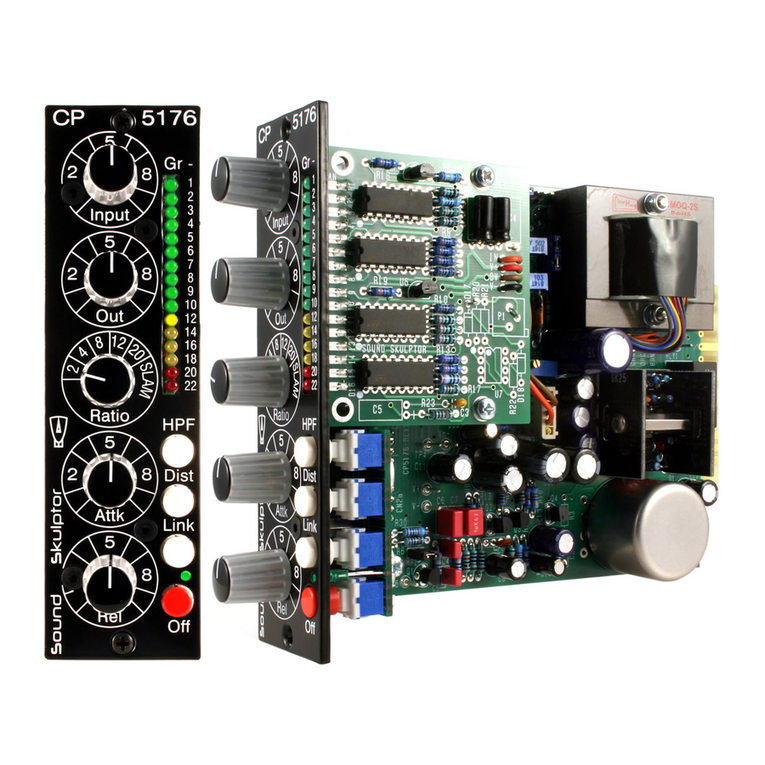

Sound Skulptor CP5176 User manual

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide

Safety warning

The kits are main powered and use potentially lethal voltages. Under no circumstance should someone undertake the

realisation of a kit unless he has full knowledge about safely handling main powered devices.

Please read the “DIY guide” before beginning.

Print or open the following documents :

• CP517 Schematics

• CP517 Components layout

• CP517 Parts list

• CP517 Setup guide

Follow this guide from item number 1 till the end, in this order. The assembly order is based on components height, from

low to high profile, in order to ease the soldering process : The component you are soldering is always taller than the

previously assembled ones and it is pressing nicely against the work area foam.

Soldering

All the PCB holes are metallized. It means the connection between the top and bottom pads is already

done. The parts must be soldered only from below (unless differently stated).

Use only small diameter solder, 0.5 or 0.7 mm, 1mm maximum. Use the minimum possible amount of

solder. Bad joints are almost always caused by too much solder.

Cut the component leads and pins totally flush with the PCB after soldering. A too long tail could create

an electric connection with the side plate.

Here are two excellent introduction to soldering videos:

http://www.eevblog.com/2011/0 /19/eevblog-180-soldering-tutorial-part-1-tools/

http://www.eevblog.com/2011/07/02/eevblog-183-soldering-tutorial-part-2/

CP517 Assembly guide – Main PCB

1. PCB split

Split the second PCB along the groove. Use extra

thin sandpaper to clean up all the rough sides.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Main PCB

2. PCB to PCB connectors

Insert the female 2x10 connectors on the male

parts and position them on the solder side of the

main PCB. Use the second PCB to create a flat

continuous surface. The female connectors must sit

flat on the second PCB. Solder one or two pins

from this side. Then turn the PCB over and solder the other pins from the components side.

Warning : The connectors are installed

on the solder side

of the PCB (the side without writings).

3. DOA Pin Sockets

Solder the 7 pin sockets for the DOA. Solder one at a time. Insert

one socket, turn over the PCB and press against a solid but flexible

surface like cork or dense foam then solder. The correct positioning

of the sockets is very important for easy insertion of the DOA.

4. Diodes

Add D1, D4 to D8. Use a lead forming tool to bend the leads at 0.4”.

Warning : Make sure to respect the direction of the diodes which is marked by a ring on the component

and a double line on the PCB marking.

5. Resistors – (1)

The best method to select and install the resistors is the following:

1. pick a row of resistors in the resistors bag,

2. Measure one of the resistors with your DMM,

3. Look up the parts-list PDF for the closest value,

4. Check the colour code and quantity for confirmation,

5. Use the search function on the Layout PDF page with the resistor value or reference: the

corresponding resistors are highlighted,

. Insert and solder.

(You can use the same method later, for the capacitors)

. Resistors - (2)

Add R1 to R27, R33 to R35, R40 to R 2.

Control the resistor values with a digital multimeter. Bend the leads at 0.4” with a lead forming tool.,

except for R23 which is bent at à 0. ”.

Warning : It is very important to check the resistors value with a DMM because the colour code can be

ambiguous. For example 1K (brown-black-black-brown-brown) can be confused with 110R (brown-brewn-

black-black-brown).

Warning : Resistors R45 ( K8) and R4 (1K) are 0.1% precision resistors. They must not be confused

with 1%, same value resistors. Their last colour ring is violet instead of brown.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Main PCB

7. Ceramic capacitors

Add C10, C2 , C17, C20, C21, C22.

8. IC Sockets

Insert and solder the 14 pins sockets of UI and U2.

Warning : Make sure to respect the socket direction, marked by a notch.

9. Relay

Add RLY1. Two pins are left without solder.

Warning : Make sure to respect the direction of the relays which is marked by a white line on the

component and on the PCB marking.

10. Test pins

Solder the 10 test pins TP1 to TP7, V+, V- and 0V.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Main PCB

11. Jumper headers

Insert the 5 pins jumper header JMP1. Solder one pin first, check verticality, then solder the other pins.

12. Transistors and regulators

Add Q1 to Q4 and U3.

Warning : Watch out the transistor direction.

13. Film capacitors

Add C1 to C4, C24, C7, C30, C5.

14. Connector

Add CN1. Solder one pin, check verticality then solder the other pins.

15. Trimmer potentiometer

Add P5, P , P7. These 3 trimmers are different from each other. Solder one pin, check verticality then

solder the other pins.

1 . Non polarized small electrolytic capacitors

Add C15, C1 .

These caps are not polarized and can be inserted in any direction.

17. Polarized small electrolytic capacitors

Add C8, C11, C23, C25, C27, C28.

Add C12, C13, C14, C29.

Add C , C9, C31, C32, C33, C34.

Warning : The +lead must go into the +hole. Do not reverse!

18. Inductor

Add L1. This inductor is installed vertically.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Main PCB

19. Input transformer

Pin 1 on the transformer is identified by a red dot. Insert the transformer, pin 1 into hole number 1 and

solder.

Warning : Double check the pin 1 position because this transformer can be mounted backwards!

20. Output transformer

The transformer is mounted using two 25mm M3 screws inserted

from the back of the board. Two metal washers are fitted on each

screw to prevent the transformer touching the PCB. One more

washer is used before the nut to protect the lams.

Shorten the leads to the necessary length, around cm. Strip on

5mm and tin. Insert in the pad hole and bend the tinned tip flat on

the pad before soldering. Cut flush.

21. Non polarized large electrolytic

Add C18. Solder one lead first, adjust verticality then solder the second lead.

This cap is not polarized and can be inserted in any direction.

Copyright ©2013 to Today SoundSkulptor

Nut

Transformer

PCB

1 Washer

2 Washers

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Main PCB

22. IC's

Insert U1 and U2 into their sockets. It is necessary to bend the pins slightly inward before inserting.

Warning: Make sure to insert the IC's in the correct direction which is identified by a notch.

23. Jumpers

Insert one jumper on JMP1 (between pins 2 & 3).

24. Gain reduction meter spacers

Insert a M3x mm screw from below PCB, add two

metal washers and the 20mm spacer.

Repeat for the second spacer.

Copyright ©2013 to Today SoundSkulptor

2 Washers

Spacer

M3x6 mm screw

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Main PCB

25. Visual check

Brush the solder side with a hard tooth brush to remove any remaining solder bits.

Make a full visual check. Any missing component on the board ? Any remaining component in the box ?

When everything looks correct, proceed with the front PCB assembly.

CP517 Assembly guide – front PCB assembly

2 . Diode

Add D3. This diode is installed vertically.

Warning : Make sure to respect the direction of the diode which is marked by a ring on the component

and letter K on the PCB marking.

1. Resistors

Add R28 to R32, R3 to 39.

Control the resistor values with a digital multimeter. The resistors are installed vertically.

2. Ceramic capacitor

Add C19.

3. Connectors 2x10

Solder the two 2x10 connectors on the back of the PCB, inserted from the solder side.

4. Spacers

Attach two 15 mm spacers with two M3x mm screws, inserted from the solder side.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – front PCB assembly

5. 2mm LED

Insert the 2mm LED, taking care of the anode/cathode

position. The shortest leg (cathode) is the closest to the

PCB edge. Temporarily attach the front panel with two

M3x8 mm screws. Adjust the LED flush with the front

panel surface. Solder.

Remove the front panel and spacers.

. Push switches

Insert the push switches, flat on the PCB, in the

correct direction and solder one pin. Check again

the good position then solder the other pins.

Warning : The switch direction is given by the

digits 2 0 1, engraved on one side of the switch.

Match the digits with the ones on the PCB.

Insert the switch caps.

7. Potentiometers

Add P1, P2, P3 and P4. Insert the potentiometers into the PCB holes from the solder side, making sure

the pins fit into the corresponding PCB pads. Attach with washer and nut on the component side, tighten

firmly to ensure a perfect perpendicular position and solder.

Warning : The 4 potentiometers have different values.

8. Rotary switch

Add the positions rotary switch RSW1.

Warning : The position of the switch is critical for a good front-plate matching. The switch rests on 3

small feet that must sit perfectly flat on the PCB. Press the switch on the PCB and solder two opposed

pins. Check position then solder the other pins.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Gain reduction meter

1. LEDs

For each one of the 1 LED's cut the short leg (cathode)

at 5mm from body and cut the long leg (anode) at mm.

Then insert the first green LED on the PCB, long leg (anode) on top. Make sure that

the leg is perfectly parallel to the pad. Solder the anode but leave the cathode free

for now. The position is still easy to adjust until both legs are soldered.

Insert and solder the next LED and repeat until the1 LEDs are in position.

Make a last visual check and correct LED's that are not perfectly lined up, then

solder the cathodes on the PCB back side.

2. Strap

Solder the strap indicated in red on the layout schematic. Use a resistor

lead that was cut previously.

3. Resistors

Add R1 to R20.

Control the resistor values with a digital multimeter. Bend the leads at 0.4” with a lead forming tool.

4. Integrated Circuits

Insert U1, U2, U3 and U4 and solder. You will need to bend the pins slightly inwards before inserting.

Warning : Make sure to respect the IC direction, marked by a semi-circular notch on the IC and a dot on

the PCB.

5. Regulator IC's

Add U5 and U . The IC's are installed flat on the PCB in order to minimize the components height.

Warning : Watch out the IC direction.

. Ceramic capacitor

Add C3. This capacitor is also installed flat on the PCB.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Gain reduction meter

7. Electrolytic capacitors

Add C1, C2. These capacitors are installed below, on the solder side of the PCB.

Warning : C1 & C2 are soldered under the PCB, on the solder side.

Warning : The +lead must go into the +hole. Do not reverse.

8. 4 pins connector CN1

Install the 4 pins header on the solder side of the PCB. Solder one pin, check verticality then solder the

other pins.

Warning : CN1 is soldered under the PCB, on the solder side.

Warning : the connector pins must be exactly perpendicular to the PCB to allow proper insertion into the

main board.

CP517 Assembly guide – Final assembly

9. Front panel and Side plate assembly

Attach the potentiometers PCB to the

front panel with two M3x black

screws, two 15mm spacers and two

M3x screws. Check that the push

buttons move freely in the panel holes.

Attach the side plate to the front panel

with two M3x black screws.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Final assembly

10. Main PCB assembly

Insert the main PCB connectors into the connectors of the potentiometers PCB until the main PCB holes

match the side plate standoffs.

Attach the main PCB with three M3x M3x25mm spacers and one M3x mm screw in the upper left

corner and four lock washers inserted at the base of the spacers.

11. Knobs

Attach the 5 knobs to the 5 potentiometers and switch spindles.

12. Test and setup

It is time for test and setup. Follow instructions on cp517 -setup-guide.pdf.

Copyright ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 2.1 – Last modification : 12/11/17

CP517 Assembly guide – Final assembly

13. Gain reduction meter assembly

Attach the GR meter on the lower spacer with

one M3x screw.

Place the 4mm spacer on the higher hole

14. Cover assembly

Place the cover on top of the compressor. Attach with 3 M3x mm countersunk screws plus one

M3x12mm in the hole corresponding to the 4mm spacer.

15. Congratulations !

You're done !

Copyright ©2013 to Today SoundSkulptor

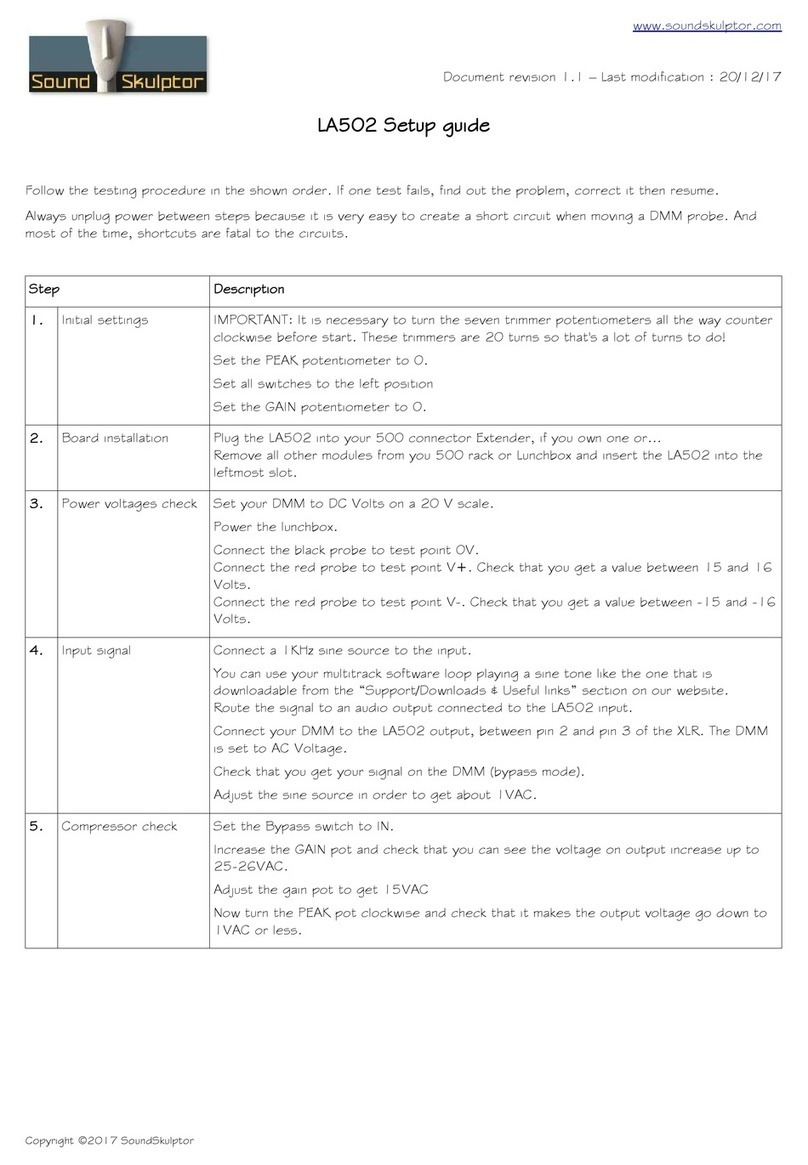

Other manuals for CP5176

1

Table of contents

Other Sound Skulptor Compressor manuals

Popular Compressor manuals by other brands

Challenge Xtreme

Challenge Xtreme CX 1500/1 operating instructions

WilTec

WilTec 24 L Operation manual

Sirus

Sirus DualCom 52 manual

Ingersoll-Rand

Ingersoll-Rand IR2PS Operation and maintenance

Renner Kompressoren

Renner Kompressoren Scroll Line Series operating manual

ATD Tools

ATD Tools ATD-3054 instructions

Gast

Gast 87R Operation and maintenance manual

J.E. Adams

J.E. Adams 8670-5WB manual

Doosan

Doosan P185WDO-T4F Installation guide, operation and maintenance manual

Sealey

Sealey SAC32055B Instructions for use

Schmalz

Schmalz SCPi Maintenance instructions

Renner Kompressoren

Renner Kompressoren RS 90/1-110 Operation manual