Southbend BGMTS-30 User manual

MANUAL 10094-SB REV 0 (04/21)

$21.00

GAS SKILLETS

MANUAL SECTION CO

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equipment:

Model #:

___________________________

Serial #:

___________________________

Date Purchased:

_____________________

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment.

Model BGMTS-60

Gas Skillets

BGMTS-30, BGMTS-40 & BGMTS-60

Installation & Operation Manual

SOUTHBEND STEAM

A Middleby Company

1100 Old Honeycutt Road Fuquay-Varina, North Carolina 27526 USA

www.southbendnc.com

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 2 OF 24

G S

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator,

service personnel, or to the equipment.

CAUTION

WARNING

NOTICE

This symbol warns of immediate hazards that will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury, product

damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous.

DANGER

WARNING

Improper installation, operation, adjustment, alteration, service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions thoroughly before installing, operating or servicing this equipment.

NOTICE

This manual should be retained for future reference.

NOTICE

This product is intended for commercial use only. NOT FOR HOUSEHOLD USE.

Copyright © 2021 by Southbend Steam. All rights reserved. Published in the United States of America.

SPECIFICATIONS

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

WARNING

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

WARNING

FOR YOUR SAFETY:

PURCHASER: Instructions to be followed in the event the operator of this appliance smells gas must be posted

in a prominent location. This information shall be obtained by consulting the local gas supplier.

The appliance area MUST be kept free and clear of combustibles.

DO NOT

Adequate clearances MUST be maintained for servicing and proper operation.

Contact the factory, the factory representative or a local service company to perform maintenance and repairs

should the appliance malfunction. Refer to warranty terms.

NOTICE

Do not attempt to operate this unit in the event of a power failure.

WARNING

contact the local gas company or gas supplier for service.

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 3 OF24

G S

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

Important Notes For Installation and Operation.................................................................... 2

Service Connections............................................................................................................. 4

Installation Instructions ......................................................................................................... 6

Operating Instructions........................................................................................................... 8

Cleaning................................................................................................................................ 10

Cooking Guidelines............................................................................................................... 11

Maintenance ......................................................................................................................... 12

Troubleshooting .................................................................................................................... 14

Material Safety Data Sheets ................................................................................................. 16

TC

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 4 OF 24

G S

SERVICE CONNECTIONS

DIMENSIONS

GAS CHARACTERISTICS

* For use on non-combustible floors only.

BTU/HR kW/HR Supply Pipe Pressure (W.C)

BGMTS-30 550 lbs.

[249 kg] 80,000 23.4 Natural

6” - 14”

(152 mm - 356 mm)

Propane

11” - 14”

(279 mm - 356 mm)

Sides 3”

(76 mm)

BGMTS-40 736 lbs.

[334 kg] 100,000 29.3 Back 6”

(152 mm)

33.25 (845)

40.50 (1029)

3.75 (95)

2.38 (60)

D

B

E

C

SERVICE CONNECTIONS

–

120 Volts, 60 Hz, single phase with grounding wire. 10 Amp minimum supply.

- COLD WATER: 3/8” O.D. tubing to faucet (OPTIONAL)

– HOT WATER: 3/8” O.D. tubing to optional faucet (OPTIONAL)

A B C D E F G H

BGMTS-30 30 Gallons

(114 liters)

36”

(914 mm)

30”

(762 mm)

72.38”

(1838 mm)

33.75”

(857 mm)

23.5”

(597 mm)

40”

(1016 mm)

3.75”

(95 mm)

Ø2 Ø3

42.63”

(1083 mm)

46.5”

(1181 mm)

BGMTS-40 40 Gallons

(152 liters)

48”

(1219 mm)

42”

(1067 mm)

71.75”

(1822 mm)

43.75”

(1111 mm)

23”

(584 mm)

40.38”

(1026 mm)

4.75”

(121 mm)

42.63”

(1083 mm)

46.5”

(1181 mm)

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 5 OF24

G S

DIMENSIONS

GAS CHARACTERISTICS

* For use on non-combustible floors only.

SERVICE CONNECTIONS

–

120 Volts, 60 Hz, single phase with grounding wire. 10 Amp minimum supply.

- COLD WATER: 3/8” O.D. tubing to faucet (OPTIONAL)

– HOT WATER: 3/8” O.D. tubing to optional faucet (OPTIONAL)

A B C D E F G

BGMTS-60 60 Gallons

(227 liters)

48”

(1219 mm)

42”

(1067 mm)

77.50”

(1969 mm)

42.88”

(1089 mm)

23”

(584 mm)

4.75”

(121 mm)

Ø2 Ø3

42.63”

(1083 mm)

46.5”

(1181 mm)

BTU/HR kW/HR Supply Pipe Pressure (W.C)

BGMTS-60 925 lbs.

[420 kg] 100,000 29.3

Natural

6” - 14”

(152 mm - 356 mm)

Propane

11” - 14”

(279 mm - 356 mm)

Side

Back

3”[ 76 mm ]

6”[152 mm]

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 6 OF 24

G S

UNPACKING

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the type of gas supply (natural or propane) and electrical service agree with the

equipment requirements do not agree, contact your dealer immediately.

I C S

Installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1INFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1, as applicable.

pressure testing of that system at pressures in excess of 1/2 psi (3.5 kPa).

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa).

Electrical grounding must be provided in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable.

Ventilation must be provided in accordance with local codes, or in the absence of local codes, with ANSI/NFPA 96 Standard

for Ventilation and Fire Protection of Commercial Cooking Operations.

L

The installation location must allow adequate clearances for servicing and proper operation.

An exhaust system and ventilation hood should be located directly above the appliance to exhaust combustion gases

generated by the unit.

construction, 3” (76 mm) on sides and 6” (152 mm) from back.

1. Place tilting braising pan in the installation position.

2. Place a carpenter’s level on top of the braising pan and turn the adjustable feet to level braising pan side-to-side and

front-to-back.

diagram on page 4.) Insert proper anchoring devices (not supplied).

5. Place tilting braising pan back in the installation position.

6. Place carpenter’s level on top of braising pan and re-level side-to-side and front to back.

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 7 OF24

G S

G C

WARNING

Do not connect the appliance to the electrical supply until after the gas connection has been made.

All gas supply connections and any pipe joint compound used must be resistant to the action of propane gases.

Connect gas supply to the appliance. The gas supply line must be at least equivalent of 3/4” iron pipe with an incoming

pressure of 7” - 14” W.C. (Water Column) for natural gas or 11” - 14” W.C. (Water Column) for propane gas. Make sure the

pipes are clean and free of obstructions, dirt and piping compound.

manifold is set at 3.5” W.C. (Water Column) for natural gas, and 10” W.C. (Water Column) for propane gas.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

E C

WARNING

CAUTION

petroleum or propane gases.

WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazard

and should be plugged directly into a properly grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug. (120V units only).

The wiring compartment is located behind the control panel. For units operated on electrical supply other than 120 volts,

remove the wiring compartment cover and make electrical connections per the wiring diagram located inside the control

housing cover panel. The braising pan must be grounded in accordance with requirements of the National Electrical Code

or applicable local code.

Replace wiring compartment cover.

NOTICE

WARNING

Do not connect the appliance to the electrical supply until after the gas connection has been made.

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 8 OF 24

G S

O I

WARNING

In the event of main burner ignition failure, a 5 minute purge period must be observed prior to re-establishing ignition source.

WARNING

The tilting braising pan and its parts are hot. Use care when operating, cleaning and servicing the tilting braising pan.

B F U

Using a non-corrosive, grease-dissolving commercial cleaner, clean the protective metal oils from all surface parts and the

interior of the tilting braising pan. Follow the cleaner manufacturer’s directions. Rinse thoroughly and drain the pan. Wipe

dry with a soft clean cloth.

POWER SWITCH (ON/OFF) .... Turn ON to supply power to the braising pan burner ignition system.

TILT SWITCH (UP/DOWN) ....... Push up to raise tilting braising pan; push down to lower tilting braising pan.

MOTOR SWITCH ......................

Note: It is not necessary to have the power on when using the braising pan. Turn power

on only when you intend to operate the tilt feature. This will save energy as well as

prevent the motor from overheating.

GREEN IGNITION LIGHT......... Will light when ignition has occurred.

RED TEMPERATURE LIGHT .. Will light when heating elements are supplying heat to the tilting braising pan.

THERMOSTAT .......................... When turned on, will initiate electronic ignition system. Temperature settings range from 1 to 10.

(See COOKING GUIDELINES in this manual for temperature ranges for settings 1-10.)

P

2. Ensure that the skillet pan is in the down or horizontal position.

3. Turn the “POWER” switch “ON”.

4. Set the thermostat dial to the desired setting. The red “TEMPERATURE” pilot will be on until the desired setting has

been reached.

5. The green “IGNITION” pilot should remain on with the “TEMPERATURE” pilot, indicating normal ignition and

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 9 OF24

G S

D S P

1. To turn tilting braising pan of, turn THERMOSTAT dial to OFF.

2. To turn power to tilt motor OFF, turn power switch to OFF.

1. DO NOT try to tilt braising pan with lid down. Turn MOTOR switch on.

2. Make sure the receiving pan is in place.

3. To tilt braising pan, push and hold TILT SWITCH in the UP mode until desired pan position has been reached. The

braising pan will empty when raised to the top tilt position.

operate when the pan is not in the horizontal or down position.

4. Food is poured through the removable strainer (Figure 1) into a food receiving pan positioned under the lip of the

pouring spout (Figure 1).

5. To lower braising pan, push and hold TILT SWITCH in the DOWN mode.

FIGURE 1

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 10 OF 24

G SC

C

WARNING

Disconnect the power supply to the appliance before cleaning or servicing.

After each use, allow the tilting braising pan to cool before cleaning. Keep exposed cleanable areas of the tilting braising

pan clean at all times. Do not get water in electrical box or on any electrical component.

1. Thoroughly wash pan, pouring spout, lid and exterior surfaces with mild detergent and warm water. If necessary, soak

pan to remove food that is stuck to pan surface. Rinse thoroughly and wipe dry with a soft clean cloth.

2. Clean removable strainer and receiving pan support with mild detergent and warm water. Rinse thoroughly and wipe dry

with a soft clean cloth.

4. Visually assure carry-over ports are unobstructed.

WARNING

The appliance and its parts are hot. Use care when operating, cleaning and servicing the skillet.

CAUTION

Do not use cleaning agents that are corrosive.

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 11 OF24

G S

C

Cooking Method Temperature (°F) Thermostat Setting

Simmering 200 Maximum 1 - 4

Sautéing 225 - 275 5 - 6

Searing 300 - 350 7 - 8

Frying 325 - 375 8 - 9

Grilling 350 - 450 9 - 10

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 12 OF 24

G SM

M

NOTICE

Contact the factory, factory representative or local service company to perform maintenance and repairs.

WARNING

Disconnect the power supply to the appliance before cleaning or servicing.

WARNING

The tilting braising pan and its parts are hot. Use care when operating, cleaning and servicing the tilting braising pan.

Set up regular schedule for checking the oil temperature, hydraulic hoses and keeping the equipment clean. A thick layer

of dirt acts as an insulation and prevents the hydraulic system from getting rid of heat.

The hydraulic system has been adjusted and tested at the factory and no further adjustment should be needed. If the unit

1. Hot oil in the Hydraulic System is one of the primary causes of poor operation. When the tilt system is not in use turn

2. Inspect hydraulic hoses for wear and aging.

6. Check the cleanliness of the oil strainer inside the reservoir once per year. This item can be washed in clean Varsol.

8. Change the oil once every two years.

aluminum manifold block. The other two control the linear speed of the actuator.

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 13 OF24

G S M

The relief valve is located underneath an aluminum hexagon cover on the side of the custom manifold block. This relief

valve is factory set to 825 P.S.I. and locked and should not be adjusted.

If adjustments are necessary, remove the hexagon cover which will give access to the relief valve screw. With the

anti clockwise to decrease pressure. While this operation is being carried out some oil will leak down the threads of the

adjusting screw.

To obtain the pressure required, a pressure gauge will have to be located in the circuit. The best location is on the

cylinder hose. To set the pressure, energize the solenoid to extend the cylinder fully and thus “deadhead” the system. The

pressure can be set as indicated above. When adjustment is complete, replace the hexagon cover. This will seal the relief

on the electric motor.

!IMPORTANT !

delivered to the cylinder will go over the relief @ 825 P.S.I. which will cause unwanted heat in the reservoir.

control valves will restrict the capacity of oil passing through them when the knurled knob is screwed in - in a clockwise

of the extension speed (travel speed should be set at minimum 20 seconds), the other (left side) the retraction speed.

(Retraction speed should be set at minimum 10 seconds).

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 14 OF 24

G S

B NN C O

1. Gas supply to unit is “OFF”.

3. Thermostat is not turned “ON”.

4. Pan not in lowest position.

5. Ignition control not functioning.

B P C D

2. Burner air not adjusted properly.

3. Wrong gas supply.

4. Incorrect pressure at supply.

1. Motor power supply not “ON”.

2. Defective UP/DOWN switch.

3. SEE TROUBLESHOOTING - HYDRAULICS.

1. Components not properly cleaned after servicing.

4. Filter dirty or ruptured.

2. Fluid contamination.

3. Suction leak to pump.

1. Fill pipes left open.

2. Moisture in cans used to replace oil in tank.

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 15 OF24

G S

1. Continuous operation at relief setting.

2. Excessive slippage or internal leakage.

3. Fluid viscosity too high or low.

4. Hose I.D. too small causing high velocity.

5. Improper air circulation around reservoir.

6. System relief valve set too high.

7. Power unit operating in direct sunlight or ambient temperature is too high.

1. Check for vacuum leaks in suction line.

2. Vacuum leak at pump shaft seal.

3. Check alignment with drive mechanism. Misalignment will cause wear and subsequent high noise level operation.

4. Relief valve set too high.

6. Worn cam ring, damaged gear, faulty bearing.

7. Reversed rotation.

8. Plugged lines.

9. Oil viscosity too high or temperature too low.

10. Loose or worn pump parts.

11. Pump housing bolts loose or not properly torqued.

1. Voltage too low.

2. Short circuit, open connection.

3. Wrong voltage.

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 16 OF 24

G S

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 17 OF24

G S

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 18 OF 24

G S

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21) PAGE 19 OF24

G S

INSTALLATION & OPERATION MANUAL 10094-SB REV 0 (08/21)

PAGE 20 OF 24

G S

This manual suits for next models

2

Table of contents

Other Southbend Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

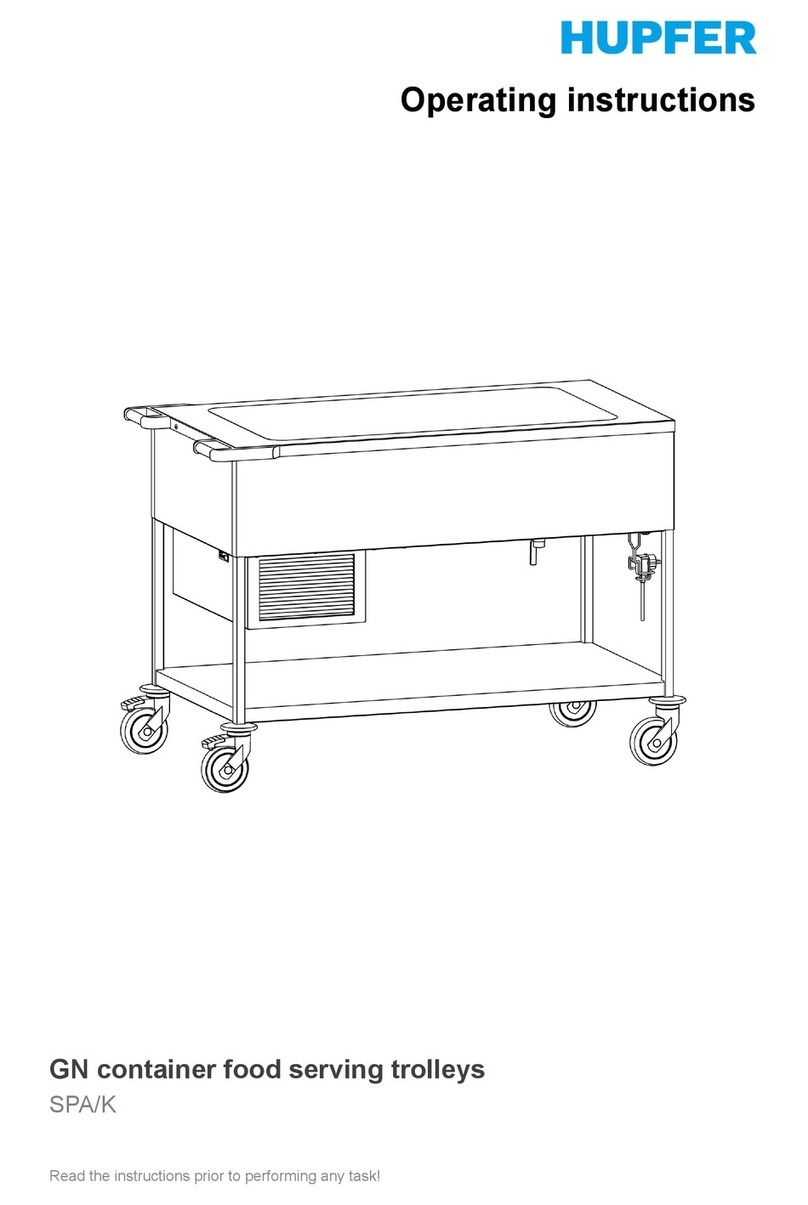

Hupfer

Hupfer SPA/K operating instructions

Diamond

Diamond Profi Line MR2/R2 Installation, use and maintenance guide

saro

saro ES 901 S/S Top operating instructions

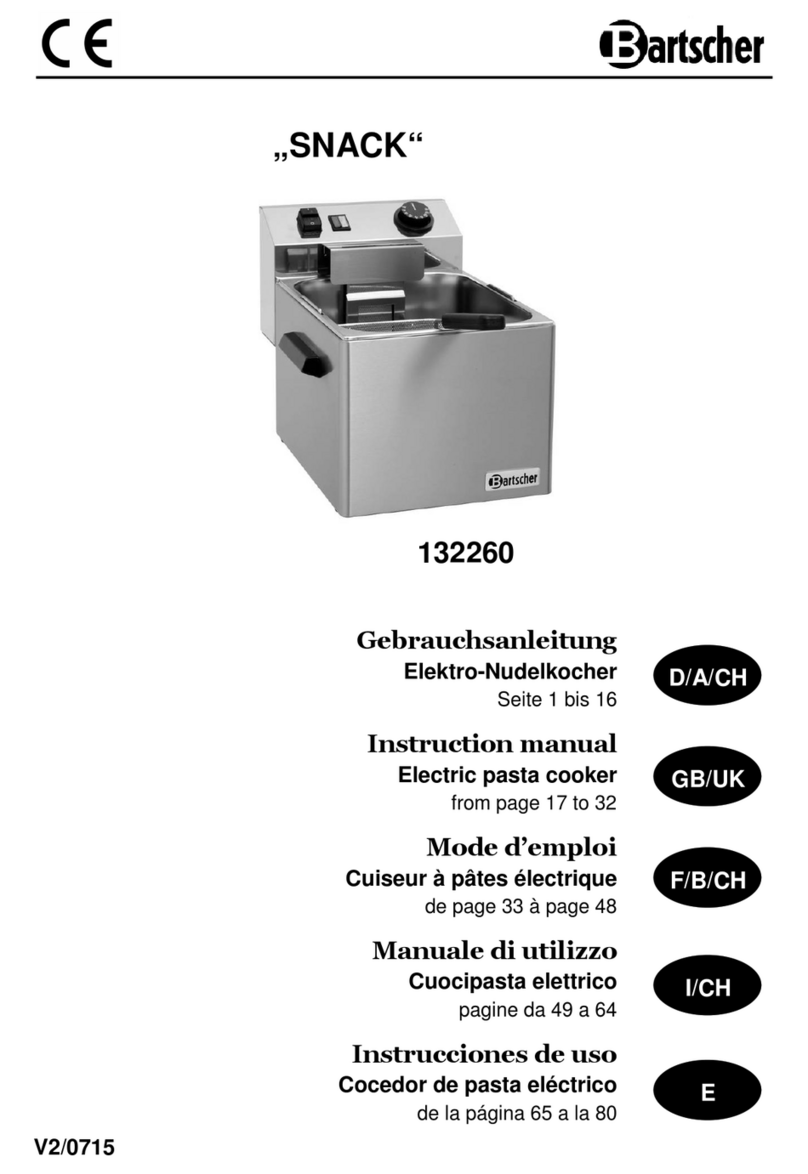

Bartscher

Bartscher SNACK instruction manual

Bartscher

Bartscher 600 Series Installation, use and maintenance

Frosty Factory

Frosty Factory 237A Service manual