Southbend BGLM-40N User manual

MANUAL 10152-SB REV 1 (05/22)

$21.00

Gas Floor Model Braising Pan

with Manual Gearbox Tilt

MANUAL SECTION CO

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equipment:

Model #:

___________________________

Serial #:

___________________________

Date Purchased:

_____________________

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment.

Gas Floor Model Braising Pan

With Manual Gearbox Tilt

BGLM-30, BGLM-40, BGLM-40N

and BGLM-60

Installation & Operation Manual

Model BGLM-40N

SOUTHBEND STEAM

A Middleby Company

1100 Old Honeycutt Road Fuquay-Varina, North Carolina 27526 USA

www.southbendnc.com

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 2 OF 20

SAFETY PRECAUTIONS

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

service personnel, or to the equipment.

CAUTION

WARNING

NOTICE

damage, or property damage.

understood, even though not dangerous.

DANGER

WARNING

Improper installation, operation, adjustment, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating and maintenance instructions thoroughly before installing, operating or

servicing this equipment.

NOTICE

NOTICE

Copyright © 2021 by Southbend Steam. All rights reserved. Published in the United States of America.

S

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

WARNING

that follow this symbol to avoid possible injury or death.

WARNING

PURCHASER

Keep the appliance area free and clear from combustibles.

Adequate clearances be maintained for servicing and proper operation.

Contact the factory, the factory representative or a local service company to perform maintenance and repairs

should the appliance malfunction. Refer to warranty terms.

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 3 OF20

Table of Contents

Important Notes For Installation and Operation.................................................................... 2

Service Connections............................................................................................................. 4

Installation Instructions ......................................................................................................... 8

Operation .............................................................................................................................. 10

Preventive Maintenance ....................................................................................................... 12

Cooking Guidelines............................................................................................................... 13

.................................................................................................................... 16

C

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 4 OF 20

SERVICE C

SERVICE C

SPECIFICATIONS

GAS CHARACTERISTICS

DIMENSIONS

* For use on non-combustible floors only.

–

maximum 2 Amps.

–

100,000 29.3 Natural

Propane

125,000 36.6

550 lbs. [250 kg] Sides 0

720 lbs. [327 kg]

ACE F G

H

Ø2 Ø3

30 Gallons

72.38"

3.75"

41.13

46.75

40 Gallons

71.88"

4.75"

41.63

46.13

100,000 30 114

125,000 40 152

–

SERVICE CONNECTIONS

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 5 OF20

SPECIFICATIONS

GAS CHARACTERISTICS

DIMENSIONS

* For use on non-combustible floors only.

–

maximum 2 Amps.

–

100,000 29.3 Natural

Propane

125,000 36.6

590 lbs. [268 kg] Sides 0

760 lbs. [345 kg]

ACE F G

H

J

Ø2 Ø3

30 Gallons

72.38"

3.75"

42.63

46.5

15.9

40 Gallons

71.88"

4.75"

42.63

46.5

22.8

100,000 30 114

125,000 40 152

–

SERVICE CONNECTIONS

O

SERVICE C

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 6 OF 20

GAS CHARACTERISTICS

DIMENSIONS

* For use on non-combustible floors only.

–

maximum 2 Amps.

–

–

SERVICE CONNECTIONS

B

DIMENSIONS

SUPPLY PIPE PRESSURE (W.C.)

GS-40N

MODEL

kW/HR.BTU/HR.

GAS SUPPLY

SERVICE CONNECTIONS

MIN. CLEARANCE*

SHIPPING WT. FABCDE

inches

UNITSMODEL CAPACITY

GS-40N

GH

SKI LL E T O PE RA T I ON

ST A R T UP PRO CEDURE

DAILY SHUT DOW N PROCEDURE

TO TILT SKILLET

TEMP

H

G

100,000 29.3

Natural

Propane

565 lbs.

[257 kg]

Sides 0

40 152

ACE F G

H

Ø2 Ø3

40 Gallons

75.50"

3.75"

42.5

48.13

B

DIMENSIONS

SUPPLY PIPE PRESSURE (W.C.)

GS-40N

MODEL

kW/HR.BTU/HR.

GAS SUPPLY

SERVICE CONNECTIONS

MIN. CLEARANCE*

SHIPPING WT. FABCDE

inches

UNITSMODEL CAPACITY

GS-40N

GH

SKI LL ET O PE RA TI O N

ST A R T UP P R O CEDURE

DAILY S HUT DO W N PROCEDURE

TO TILT SKILLET

TEMP

H

G

SERVICE C

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 7 OF20

GAS CHARACTERISTICS

DIMENSIONS

SERVICE CONNECTIONS

–

125,000 36.6 Natural

Propane

755 lbs. [342 kg]

Sides 0

ACE F G

H

Ø2 Ø3

60 Gallons

77.03"

4.75"

41.63

46.13

* For use on non-combustible floors only.

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 8 OF 20

UNPACKING

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

Immediately after unpacking the steamer, check for possible shipping damage. If the steamer is found to be damaged,

save the packaging material and contact the carrier within 15 days of delivery.

and equipment requirements do not agree, contact your dealer.

II

clearance for air openings into the combustion chamber must be provided. Make sure there is an adequate supply of air in

the room suitable for the amount of combustion gas feeding the braising pan burners.

braising pan. Avoid wall-type fans which create air cross currents within the room.

I C S

Electrical grounding must be provided in accordance with local codes, or in the absence of local codes, with the National

F C

WARNING

I

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 9 OF20

I

A

1. Set the appliance in place and level left to right and front-to-back using spirit level.

4. Set unit back in position and re-level left to right and front to back.

WARNING

G C

All gas supply connections and any pipe joint compound used must be resistant to the action of propane gases.

Make sure the pipes are clean and free of obstructions, dirt and piping compound.

WARNING

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 10 OF 20

Using a non-corrosive, grease-dissolving commercial cleaner, clean the protective metal oils from all surface parts and the

dry with a soft clean cloth.

C

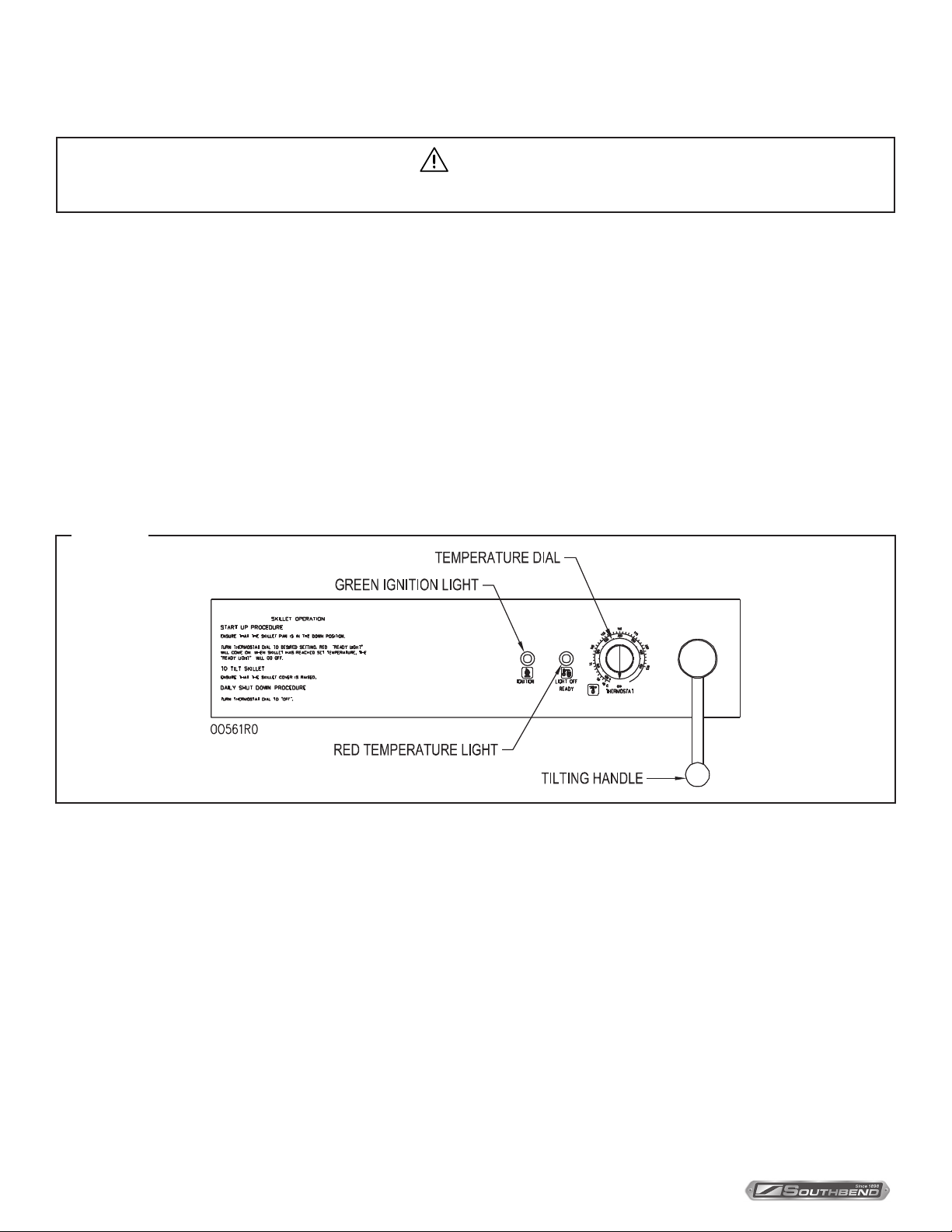

Green Ignition Light .............

Red Temperature Light ........

Thermostat............................

on the control panel in C and F.

Manual Lift Crank Handle .... Used to manually raise and lower braising pan.

Figure 1

S- P

electronic ignition which will light the burners.

restart.

minutes, then repeat Steps 1 through 4 to restart.

O

CAUTION

O

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 11 OF20

O

S P

P

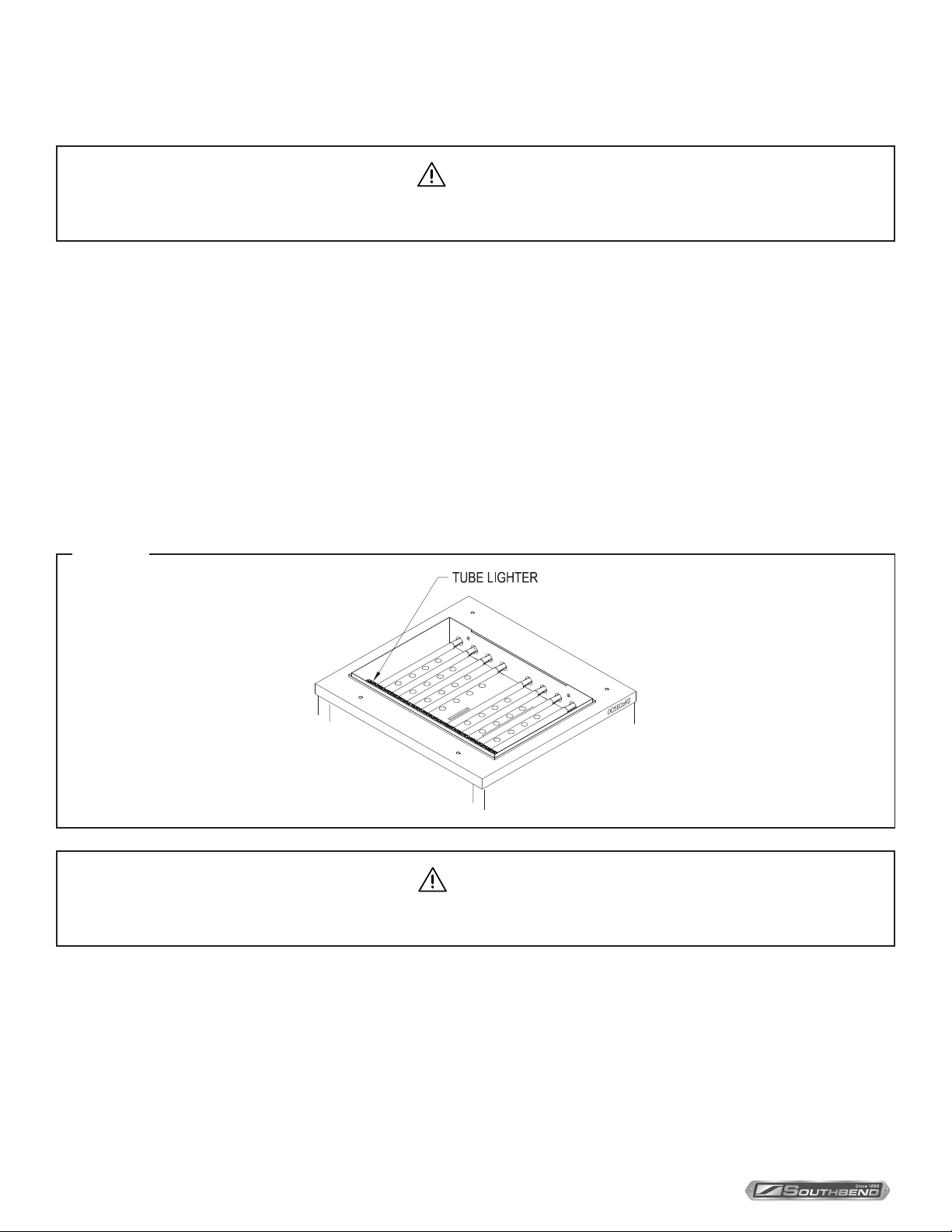

2. Make sure the receiving pan is in place.

pan has been tilted.

Figure 2

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 12 OF 20

P M

WARNING

CAUTION

C

After each use, allow the tilting braising pan to cool and clean it. Keep exposed cleanable areas of the tilting braising

If necessary, soak pan to remove food that is stuck to pan surface. Rinse thoroughly and wipe dry with a soft

clean cloth.

thoroughly and wipe dry with a soft clean cloth.

Figure 3

A

All tilting braising pans are adjusted at the factory.

performance.

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 13 OF20

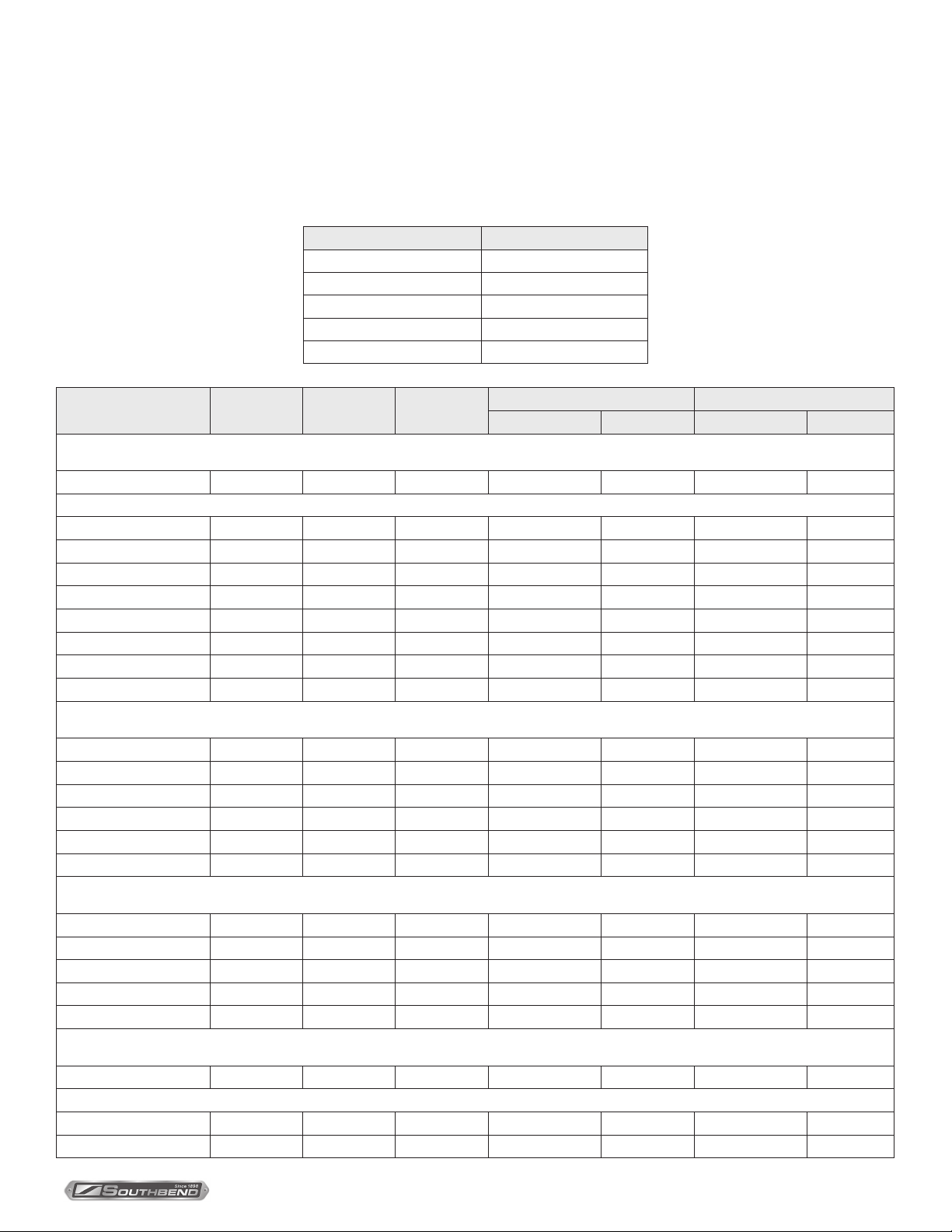

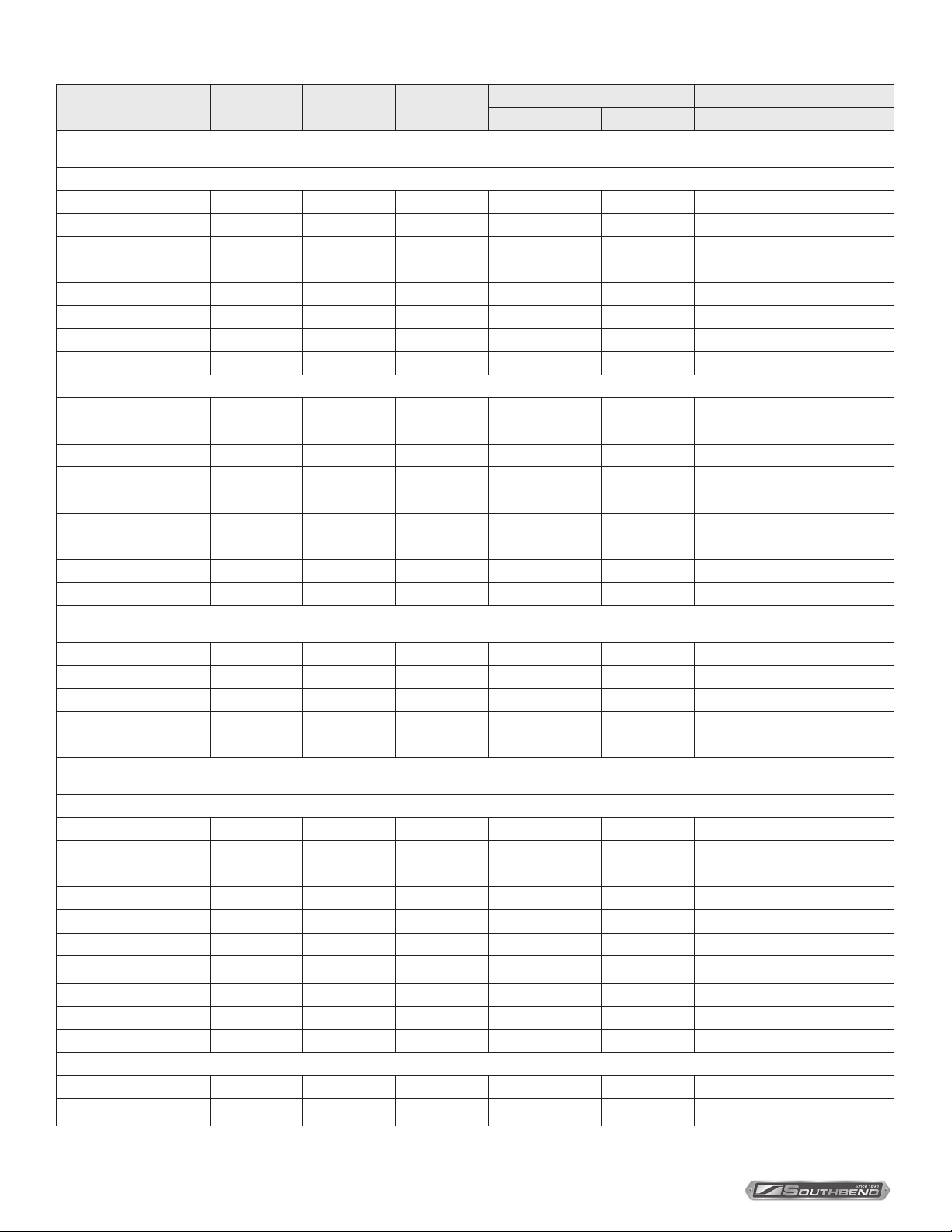

COOKING G

COOKING G

estimated numbers of orders per load

C M

Simmering 200 Maximum

Sautéing 225 - 275

Searing 300 - 350

Frying 325 - 375

Grilling 350 - 450

ITEM

PORTION

SIZE TEMP.(EF)

BATCHES

PER HOUR

BGLM-30 PER LOAD BGLM-40 PER LOAD

QTY. PORTIONS QTY. PORTIONS

BREAKFAST FOODS

3 slices 350 12 2 lb 10 3 lb 15

Eggs

1 egg 225

5

50 eggs 50 75 eggs 75

1 egg 225

8

50 eggs 50 75 eggs 75

- Fried 1 egg 400

4

30 eggs 30 45 eggs 45

- Poached 1 egg 225

5

36 eggs 36 60 eggs 60

- Scrambled 300-200

1

18 gal. 720 28 gal. 1100

3 slices 450

7

35 slices 12 50 slices 17

Regular Oatmeal 250

2

500 1000

Pancakes 2 each 400 10 30 each 15 50 each 25

FISH

Clams 1 pint 400 10 10 quarts 20 15 quarts 30

Fish Cakes 400

5

35 55

Haddock Fillet 400

4

60 90

Halibut Steak 450

3

60 90

1 - 1 lb 350

4

20 - 1 lb 20 30 - 1 lb 30

450

3

50 75

SAUCES, GRAVIES, SOUPS

350 - 200

2

18 gal. 2300 35 gal. 4500

Cream Sauce 250 - 175

1

18 gal. 1150 35 gal. 2250

Cream Soup 200

1

18 gal. 375 35 gal. 725

French Onion Soup 225

1

18 gal. 350 35 gal. 700

Meat Sauce 350 - 200

1

18 gal. 575 35 gal. 1100

VEGETABLES

CANNED 400

6

30 lb 125 45 lb 200

FRESH

400

3

25 lb 125 50 lb 250

400

1

30 lb 125 60 lb 300

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 14 OF 20

COOKING G

ITEM

PORTION

SIZE TEMP.(EF)

BATCHES

PER HOUR

BGLM-30 PER LOAD BGLM-40 PER LOAD

QTY. PORTIONS QTY. PORTIONS

VEGETABLES (continued)

FRESH (continued)

400

3

25 lb 125 40 lb 200

Cabbage 400

5

20 lb 80 30 lb 125

Carrots 400

2

35 lb 150 70 lb 300

250

5

15 lb 75 25 lb 125

Corn 1 ear 400

8

50 ears 50 75 ears 75

Potatoes 400

2

40 lb 200 60 lb 300

Spinach 250 10 40 lb 200 9 lb 35

400

2

20 lb 100 30 lb 150

FROZEN

400

6

15 lb 60 90

250

4

15 lb 60 90

400

8

12 lb 50 18 lb 75

Sliced Carrots 250

6

15 lb 60 90

250

3

15 lb 50 90

Corn 250 18 15 lb 50 90

250

7

15 lb 50 90

Peas 400 10 15 lb 75 110

Spinach 400

3

15 lb 75 110

DESSERTS, PUDDINGS, SWEET SAUCES

200

1

18 gal. 2300 35 gal. 4500

Cherry Cobbler 200

1

18 gal. 750 35 gal. 1500

Chocolate Sauce 200

1

18 gal. 2300 35 gal. 4500

Cornstarch Pudding 200

1

18 gal. 575 35 gal. 1100

Fruit Gelatin 250

2

18 gal. 750 35 gal. 1500

MEAT-POULTRY

BEEF

American Chop Suey 400 - 225

2

18 gal. 350 35 gal. 700

300

-

18 gal. 280 35 gal. 560

400

5

16 lb 50 25 lb 75

Cheeseburger 300 12 7 lb 35 10 lb 50

Hamburger 300 15 7 lb 35 10 lb 50

Meatballs 400 - 225

3

65 18 lb 100

Pot Roast 350 - 200 120 lb 500 180 lb 750

Salisbury Steak 400

3

16 lb 50 24 lb 75

Sirloin Steak 400

5

15 lb 40 60

Swiss Steak 300 - 200

1

25 lb 110 40 lb 160

CHICKEN

Pan Fried 350

3

50 pieces 25 80 pieces 40

350 - 200 16 - 5 lb 200 24-5 lb 265

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 15 OF20

COOKING G

ITEM

PORTION

SIZE TEMP.(EF)

BATCHES

PER HOUR

BGLM-30 PER LOAD BGLM-40 PER LOAD

QTY. PORTIONS QTY. PORTIONS

MEAT-POULTRY (continued)

FRANKFURTERS

Grilled 300

8

22 lb 176 33 lb 264

250 12 16 lb 128 25 lb 200

PORK

3 slices 350 12 2 lb 10 3 lb 15

Ham Steak 400

8

10 lb 50 15 lb 75

Pork Chops 350

4

15 lb 50 25 lb 75

3 links 350

7

30 lb 120 45 lb 180

TURKEY

400 - 200

–

3 - 26-30 lb 200 4 - 26-30 lb 275

On Carcass 400 - 200

–

4 - 16-20 lb 175 6 - 16-20 lb 265

MISCELLANEOUS

Grilled Cheese Sandwich

1

sandwich 400

8

35 sandwiches 35 50 sandwiches 50

Macaroni & Cheese 200

2

18 gal. 300 35 gal. 525

Rice 350 - 225

1

20 lb raw 320 40 lb raw 650

Spaghetti 350 - 225

2

8 lb raw 200 12 lb raw 300

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 16 OF 20

NN C O

4. Pan not in lowest position.

5. Ignition control not functioning.

6. Unit electrical supply is not plugged in or turned on.

P C

4. Incorrect pressure at supply.

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 17 OF20

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 18 OF 20

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22) PAGE 19 OF20

INSTALLATION & OPERATION MANUAL 10152-SB REV 1 (05/22)

PAGE 20 OF 20

however, that replacement parts and occasional professional service may be necessary to extend the useful life of this

confusion, always refer to the model number, serial number, and type of your appliance.

SOUTHBEND STEAM

A Middleby Company

1100 Old Honeycutt Road Fuquay-Varina, North Carolina 27526 USA

www.southbendnc.com

This manual suits for next models

3

Table of contents

Other Southbend Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Winston foodservice

Winston foodservice CVap HOV5 owner's manual

Infrico

Infrico medcare BBMD Series User manual and warranty

Culinaire

Culinaire CH.BMH.U Specification, installation and operation manual

Skope

Skope FDM Series user manual

CombiSteel

CombiSteel 7178.0100 User and maintenance instructions

freor

freor JUPITER Operation manual