3

Table of Contents - Series II Rotary Cutter

Table of Contents

Introduction .................................................................................................................................5

Safety............................................................................................................................................6

• Safety Instruction.............................................................................................................6

• General Safety..................................................................................................................7

• Start-up Safety .................................................................................................................7

• Operation Safety ..............................................................................................................7

• Transport Safety...............................................................................................................7

• Service and Maintenance Safety ....................................................................................8

• Storage Safety..................................................................................................................8

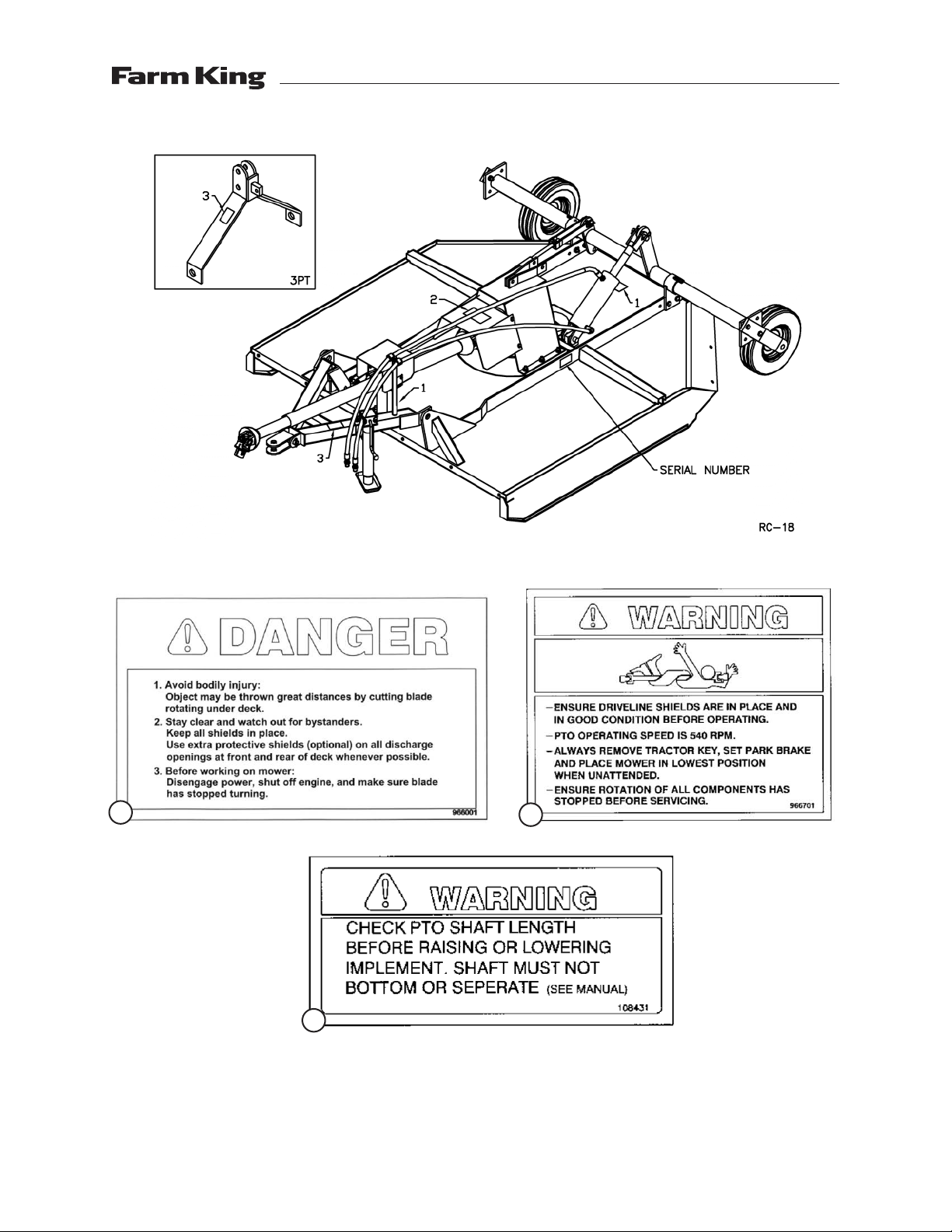

• Safety Signs .....................................................................................................................8

• Safety Sign Installation ...................................................................................................8

Assembly....................................................................................................................................10

• 3-Point Hitch Mounted Assembly Instructions ............................................................10

• Trailing Model Assembly Instructions..........................................................................10

• Chain Kit Assembly Instructions................................................................................... 11

Operation ...................................................................................................................................12

• Theory of Operations.....................................................................................................14

Maintenance ..............................................................................................................................15

• Service ............................................................................................................................15

Bolt Torque .................................................................................................................................16

• Checking BoltTorque .....................................................................................................16

Part Drawings.............................................................................................................................18

• 3-Point Hitch Mounted Drawing ...................................................................................18

• Trailing Drawing.............................................................................................................19

• Parts List .........................................................................................................................20

• Chain Kit Drawing (Optional)........................................................................................24

• Chain Kit Parts List (Optional).......................................................................................25

• 510 PTO Shaft Drawing..................................................................................................26

• 510 (Shear Pin)Trailing Parts List..................................................................................27

• 510 (Shear Pin) 3-Point Hitch Parts List ........................................................................28

• 620 & 720 PTO Shaft Drawing.......................................................................................30

• 620 (Slip Clutch) 3-Point Hitch Parts List ......................................................................31

• 620 (Slip Clutch)Trailing Parts List................................................................................32

• 36