Southbend RapidSteam R2 User manual

1

First

in

Cooking,

Buitt

to

Last

BDuthbend

IMPORTANT

FOR

FUTURE

REFERENCE

Piease

compete

this

information

and

retain

this

manual

tor

the

life

of

the

eouipment.

MODEL#

SERIAL#

A

Minm

FRV

COMPANY

DATE

PURCHASED

OPERATOR’S

MANUAL

INSTALLATION

OPERATION

AND

MAINTENANCE

INSTRUCTIONS

COUNTERTOP

CONVECTION

STEAMER

MODEL:

R2

Awarning

Improper

installation,

service,

or

maintenance

can

cause

property

damage,

injury

or

death.

Read

the

installation,

operation

and

maintenance

instructions

thoroughly

before

instaltng

and

operating

this

equipment.

“Our

Goal-First

Time

Fix”

1100

0*3

Honeycutt

Road

•

Fucjuiy-Varina.

NC

27526

(

919

}

552-9161

•

(

800

)

348-2558

FAX

(800]

910*9915-

FAX

(919)

552-8682

H2

COUNTERTOP

CONVECTION

STEAMER

Manual

1177*93

(*3/10)

1-18.00

Congratulations'

You

have

purchased

one

o!

the

finest

peces

of

heavy-duty

commercial

cooking

equipment

or

the

market.

You

v/ilt

find

tha

your

new

equipment,

like

;ll

Southbend

equipment

has

been

designed

and

manufactured

to

meet

the

tough¬

est

standards

in

the

industry.

Each

piece

ot

Southbend

equipment

is

carefully

engineered

and

designs

are

verified

through

laooratory

tests

and

field

installations.

With

proper

care

and

field

mainienar.ee.

you

will

experience

years

ot

reliable,

trouble-

free

operation.

For

best

results,

read

this

manual

carefully.

RETAIN

THIS

MANUAL

FOR

FUTURE

REFERENCE.

TABLE

OF

CONTENTS:

Safety

Precautions...

Specifications.

Installation.|.

Operation..

Cooking

Times/Hints.

Maintenance..

AdJustmentsT

rouble

shoeing.

Parts'Auucssc

ries.

Warranty.

.2

.3

.4-9

.10-11

.11-13

.14-15

17

13

LOCATION

A'JD

IDENTIFICATION

OF

NAME

PLATE

The

serial

plato

with

voltago.

model,

and

ce-ial

information

is

located

on

She

right

hard

side

of

the

ctoamor

cavity

on

tho

uppo-

rear

comer.

Or

single

units

a

second

tag

ts

located

on

the

face

of

the

fioor

which

wil

show

only

mocel

and

serai

number.

On

Tandem

unts

a

second

tag

is

located

on

the

left

side

of

the

left

unit

and

the

right

side

ot

the

right

unit.

Read

these

instructions

carefully

before

attempting

installation.

“Installation’

and

“

Start

Up’

should

be

performed

by

a

quali¬

fied

installer.

Ur.iess

the

installation

instructons

for

the

above-described

Southbend

product

are

followed

and

performed

by

a

qualified

service

technician

(a

person

experienced

in

and

knowledgeable

of

the

installation

of

commercial

gas

and’or

etectn-

cai,

ana

water

specrtrcaiions

for

cooking

equipment;

men

tne

terms

ana

conditions

ct

tne

Manufacturers

Limited

warranty

wll

be

rendered

void

and

no

warranty

of

any

kind

shall

apply.

In

the

event

you

have

questions

concerning

the

installation,

use.

care,

or

service

of

the

product,

write

to

the

Technical

Service

Department.

Scuthbend.

110C

Old

Honeycutt

Rd..

Fuquay-Vartna.

North

Carolina

27526.

NOTICE

This

oroduct

is

intended

for

ccmmorcia!

ueo

only;

not

for

household

use.

IMMEDIATELY

INSPECT

FOR

SHIPPING

DAMAGE

All

containers

should

be

examined

for

damage

before

and

during

unloading.

The

freight

carrier

has

assumed

responsibility

tor

its

sate

transit

and

delivery,

it

damaged

equipment

is

received,

eitner

apparent

or

concealec,

a

claim

must

be

made

with

the

delivering

carrier.

A)

Apparent

damage

cr

loss

must

be

noted

on

the

freight

bll

at

the

time

of

delivery.

The

freight

bill

must

tnen

be

signed

by

tre

earner

representative

(Driver).

If

the

Dill

is

not

signed,

the

earner

may

refuse

the

claim.

The

carrier

can

supply

the

necessary

forms.

B)

A

request

for

inspection

must

be

made

to

the

carrier

within

15

days

if

there

is

concealed

damage

or

loss

that

is

not

apparent

until

alter

the

equipment

is

ununsled.

Tire

carrier

shouhJ

arrange

ar,

inspec¬

tion.

Be

certain

to

hold

ail

contents

plus

all

packing

material.

rpTj

ti

CMC

id

ion

southbend

*ti'05l£fl»C01WAV'

1100

Old

Hon«yCUt1

Peed

-

Fuquay

Vcrina.

NC

27616

1919)

552-9161

•

(8C0)

348-25£S

FAX

(800)

9109915

-

FAX

(919)

552-86*2

PAGE?

SAFETY

PRECAUTIONS

Before

installing

and

operating

this

equipment,

be

sure

everyone

involved

in

its

operation

is

tuily

trainee

and

aware

ot

precau-

liviis.

Accidents

and

pioOfems

can

be

caused

by

Ccsiluie

lb

follow

fundamental

iuIcj

and

prccautwis.

The

following

symbols,

found

throughout

this

manual,

atert

you

to

potentially

dangerous

conditiore

to

tho

operator.

ccrvico

personnel,

or

tc

tho

equipment-

This

symbol

warns

of

immediate

hazards

which

will

result

in

severe

injury

o'

death.

This

symbol

refers

to

a

potential

ha2ard

or

unsafe

practice

which

could

result

in

imury

or

death.

This

symbol

refers

to

a

potential

hazard

or

unsafe

practice

which

could

result

in

injury,

product,

or

property

damage.

Thic

eymbol

refers

to

information

that

needs

special

attention

or

must

be

fully

understood,

even

though

not

dangerous.

A

DANGER

A

WARNING

A

CAUTION

NOTICE

PAGE

3

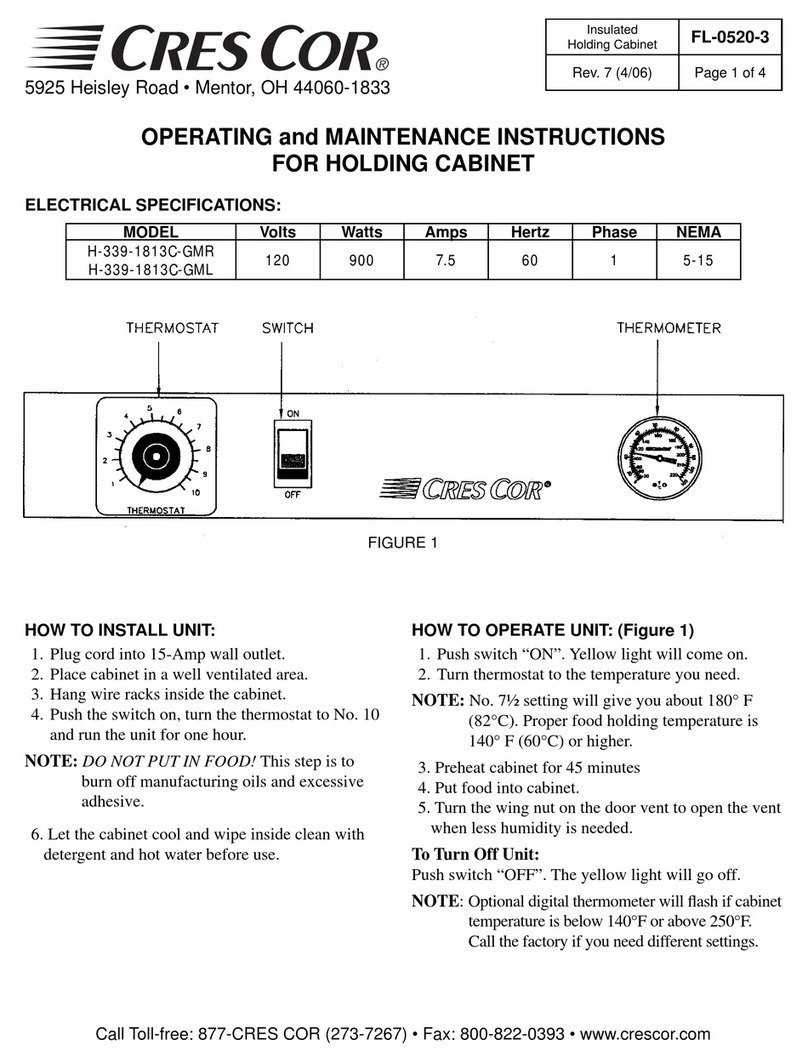

FRONT

VIEW

SIDE

VIEW

F

TOP

VIEW

*

Electric

connection

-

terminal

Keel:

3*

Dram

1

1/4'

o.d.,

leave

open,

do

njl

connect

to

toor

drain

~

Co6d

water

ntet

1/4*.

30

p.S.i.

min.-60

p.s.i.

max

MM

Heiyit

s

16"

wa"h

ELEC-

CO-IN

MODEL

P2

UTILITY

INFORMATION:

ELECTRIC:

One

electric

cameehon

DM

unit

K

woirae

Mtrieny^

I

...v

...rrncmmr

WATER

USAGE

AT

TMED

OR

MANUAL

COOKIN3:

SMGLE

UNIT

TOTAL

CONNECTED

AMPS

MAX.

AMPS

PER

LINE

208

V

60

Hz

44

25

!

220

V

5060

Hz

41

2-1

240

V

60

Hz

38

22

4

A

•Vll

B

r

rl

1

V

rw|

n

/

41S’240

V

50

Hz

<*•

22

-—-1

13

480

V

60

Hz

ifl

ii

0

46

total

gale'll

pormriuta

ai

<5

IMPORTANT:

UNIT

MUST

BE

LEVEL

FOR

PROPER

OPERATION.

WARRANTY

WILL

BE

VOIDED

FOR

IMPROPER

l*STALLAT!ON.

”AE

unts

snippeo

OB'

easterner

crxr

Circe

erase

sr

srtjie

prase

II

necsssary

t>

charge

see

insaJIaOx:

sector

Ipr

cjnverst-n

C.rcurf

maw

O

o

wtrod

»r

maxmum

ampc

af

icxjisrcd

voftage.

|

WAI

fcK

SPhClFICA

I

IONS:

To

meet

warranty

’eemrerrents

scpcV

water

must

De

as

loliow

Connectoc.:

I

i/«'cog

water

Pressjre:

__

Total

Dissolved

Solids

TPS):

Hard

ness:

_

_

_

PH

Facto-:

iw

cow

water

i_

30to

EG

PSI

60

PPM

2

grai

ns

or

35

PPM

7.0

tc

7.5

PAGE

4

INSTALLATION

PAGE

5

INSTALLATION

NOTE:

This

unit

has

one

power

supply

for

controls

and

elements,

as

well

as

one

ground

wire.

A

POSITIVE

GROUND

CONNECTION

IS

ESSENTIAL.

DO

NOT

ALLOW

ANY

TAMPERING

OR

ADJUSTMENT

OF

ANY

CONTROL

OR

WIRING.

THE

UNIT

IS

FAC¬

TORY

SET

ADJUSTMENT

OF

ANY

INTERNAL

COMPONENT

OTHER

THAN

THE

FIELD

TERMINAL

BLOCK

CAN

VOID

THE

WARRANTY.

ELECTRICAL

CONNECTION

NOTE:

A

i

200-220-240

and

405

volt

units

will

have

three

terminal

btocK

sections.

"LVL2-L3.*

lor

use

with

either

3-wire

3-phase

or

2-wire,

single-phase,

50

or

60

Hz.

AJi

380V

and

415V

units

will

have

tour

terminal

block

sections.

'L1-L2-L3-N•or

use

with

European

style

4-wtre

3-phase

with

neutral.

THREE

PHASETO

SINGLE

PHASE

CONNECTION:

3e

sure

that

the

input

voltage

matches

the

requirement

on

the

serial

plate.

The

unit

is

factory

wirec

per

customer

order.

If

necessary

to

change

phase,

remove

control

pane.,

item

'A*

in

figure

2,

and

rearangc

element

lead

wires

2

and

3

as

sbtwn

Detow.

206

-

22C

-

24C

-

48CV

INSIDE

RIGHT

SIDE

0-ENiNG

1

WIRES

CONTACTOR

3-PHASE

WIRES

CON~AC

_

CR

1

3

5-P

z

2

4

6-fcj

ARRANGE

ELEVEN"

Vv'RES

AS

SHOWN

J

1

-

SINGLE—PHASE

—L2

FIGURE

2

WATER

CONNECTION:

Connect

cold

water

Ime,

1/4'

(6mm)

NPT

into

female

side

of

strainer

located

at

right

lower

side

of

unit

as

you

face

the

tack

ol

me

steamer.

Water

line

preceuro

ehauld

bo 30

pci

(205

kpa)

minimum

to

60

pci

(410

kpa)

maximum.

NOTE:

To

facilitate

cleaning,

and

allow

access

to

rear

of

unit,

flexible

connections

are

recommended.

Recommended

Plumbng:

(Furnished

by

Installer)

DA

AIN

COLD

WATER

SUPP-V

PRESSURE

REDUCING

VALVE

IF

REQUIRED

CHECK

VALVE

/h

WARNING

Co

not

connect

steamer

to

a

hot

water

hose.

A

ho:

water

connection

will

damage

the

s:eamer.

PAGE

7

WATER

SPECIFICATION:

To

meet

warranty

r&quire-narls.

supply

water

must

'naat

the

following

specification:

Pressure:

30

to

60

psi

Total

Dissolved

SoliC3

(TDS;:

00

PPM

Hardness:

2

Grains

or

35

P

PM

pi

I

factor

7.0

to

7.5

DRAIN

LINE:

The

Orain

ime

connecter

size

from

the

unit

is

V

f\PT

(32

mm).

Position

the

unit

near,

but

no:

on

top

of.

an

open

floor

drain.

DO

NOT

directly

pumb

to

the

unit

unless

you

also

install

an

“open

funner

downst-eam

of

this

connection

in

the

drain

system

Make

the

cran

nne

from

the

unit

to

'-he

air

gap

aoo/e

the

"open

tunneT’

as

short

as

Dossiole.

There

should

x

no

rorzcntai

piping

oerween

the

urn

ana

the

ar

gao

above

the

"open

tunnel.'

The

"open

funnel”

is

intended

to

elimi¬

nate

any

water

from

entering

the

steamer

because

of

a

Dlocked

dram

and

it

also

prevents

any

Pack

pressure

within

the

sleainef

wsviy.

The

unit

must

be

freeze*itiug

to

fit

atmosphere

Any

cxxinection

that

allows

the

DullOup

oT

Pack

pres¬

sure

in

the

unit

such

as

a

reduction

ir

pipe

size

to

s

line

small#?

than

1

"

or

a

00

degree

angle

in

the

line

pner

to

the

•open

funner

drain

Recharge

point

may

cause

perasnai

or

property

damage

and

therefore

will

void

the

warranty.

This

is

a

pressureess,

free-ventng

steam

oooker

and

will

not

operate

property

unless

the

drain

line

is

short,

at

a

steep

aigle.

and

opanl

Soo

figure

3.

Side

View

Rear

View

FIGURE

3

/h

WARNING

BURN

HAZARD

It

is

imperative

that

the

drain

connection

be

installed

per

instructions

ana

Kept

clean

(open)

to

assure

free

venting

to

atmosphere.

A

clogged

drain

will

cause

pressure

to

build

up

inside

the

steamer

cavity

and

can

endanger

the

operator

when

opening

the

door.

It

will

al30

cause

excessive

leakage

of

steam

from

the

door.

NOTICE

Floor

drain

must

be

located

outsde

the

confines

of

the

equipment

base

or

damage

to

equipment

may

occur.

Do

not

locate

unit

adjacent

to

any

high

heat

or

grease

producing

piece

of

equipment,

such

as

a

range

top,

gridcSe.

fryer,

etc.,

that

oould

altow

radiant

heat

to

raise

the

exterior

temperature

of

the

steam

body

above

13C°F

(54°C).

DO

NOT

MOUNT

ABOVE

OTHER

COOKING

EQUIPMENT.

PAGE

8

INSTALLATION

INSTALLATION

NOTICE

Local

codes

regarding

installation

vary

greatly

from

one

a

r

ea

to

another.

The

National

Fire

Protection

Association.

Inc.

states

in

its

NFPA

96

latest

edition

that

local

codes

are

"authority

having

jurisdiction"

when

it

comes

to

installation

requirements

for

equipment

Therefore,

installations

should

comply

with

ail

local

codes.

EXHAUST

FANS

AND

CANOPIES:

t

is

recommended

that

the

steamer

be

installed

under

a

ventilation

hood.

Consult

local

codes

fcr

proper

installation

d

hoods.

LEVELING:

Unit

nust

be

level

to

assure

maximum

performance.

Improper

leveling

may

void

warranty

2.

Do

not

remove

any

tags

cr

labels

until

unit

is

installed

and

working

property.

3.

II

unit

is

to

be

installed

on

leys,

k»-ote

legs

and

install

as

shown

on

drawing.

(See

Figure

4.)

FIGURE

4

PAGE

9

4

II

unit

is

to

te

installed

on

a

counter

top

or

other

suriace

without

using

legs

the

unit

must

be

sealed

to

the

surface

to

prevent

any

water,

grease,

etc.

Irom

accumulating

under

the

steamer.

The

steamer

can

be

bolted

to

the

counter

but

will

still

have

to

be

sealed.

The

Instaler

may

use

G.E.

or

DOW

CORNING

RTV

type

sealant.

(Consjtt

local

code

for

exact

requirements.)

See

figure

5.

PERFORMANCE

CHECK:

The

following

items

should

be

checked

within

the

first

3C

days

o*

operation

by

a

qualified

service

technician.

1.

Check

doors

for

[xope-alignment

2.

Check

door

gaskets

fo*

wear

and

sealing

abdrty.

3.

Check

spray

tubes

o*

nozzles

for

cleanliness

and'or

leakage

4.

Check

all

gauges,

timers,

valves

ana

switches

for

proper

operation.

5.

Visually

ooeck

control

compartment

wiring

for

burned

or

loose

connections.

6

Check

electrical

ioad

cn

elements

for

proper

waitage.

7.

Be

sure

operators

understand

the

importance

of

proper

cleaning

and

maintenance.

PAGE

10

INSTALLATION

OPERATION

THEORY

OF

OPERATION

Compared

to

other

seam

cookers

with

compteated

boilers,

the

R2

is

a

very

smple

machine.

Immersion

elements

are

installed

on

the

left

side

of

the

cevty

and

when

.voter

covers

the

elements,

water

starts

to

boD

and

fcim

to

steair.

There

is

no

pressure

in

this

unit.

The

Steam

Master

R2

is

designed

to

provide

quck

heat-up

tom

a

cold

start.

All

nquipmanT

mnct

ho

installed

rrrrortly

to

ensure

proper

ceeration

and

reliable

service.

Installation

instruction

must

Do

followed

oy

a

qualified

technician.

Betore

you

turn

the

unR

on,

be

sure

that

you

nave:

POWEH

:o

unit,

WATER

to

unit,

anc

ar

OPhN

DKAIN.

CONTROL

OPERATIONS

START

UP:

1.

Close

the

drain

valve

(tun

lever

to

the

run

position

).

?

Turn

power

switch

nn

l.i-vt

will

fil

anc

begin

heating

Unit

will

be

up

tc

operating

temperature,

ready

to

use.

in

approximately

ten

(10)

mnutes.

The

"Ready*

light

wil

light

up

when

tne

unit

is

ready

to

use.

NORMAL

OPERATION:

2.

’Manual'

-

"his

unit

runs

full-power

ccntnuously.

NORMAL

OPERATION:

REVIEW

—

•

Use

timer

as

desired,

put

rt

"Manual"

position

to

disable

buzzer.

Timer

has

r»

impac:

on

operation.

•

To

conserve

water

and

eeetrietty

during

"Mow*

period?,

shut

unit

off.

do

not

open

drain

valve

SHUTOFF:

Tum

power

switch

*OH.'

Turn

the

drain

valve

lever

io

‘DRAIN’.

OPERATING

INSTRUCTIONS:

1.

De-ume

Indicator

Ugh:

-

The

"De-Lime"

indicator

light

wV

illuminate

when

the

unit

senses

tnat

the

elements

need

cleaning.

Usually

a

rhin

layer

a*

deposits

are

present

when

this

occurs.

When

the

light

signaling

the

opera¬

tor

tna:

cieaning'oe-iiminc

snouid

be

performed,

see

"Maintenance.

Periodic

Cleaning*

under

servee

section

for

-ecommended

procedures.

2.

Cleaning

must

be

performed

to

restore

normal

operation

of

the

unit.

When

the

"DE-LIME"

light

comes

on.

the

contactor

shuts

off

power

to

the

elements.

/h

WARNING

BURN

HAZARD

When

door

is

being

openec.

hot

steam

or

hot

water

may

escape

from

steamer.

Stand

back

when

opening

door

PAGE

11

SUGGESTED

COOKING

TIMES:

Timet

sennas

are

for

general

guidance

only.

Differences

m

fooa

quality,

size,

snape.

tresnness,

»ac

size

and

degree

of

Goneness

desired

must

Be

considered

and

aciustments

made

in

time

i

necessary.

PRODUCT

WEIGHT

PORTIONS

COOKING

TIME

(Minutes)

PAN

USED

Asparagus

Fresh

3V*

lbs.

14

(4

oz.)

8-10

Full-Perforated

Frozen

Spears

(Thawed)

5

lbs.

20

(4

oz.)

9

Full

Perforated

Beans

Green

-

Frozen.

Cut

5

IDS.

2b

(4

OZ.)

12

FullPerforated

Green

-

Fresh

5

lbs.

20

(4

oz.)

15-17

FullPerforated

Wax

-

Frozen

5

lbs.

20

(4

oz.)

13

FullPerforated

Lima

-

Frozen

5

lbs.

20

(4

oz.)

10

FullPerforated

Broccoli

Spcarc

Froch

4

Ibc.

IS

(4

oz.)

10-12

FullPerforated

Spears

-

Frozen

(Thawed)

5

lbs.

20

(4

oz.)

8

FullPerforated

Brussel

Sprouts

Fresh

5

lbs.

20

(4

oz.)

15-17

FullPerforated

Fresh

5

lbs.

20

(4

oz.)

13

FullPerforated

Carrots

Frozen

-

Whole

Baby

5

lbs.

20

(4

oz.)

12

FullPerforated

rrcsh

—

V*

-Inch

Dias

Cut

5

lbs.

20

(4

oz.)

12

FullPeiforaled

Cabbage

Green.

Cut

Into

Wedges

24

15

FullPerforated

Red,

Cut

Into

Wedges

16

18-20

FullPerforated

Cauliflower

Fresh,

Whole

2

lbs.

8

(4

oz.)

9-10

FullPerforated

Fresh,

Whole

2

tos.

12

oz.

11

(4

0Z.)

15

FullPerforated

Frozen,

Flowerelles

5

lbs.

20

(4

oz.)

10-12

FullPerforated

Com

Fresh,

Cob,

4-5

Inch

Ears

5

V

a

lbs.

15

13-15

TullPed

orated

Frozen

-

Whole

Kernel

Rlhs

20

(4

oz.)

8

FullPerforated

Frozen

-

Cob.

6

Inch

Ears

9

lbs.

14

12-14

FullPerforated

Mixed

vegetables

Frozen_

51*.

20

(4

oz.)

12

FullPerforated

Peas

Frozen

5

lbs.

20

(4

oz.)

a

r

ullPerf

orated

Potatoes

Red

Bliss-Whole

7

lbs.

28

35

FullPerforated

Russetts

-

Whole

8

lbs.

20

23-25

FullPerforated

Russetts

-

Peeled

5

lbs.

12

20

FullPerforated

Russetts

1-lnch

Cubes

5

lbs.

20

(4

OZ.)

17

FullPerforated

Spinach

Fresh,

Leaf

27,

fo3.

10

(4

oz.)

5

T

ultPerforated

Frozen,

Chopped

6

lbs.

24

(4

OZ.)

35

FullPerforated

Zucchini

Fresh

-

Slices

’/.-Inch

Thick

5

lbs

20

(4

02

.)

6-8

FullPerforated

Eggs

Large

-

Hard

Cooked

12

lbs.

12

15-16

'h

Perforated

PAGE

12

OPERATION

OPERATION

PRODUCT

WEIGHT

PORTIONS

COOKING

TIME

(Minutee)

PAN

USED

Meats

Corned

Beef

67.

ibs

18

(6

OZ.)

2

hours

Full

Hot

Dcgs,

Thawed

Hot

Dcgs.

Frozen

5

lbs.

5

Ibs.

40

(2

OZ.)

40

(2

oz.)

5

10

Ful/Perforated

Full-Perforated

Fowl

Boneless

Chicken

3reast

4'/*

tos

12

(6

oz.)

15

Ful,

1

Perforated

Tamales,

Frozen

Tortilla,

Frozen

8-lrch

3

Ibs.

4

Tortillas

12

(4

oz.)

4

20

45

Seconcs

Ful/Perforated

Halt-Perforated

Beef

Ravioli,

Frozen

48

Ravioli

(IhRnr)

8

5-6

Ful/Perforated

Eibow

Macaroni

2

Ibs.

32

(2

oz.)

7

In

Perforated

Par

Uncooked

Nested

in

Solid

Pan

Spaghetti

2

Ibs.

Uncooked

32

(2

oz.)

14

In

4-Inch

Full-Perforated

Fgg

Noodles

7

lbs.

Uncooked

X>

(Z

07

.)

in

Fun-Perforated

Converted

Rice

2

lbs.

25

Full-Perforated

27,

Qts.

Water

+

QU

&

Salt

Navy

Beans

2

lbs.

Place

beans

in

pan

and

cover

with

3-quarts

hot

tap

water.

Steam

for

2

minutes:

remove

from

steame-

and

cover

for

1

hour.

FullPerf

orated

Remove

cover

aid

place

back

In

steamer

tor

40

minutes.

Black

Eyed

Peas

2

lbs.

Place

peas

in

pan

and

cover

with

3-quarts

hot

tap

water.

FullPerf

orated

Steam

for

2

minutes:

remove

from

steamer

and

cover

for

1

hour.

Remove

cover

and

place

back

In

steamer

for

35

minutes.

Seafood

Oysters

5

Ibs.

16

Count

12

Perforated

Pan

Nested

m

a

Full

Pan

27,-Inch

Deep

Shrimp,

Fresh,

Medium.

Head3

Removed

5

Ibs.

6-7

Full'Perf

orated

Shrimp,

Frozen.

Large,

Peeled

&

Dcveiired

5

Ibs.

8

FulfPertorated

Lobster

17,

Ibs.

8

FullPerf

orated

Alaskan

King

Crab

Legs

1

lb.

4-5

FullPerforated

Cherrystone

Clams

5

Ibs.

12

7

Ful

IP

erf

orated

Fish

Filets

77,

Ibs.

12

(10

oz.)

18

FullPerforated

Nested

in

Full

Hotel

Pan

END

USER

TIPS:

Schedule

cocking

of

fresh

vegetables

so

that

they

will

be

served

soon

after

they

are

cooked.

If

rt

is

necessary

to

prepare

them

in

advance,

the-/

can

be

plunged

into

cold

water,

drained

thoroughly

and

held

under

refrigeration

until

needed

for

service.

Five

pounds

of

cold

aoked

veoetabes

can

be

reheated

in

the

steamer

in

5

to

10

minutes,

(Spending

upon

the

variety.

PAGE

13

Adding

sal

to

the

water

tor

eggs

cioked

in

the

shell

makes

the

cooking

water

more

efficient

and

faster

at

its

jot>.

If

the

egg

cracks,

the

white

is

cocked

at

the

crack

and

is

seated

right

away.

To

avoid

green

yelk

(which

is

a

deposit

of

iron

sulfide)

chit!

the

eggs

immediately

alter

removing

from

Ure

steamer

by

plunging

tnem

into

a

ccfcJ

water

bah

(preferably

containing

ice).

A

cuick

and

easy

tvav

to

cook

eats

lor

a

salad

mixture

is

to

crack

them

directly

into

a

solid

steam

tabte

par

which

has

bear

lightly

ccatec

with

salad

oil.

Do

not

mix.

Steam

until

they

are

hard

cookec.

Remove

and

chop

as

you

would

for

egg

salad

The

pb

of

peeling

has

been

eliminated.

Transfer

steamed

:kk

chicken

to

oaep

par.,

cover

with

Cacciatore

Sauce

and

finish

in

oven.

Bake

20

to

30

mnutes.

May

uclrddon

steam

table.

After

steaming,

chicken,

sausage,

and

fish

may

te

browned

in

Infra-Red

or

Radiant

Broiler.

Brush

with

melted

rr.argame

mued

with

salad

oJ

to

give

a

gokten

brown

cotor.

Jse

juice

saved

rrem

steamed

chicken

cr

turkey

to

make

soups,

sauces,

or

cassciulc

b-snes.

Chcken

may

Be

steamed

in

advance

and

held

unaer

refrigerator

for

next

day's

use.

Be

sure

to

bring

product

back

to

18C

C

F

before

servhg.

Gere

the

|utce

lion

the

ccmcd

beef.

Alta

tne

cabbage

has

beer*

steamed,

place

it

in

a

scTiJ

pen

umj

«U0

Uic

juice

lo<

llc-

vor

ng

and

holding

on

a

steam

tabie.

Steaming

brisket

is

a

definite

time

saver.

Boiiing

ir.

water

takes

4C

to

50

minutes

per

pound.

Using

the

R2

can

save

50%

in

cocking

time.

Oaotage,

wtien

steamed,

retains

ss

color

and

wedge

identity,

li

will

not

break

apart

as

i:

does

wnen

boiled

In

ar.

open

pot.

Wten

removing

items

prepared

in

a

perforated

pan.

put

a

solid

pan

underneath

the

perforated

pan

to

hold

the

pan

of

cocked

food.

The

w.ll

prevent

dripping

on

the

floor.

Tne

R2

is

designee

to

accept

standard

12

x

20

pars.

Fractional

sze

pans

and

ctshes

can

be

used

as

well

with

the

optional

perforated

ehtX!.

For

stirrng,

the

par.

does

not

have

to

be

removed

from

the

steamer.

Pub

pan

1/3

way

out

of

the

cavity

and

the

entire

sur¬

face

is

accessbie.

Tho

door

may

ba

opened

at

any

timo

during

operation

to

remove

or

add

food.

PAGE

14

OPERATION

SERVICE

MAINTENANCE

Southbervd

equipment

is

sturdily

constructed

of

the

best

quality

materials

and

is

designed

to

provide

durable

service

when

treated

with

ordinary

care.

To

expect

the

best

performance,

your

equipment

must

be

maintained

in

ywd

condition

aid

deanec

daily.

Naturally,

the

periods

for

this

care

and

clearing

depend

on

tie

amount

and

degree

oi

usage.

Following

daily

and

periodic

maintenance

procedures

will

i'crease

the

life

of

your

equipment.

Climatic

cordWons

—

sail

ei

—

seasonings

-

water

quality

-

may

require

more

thorough

and

frequent

cleaning

or

the

life

ol

the

equipment

could

oe

adversely

averted

DAILY

CLEANING

YOUR

R2

MUST

BE

THOROUGHLY

CLEANED

EVERYDAY.

•

Remove

the

pan

supports

and

well

cover.

Wash

sepa

ately

in

a

sink

with

a

mild

detergent

and

warn

water.

Dry

thor¬

oughly

wih

a

clean

cloth.

Scotch

Biite

scouring,

pads

may

be

used

for

uaked-uu

deposits

•

Wash

interior

surfaces,

including

the

heating

elements

with

a

mild

detergent

and

warm

water.

Rirse

with

dean

water.

Dry

thoroughly

with

a

clean

cloth.

I'

discoloration

starts

due

tc

brnld

up

of

seasonings

cr

food

products,

remove

by

using

Scotcb-Bnte

scouring

pad.

Then

wash,

mse,

and

dry

as

aoeve.

•

Wash

floats

carefully,

check

that

float

stems

are

dean

and

floats

move

freely

•

Wipe

exterior

surface

with

a

dean

damp

doth.

-

Return

a»

cleaned

parts

to

the

unit.

pJaong

in

their

proper

positron.

•

LEAVE

THE

DOOR

OPEN

AT

NIGHT

AFTER

CLEAN

IMG.

This

allows

the

unit

to

dry'

thoroughly

after

cleaning

and

also

prolongs

toe

life

ot

the

dcor

gasket.

PERIODIC

CLEANING-AS

REQUIRED:

If

a

lime

or

mineral

deposit

starts

to

burid

up

in

the

interior,

this

sboukl

be

deaned

by

usmg

Southbend

‘descalor"

or

otter

non-caustic

deliming

solution.

Follow

manufacturer’s

recommended

procecures

Thoroughly

rinse

out

unit.

To

remove

food

build

up

or

discoloration,

apply

deanser

tc

a

damp

doth

or

sponge

ard

rub

deanser

on

toe

material

in

trie

direction

of

trie

polishing

lines

on

the

metal.

Never

rub

with

a

circular

motion.

Soil

and

discoloration

which

do

not

respcnc

to

the

above

procedure

can

usually

be

removed

by

rubbing

the

surface

with

Gcotch-Dritc

scoumg

oads.

A

CAUTION

DO

NOT

GET

WATER

IN

THE

CONTROLS.

Could

result

in

expensive

repairs

or

elecirical

shock.

DO

NOT

IISF

ordinary

<tfao

wool

as

any

parfidns

loft

on

ttio

surface

will

met

NEVER

USF

a

wire

brush,

stool

or

ahrasiva

scouring

pads,

scraper,

file

or

other

steel

tcols.

Surfaces

wnich

are

marred

collect

dirt

more

rapidly

and

become

more

dff-

cuft

to

dean.

Mamng

also

increases

the

possibility

of

corrosive

attack.

DO

NOT

clean

door

gasket

with

a

high

chlorine

solution

or

bleach.

NEVER

USE

A

CORROSIVE

CLEANER.

USE

ONLY

CLEANERS

APPROVED

FOR

STAINLESS

STEEL

STAINLESS

STEEL:

To

remove

norma!

dirt,

grease,

or

product

residue

from

stainless

steel,

use

ordinary

soap

and

water

(with

cr

without

detergent)

applied

with

a

sponge

or

cloth.

Dry

thoroughly

with

a

dean

doth.

Never

use

vinegar

or

any

corrosive

©earner.

To

remove

crease

and

food

splatter

or

cordensed

vapors

that

have

baked

on

the

equipment,

apply

deanser

to

a

damp

doth

or

sponge

and

rub

deansef

on

the

metal

in

the

direction

of

the

polishing

lines

on

the

metal.

Rubbing

cleanser

as

gen-

tJy

as

possibe

in

the

direction

of

the

polished

lines

will

not

mar

the

finish

&

the

stainless

steel.

NEVER

RUB

WITH

A

CIR¬

CULAR

MCnON.

Soil

and

burnt

deposits

which

do

not

respond

to

the

above

procedure

can

usualy

be

removed

by

rub¬

bing

the

surface

with

SCOTCH-8RITE

scouring

pads.

DO

NOT

USE

ORDINARY

STEEL

WOOL

as

any

panicles

left

on

toe

surface

-nil

rust

and

further

sped

toe

appearance

of

toe

finish.

NCVCR

UGC

A

WiFC

DRUGII,

GTCCL

GCOUDINC

PAD.

SCRA=ER,

FILE

OR

OTHER

STEEL

TOOLS.

Surfaces

which

are

marred

collect

dirt

more

rapifiy

and

become

more

difficult

tn

dean

Marring

also

increases

the

possibility

of

corrosive

aback

Refinishing

may

then

be

required

PAGE

15

MAINTENANCE

PAGE

16

SERVICE

SERVICE

ADJUSTMENTS

NOTICE

Service

work

should

be

performed

only

ty

a

qualified

technician

who

is

experienced

in.

and

knowledgeable

of.

the

operation

of

commercial

oac.

electric,

and

steam

cooking

equipment.

Contact

the

Authorized

Service

Agency

for

reliable

service,

cependable

advice

or

other

accstanco,

and

for

genuine

factory

parte.

Warranty

will

be

void

and

the

manufacturer

ie

relieved

of

all

liability

if:

(A)

Service

work

is

performed

by

other

than

a

qualified

technician.

OB

(Bj

Other

than

genuine

Scuthbenc

repacement

parts

are

installed.

TROUBLE

SHOOTING

GUIDE

Symptom:

Oeck

or

Replace:

Nc

power

Check

droit

breaker

Nc

water

Check

water

supply

Heating

elements

wll

only

operate

for

bnef

regular

cycles

and

delime

hght

s

iilumnated.

Clean

and

delim?

steame-

/^WARNING

SHOCK

HAZARD

De-ernergbe

all

pnwer

to

equipment

before

servicing

the

equipment

At

least

twice

a

year,

nave

your

scuthbena

Authorized

Service

Agency

or

anotner

qualified

service

technician

clean

and

adjust

the

unit

ior

maximum

performance.

Consul:

the

South

Pend

Authorized

Parts/Service

Distributor

list

for

the

Authorized

Service

Representative

in

your

area

li

this

is

nnt

available,

call

the

Service

DepartmenT

a!

Southbenri.

'.-fifC-34A-?5SB

for

their

name

and

num¬

ber.

PAGE

17

PARTS

-

ACCESSORIES

NOTICE

INSTALLATION

OF

OTHER

THAN

GENUINE

SOUTHBEND

PARTS

WILL

VOID

THE

WARRANTY

ON

THIS

EQUIPMENT.

The

serial

piate

with

voltage,

model.

and

serial

Information

is

located

on

the

right

side

of

the

steamer

cavity

on

the

upper

rear

comer.

On

single

units

a

second

tag

is

located

on

the

face

cf

the

door

which

will

show

only

model

and

ser¬

ai

mmoer.

On

Tandem

unis,

a

second

tag

is

or.

the

right

side

ot

the

rant

unit

and

the

left

sice

of

the

left

unit.

Repacoment

pane

may

bo

ordered

either

th-ouoh

a

Southbend

Authorized

Parte

Distributor

or

a

Southbend

Authorized

Service

Agency.

When

onJeiing

puita,

please

supply

Hie

Model

Numbei,

Seiial

Numbei.

Pail

Number.

DeaoiipttOil,

Finish,

and

Becirical

Characteristics

as

apptcable.

For

carts

not

listed,

consult

a

Souihbend

Authorized

Parts

Distributor

or

Southbend

Authorized

Service

Aoercy.

Consult

the

Southbond

Authorized

Partc’Sorvice

Distributor

list

for

tho

Authorized

Parte

supplier

in

your

area

If

'hie

list

ss

not

available,

call

the

Se-vice

Department

at

Southbend.

*-800-343-2553

for

same.

EiSUBES

ITEM

PART

NC.

DESCRIPTION

A

1173224

Screw

1/4

-

20

x

SB

5

OT

B.

1173195

Retainer

Panel

Assemby

c

.1177072.

Door

Gasket

D

"Z'lZ"

1174587

.1178268

Cavity,

Side

Rack

.Weil

Cover

Deflector

F

•

117700C

4450D02

Door

Striker

Technical

Manual

•

1176561

Cleaning

Instructions

•

PM

162

Cleaning

Pad

*

4450020

SteamMaster

ctescaler

24

pack

i.

-

.

4450021

SleaniMaato.

Douotet

Vtastei

Pauk

(Contains

8

of

lire

4450020)

PAGE

18

PARTS

No

Quibble

Warranty

Q

If

a

customer

calls

wfth

a

problem

involving

any

Scuthbend

product,

we

wil

rectify

it,

no

charge:

24

hours

a

day,

?

days

a

week,

355

days

a

year.

Oui'Nu

QuiUbte’

Waiiciity

means

there

will

be

no

charge

to

the

customer

for

llie

call,

ports,

travel

or

for

premium

time.

If

the

proolem

tome

out

that

the

unit

is

unplugged,

the

circuit

breaker

is

tripped,

the

gas

is

shut

off,

or

even

if

the

customer

doesn’t

(mow

how

to

operate

the

equipment,

etc..—ife

covered.

The

foregoing

warranty

is

exclusive

and

in

lieu

of

all

other

warranties,

CApieaaed

vi

implied.

Thcie

o/e

nv

Implied

tvaiioiilica

vt

nitri

v!

mi

liability

or

of

fitness

for

a

particular

purpose.

p^j

This

warranty

is

eltectivs

on

southDend

equipment

sold

on,

or

attar

Fob.

16,1696.

VA

Southtend,

hereinafter

referred

to

as

the

seller,

warrants

equipment

manufactured

by

it

to

be

free

from

defects

in

material

and

workmanship

for

which

it

i3

responsible.

The

seller’s

obligation

under

this

warren

ty

shall

be

Kmitsd

to

replacing

or

repairing

such

part.

Such

warranty

shall

bo

limited

to

the

original

pur¬

chaser

only

and

shall

he

effective

for

a

period

of

one

yearfrnm

date

nf

original

installation

nr

1

ft

months

from

date

of

purchase,

whichever

is

earlier

provided

that

the

terms

of

payment

have

been

fully

met.

d

Normal

maintenance

functions,

including

lubrication,

cleaning

cr

customer

abuse

are

not

covered

by

this

No

Quibble

Warranty.

Wa

The

seller

shall

be

responsible

only

for

repairs

or

replacements

of

defective

parts

performed

by

sellers

authorized

eorvice

personnel.

Authorised

eorvice

agencies

aro

looated

in

pnnciplc

cities

throughout

tho

contiguous

United

States

and

Hawaii.

This

warranty

is

valid

in

the

United

States

and

is

void

elsewhere

unless

the

product

is

purchased

through

Middleby

International

with

warranty

included:

WA

The

foregoing

shall

be

tne

setters

sole

and

exclusive

obligation

and

the

buyer's

sole

and

exclusive

remedy

forany

action

irdudng

breach

tf

contract

or

negigence.

In

no

event

shall

the

seller

be

liable

for

a

sum

in

excess

c

t

the

purchase

price

of

the

item.

The

setter

shall

not

be

liable

for

any

prospective

or

lust

profits

of

lire

buyer.

__

_—-

*

PAGE

19

SOUTHBEND

LIMITED.

WARRANTY

Souhbend

warrants

tiat

the

equipment,

as

supplied

by

the

factory

to

the

original

purchasers,

is

free

from

defects

in

materials

and

workmanship.

Should

any

part

thereof

become

defective

as

a

result

of

normal

use

within

the

period

and

limits

defined

below,

then

at

the

option

of

Southbend

such

parts

will

be

repaired

or

replaced

by

Southbend

or

its

Authorized

Ucakc

Agency.

1

his

warranty

*

subject

to

the

following

conditions

If

upon

inspection

by

Soutnbend

or

its

Authorized

Service

Agency

it

is

determined

that

this

equipment

has

not

oeen

useo

in

an

appropriate

manner,

nas

been

modiiied,

has

not

been

properly

maintained,

or

has

been

subject

to

meuse

or

misapplication,

neglect,

abuse,

accident,

damage

during

transit

or

delivery,

fire,

flood

riot

or

Act

of

God,

then

this

warranty

shall

b©

void.

Specifically

oxcludsd

under

this

warranty

are

claims

relating

to

installation:

examples

arc

improper

utility

connections

and

mproper

utilities

eupply.

Claims

relating

to

normal

core

and

maintcncnce

are

also

excluded;

examples

are

calibration

of

con¬

trols

and

adjustments

to

pilots

anc

burners.

Equiomont

failure

caused

by

inadequate

water

quality

is

not

covered

under

warranty.

WATER

QUALITY

must

not

exceed

the

fol¬

lowing

limits:

Total

Dissolved

Solids

(TDS)

-

60

PPM

(Parts

Per

Million).

Hardness

-

2

Grains

or

35

PPM.

PH

Factor

-

7.0

tc

7.5.

Water

pressure

30

PSI

minimum.

60

PSI

maximum.

Boiler

maintenance

is

the

responsibility

of

the

owner

and

s

not

covered

By

warranty.

This

equipment

is

intended

for

commercial

use

onlv.

Warranty

is

void

if

equipment

is

instaBed

in

other

than

commercial

apofcca-

tion.

Repairs

under

this

warranty

are

to

ce

performed

only

bv

a

Southbend

Authorized

Service

Agency.

Southbend

cannot

be

responsible

for

charges

incurred

from

other

than

Authorized

Southbend

Agencies.

THIS

WARRANTY

MUST

BE

SHOWN

TO

AN

AUTHOF5ZED

SERVICE

AGENCY

WHEN

REQUESTING

'N-WARRANTY

SER¬

VICE

WORK.

THE

AUTHORIZED

SERVICE

AGENCY

MAY

AT

HIS

OPTION

REQUIRE

PROOF

OF

PURCHASE.

This

warranty'

does

net

cover

services

performed

at

overtime

or

premium

labor

rates

nor

does

Southbend

assume

any

liability

for

extended

delays

in

replacing

or

repairirg

any

items

in

the

equipment

beyond

the

control

cf

Southbend.

‘Southbend

shall

rot

be

iiabie

tor

consequential

or

special

damages

of

any

nature

that

may

arise

n

connection

with

such

product

o-

part.'

Should

service

be

icquircU

ai

limes

much

normally

involve

overtime

or

premium

taixx

rains,

the

owner

snail

t>e

cnargeo

lor

tne

diiterence

between

normal

service

rates

and

such

premium

rates.

In

all

circumstances,

a

ur

one

hundred

miles

ir,

travel

and

two

and

cne

halt

hours

(2.5)

travel

time

Shall

be

allowable.

in

ail

cases,

the

closest

Southbend

Authored

Agency

must

be

used.

The

actual

warranty

time

periods

and

exceptions

are

as

fuSowt*.

Thb

warranty

only

covers

product

shipped

into

me

48

contiguous

United

States

and

Hawaii,

cn

e-year

labor,

one-year

parts

effec¬

tive

rom

the

date

of

original

purchase.

There

wifi

be

rrc

labor

coverage

foi

equipment

located

on

any

island

noi

connected

by

roadway

to

the

mainland.

Exceptions

to

standard

warranty,

effective

within

above

limitations:

Glass

Windows.

Door

Seals.

Rubber

Seals.

Light

Bulbs,

Ceramic

Bricks,

Sight

Glacecc.

Cathode

D

©coolers

or

Anodes.80

days

material

and

laboi

Starless

Steel

Fry

Pet.4

years

extended

material

warranty

on

h\

pot

only

—-

no

labor

Stainless

Steel

Open

Top

Burners.

4

years

exienoea

material

warranty

on

burners

only

— no

labor

Pressure

Steam

Boiler

Shell..Prorated

4

years

extended

warranty

on

boiler

shell

only

—

no

labor

Boiler

shells

wticn

nave

no;

been

property

matniaJneo

will

no

f

do

covered

by

warranty.

h

a!

cases,

parts

covered

by

a

five-year

warranty

will

be

shipped

FOB

the

factory

after

tne

first

year.

Our

warranty

on

ail

replacement

parts

which

are

replaced

in

the

field

by

our

Authorized

Service

Agencies

will

be

limited

to

tnree

months

on

labor,

six

months

on

materials

(parts)

effective

from

the

date

of

installation.

See

LIMITED

WARRANTY

-

RCP-ACCMEN

i

PART3

for

conditions

and

hmitalions.

If

the

equipment

has

been

changed,

altered,

modified

or

repaired

by

ether

than

a

qualified

service

technician

during

or

after

the

one-year

limited

warranty

period,

then

the

manufacturer

shall

not

be

liable

fui

any

damages

!u

any

person

or

lo

any

property

which

may

result

from

the

use

of

the

equipment

thereafter.

-THE

FOREGOING

WARRANTY

IS

IN

LIEU

OF

ANY

AND

ALL

071ICP

WARRANTIES

EXFRE33ED

CR

IMPLIED

INCLUD¬

ING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS.

AND

CONSTITUTES

THE

ENTIRE

LIABILITY

OF

SOUTHBEND.

IN

NO

EVENT

DOES

THE

LIMITED

WRRANTY

EXTEND

BEYOND

TH=

DURATION

OF

ONF

YEAR

FROM

THE

EFFECTIVE

DATE

OF

SAID

*WARRANTY*

Consult

the

Southbend

Authorized

Pans/Service

Distributor

list

for

the

Authorized

Service

Representative

in

your

area.

If

this

Hot

b

not

available,

call

the

Service

Department

al

Southbend,

1

-030-340-2550.

PAGE

20

Other Southbend Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Bonnet Neve

Bonnet Neve BOWL EVO LT User instructions

Diamond

Diamond DST/2-15 AG Operating and maintenance manual

Costan

Costan VELVET User instructions

Nordcap

Nordcap PATMOS 2.0 TC 1250 HOT Use and maintenance manual

PARRY

PARRY AITT1875-IFR Product instructions

Kelvinator

Kelvinator KCHUC23F Service, installation and care manual

Rühle

Rühle MPR 600 Translation of the original instructions

Bourgeat

Bourgeat HARMONIE Series Instructions for use and maintenance

Expondo

Expondo Royal Catering RCMC-400W user manual

MINERVA OMEGA

MINERVA OMEGA C/E 652 operating instructions

BETTCHER INDUSTRIES

BETTCHER INDUSTRIES Whizard Quantum Air 360 Operating instructions & parts list

Skyfood

Skyfood DMS-30 instruction manual