SOUTHERN MACHINERY SM-306 User manual

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

Shenzhen Southern Machinery Sales and Service Co.,Ltd

SM-306 Automatic bulk components cutting machine

Operation and Maintenance Manual

Design, manufacture and sales:

Electronic components molding machine, electronic components casing machine, electronic

components taping machine.

PCB splitter, screw locking machine, dispensing machine, soldering machine.

Assembly automation equipment.

Non standard design and manufacturing automation equipment.

Address: Rm 1806, Block 3, Jinyun COFCO, Qianjin 2 Road, Xixiang, Baoan District,

Shenzhen City.

Web:Http://www.smthelp.com E-mail:E-mai:[email protected]

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

Catalog

1. Preface......................................................................................1

2. Outline.................................................................................... 1

3. Features of the machine ......................................................2

4. Structure description.............................................................3

5. Vibrating Feeder.....................................................................4

6. Host.........................................................................................5

7. Cutter adjustment instructions....................................................6

8. Operation process................................................................. 7

9. Parameters of the machine................................................... 9

10. Maintenance......................................................................... 9

11. Matters needing attention....................................................10

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

1

1.Preface

SM is a powerful electronic equipment company in China, Professional design and manufacture of

automation equipment,

The automation equipment developed and produced by our company integrates advanced

technology at home and abroad and adopts high-quality imported spare parts, so that the products

are at the leading level in the same industry.

2.Outline

Before using the equipment, please read this instruction manual first to avoid some improper

operation and accidents, so as to shorten the service life of the equipment

2.1 Please read the manual carefully before using the equipment, and then operate and maintain it

on duty;

2.2 Please place this manual at random for long-term use;

2.3 The warranty period of this machine is one year (except for wearing parts). If it can't work

normally due to quality reasons within one year, please contact our sales department or after-sales

department in time to avoid delaying the production of your company;

2.4 The following conditions are not covered by the warranty

(1)Damage caused by improper use by users.

(2)Damage of parts and components caused by self dismantling machine.

(3)The voltage of the power supply does not meet the requirements.

(4)Damage caused by force majeure.

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

2

3.Features of the machine

3.1 This machine is suitable for mass production and is the best auxiliary equipment for short leg

operation.

3.2 The equipment is composed of three parts: the lead shearing machine, the vibrating feeding

plate and the supporting trolley; the shearing machine unit and the vibrating feeding plate can be

used separately or in combination, so as to increase the use scope of the equipment.

3.3 The vibration feeding tray can realize automatic feeding operation for electrolytic capacitor

(3-10 mm, height no more than 16 mm, flat bottom), LED (diameter 3-8 mm), triode, transistor and

some safety regulations, ceramic capacitors and other parts; other special-shaped components can

also be customized to achieve automatic lead cutting function.

3.4 With special cutting method, the cutter is made of Japanese imported material (SKD11 after

special treatment), with long wear resistance and long service life.

3.5 The machine is fully automatic control; automatic state steps: feeding, cutting lead, blanking

and feeding Step cycle.

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

3

4.Structure description

Figure 1

Support Trolley

Host

Vibrating Feeder

Material Box

Vibrating Feeder

Speed Control box

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

4

5.Vibrating Feeder

Figure 2

Note: there should be no lubricating oil or antirust agent on the surface of the

vibrating plate, otherwise the material will slip.

Gap should be adjusted according to

different materials and sizes

Block is not arranged and easy to

use. Adjust the high and lower

according to the material size.

Material flow

regulation

Intercross cross stainless

steel. Adjust according to

the material size.

There is a ring of magnetic strips around the

vibration. Adjust higher and lower according

to the material size.

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

5

6.Host

Figure 3

Power switch for horizontal

transmission track

Horizontal transmission track vibration

frequency adjustment knob 1-100.

Cutter motor switch

Main power switch

Cutter height

adjustment

Paraseismic orbit

Built in flat vibration coil

Lower hopper

Pressing device

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

6

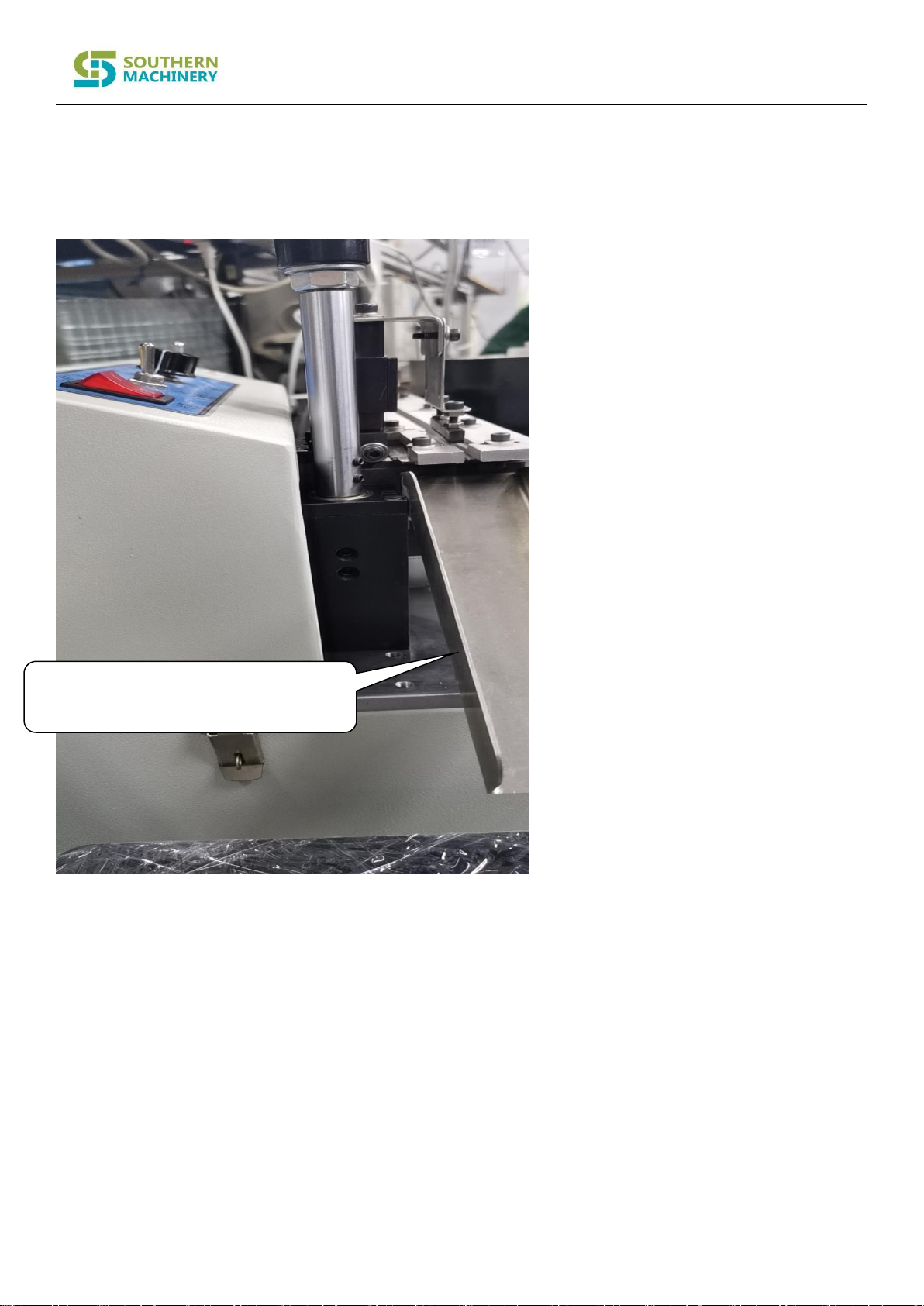

7.Cutter adjustment instructions

Figure 4

Dovetail seat for cutter height adjustment

(2-m8 hexagon socket head screw)

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

7

8.Operation process

Use and adjustment of main engine

1. Main power switch: when the power is on, when the switch is turned on, the red

device is powered on, and when it is off, the device is powered off.

2. Cutter motor switch: when the switch is set to on, the motor will work, and when it

is turned to off, the motor will stop working.

3. Leveling knob: (the premise is to turn on the power switch of the vibration coil of

the horizontal motion track) the adjustment switch of the vibration frequency of the

flat motion track is usually adjusted to 15 - 20.

4. Flat vibration and vibration panel power switch: when the switch is turned to on,

the vibration panel will work, and when it is turned to off, the vibration panel will stop

working.

5. Vibration knob: (the premise is to turn on the power switch of the vibration coil and

vibration plate of the horizontal transmission track) the frequency adjustment switch

of the vibration disk is usually adjusted to 15 - 20.

6. Flat track: according to different materials to adjust the width of the track,

generally can pass through a material for the best state.

7. Material pressing device group: it is necessary to adjust the height of the pressure

bar of the material pressing device according to the height of the material, so as to

prevent the material from shaking, thus affecting the accuracy of the cutting lead

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

8

material.

8. Adjustment of cutting lead length: according to the length of the material to be

processed, first loosen several jackscrews of 4-M8, then rotate the cutter height knob

left and right, adjust to the required size, and then tighten several jackscrews of - M8

(to prevent running).

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

9

9.Parameter of the machine

10.Maintenance

Clean up the accumulated dust and sundries inside the equipment regularly, and

check whether the connector wiring inside and outside the control box is loose or

not in good contact, so as to ensure the normal use of section delivery and

prolong its service life;

Clean the dirt on the mould and worktable regularly;

Regularly check all fixing screws for looseness;

Add lubricating oil to the sliding strip of cutter regularly.

Project

Parameter

Power Supply

AC220V±10% 50Hz

Power of Host and feeder

210W

Supply Current

0.95A

Work Cycle

0.5S~2S

Cutter Die

SKD11

Working Temperature

-5~+50OC

Altitude

≤1000 米

Relative Humidity

≤95%(25OC)

Volume

1100*650*1000 mm

Weight

150 kg

Shenzhen Southern Machinery Sales and Service Co.,Ltd

Add : Room 10B-1, Chuangjian Building, Qianjing 2 Road ,Baoan District, Shenzhen City, China

TEL: 0755-83203237; FAX:0755-23240492 website:www.smthelp.com

10

11.Matters needing attention

When replacing the mold, the power supply and air source are turned off;

Do not disassemble or disassemble the moving slider at will;

Do not knock the flat vibration and mold parts.

Troubleshooting and troubleshooting

The whole machine has no power supply after startup:

Check whether the external power supply is normal for section delivery;

Check whether the fuse is blown and determine whether it is replaced.

Poor operation:

Check whether the fixing screws of each slide guide are loose, which causes the

guide rails not parallel;

Loosen the fixing screw to detect the single slider, and observe whether there are

impurities entering the slider and jamming the slider.

Table of contents