Sourcetronic ST1963 User manual

SOURCETRONIC −Quality electronics for service, lab and production

ST1963 6½ Digit Multimeter

User Manual

2

Contents

Chapter 1 General Information.................................................................................................................................. 4

1.1 Feature Overview......................................................................................................................................... 4

1.2 Operating Environment ............................................................................................................................... 4

1.3 Dimensions and Weight............................................................................................................................... 4

1.4 Safety symbols and Precautions .................................................................................................................. 5

1.5 Unpacking Inspection.................................................................................................................................. 5

1.6 Mark............................................................................................................................................................. 5

1.7 Warranty....................................................................................................................................................... 6

1.8 Limitation of Warranty ................................................................................................................................ 6

Chapter 2 Specifications and Features....................................................................................................................... 7

2.1 Specifications............................................................................................................................................... 7

2.2 Supplementary specifications.....................................................................................................................11

Chapter 3 Instructions for use.................................................................................................................................. 12

3.1 Front Panel Menu Reference ..................................................................................................................... 12

3.2 Measurement ............................................................................................................................................. 14

3.2.1 DC Voltage...................................................................................................................................... 14

3.2.2 DCV Ratio ...................................................................................................................................... 15

3.2.3 AC Voltage...................................................................................................................................... 15

3.2.4 DC Current...................................................................................................................................... 17

3.2.5 AC Current...................................................................................................................................... 18

3.2.6 Resistance 2W ................................................................................................................................ 19

3.2.7 Resistance 4W ................................................................................................................................ 21

3.2.8 Capacitance Measurement.............................................................................................................. 22

3.2.9 Diode .............................................................................................................................................. 23

3.2.10 Continuity..................................................................................................................................... 24

3.2.11 Temperature test............................................................................................................................ 25

3.2.12 Frequency measurement............................................................................................................... 26

Chapter 4 Arithmetical Operation............................................................................................................................ 28

4.1 Null Operation........................................................................................................................................... 28

4.2 Statistics..................................................................................................................................................... 28

4.3 Limit .......................................................................................................................................................... 28

4.4 dB Calculation........................................................................................................................................... 28

4.5 dBm Calculation........................................................................................................................................ 29

4.6 mX+b......................................................................................................................................................... 29

4.7 Percent....................................................................................................................................................... 29

Chapter 5 Interface .................................................................................................................................................. 30

5.1 RS-232 interface........................................................................................................................................ 30

5.1.1 RS-232 Interface Operation............................................................................................................ 31

5.2 Handler Interface....................................................................................................................................... 33

5.2.1 Handler setup.................................................................................................................................. 34

5.3 USB Interface ............................................................................................................................................ 35

5.3.1 USB Host........................................................................................................................................ 35

3

5.4 LAN Interface............................................................................................................................................ 35

5.5 GPIB Interface........................................................................................................................................... 36

5.5.1 GPIB Bus........................................................................................................................................ 36

5.5.2 Setting the GPIBAddress............................................................................................................... 37

5.5.3 General Bus Commands ................................................................................................................. 37

5.5.4 Setting through the interface........................................................................................................... 38

Chapter 6 System Settings....................................................................................................................................... 39

6.1 Set the language......................................................................................................................................... 39

6.2 Setting the date/time.................................................................................................................................. 39

6.3 Setting the buzzer and brightness.............................................................................................................. 39

6.4 Setting the format of the digital display..................................................................................................... 39

Chapter 7 SCPI Command Reference ..................................................................................................................... 40

7.1 SCPI Language Profile.............................................................................................................................. 40

7.1.1 Grammatical conventions............................................................................................................... 40

7.1.2 Command separator........................................................................................................................ 40

7.1.3 Using MIN, MAX and DEF parameters......................................................................................... 41

7.1.4 Query Parameter Settings ............................................................................................................... 41

7.1.5 Parameter Type ............................................................................................................................... 41

7.2 Subsystem commands................................................................................................................................ 42

7.2.1 CONFigure Subsystem ................................................................................................................... 42

7.2.2 MEASure subsystem....................................................................................................................... 45

7.2.3 TRIGger subsystem ........................................................................................................................ 48

7.2.4 [SENSe:]VOLTage subsystem........................................................................................................ 51

7.2.5 [SENSe:]CURRent Subsystem....................................................................................................... 54

7.2.6 [SENSe:]{RESistance|FRESistance} subsystem............................................................................ 56

7.2.7 [SENSe:]{FREQuency|PERiod} Subsystem.................................................................................. 57

7.2.8 [SENSe:]TEMPerture Subsystem................................................................................................... 59

7.2.9 [SENSe:]CAPacitance subsystem................................................................................................... 60

7.2.10 SYSTem Subsystem - I/O Configuration...................................................................................... 61

7.2.11 SYSTem Subsystem - General Command .................................................................................... 63

7.2.12 DATA2 subsystem ........................................................................................................................ 64

7.2.13 NULL subsystem.......................................................................................................................... 64

7.2.14 CALCulate:SCALe subsystem ..................................................................................................... 66

7.2.15 CALCulate: LIMit subsystem....................................................................................................... 68

7.2.16 CALCulate: AVERage Subsystem................................................................................................ 68

4

Chapter 1 General Information

Thank you for purchasing and using our products. Before using the instrument, first inspect it according to the

“1.5 Unpacking Inspection” section of this chapter in this manual. If there is any discrepancy, please contact our

company as soon as possible to protect your rights. If you still have questions after reading this manual, please

contact your local distributor or call our company's engineers directly for further consultation.

1.1 Feature Overview

The ST1963 is a 6½ digital multimeter with high accuracy, stability and speed. The digital multimeter provides a

maximum measurement speed of 1000 readings/sec. ST1963 has a 0.0035% DC voltage basic accuracy, 0.0100%

basic resistance accuracy and other high performance.

ST1963 has broad measurement ranges:

DC voltage from 0.1μV to 1000V

AC voltage from 0.1μV to 750V, peak value of 1000V

AC/DC voltage from 1μV to 750V (RMS)

DC current from 10nA to 10A

AC current from 10nA to 10A

Resistance measurement from 0.01mΩ to 120MΩ

Frequency from 2Hz to 1MHz

Some additional capabilities of Model ST1963:

Full range of functions: In addition to those listed above, ST1963 functions include period, dB, dBm,

continuity, diode testing, arithmetical operation (mX+b) and percent.

Programming languages and remote control interfaces: ST1963 provides the SCPI programming

language and the remote control interface ports USB Device, RS-232C, LAN, IEEE-488/GPIB (option),

and Handler (option) interface.

Readings and instrument settings: Up to 10,000 readings can be stored in local mode.

Completed calibration: The unit can be calibrated either from the front panel or through the remote

control interface.

1.2 Operating Environment

Power supply: 110V/220V ±10%

Line frequency: 50Hz / 60Hz ±5%

Power consumption: ≤30VA

Operating temperature: 0°C to 40°C

Humidity: ≤ 90%RH

1.3 Dimensions and Weight

Dimensions (W×H×D): 225mm×100mm×355mm

Net weight: Around 2.5Kg

5

1.4 Safety Symbols and Precautions

The symbol on the instrument indicates that user should refer to the operating instructions located in the

manual before performing.

The symbol on the instrument shows that high voltage may be present on the terminal(s). Be careful to

avoid personal contact with these voltages.

The symbol on the instruments means earth grounding.

The WARNING heading used in the manual explains high voltage danger that might result in personal injury or

death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the manual reminds user that hazards could damage the instruments if not according

to operating instructions. Such damage may invalidate the warranty.

1.5 Unpacking Inspection

Your ST1963 was carefully inspected mechanically and electrically before shipment. After unpacking all items

from the shipping carton, please check for any obvious signs of physical damage that may have occurred during

transportation. Report any damage to the shipping agent immediately. Save the original packing carton for

possible future reshipment. The following items are included with every Model ST1963 order:

Model ST1963 61/2Digital Multimeter

Test leads (Model ST26036)

USB interface connection cable (ST26017)

Power cord

T500mAL fuse

T3.15AL fuse

Test report

This operation manual

Other optional accessories, if ordered

Verify that you have received all the items above when you get the multimeter. If anything is missing, please

contact our representative or our sales office.

Note: The IEEE-488 interface and Handler interface of this instrument are optional and need to be purchased

separately. These two interfaces cannot be installed at the same time.

1.6 Mark

The following marks are on each instrument panel or nameplate:

•Manufacturer's name or trademark

•Product name and model

•Product number

6

•Manufacturing measuring instrument license signs and numbers

•Test terminal mark

1.7 Warranty

Sourcetronic warrants this product to be free from defects in material and workmanship for a period of one year

from the date of shipment. During the warranty period, we will, at our option, either repair or replace any product

that proves to be defective.

1.8 Limitation of Warranty

This warranty does not apply to defects resulting from product modification without our express written consent,

or misuse of any product or part. This warranty also does not apply to fuses, software, or problems arising from

normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER SOURCETRONIC NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF SOURCETRONIC HAS BEEN ADVISED IN ADVANCE OF THE

POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT

LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF

INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

7

Chapter 2 Specifications and Features

Technical description of test performance data

One year calibration cycle

Operating environment temperature: 18 °C ~ 28 °C

Calibration environment temperature TCAL=23°C

Calibrated after warming up for 60 minutes

Accuracy data specification: ± (% of reading + % of full range)[1]

Operating humidity environment: at 0 °C ~ 18 °C, ≤80%RH (when the resistance range is ≥10M, ≤70% RH),

at 28°C~40°C, ≤70%RH

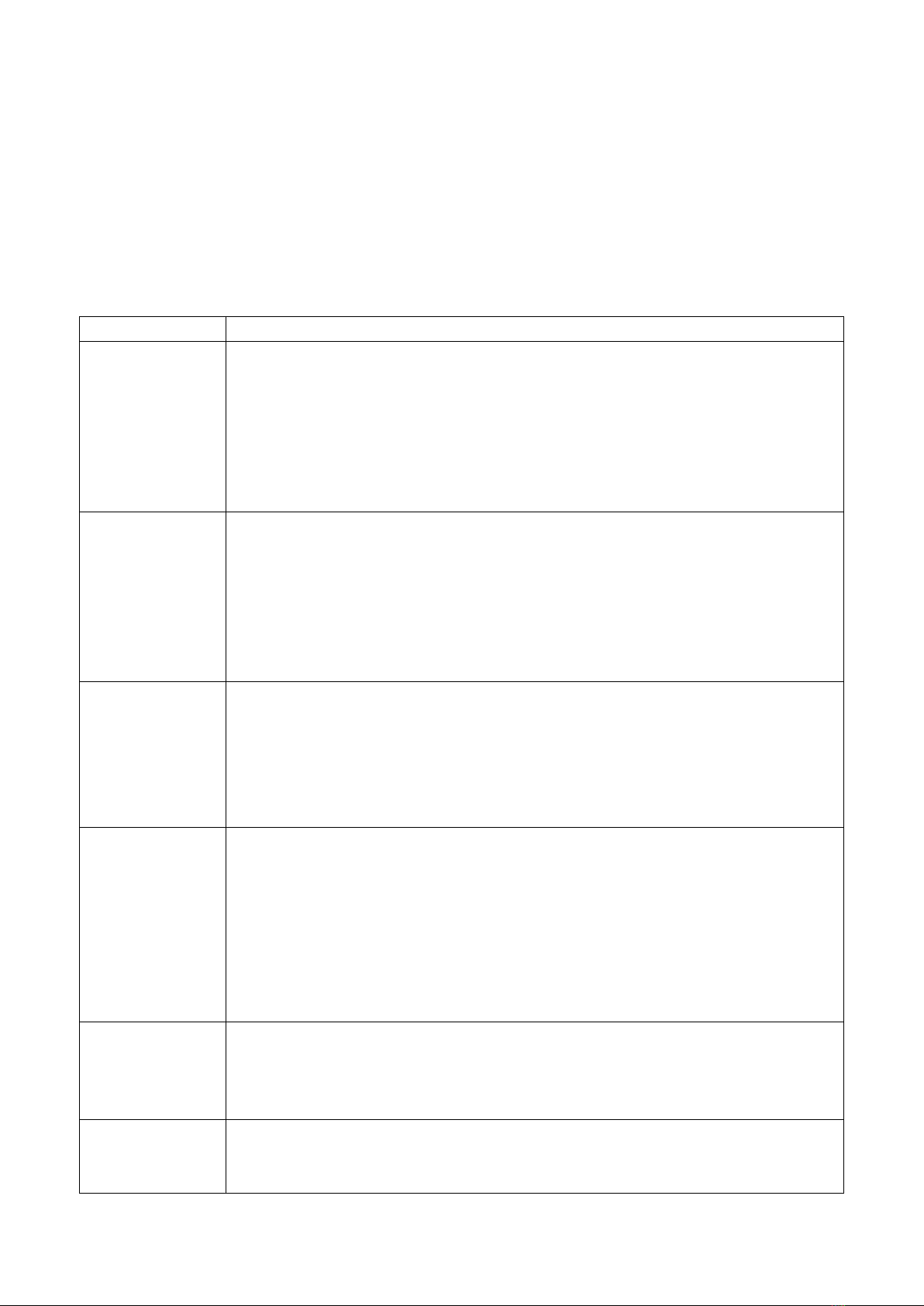

2.1 Specifications

All values given as ± (% of reading + % of full range)[1]

DC voltage specification

Range

Resolution[4]

24 hours [3]

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

Temperature

coefficient/°C[2]

100.0000mV[5]

0.1uV

0.0030+ 0.0030

0.0040 + 0.0035

0.0050 + 0.0035

0.0005 + 0.0005

1.000000V

1uV

0.0020+ 0.0006

0.0030 + 0.0007

0.0040 + 0.0007

0.0005 + 0.0001

10.00000V

10uV

0.0015+ 0.0004

0.0020 + 0.0005

0.0035 + 0.0005

0.0005 + 0.0001

100.0000V

100uV

0.0020+ 0.0006

0.0035 + 0.0006

0.0045 + 0.0006

0.0005 + 0.0001

1000.000V[6]

1mV

0.0020+ 0.0006

0.0035 + 0.0010

0.0045 + 0.0010

0.0005 + 0.0001

DC current specification

Range

Internal

resistance

voltage drop

Minimum

resolution

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL± 5°C

Temperature

coefficient/°C[2]

100uA

<0.011V

0.1nA

0.010 + 0.020

0.040 + 0.025

0.050 + 0.025

0.0020+ 0.0030

1mA

<0.011V

1nA

0.010 + 0.006

0.030 + 0.006

0.050 + 0.006

0.0020+ 0.0005

10mA

< 0.05 V

10nA

0.010 + 0.020

0.030 + 0.020

0.050 + 0.020

0.0020+ 0.0020

100mA

< 0.5 V

100nA

0.010 + 0.004

0.030 + 0.005

0.050 + 0.005

0.0020+ 0.0005

1A

< 0.7 V

1uA

0.050 + 0.006

0.080 + 0.010

0.100 + 0.010

0.0050+ 0.0010

3A

< 2.0 V

1uA

0.180 + 0.020

0.200 + 0.020

0.200 + 0.020

0.0050+ 0.0020

10A

< 0.5 V

10uA

0.050 + 0.010

0.120 + 0.010

0.120 + 0.010

0.0050+ 0.0010

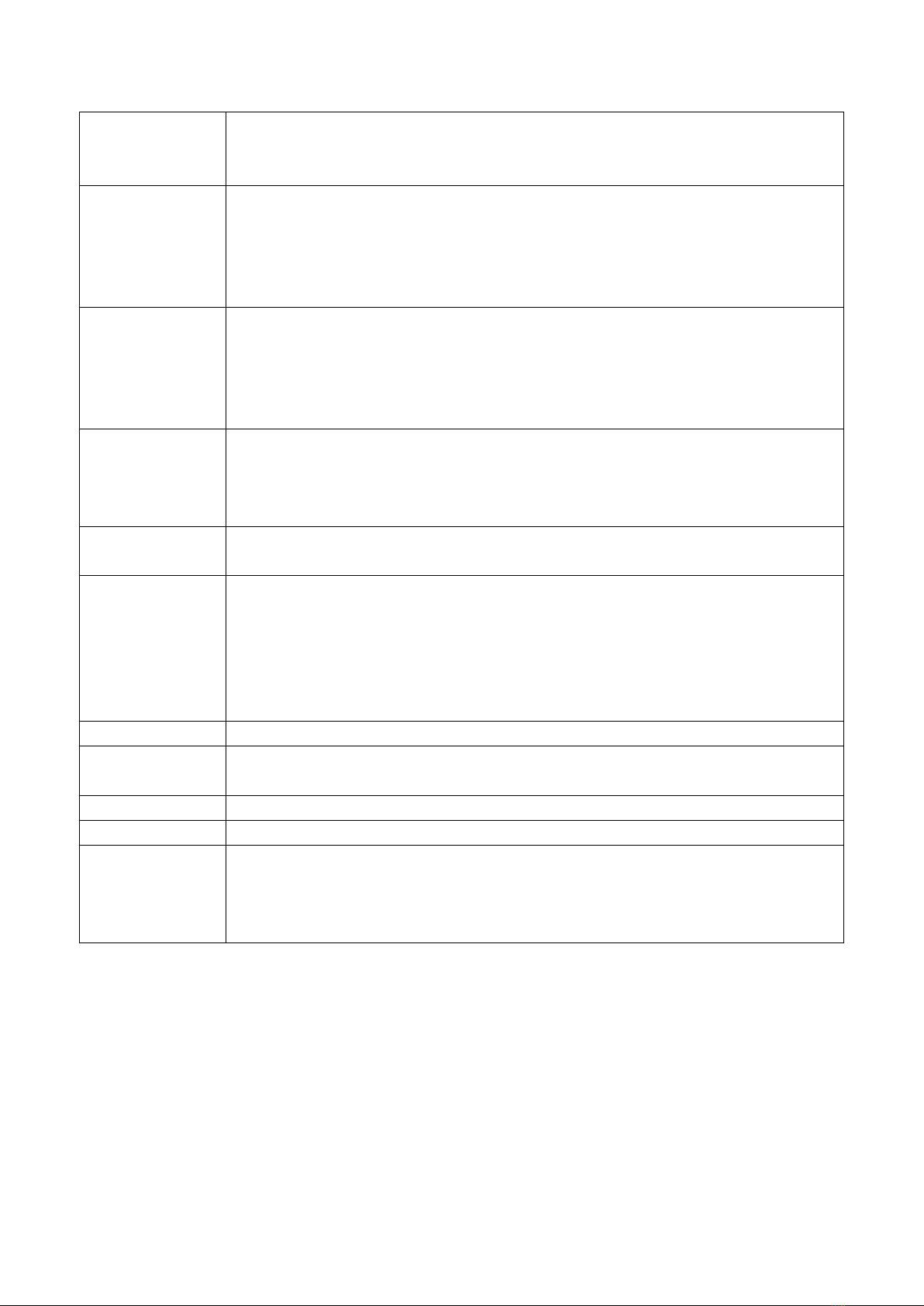

8

DC resistance specification[7] [8]

Range

Test

current

Resolution

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

Temperature

coefficient /°C

10.00000Ω

10mA

10uΩ

0.0050+0.0040

0.0080+0.0060

0.0100+0.0080

0.0006+0.0008

100.0000 Ω

10mA

0.1mΩ

0.0030+0.0020

0.0080+0.0030

0.0100+ 0.0040

0.0006+0.0005

1.000000kΩ

1mA

1mΩ

0.0020+0.0005

0.0080+0.0010

0.0100+ 0.0010

0.0006+0.0001

10.00000kΩ

100uA

10mΩ

0.0020+0.0005

0.0080+0.0010

0.0100+ 0.0010

0.0006+0.0001

100.0000kΩ

10uA

100mΩ

0.0020+0.0005

0.0080+0.0010

0.0100+ 0.0010

0.0006+0.0001

1.000000MΩ

5uA

1Ω

0.0020+0.0010

0.0080+0.0010

0.0100+ 0.0010

0.0010+0.0002

10.00000MΩ

500nA

10Ω

0.0150+0.0010

0.0200+0.0010

0.0400+ 0.0010

0.0030+0.0004

100.0000MΩ

500nA/10M

100Ω

0.3000+0.0100

0.8000+0.0100

0.8000+ 0.0100

0.1500+0.0002

Continuity (conduction) test specification

Function

Range

Test current

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

Temperature

coefficient /°C

Continuity

1kΩ

1mA

0.002 + 0.030

0.008 + 0.030

0.010+ 0.030

0.0010+ 0.0020

Diode test specification

Function

Range

Test current

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

Temperature

coefficient /°C

Diode[12]

5V

1mA

0.002 + 0.030

0.008 + 0.030

0.010+ 0.030

0.0010+ 0.0020

Temperature test specification

Temperature

PT100 (DIN/ IEC 751)

Probe accuracy + 0.05°C

5 kΩ thermistor

Probe accuracy + 0.10°C

Capacitance test specification

Range

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

Temperature

coefficient /°C

1.0000nF

0.5+0.10

0.5+0.40

1.0+0.50

0.02+0.001

10.000nF

0.2+0.05

0.5+0.10

1.0+0.10

0.02+0.001

100.00nF

0.2+0.05

0.5+0.10

1.0+0.10

0.02+0.001

1.0000uF

0.2+0.05

0.5+0.05

1.0+0.10

0.02+0.001

10.000uF

0.2+0.05

0.5+0.05

1.0+0.10

0.02+0.001

100.00uF

0.2+0.05

0.5+0.05

1.0+0.10

0.02+0.001

1.0000mF

0.2+0.05

0.5+0.05

1.0+0.20

0.02+0.001

10.000mF

0.5+0.20

0.5+0.30

1.0+0.50

0.02+0.001

AC voltage test specification[6] [9] [10]

Frequency/range

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

Temperature

coefficient /°C

3 Hz - 5 Hz

1.00+0.02

1.00+0.02

1.00+0.03

1.00+0.03

9

5 Hz - 10 Hz

0.35+0.02

0.35+0.03

0.35+0.03

0.35+0.03

10Hz - 20kHz

0.04+0.02

0.05+0.03

0.06+0.03

0.07+0.03

20kHz - 50kHz

0.10+0.04

0.11+0.05

0.12+0.05

0.13+0.05

50kHz - 100kHz

0.55+0.08

0.60+0.08

0.60+0.08

0.60+0.08

100kHz - 300kHz

4.00+0.50

4.00+0.50

4.00+0.50

4.00+0.50

AC current test specification[6] [10] [11]

Frequency/range

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

Temperature

coefficient

/°C

Range

Voltage drop

100μA,1mA,

10mA and

100mA

<0.011V, <0.11V,

<0.05V and

<0.5V

3Hz- 5Hz

1.00+0.02

1.00+0.02

1.00+0.04

0.100+0.006

5Hz- 10Hz

0.30+0.02

0.30+0.03

0.30+0.04

0.035+0.006

10Hz- 5kHz

0.10+0.04

0.10+0.04

0.10+0.04

0.015+0.006

5kHz - 10kHz

0.10+0.04

0.10+0.04

0.10+0.04

0.030+0.006

1A range

<0.7V

3Hz- 5Hz

1.00+0.02

1.00+0.02

1.00+0.04

0.100+0.006

5Hz- 10Hz

0.30+0.02

0.30+0.03

0.30+0.04

0.035+0.006

10Hz- 5kHz

0.10+0.04

0.10+0.04

0.10+0.04

0.015+0.006

5kHz - 10kHz

0.30+0.04

0.30+0.04

0.30+0.04

0.030+0.006

3A range

<2.0V

3Hz- 5Hz

1.00+0.02

1.00+0.02

1.00+0.04

0.100+0.006

5Hz- 10Hz

0.35+0.02

0.35+0.03

0.35+0.04

0.035+0.006

10Hz- 5kHz

0.23+0.04

0.23+0.04

0.23+0.04

0.015+0.006

5kHz - 10kHz

0.30+0.04

0.30+0.04

0.30+0.04

0.030+0.006

10A range

3Hz- 5Hz

1.00+0.02

1.00+0.02

1.00+0.04

0.100+0.006

5Hz- 10Hz

0.30+0.02

0.30+0.03

0.30+0.04

0.035+0.006

10Hz- 5kHz

0.15+0.04

0.15+0.04

0.15+0.04

0.015+0.006

5kHz - 10kHz

0.15+0.04

0.15+0.04

0.15+0.04

0.030+0.006

Frequency test count specification[13] [14]

100 mV, 1 V, 10 V, 100 V

and 750 V range

24 hours

TCAL ± 1°C

90 days

TCAL ± 5°C

1 year

TCAL ± 5°C

2 year

TCAL ± 5°C

Temperature

coefficient /°C

2-10Hz

0.100

0.100

0.100

0.100

0.0002

10-100 Hz

0.030

0.030

0.030

0.035

0.0002

100Hz-1kHz

0.003

0.008

0.010

0.015

0.0002

1-300kHz

0.002

0.006

0.010

0.015

0.0002

300kHz-1MHz[15]

0.002

0.006

0.010

0.015

0.0002

Square wave[16]

0.001

0.006

0.010

0.015

0.0002

10

Additional gating error

Frequency

1sec.

0.1 sec.

0.01 sec.

2-10Hz

0

0.200

0.200

10-100 Hz

0

0.060

0.200

100Hz-1kHz

0

0.020

0.200

1-300kHz

0

0.004

0.030

300kHz-1MHz[15]

0

0.004

0.030

Square wave[16]

0

0

0

[1]. For DC: The technical specifications are valid when the instrument has preheated for 60 minutes, the

integration time is set to 10 or 100 NPLC, and auto zero is enabled. For AC: The technical specifications are valid

after 60 minutes of preheating, slowAC filtering, and sine wave.

[2]. Outside the range of TCAL ± 5 °C, the temperature coefficient is increased by 1 for every 1 degree Celsius

change.

[3]. Relevant calibration standards.

[4]. The smallest data change that can be displayed, i.e. the value of the least significant digit.

[5]. Full-scale accuracy, there is need to perform NULL (clearing) operation in order to get better accuracy.

[6]. DC 1000V, AC 750V, AC current 3Aand DC current 3Acan only test 5% of the overrange.

[7]. When measuring resistance, it is better to use shielded line test when the resistance is greater than 100kΩ.

Because the intersecting magnetic field generates an induced current, and a large resistor has a relatively small test

current, the signal-to-noise ratio will be small and the test will be unstable.

[8]. Specifications are applicable to 4-wire or 2-wire resistance measurements. When zero clearing is not activated,

the 2-wire resistance measurement will introduce an additional error of 0.2Ω.

[9]. Specifications are valid when the sine wave input is >0.3% of the range and greater than 1mVrms. The

750-ACV range is limited to the 8 x Volt–Hz range.

[10]. Low Frequency Performance: three filter settings are available: 3 Hz, 20 Hz, 200 Hz. The frequency above

the filter setting is specified and no additional errors will occur.

[11]. Specifications are valid when sine wave input >1% range and >10μA AC. The 10A range is only available on

the front connector.

[12]. Specifications are applicable to the voltage measured at the input terminal. The 1 mA test current is a typical

value.A change in the current source will cause a change in the voltage drop across the diode junction.

[13]. Unless otherwise stated, the specifications are valid when the instrument has warmed up for 60 minutes and

has a sine wave input. Specifications apply to 1s strobe time (7 digits). The signal needs to be greater than 10% of

the selected range.

[14]. This is applicable when the sine and square wave are input larger than 100 mV. For a 10 mV to 100 mV

input, multiply the % of the reading error by 10.

[15]. High-frequency signals have serious attenuation in the latter stage, so the input voltage of the test signal

should be relatively large. The test signal is 1V-1MHz, and the input signal is preferably greater than 50% of the

range.

[16]. The square wave input is specified as 10 Hz-300 kHz.

11

2.2 Supplementary specifications

Display readings and measuring speed

DC resistance, DC voltage, DC current [1]

Integral time

Default

digits [2]

Reading/second[3]

System

speed [4]

Extra error

100PLC/2s(1.67s)

0.5(0.6)

0.5(0.6)

0

10PLC/200ms(167ms)

5(6)

5(6)

0

1PLC/20ms(16.7ms)

45(55)

45(55)

0.001% range

0.2PLC/4ms

200

50

0.001% range [5]

0.02PLC/400μs

1000

50

0.01% range [5]

AC voltage, AC current [2] [3]

Full scale display

Default display

Reading / second

Speed

1199999

119999

7sec./reading[6]

Slow

1199999

119999

1[6]

Medium

1199999

119999

1.6[6]

Fast

1199999

119999

10

Fast[7]

1199999

119999

50

Fast[8]

[1]. Reading rate at 60-Hz and 50-Hz operating conditions, turning off auto zero, within a fixed range.

[2]. The number of display digits in the case of automatically displaying the number of digits. If a fixed number of

digits are selected, the number of displayed digits does not change due to the test speed.

[3]. The average speed at which theADC continuously sampling to the data transmission and display.

[4]. Read data by instructions.

[5]. Add 20μV to DCV; increase resistance by 20 mΩ. When DCA increases by 0.2μA, 100uA, 10mA range, the

range error is increased by 10 times.

[6]. Read stable data. The actualADC sampling speed is faster than the stable speed.

[7]. External trigger or remote operation, using the default stable delay (automatic delay).

[8]. Use the default maximum value, set the delay to expire.

12

Chapter 3 Instructions for use

When using the instrument for the first time, first familiarize yourself with the functions of the buttons and logos

on the front panel. We have written this chapter to make you more familiar with using this multimeter.

3.1 Front Panel Menu Reference

Key

Usage

DCV(DCI)

To configure the DC voltage measurement, including DC ratio measurement

Range: 100mV, 1V, 10V, 100V, 1000V

Automatically adjusts the range by default

NPLC: {0.02, 0.2, 1, 10, 100} Default: 10 PLC

Auto zero setting: OFF or ON (default: ON)

Input impedance: 10M or HighZ (>1G)

DC ratio: OFF (default) or ON

Shift + DCV(DCI)

To configure the DC current measurement

Range: 3Aterminal (100uA, 1mA, 10mA, 100mA, 1A, 3A) auto range (default)

10A port 10A range

NPLC: {0.02, 0.2, 1, 10, 100} Default: 10 PLC

Automatically adjusts the range by default

NPLC: {0.02, 0.2, 1, 10, 100} Default: 10 PLC

Auto zero setting: OFF or ON (default: ON)

ACV(ACI)

To configure the ACV AC voltage

Range:Auto (default), 100mV, 1V, 10V, 100V, 750V

Filter: 3Hz (slow speed)

20Hz (medium, slow speed)

200Hz (fast, medium and slow speed)

Default: 20Hz filter, medium speed

Shift + ACV(ACI)

To configure theACVAC current measurement

Test terminal: 3A 10A

Range: 3Aterminal (100uA, 1mA, 10mA, 100mA, 1A, 3A) auto range (default)

10A port 10A range

Filter: 3Hz (slow speed)

20Hz (medium, slow speed)

200Hz (fast, medium and slow speed)

Default: 20Hz filter, medium speed

Ω2W(Ω4W)

To configure the two-wire resistance test

Range: Auto Range (default) {10Ω, 100Ω, 1kΩ, 10kΩ, 100kΩ, 1MΩ, 10MΩ, 100MΩ}

NPLC: {0.02, 0.2, 1, 10, 100} Default: 10 PLC

Auto zero setting: OFF or ON (default: ON)

Shift +Ω2W(Ω4W)

To configure the four-wire resistance test

Range: Auto Range (default) {10Ω, 100Ω, 1kΩ, 10kΩ, 100kΩ, 1MΩ, 10MΩ, 100MΩ}

NPLC: {0.02, 0.2, 1, 10, 100} Default: 10 PLC

13

Freq (Temp)

To configure the frequency and period measurements

Filter: 3Hz, 20Hz, 200Hz

Gating time: 10ms, 100ms (default), 1s

Shift +Freq (Temp)

To configure the temperature test

Probe type: two-wire test (default) or four-wire test

R0: resistance at 0 °C, default: 100Ω

NPLC: {0.02, 0.2, 1, 10, 100} Default: 10 PLC

Unit: °C, °F, K,

Cont (diode)

Conduction (continuous) configuration

Test range: 1kΩ

Test current: 1mA

Buzzer: ON (default) or OFF

Door threshold: default 10Ω, can be set separately

Shift +Cont (diode)

Diode configuration

Test voltage range: 0~5V

Test current: 1mA

Buzzer: ON (default) or OFF

CAP(MATH)

Capacitance measurement configuration

Range:Auto (default) {1nF, 10F, 100nF, 1uF, 10uF, 100uF, 1mF, 10mF}

Shift+CAP(MATH)

Math zero calculation (NULL), you can set parameters

dB/dBm operation

smoothing

scal: Mx+b, Percent

statistics

Limit

NULL (PrtSc)

Mathematical zeroing calculation, the calculated value is the current measured data

Shift+NULL

(PrtSc)

Print the picture and save the current display interface

R/S

Run or Stop

Trigger

Single trigger

Menu

Menu Settings

Display: display settings

Acquire: trigger option

Utility: general function

14

3.2 Measurement

3.2.1 DC Voltage

Step 1: Connect the input terminals correctly and the specific connection is as shown below.

Step 2: Enter the measurement interface and press the [DCV] button on the front panel to enter the DCV

measurement function.

Step 3: Range selection.

Press Range and select the range. Auto range (Auto) can automatically selects the appropriate range for

measurement based on the input signal. The auto range is adjusted upwards to 120% of the current range and

down to 10% of the current range.

Step 4: Set the integration time.

The setting of the integration time affects the measurement speed and measurement accuracy. The longer the

integration time, the higher the accuracy but the slower the measurement. 1PLC, 10PLC, 100PLC can inhibit the

power supply noise. Selecting 100PLC can provide the best noise rejection, but at a slower rate.

15

Step 5: Auto Zero.

Auto-zeroing results in more accurate test results, but requires more test time. With auto zero enabled, the

multimeter internal offset is measured each time the input signal is measured. Then subtract the offset from the

previous reading. This avoids the effect of the offset voltage on the input circuit of the digital multimeter on the

measurement accuracy. In the case of auto-zeroing, the digital multimeter measures the offset once and subtracts

the offset from all subsequent measured parameters. The DMM makes a new offset measurement each time you

change the function, range, or integration time.

The red mark is indicating the auto-zero is ON. If the OFF state is required, it will change from ON to OFF as

long as the corresponding button is pressed. The default state is ON.

Step 6: Input Z internal resistance selection

Select the data input impedance. The input impedance can be automatic or 10MΩ. Automatic mode selects high

impedance (HighZ), which is appropriate for 100mV, 1V, 10V range. The internal resistance of the 100V and

1000V ranges is fixed at 10MΩ.

3.2.2 DCV Ratio

Step 1: Properly connect the input terminals.

Step 2: Turn on the DCV Ratio function to compare the two voltages.

3.2.3 AC Voltage

This section describes how to configure the measurement of theAC voltage.

This DMM select the default delay to give the correct first reading for most measurements. In order to get the

16

most accurate measurement, the corresponding RC time constant must be stable to 1/50 of the input AC signal

level.

Signals greater than 300 V (RMS) or 1 A (RMS) can cause self-heating of the signal conditioning components.

These errors are included in the instrument's specifications. Internal temperature changes caused by self-heating

may cause additional errors in other functions or ranges. Additional errors typically disappear within a few

minutes. Take the 100 mVAC signal with a 10 VDC bias voltage as an example, the 10 VDC bias voltage should

be stable at 1/50 of 100mVAC or 1/50 of 2mVDC. The ACV function should be selected after the signal is

connected to the digital multimeter's ACV input or when the signal has been connected, enough extra delay should

be given to stabilize the signal. If the DC bias remains the same, a completely accurate subsequent measurement

can be made without additional stabilization delay.

Step 1: Configure the test leads as shown below.

Step 2: Press the [ACV] button on the front panel to enter the ACV test interface.

Step 3: Range adjustment.

Press Range and select the range. Auto range (Auto) automatically selects the appropriate range for measurement

based on the input signal. The auto range is adjusted upwards to 110% of the current range and down to 10% of

the current range.

Step 4: AC Filter Selection.

The instrument offers three filter options of 3Hz, 20Hz and 200Hz. The filter you choose should be less than the

frequency of your test signal. In order to get stable data faster, the filter is best chosen to be close to the test

17

frequency of your input signal. For example, if the input signal is 300Hz, the stable data can be obtained as soon

as the filter selects 200Hz.

Step 5: Speed selection.

Filter

Slow

Medium

Fast

3Hz

√

﹣

﹣

20Hz

√

√

﹣

200Hz

√

√

√

Different filters have different test speeds, so choosing the right measurement speed based on the filter can result

in more accurate test results or faster test speeds.

3.2.4 DC Current

Step 1: Configure the test leads as follows:

Step 2: Press the shift button on the front panel and press [DCV] to select the DCI function and enter the DCI

measurement interface.

Step 3: Select the range.

Select the input terminal for the test signal. If you select 10A input terminal, there is only 10A range. If you select

3A input terminal, there are multiple ranges. At this time, you can select auto range test.

The range that can be selected by selecting the 3A input terminal is as follows:

The range that can be selected by selecting the 10A input terminal is as follows:

If selecting the 3A terminal, there are multiple ranges to choose from at this time. You can select 100uA, 1mA,

10mA, 100mA, 1A, 3Aor auto range as needed.

Step 4: Set the integration time.

The setting of the integration time affects the measurement speed and measurement accuracy. The longer the

integration time, the higher the accuracy but the slower the measurement. 1PLC, 10PLC, 100PLC can inhibit the

power supply noise. Selecting 100PLC can provide the best noise rejection, but at a slower rate.

18

Step 5: Auto Zero.

Choose whether to turn on the automatic zeroing. Auto-zeroing results in more accurate test results, but requires

more test time. With auto zero enabled, the multimeter internal offset is measured each time the input signal is

measured. Then the offset is subtracted from the previous reading. This avoids the effect of the offset voltage in

the input circuit of the digital multimeter on the measurement accuracy. In the case of auto-zeroing, the digital

multimeter measures the offset once and subtracts the offset from all subsequent measured parameters. The DMM

makes a new offset measurement each time you change the function, range, or integration time.

3.2.5 AC Current

Step 1: Configure the test leads as follows:

Step 2: Press the shift+ACV button on the front panel to enter theACI test interface.

19

Step 3: Range adjustment

Press Range and select the range. Auto range (Auto) can automatically selects the appropriate range for

measurement based on the input signal. The auto range is adjusted upwards to 110% of the current range and

down to 10% of the current range.

Step 4: AC Filter Selection

The instrument offers three filter options of 3Hz, 20Hz and 200Hz. The filter you choose should be less than the

frequency of your test signal. In order to get stable data faster, the filter is best chosen to be close to the test

frequency of your input signal. For example, if the input signal is 300Hz, the stable data can be obtained as soon

as the filter selects 200Hz.

Step 5: Speed selection

Filter

Slow

Medium

Fast

3Hz

√

﹣

﹣

20Hz

√

√

﹣

200Hz

√

√

√

Different filters have different test speeds, so choosing the right measurement speed based on the filter can result

in more accurate test results or faster test speeds.

3.2.6 Resistance 2W

Step 1: Configure the test leads as follows:

20

Step 2: Press the [Ω2W] button on the front panel to enter the two-wire resistance test interface.

Step 3: Select the range.

Press Range and select the range. Auto range (Auto) can automatically selects the appropriate range for

measurement based on the input signal. The auto range is adjusted upwards to 110% of the current range and

down to 10% of the current range.

Step 4: Set the integration time.

The setting of the integration time affects the measurement speed and measurement accuracy. The longer the

integration time, the higher the accuracy but the slower the measurement. 1PLC, 10PLC, 100PLC can inhibit the

power supply noise. Selecting 100PLC can provide the best noise rejection, but at a slower rate.

Step 5: Auto Zero.

Auto-zeroing results in more accurate test results, but requires more test time. With auto zero enabled, the

multimeter internal offset is measured each time the input signal is measured. Then subtract the offset from the

previous reading. This avoids the effect of the offset voltage on the input circuit of the digital multimeter on the

measurement accuracy. In the case of auto-zeroing, the digital multimeter measures the offset once and subtracts

the offset from all subsequent measured parameters. The DMM makes a new offset measurement each time you

change the function, range, or integration time.

Table of contents

Other Sourcetronic Multimeter manuals