Sottoriva SPT0/1-E User manual

INSTRUCTION MANUAL

Mod. SPT0/1-E - SPT3/1-E

Dough Sheeter

Version: ENGLISH Arch.: 86

Code: 3529.0031.01

Revision: A dated 06/09/2011

Costruzioni Meccaniche SOTTORIVA S.p.A.

Via Vittorio Veneto, 63 - 36035 MARANO VICENTINO (VI) ITALIA

Phone (+39) 0445.595.111 - Fax (+39) 0445.595.155

Web site: www.sottoriva.com - E-mail: sottoriva@sottoriva.com

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 1

MANUAL DOUGH SHEETER

mod. SPT0/1-E

and

mod. SPT3/1-E

Photo 1

This manual contains the guarantee coupon

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

2 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 3

1- GENERAL .............................................................................................................4

1.1. GUARANTEE................................................................................................................. 5

1.2 GENERAL WARNINGS AND APPLICATION....................................................................... 6

1.3 RATING PLATE DATA......................................................................................................... 7

1.4 TRANSPORT INSTRUCTIONS............................................................................................ 8

1.5 ASSEMBLY.......................................................................................................................... 9

1.6 INSTRUCTIONS FOR INDOOR HANDLING ..................................................................... 11

1.7 DECOMMISSIONING ........................................................................................................ 11

2- TECHNICAL SPECIFICATIONS.........................................................................12

2.1 TECHNICAL DESCRIPTION.............................................................................................. 13

2.2 TECHNICAL SPECIFICATIONS ........................................................................................ 15

3- STARTING UP.....................................................................................................16

3.1 INSTALLATION.................................................................................................................. 17

3.2 CONNECTION TO THE MAINS......................................................................................... 18

4 - INSTRUCTIONS FOR USE................................................................................19

4.1 GENERAL INFORMATION................................................................................................ 20

4.2 USE OF THE MACHINE .................................................................................................... 21

4.3 MACHINE CONTROLS...................................................................................................... 22

5- MAINTENANCE AND CLEANING......................................................................23

5.1 MAINTENANCE.................................................................................................................24

5.2 CLEANING......................................................................................................................... 24

6- OPERATING FAULTS ........................................................................................26

6.1 TROUBLE SHOOTING...................................................................................................... 27

7- SAFETY WARNINGS..........................................................................................28

7.1 SAFETY DEVICES............................................................................................................. 29

7.2 SAFETY AND IDENTIFICATION PLATES......................................................................... 30

7.3 PROHIBITIONS AND OBLIGATIONS FOR PREVENTION OF ACCIDENTS.................... 31

8 - SPARE PARTS ..................................................................................................32

8.1 INSTRUCTIONS FOR ORDERING.................................................................................... 33

8.2 PLATE N° 1 - STRUCTURE AND COMPONENTS.......................................................... 34

8.3 PLATE N° 2 - PULLEY AND MOTOR UNIT SPT0/1-E – SPT3/1-E................................... 35

8.5 PLATE N° 4 - HANDLE UNIT........................................................................................... 37

8.5 PLATE N° 4 - HANDLE UNIT............................................................................................ 38

8.6 PLATE N° 5 - CONVEYOR BELT UNIT............................................................................ 39

8.7 TAV. N°7 - SCRAPERS ..................................................................................................... 40

8.8 TAV. N° 7 – BASEMENT GROUP.................................................................................... 41

8.9 ADVISABLE SPARE PARTS ............................................................................................. 45

9- ACCESSORIES ON REQUEST..........................................................................47

9.1 2-SPEED MACHINE FOR CUTTING DEVICE APPLICATION........................................... 48

9.2 ROLLERS HOLDER FOR DOUGH CUTTING ................................................................... 48

9.3 ROLLERS WITH VARIOUS SIZES AND SHAPES ............................................................ 48

10- ELECTRICAL EQUIPMENT..............................................................................49

10.1 DESCRIPTION................................................................................................................. 50

10.2 DOCUMENTATION.......................................................................................................... 51

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

4 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

1- GENERAL

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 5

1.1. GUARANTEE

The manufacturer guarantees the good working and the quality of this sheeter for a period of 6

months from the shipping date, in the case ONLY of mailing the underneath filled and signed

coupon within 15 days from receipt of the machine.

The guarantee will be valid only with the correct use and maintenance of the machine as per

enclosed instructions.

The guarantee won’t be any more valid in in the following cases:

− non-authorised modifications or work on the machine;

− use of non-original spare parts or parts not specific for the model;

− failure to follow the instructions, even partially.

− normal wear of the concerned parts.

The guarantee is limited to the substitution of the defected part only. All the other claims such as

indemnities for interruption of the production or similar are not considered in the guarantee.

If necessary, the supplier can ask the machine to be returned for repair during the guarantee

period.

---------------------------------------------------------------------------------------------------------------------------------

to be rendered to the supplier

This coupon has to be mailed back to the supplier before starting working with the

machine

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

6 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

1.2 GENERAL WARNINGS AND APPLICATION

The aim of this manual is:

− To facilitate understanding and operation of the machine and enable the system to be used to

its full technical potential.

− To provide instructions for the most effective and rational maintenance and help the operator to

understand any faults and how to remedy them.

− To warn against risks inherent in use of the machine due to failure to observe the safety

regulations.

− To indicate working limits for maintaining hygiene and environmental conditions and to ensure

health at work.

These pages must be read carefully before starting the machine.

This manual forms an integral part of the product; it must be kept near the machine for prompt

easy consultation and must also be kept for future reference until the machine is scrapped.

The manufacturer does not guarantee the technical-legal suitability of the installation premises and

machine supporting services but provides all instructions for correct installation in the relevant

section of this manual.

For the above, the user is advised to contact an expert professional technician, also for

compliance with any local laws or regulations.

• The machine is designed for the food industry.

It is a machine designed for sheeting of dough obtained with different types of ingredients like

flour, water, sugar, fat, butter, salt, yeast, etc. and of medium consistency for cake-making in

general.

• The machine must be used only for the purpose for which it has been designed. All other uses

are considered inappropriate and therefore unreasonable.

The manufacturer cannot be held liable for incorrect use, inappropriate and/or

unreasonable acts.

The manufacturer cannot be held liable for any damage caused by inappropriate, incorrect or

unreasonable use, for example:

− inappropriate use by non-trained personnel;

− non-authorised modifications or work on the machine;

− use of non-original spare parts or parts not specific for the model;

− failure to follow the instructions, even partially.

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 7

1.3 RATING PLATE DATA

The picture 0A shows exactly the registration plate applied on the machine. On picture 2 an arrow

indicates the position where this plate is fixed on the basement of the machine. The plate is

realised in serigraphed aluminium and all the registration datas are engraved, to last as long as

possible.

picture 0A

C. M. SOTTORIVA S.p.A.

Via Vittorio Veneto, 63

36035 MARANO VIC.NO

(VICENZA) - ITALY

Mod.

N°

V Hz

kW

201_

Tel. (+39) 0445.595.111

Fax (+39) 0445.595.155

Email: sottoriva@sottoriva.com

Web site: www.sottoriva.com

SPT0/1-E (o SPT3/1-E)

A 3 AC + (N) + T

Massa kg

Photo 2

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

8 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

1.4 TRANSPORT INSTRUCTIONS

A B

PACKAGING DATA

− The machine is supplied on a pallet, in a strapped triple-layer corrugated cardboard box.

MACHINE MOD. TYPE OF PACKAGING WEIGHT KG A mm B mm H mm

SPT0/1-E Pallet and cardboard box 1120 1170 1740

SPT0/1-L-E Pallet and cardboard box 1120 1170 1740

SPT3-1-L Pallet and cardboard box 1120 1170 1740

INSTRUCTIONS FOR TRANSPORT AND UNLOADING

− Loading and unloading from the vehicle can be performed:

− by means of crane, see figure “A”

− by means of forklift truck, see figure “B”.

− The machine must be transported adopting all precautions to prevent damage to the machine.

− In particular the machine must not be placed on top of other materials and vice versa either

during transport or storage.

− During transport the machine must be positioned so that it cannot be knocked by other

materials loaded on the same vehicle.

− Before unloading from the vehicle, check that the packaging is intact and that there is no risk of

tipping over.

− During unloading, place the machine carefully on the ground to prevent it being knocked.

!CAUTION When handling, pay attention to all the indications on the packaging. The

capacity of the belts must be adequate for the weight of the packages. Do

not use metal belts.

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 9

1.5 ASSEMBLY

The machine is delivered on a pallet and wrapped with plastic. In order to

assure a safe transportation, the working tables are diassembled and the

basement is fixed with 4 screws.

It is necessary to take off the plastic carefully in order to avoid the tables

or other compounds to fall down.

On the picture is indicated with number 1 a shaft located behind the

tables which has to be used as table support. Unscrew the screw nr.2 to

release the shaft and turn round the plate nr 3. This operation has to be

done on both sides of the machine.

Be carefull not to loose the 2 white plastic rings on the shaft 1

Photo 3

the shaft will be hanged on the table from side to side.

The 2 white rings are mounted on each end of the shaft

Photo 4

Now the table will be hoisted in order to replace the shaft on its

seat, then it is necessari to block it with the plate nr 3 and fix the

plate with the scre as indicated on number 2 on the side picture

Photo 5

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

10 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

Inside the packing is located the 2 table supports. The assembly of

these supports is very easy.

Once the table is assembled, it is necessary to keep it up to mount the

supports.

The supporting leg has to be hanged inside the porthole as indicated in

the side picture

Revolve lightly the leg and lift it up till the screws on the table,

unscrew the screws and fix them with the leg ends as indicated

on the side picture.

Photo 6

The table ends are fitted with 2 belt ties Le estremità del piano

sono dotate di una coppia di tirannti tappeto che servono anche

da appoggio per i piani. Come indicato nella foto a lato con il

mumero 6.

Photo 7

Unscrew the 2 screws indicated on point 7, revolve all the group

(the 2 legs and the free wheel) until the position indicated on side

picture, then screw back again the screw 7 as previous position

tightening the belt.

Now the table is completely assembled, proceed on the same

way to assemble to opposite one. To unpack completely the

machine, it is necessary to open the 2 side doors; inside the

basement is fixed to the pallets by 4 screws. Remove the screws

to take off the machine

Photo 8

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 11

1.6 INSTRUCTIONS FOR INDOOR HANDLING

The dough sheeter mod.SPT0/1-E – SPT3/1-E is provided with three wheels, two rear wheels(*)

and one front wheel, and two stabiliser feet located at the side of the front wheel. The front wheel

is operated by a mechanical pedal located at the front of the machine just above floor level. The

stabiliser feet are designed to ensure correct machine stability with respect to the floor. The

machine must be positioned in its place of work using the wheels. As soon as you have found the

ideal work position, press the pedal: the machine will be lowered slightly and the two feet will rest

on the floor. To move the machine again, raise it four centimetres by means of the handle and

release the weight. The front wheel is now ready for operation.

If you need to clean the floor or other, the two side worktops can be raised. This operation must be

performed raising one worktop at a time. Once maximum lifting position has been reached, a

mechanical stop will cut in consisting of a pin in the worktop engaging in a slot in the protection

grid.

Once the machine is positionned on the other place, stabilise it through the pedal located on the

bottom of the basement.

!CAUTION Indoor handling must be performed by adopting all the precautions

necessary to prevent damage to the machine components.

(*) The front or rear position is defined with respect to an operator standing in front of the

calibration thickness adjustment handle.

1.7 DECOMMISSIONING

1.7.1 SETTING ASIDE

− If the machine has to be stored, it must be protected against dust and stored in a covered

place.

− If the machine is not going to be used for a long time, it must be protected against dust and

atmospheric agents by means of appropriate covering.

− No special precautions are required for the motor and electrical system; simply follow the above

instructions.

1.7.2 SCRAPPING

− To scrap the machine, proceed as follows:

1. Eliminate the electricity supply cable.

2. Remove all moving parts that could be a hazard.

3. Dispose of the majority of parts as scrap metal and take to authorised scrapyards.

4. The other parts, plastic for example, must be disposed of according to current

regulations, via specialist firms if necessary.

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

12 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

2- TECHNICAL SPECIFICATIONS

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 13

2.1 TECHNICAL DESCRIPTION

APPLICATION

• The machine is designed for the food industry.

It is a machine designed for sheeting of dough obtained with different types of ingredients like

flour, water, sugar, fat, butter, salt, yeast, etc. and of medium consistency for cake-making in

general.

• The machine must be used only for the purpose for which it has been designed. All other uses

are considered inappropriate and therefore unreasonable.

COMPOSITION OF THE MACHINE

Model SPT0/1-E – SPT3/1-E

− The dough sheeter consists mainly of a supporting structure (1) and three plastic covering

panels (2) - (4).

− The supporting structure (1) consists of a shaped welded metal sheet made of painted steel

with two sides (in aluminium) fitted above it and screwed together by means of metal spacers.

− Cover (2) houses the belt drive unit. Cover (3) houses the electric motor and cover (4) the drive

unit, called clutch unit, for reversing the movement of the machine.

− The base is provided with levelling system (5) to ensure machine stability.

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

14 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

OPERATION

Model SPT0/1-E – SPT3/1-E

− The conveyor belts (6) are operated by the control lever (7), with movement according to the

position of the lever. It has two side operating positions and one central position (idle). By

turning the lever to the left, the conveyor belt (6) will move from right to left and vice versa; if

the lever is set to the central intermediate position (idle) the conveyor belts will be at a standstill.

− If devices other than the control lever (7) are activated during operation, for example one of the

two safety grilles (10) is raised, the machine will immediately stop. Press the start button (9) to

re-start the machine.

− Via the handle (11) the product thickness can be varied from zero (0) millimetres to thirty-five

(35) millimetres. The rolling thickness expressed in millimetres can be read on the self-adhesive

label coinciding with one of the handle references. Rolling must be performed gradually,

starting from the thickest size (35 mm) and gradually reaching the thickness required.

MACHINE MOVEMENT

− The single-speed motor operates the calibration cylinders via pulley, belt and driven pulley. In

their turn, the calibrating cylinders operate the clutch centre drive. The electric motor rotation

can be reversed by means of the control lever (7) in conjunction with internal switches. This

control lever pivots the coupling gears which, according to the motor rotation direction, engage

the drive cylinder of one of the conveyor belts.

PROTECTIONS

− The central area consisting of the two calibrating cylinders, considered the most dangerous

area for the operator, is completely covered and protected by two side protection grilles (10).

They are made entirely of stainless steel. If one of the two grilles is raised, even by a few

millimetres, a microswitch will cut in, immediately stopping the machine.

− The conveyor surfaces, on which the conveyor belts rotate, are designed so that the operator

cannot insert his fingers between the surface and the belt.

ELECTRICAL SYSTEM

All the electrical components subject to rated voltage and the electric motors are enclosed in a

casing with IP 54 protection rating. The control elements, push-buttons and selectors operate at

low voltage (24V) and are enclosed in casing with IP 54 protection rating.

The machine is designed for earth connection to protect against indirect contact risks (Chap. 10).

The electrical power and control circuit is provided with its own protection devices against short

circuits and overloads.

On the front of the machine, opposite the operator’s normal working position, is the

stop/emergency button (see chap. 4.2). This button disables the start buttons, thus preventing the

machine from being started. Reset, which is obtained by pulling the button cap, does not

automatically restart the machine.

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 15

2.2 TECHNICAL SPECIFICATIONS

MODEL Cylinder

diam. Cylinder

opening Outlet belt

speed Belt

width Belt

length Motor power

kW Weight

kg

SPT0/1-E 84 mm 0.2-35 mm 50 cm/sec 500 750 0.55 140

SPT0/1-L-E 84 mm 0.2-35 mm 50 cm/sec 500 1000 0.55 150

SPT3/1-E 84 mm 0.2-35 mm 50 cm/sec 600 1000 0.55 160

NOISE: below 70 dB.

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

16 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

3- STARTING UP

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date

06/09/2011

Arc. 86 Technical Assistance Service - Phone (+39) 0445.595.111 17

3.1 INSTALLATION

− Choose a suitable place for

installing the machine, observing

the minimum distances from the

walls as shown in the figure at

the side. These spaces are

necessary for cleaning and

routine maintenance operations

and also ensure safe operating

conditions without the danger of

dragging in and/or crushing.

− The room must be provided with

adequate lighting and ventilation.

− Check that the connections have been made as specified in this manual (electricity).

− After unpacking the machine, ensure that it is in perfect condition, checking that there are no

visibly damaged parts. If in doubt, contact professionally qualified personnel (your dealer) and

do not use the machine.

− The packaging elements (plastic, nails, screws, wood etc.) must not be left within the reach of

children as they are potential hazards; they must be appropriately disposed of, especially if they

are polluting.

!CAUTION For ambient lighting you are advised to follow the specifications of the laws

in force.

− Position the machine and ensure

that it is stable:

• Adjust the height of the foot by

tightening or loosening it until the

machine is stable.

Once the machine has been levelled, it

will remain stable and does not require

any anchoring to the ground.

N.B.: All the machine feet are

adjustable.

USE AND MAINTENANCE MANUAL

MANUAL DOUGH SHEETER

Mod. SPT0/1-E - SPT3/1-E

Code

3529.0031.01

Revision A

date 06/09/2011

18 Technical Assistance Service - Phone (+39) 0445.595.111 Arc. 86

3.2 CONNECTION TO THE MAINS

− The machine is provided with one single electrical connection with connection cable at the rear.

− Check that the rating plate voltage corresponds to the mains voltage.

− The machine must be connected to a manual control voltage disconnection device fitted in an

easily accessible position so that the machine electrical equipment can be separated from the

mains when necessary (e.g. during maintenance or cleaning).

− For sizing of the cable and disconnection device, see wiring diagram data.

− If not supplied, fit a retention plug to the machine connection cable suitable for the

disconnecting device installed and connect to the socket.

− Following the operating instructions (Chap. 4), with the machine empty, start and run a few right

and left rolling tests, adjusting the rolling thickness.

− To connect the plug to the supply cable (when not provided) refer to figure –a1-; this operation

must be performed in compliance with the “CAUTION” note at the foot of the page.

Fig. –a1-

NOTE: REGULATIONS FOR SAFETY OF ELECTRICAL SYSTEMS

In Italy electrical equipment must meet the requirements not only of the CEI technical

specifications but also the provisions of the law of 5.3.1990, no. 46, and related Implementation

Regulation, DPR 6.12.1991, no. 47.

In particular, the system must be installed by a technically and professionally qualified electrician

listed in the appropriate register. The installer is obliged to provide the customer with a declaration

of conformity.

Old systems should be checked in order to adapt them to the latest safety regulations and state-

of-the-art.

!CAUTION Operations on the electrical part of the machine, even if minor, must be

performed by professionally qualified personnel.

This manual suits for next models

1

Table of contents

Other Sottoriva Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Cambro

Cambro Camtherm CHPL100 owner's manual

Diamond

Diamond ES6/BMT-N manual

Redfox

Redfox BR 70/80 G Instructions for installation and use

Salvajor

Salvajor ScrapMaster 300-SM Installation & operating instructions

Antunes

Antunes Chick-fil-A ES-600R owner's manual

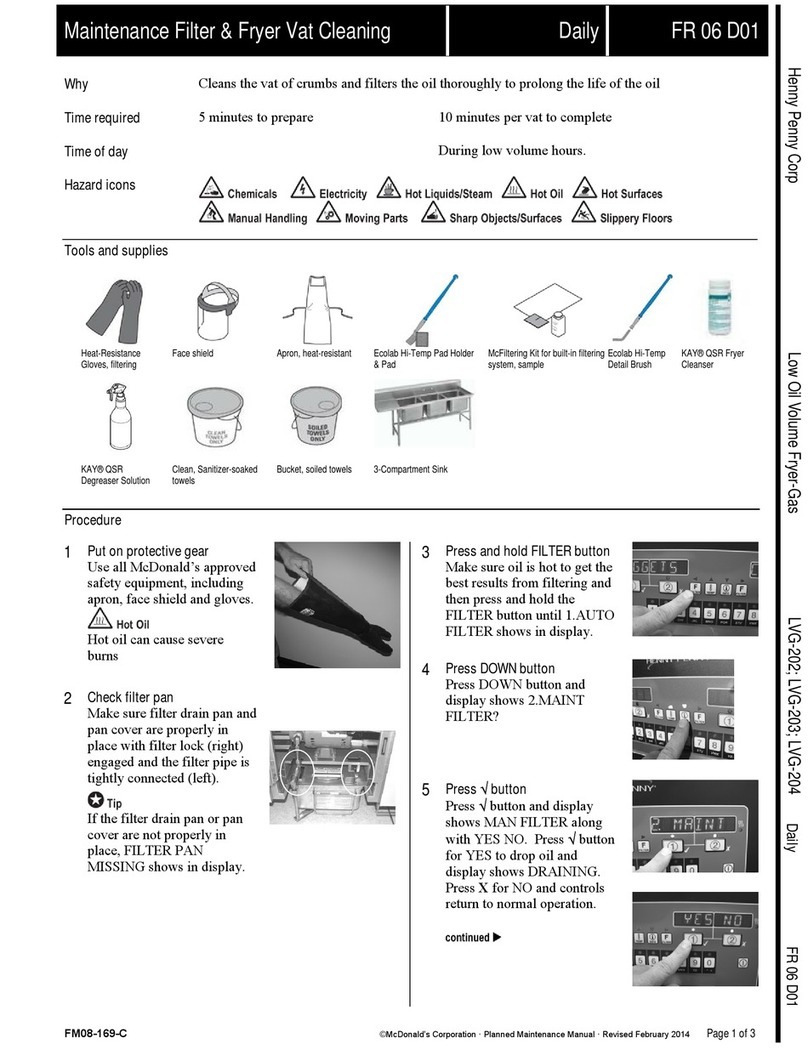

Henny Penny

Henny Penny LOV Gas 200 Series quick start guide

Redfox

Redfox FE 70/04 E Instructions for installation and use

Allure

Allure Melanger 4-0.25-230-50-A owner's manual

frost-trol

frost-trol ALBORAN BM Installation and maintenance manual

Reveal

Reveal ZERO ZONE Installation & operation manual

BRIKA

BRIKA BSP-12 product manual

Ritter

Ritter Solida 4 operating instructions