that show manufacturing defects with the exception of

the electrical plant.

The guarantee is not applicable to parts of the machine that have been

damaged during transport, due to poor or incorrect installation or main-

tenance, and due to negligence or unskilled use.

The guarantee holdsvalid only for the original purchaser of the machine and

shall not envisage the complete replacement of the machine under any

circumstances. The guarantee shall be null and void if the machine has

been tampered with, modified or repaired by personnel who have not been

previously authorised by C.M. SOTTORIVA S.p.A.

The Manufacturer shall not be held liable for possible direct or indirect

damage or injury to animals, persons or property caused by malfunctions of

the machine or any damages resulting from the failure of the machine to

operate. The repair or replacement of defective parts of the machine is

normally carried out on the client’s premises and is therefore subject to

charges for travel, board and accommodation for the personnel sent to carry

out the work. The client will also be charged for travelling time and working

hours of the relative personnel, in accordance with the A.n.i.m.a. (Italian

association of food machinery manufacturers) scale. If, at the final decision

of C.M. SOTTORIVA S.p.A. technical personnel, it is impossible to carry out

the work at the client’s premises, the client is required to ship the machine

carriage paid to C.M. SOTTORIVA S.p.A. and, after having carried out the

repairs and maintenance work free of charge, C.M. SOTTORIVA S.p.A. will

ship the machine to the client carriage forward.

When the foregoing guarantee period has elapsed, repair and maintenance

will be carried out and labour costs (according to A.n.i.m.a. scale) travel,

board and accommodation, the cost of the replacement parts and any

relative transport costs will be borne by the client.

Labour rates in accordance with the A.n.i.m.a. scale will be in the

possession of the technical personnel that perform the work.

For valid guarantee claims, the guarantee certificate (see facsimile below)

must be duly compiled in all its parts and returned within

15 days

of the date

of delivery.

Caution!

Before starting the machine

read carefully the instructions in this

handbook and adhere strictly to the recommendations contained

herein.

CONSERVE this handbook and all attached documentation in a

place that is accessible and known to all operators and maintenance

personnel; the handbook must be kept in a dry place, preferably in

an envelope to protect it against dust, damp, light, etc.

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

4

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-I

In the event that the party making the claim is unable to exhibit a copy of the

certificate (responsibility of the customer), the guarantee may be considered

null and void.

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-I

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

5

1.3 User instructions and warnings

The manufacturer declines all liability for injury to persons or animals and

damage to property resulting from the failure to observe the

recommendations for the use and maintenance of the machine as specified

in this handbook.

z

DO NOT USE

the machine for uses and/or loads other than those indica-

ted by the manufacturer.

z

z

CARRY OUT CHECKS

on a dailybasis ofall safety devices, oil levels and

general condition of the machine.

z

z

CLEAN

the machine thoroughly every day.

z

z

ADOPT

suitablemeasuresandprecautionstomakesurethat themachine

cannot be started by other persons - even accidentally - while loading,

adjusting, changing parts, cleaning, repairing or servicing the machine.

z

z

DO NOT TAMPER WITH

the safety guards and safety devices on the

machine.

z

z

DO NOT REMOVE

the guards and the safety devices unless strictly

necessary for operational requirements and after having taken all the

necessary measures to minimise risks deriving from such action as descri-

bed in detail in this handbook.

z

z

REPLACE

all guards and safety devices as soon as the reasons that cal-

led for their temporary removal are no longer applicable.

z

OBSERVE THE FOLLOWING REGULATIONS

regarding workplace

safety and procedures:

-

regulations on safety notices and warnings as stated in DD.PP.RR.27/4/55,

n° 547 and n° 524 ofdate 8/6/82 and in D.Lgs 493/96 forItaly,or equivalent

regulations in the country where the machine is used;

-

European directives concerning workplace safety as stated in 89/391/CEE,

89/654/CEE, 89/655/EEC, 89/656/EEC, 90/269/EEC, 90/270/EEC,

90/394/EEC, 90/679/EEC, 95/63/EEC;

-

European directives concerning individualprotection measures as stated in

89/656/EEC and 89/686/EEC;

-

European directives on the environment, with special regard to

91/156

/EEC

concerning waste disposal,

91/689

/EEC on the disposalof dangerous waste

and 75/439/EEC on the disposal of used oils.

z

INFORM ALL PERSONNEL

of the specific hazards present in the work-

place.

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

6

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-I

Photo 1

2

1

5

3

4

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-II

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

7

2. Descriptive manual

2.1 Foreword

The machine shown in photo 1 and described in this handbook is designed

for use in bakeries and confectionaries for the production of round forms of

dough for special bakery and/or confectioner’s products whose basic

components are wheat flour and water.

Any attempt to employ the machine for other uses is potentially dangerous

for the mechanical devices on the machine and hence for the operator.

The positions normally occupied by the operator are shown below and

marked Lp. These are also the reference positions for noise testing

(see par.

5.5

).

2.2 Description

The machine (see

Photo 1

) is fitted with a hopper

ref. 1

Photo 1

into which

to load the dough to be divided.

A piston type dividing system located beneath the hopper approximately in

the area indicated by

ref. 2

divides the dough into pieces of a set weight.

The pieces are conveyed out by means of a conveyor belt

ref. 3

Photo 1

which can be of two different lengths.

The electrical panel

ref. 4

Photo 1

is located below the infeed belt.

Lp 1

Lp 2

Lp 3

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

8

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-II

Photo 2

Fig. 1

1

3

5

4

2

6

5

6

3

2

4

1

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-II

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

9

A flour unit

ref. 5

Photo 1

is located above the outfeed belt and can be

switched on or off when the machine is running by means of a lever switch

positioned on the unit itself.

The quantityof flour per unit time delivered onto the belt, and hence onto the

product, can be adjusted with the knob on the front of the flour unit.

The long version of the outfeed belt can be folded back on itself when the

machine is at rest simply by lifting it with one hand, in order to reduce the

overall dimensions of the machine.

Finally, the version of the machine with geared motor marked “R” can

produce pieces in either 1 or two rows (obtainable product weights change

of course).

The following devices are located on the control panel

ref. 1

Photo 2

(see

Fig. 1

):

Ref. 1:

emergency stop pushbutton

Ref. 2:

run pushbutton

Ref. 3:

main stop pushbutton

Ref. 4:

power ON warning light (white)

Ref. 5:

divider only stop pushbutton

Ref. 6:

oil alarm warning light (red)

The following control and adjustment devices are also located on the

machine:

z

Handwheel

ref. 2

Photo 2

: for adjusting production speed or number of

pieces per unit time for the same number of rows (see para. 3.6).

z

Handwheel

ref. 3

Photo 2

: for adjusting the weight of the dough pieces.

z

Main switch

ref. 4

Photo 2

located on the electrical panel.

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

10

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-II

Fig. 2

Fig. 3

1180380

1560

590

ø D

1560

342

728

1060 208

1650

800-900

Via Vittorio Veneto, 63

36035 MARANO VICENTINO

(Vicenza) - ITALY

Phone (+39) 0445.595.111

Fax (+39) 0445.595.155

E-mail:sottoriva@sottoriva.com

P.I. 00768890246

Mod.

n°

V

XXX

Hz

XX

kW

XX

SVP ...-E

XXXXXX

A

XX 3 AC + (N) + T

Mass kg

XXXX

200_

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-II

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

11

2.3 Overall dimensions and other specifications

Fig. 2

shows the dimensions of the machine; the diameter D of the hopper

mouth depends on its capacity as follows:

*

Diameters for SVP machines which can be combined with SC

SOTTORIVA lifting/turnover units; for SVP units that can be combined with

other machines, these diameters may vary even for the same hopper

capacity.

Table 1 shows the installed power and other characteristics data.

N

indicates the normal version and

R

indicates the version with geared

motor.

Table 1

2.4 Machine identification plate

Fig. 3

shows the data plate, and

Fig. 2

shows the position in which it is fixed

to the machine with rivets or screws. It is made of aluminium, with the data

indelibly stamped or screen printed on to it.

C

A

P

A

C

I

T

Y

(kg)

D

70

mm 560

160

mm 1100*

240

mm 1400*

SVP/0-E

SVP/1-E

SVP/2-E

SVP/3-E

N

R

N

R

N

R

N

R

Min/max pieces size (g)

90

900

30

200

200

1700

50

300

300

2700

100

500

500

4000

250

1000

Divider motor power (kW)

1.10

1.10

1.10

1.10

Machine Mass (kg)

660

675

680

700

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

12

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-II

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-III

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

13

3. Operation and installation

manual

3.1 Foreword

In accordance with European Community Directive No. 98/37/CEE, and for

the purposes of this manual, the following definitions will be used:

1) "

Hazard zone

": any zone inside and/or near the machine, where the pre-

sence of a person constitutes a risk for the health and safety ofthat person.

2) "

Person at risk

": anyone inside or partially inside a danger zone.

3) "

Operator

": the person or personsresponsible for installing, running, adju-

sting,cleaning, repairing, transporting or performing maintenance work on

a machine.

3.2 Workplace requirements

The room where the machine is to be installed, assuming that it is to be

used for the production (cooking included) of bakery products, must meet

the following requirements:

z

it musthave spaces wide enough to allow transit ofthe bulkiest parts of the

machine;

z

it must be built in compliance with current regulations;

z

it must have an electrical system that complies with current regulations,

especially the earth connection system and the main electrical panel with

current overload and short circuit protection devices. The installed power

rating is stated on the machine identification plate.

The entire electricalsystem must be properly installedand subject to perio-

dic maintenance and inspection by professionally trained personnel who

are able to certify each of the jobs they perform with a declaration of "good

workmanship".

3.3 Transporting the machine

Fig. 4

shows the system for securing the machine for lifting, having first

removed the upper protection guards.

Lift the machine using belts or ropes of adequate capacity and which comply

with the relevant laws and standards.

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

14

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-III

Fig. 4

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-III

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

15

3.4 Machine installation

3.4.1

Installation warnings

Position the machine so that the free length of power cable from the

machine to the socket is as short as possible.

3.4.2

Notes for the electrical installation personnel

The electrical installer must be qualified and experienced in carrying out

work of this nature and should therefore be aware of the various technical

notions and applicable standards to guarantee high standards of

workmanship.

Hook-up of the machine to the bakery electrical installation must be carried

out in compliance with the established regulations and prescriptions with

reference to the information and instructions contained in the present

handbook. For this work the machine is supplied with a CEI 20-22 electrical

cable and an EC standard plug with as many poles as indicated on the

machine dataplate. The machine must be connected to a proper and

efficient earthing plant. Do not use makeshift solutions by connecting the

earth to water pipes, gas pipes or other metal structures.

The power feeding cable must be kept well clear of heated surfaces and

moving parts. It must also be installed in such a way that it does not present

an obstruction to the movement of personnel and materials in the bakery.

Caution!

Before lifting the machine, make sure that the lifting ropes and lifting

equipment are of suitable load capacity in relation to the weight of

the machine.

Caution!

When lifting and lowering the machine, the ascent and descent

movements must be as gradual and smooth as possible, avoiding

jerkiness and sudden increases in kinetic energy that are difficult to

withstand when the movement is stopped suddenly.

Caution

!

Make sure that line voltage is the same as the voltage required by the

machine as clearly shown on the machine dataplate (heading 2.4).

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

16

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-III

3.5 Start up

1) Make sure that the machine voltage shown on the dataplate (see

2.4

) cor-

responds to the line voltage available in the place of installation; if it does

not,donotmaketheelectricalhook-up;contactyour dealeror themachine

manufacturer immediately.

2) Make sure that the motors rotate in the correct direction; to do this, plug

the machine into the power socket, set the main switch to position 1 (the

warning light

ref. 4

Fig. 1

will indicate that the power is on); press the start

button

ref. 2

Fig. 1

, standing by to press the emergency stop pushbutton

ref. 1

Fig. 1

if necessary. The direction of movement of the top of the

outfeed belt

ref. 3

Photo 1

must be outwards from the machine. Ifit moves

in the opposite direction, press pushbutton

ref. 1

Fig. 1

; unplug the

machine, open the plug by unscrewing the screws shown in the figure

below and invert the position of the brown and black wires.

If the connection is three phase + neutral + earth there will be two black

wires. In this case either of the black wires can be inverted with the brown

wire. In the case of a three phase + earth cable there is only one black wire

so there is no alternative for the inversion with the brown wire position.

Close the plug with the screws as shown in the above figure and re-insert it

in the power socket. Repeat the steps described at the beginning of this

heading to make sure that the direction of rotation of the motors is correct.

Once you have checked the direction of rotation, switch the machine off.

Caution

Never disconnect or change the position of the yellow/green wire

(earth) and/or the blue wire(s).

Caution

Tampering with/replacing one or more machine components or

assemblies, and/or the use of accessories/attachments or con-suma-

bles that are different from the parts recommended by the Manufac-

turer can result in potential danger of injury to the machine operator

or exposed persons and will auto-matically relieve the Manufacturer

of any what-soever liability for injury to persons and/or damage to

property that may arise.

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-III

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

17

Photo 3

Foto 3/B

Foto 3/C

Photo 3

Photo 3/A

Right position

Wrong position

2

1

3

Rev. 0

dated 19/06/2001

SVP 0/1/2/3-E - Code: 3529.0091.01

18

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

601

PP

601

GC

601

16-III

Photo 4

SVP 0/1/2/3-E - Code: 3529.0091.01

Rev. 0

dated 19/06/2001

16-III

PT

601

PP

601

GC

601

Technical Assistance Service

Tel. (+39) 0445.595.111

19

3.6 Operation

This section describes the operating modes of the machine, what they are

used for, how the various controls are used and the order in which

operations must be performed.

If you have the version with long outfeed belt, bring the belt into a horizontal

position before starting the machine. It is strictly forbidden to start the

machine with the outfeed belt raised and/or folded. The belt must be lifted

and folded only when you want to put the machine in the rest state in a non-

working area or for the purpose of transport. Before lifting and/or folding it,

always unplug the machine.

If you have the version "with geared motor" (e.g. SVP1/R), before starting it,

select the desired number of rows (1 or 2) as follows:

-

lock the pin

ref. 1

Photo 4

in the raised position (also see photo 3/A) if you

want the machine to work in a single row.

-

ifthe pin

ref. 1

Photo 4

is in the lowered position (see photo 3/A) (to do this,

simply lift and turn until the transverse pin

ref. 2

Photo 4

can enter the

appropriate groove in the support

ref. 3

Photo 4

) the machine will work in

two rows.

Set the desired product weight by turning the handwheel

ref. 3

Photo 2

and

referring to the mark on the lateral graduated scale.

Place the pin

ref. 1

Photo 4

in the appropriate hole for the desired piece

size: the table below gives a guide to positioning the pin

ref. 1

Photo 4

, and

the piece size index to set, according to desired piece

size and machine

version, for dividers not equipped with geared motor (if the machine has a

geared motor, simply draw up a table similar to the one below).

Caution

Before performing any manoeuvre, make certain that the mains vol-

tage is the same as the voltage required by the machine and clearly

marked on the identification plate (

2.4

).

Caution

When the pin is lowered, its bottom end must be positioned as shown

in photo 3/B in relation to the bronze protrusion on the geared motor

piston. Do not position it on the other side (as in photo 3/C) as this

would cause serious mechanical damage to the machine.

This manual suits for next models

3

Table of contents

Other Sottoriva Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Inoksan

Inoksan 700 Series instruction manual

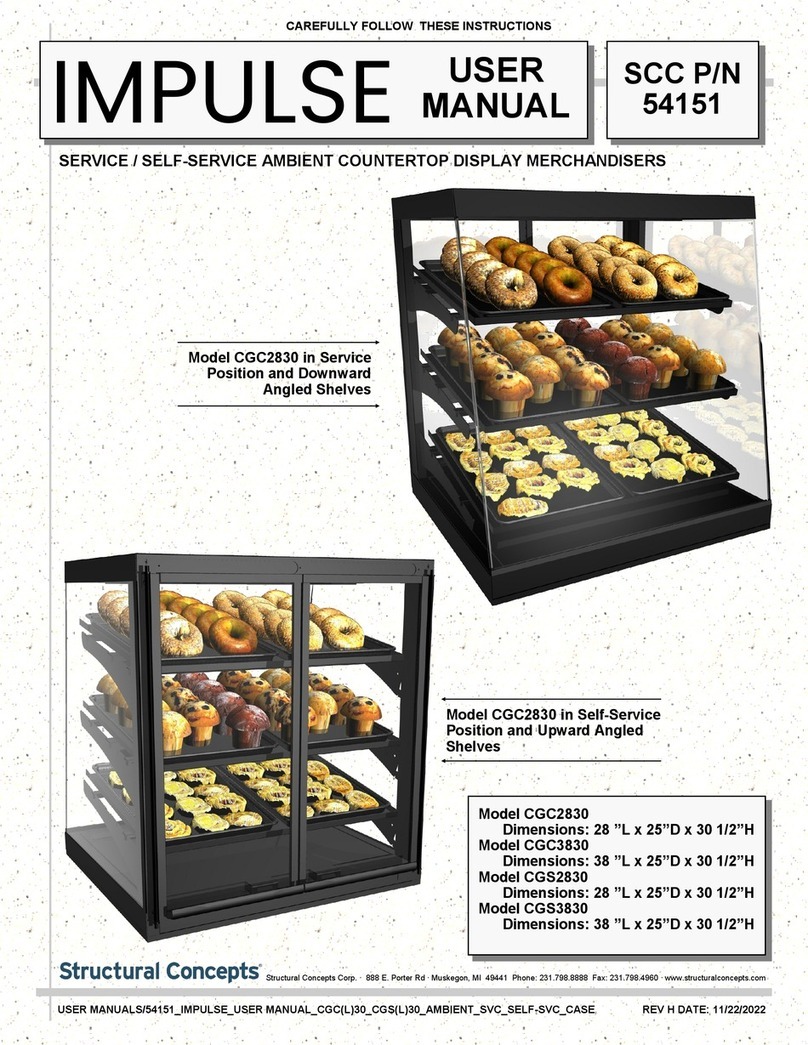

Structural Concepts

Structural Concepts IMPULSE CGC2830 user manual

Salvis

Salvis GreenVac instruction manual

Vollrath

Vollrath 60038 Operator's manual

Rieber

Rieber Rolling Buffet Series Translation of the original operating instructions

Silver King

Silver King SKFMW34-ELUS5 Technical manual