TABLEOFCONTENTS

Operation&MaintenanceManual

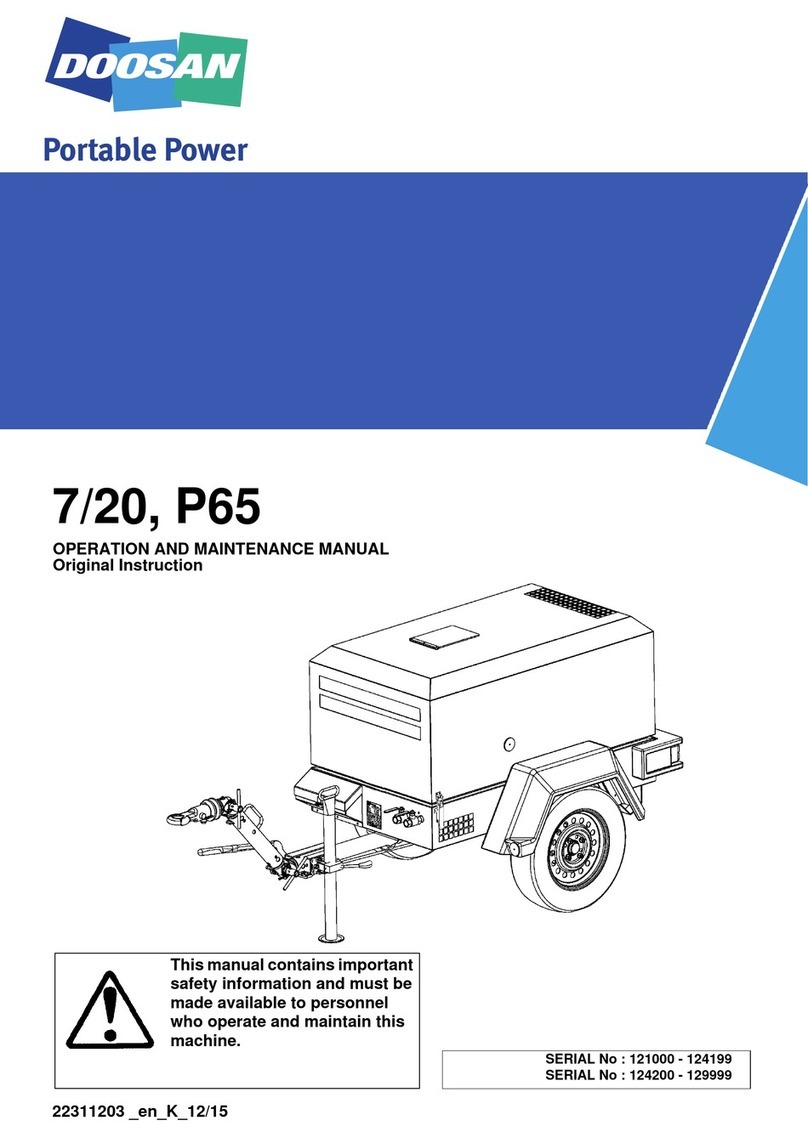

TITLEPAGE

QuickViewScreens........................................................................................................................41

FaultandAlert................................................................................................................................41

ServiceIntervalSetUp...................................................................................................................44

LanguagesandUnitsSetUp..........................................................................................................46

DisplaySetup.................................................................................................................................47

CompressorIDSetUp....................................................................................................................48

BeforeTowing.................................................................................................................................50

SettingUp.......................................................................................................................................51

Towing............................................................................................................................................52

BeforeStarting...............................................................................................................................52

Starting...........................................................................................................................................53

Shutdown.......................................................................................................................................54

PressureRegulatorAdjustmentInstructions.................................................................................55

ENGINEOPERATION..........................................................................................................57

EngineOperationandMaintenance................................................................................................58

SAFETY.....................................................................................................................................58

Instructions................................................................................................................................59

GeneralRepair...........................................................................................................................61

EnvironmentalPollution..............................................................................................................62

EngineManagement...................................................................................................................63

PreventionofPollution................................................................................................................64

StartandShutdown....................................................................................................................65

Break-inPeriodofEngine............................................................................................................66

InspectionafterStartingtheEngine.............................................................................................67

OperationinWinter.....................................................................................................................68

RegularInspection......................................................................................................................69

CheckingtheEngineOil........................................................................................................70

ReplacementofEngineOil....................................................................................................72

Coolant................................................................................................................................75

CheckingtheCoolant......................................................................................................76

ReplenishmentofCoolant...............................................................................................78

ReplacementofCoolant..................................................................................................79