Struers Discotom-100 User manual

Discotom-100/-10

Instruction Manual

Manual No.: 16157001

Date of Release 06.03.2015

Discotom-100 /-10

Instruction Manual

Table of Contents Page

User’s Guide ............................................................... 1

Reference Guide ....................................................... 56

Quick Reference Guide ............................................ 88

Always state

Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the

Date

and

Article No of the manual. This information is found on the front cover.

The following restrictions should be obser

ved, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals:

Struers Instruction Manuals may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals:

Struers Se

rvice Manuals may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to change without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

Original instructions.

The contents of this manual are the property of Struers. Reproduction of any part of

this manual without the written permission of Struers is not allowed.

All rights reserved. © Struers

2015.

Struers A/S

Pederstrupvej 84

DK

-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the Instruction Manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own

expense.

Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to

this product not expressly approved by Struers A/S could cause harmful

radio interference and void the user’s authority to operate the equipment.

Discotom-100 /-10

Instruction Manual

Discotom-100 /-10

Safety Precaution Sheet

To be read carefully, before use

1. The operator(s) should be fully instructed in the use of the machine and

its cut-off wheels according to the Instruction Manual and the

instructions for the use of cut-off wheels.

2. The machine must be installed in compliance with local safety

regulations.

3. The machine must be placed on a safe and stable support table. All

safety functions and guards of the machine must be in working order.

4. Use only intact cut-off wheels. The cut-off wheels must be approved for

use with rotational speeds between 1500 and 3000 rpm.

5. The machine is not for use with saw-blade type cut-off wheels.

6. Observe the current safety regulations for handling, mixing, filling,

emptying and disposal of the additive for cooling fluid.

7. The workpiece must be securely fixed in the quick-clamping device or

similar. Large or sharp workpieces must be handled in a safe way.

8. Do not work on or around cutting table when the table is repositioned

using the Y-table positioning joystick.

9. To achieve maximum safety and lifetime of the machine, use only

original Struers consumables.

10. The cutting arm should be lowered slowly and carefully, in order to

avoid breaking the cut-off wheel.

11. Never look directly into the laser beam. (Line laser option)

12. Struers recommends the use of an exhaust system as the materials

being cut may emit harmful gasses or dust.

13. The machine emits only moderate noise. However, the cutting process

itself may emit noise, depending on the nature of the workpiece. In

such cases, the use of hearing protection is recommended.

14. The machine must be disconnected from the mains prior to any service.

15. Use of working gloves is recommended as workpieces may be both

very hot and produce sharp edges. Wearing of gloves is also

recommended when flushing and cleaning the machine.

16. Struers recommends the use of safety shoes when working with heavy

samples.

Discotom-100 /-10

Instruction Manual

17. Use of safety goggles is recommended when using the flushing hose.

18. If any of the cutting-chamber cover springs are damaged (at the rear of

machine), they must be replaced before the machine is used again.

19. When a recirculation cooling unit is used, observe the current safety

regulations for handling, mixing, filling, emptying and disposal of the

additive for cooling fluid.

Do not use flammable cooling fluid.

20. When lifting the machine using a forklift, lift from front or rear - never lift

the machine from the side.

21. When lifting the machine using lifting straps, ensure that the straps are

crossed and do not press on the sides of the machine.

1. Prior to any service, disconnect the machine then wait until residual

potential on the capacitors is discharged.

2. Do not cycle mains power more than once every three minutes.

Damage to the frequency converter will result.

Discotom-100

The equipment should only be used for its intended purpose and as detailed in the Instruction Manual.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.)

Discotom-100 /-10

Instruction Manual

Disposal

Equipment marked with a WEEE symbol contain electrical and

electronic components and must not be disposed of as general

waste.

Please contact your local authorities for information on the correct

method of disposal in accordance with national legislation.

Discotom-100 /-10

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of the Packing Box ........................................ 3

Placing Discotom ............................................................................... 4

Lifting Instructions .............................................................................. 6

Getting Acquainted with Discotom ..................................................... 8

Two-handed Operation ........................................................... 10

Noise Level ...................................................................................... 10

Power Supply ................................................................................... 11

Connection to an External Exhaust System ..................................... 13

Connecting a Recirculation Cooling Unit .......................................... 14

2. Basic Operation

Using the Controls ............................................................................ 15

Front Panel Controls of Discotom ........................................... 15

Front Panel Controls ........................................................................ 16

Flush Hose ....................................................................................... 17

Moveable Table ................................................................................ 17

Y-Table ................................................................................... 17

Reading the Cutting Display ............................................................. 18

Reading the Display ................................................................ 19

Manoeuvring in the Menu Structure ........................................ 21

Acoustic Signals ...................................................................... 21

Software Settings ............................................................................. 22

Changing the Language .......................................................... 25

Editing Numeric Values ........................................................... 27

Editing Alphanumeric Values .................................................. 28

Operation Mode ............................................................................... 30

Changing Operation Mode ...................................................... 30

New Pass Code ............................................................................... 31

Changing Cutting Mode and Cutting Parameters............................. 32

Changing Cutting Mode .......................................................... 32

Changing Cutting Parameters ................................................. 33

Selecting a Cut-off Wheel ....................................................... 33

Changing the Wheel Speed .................................................... 38

Selecting the Cutting Mode ..................................................... 39

Stop Modes ...................................................................................... 44

Auto ......................................................................................... 44

Relative Stop Position ............................................................. 46

Absolute Stop Position ............................................................ 47

Using Motor Load and Temperature Display .......................... 48

OptiFeed ................................................................................. 48

Discotom-100 /-10

Instruction Manual

2

Fitting or Changing the Cut-off Wheel .............................................. 49

Clamping the Workpiece .................................................................. 49

Positioning the Cutting Table ........................................................... 49

Starting/Stopping the Cutting Process ............................................. 50

Automatic Cutting .................................................................... 50

Manual Cutting ........................................................................ 51

Combining Manual and Automatic Operation ........................ 51

3. Routine Maintenance

AxioWash ......................................................................................... 52

Daily Service .................................................................................... 53

Cleaning of Flush Hose Nozzle ........................................................ 53

Weekly Maintenance ........................................................................ 54

Monthly Maintenance ....................................................................... 54

Replacing the Cooling Water .................................................. 54

Lubricating the Cutting Table .................................................. 54

Yearly Service .................................................................................. 55

Inspection of Cover ................................................................. 55

Discotom-100 /-10

Instruction Manual

3

1. Getting Started

In the packing box you should find the following parts:

1 Fork spanner (24 mm) for cut-off wheel

1 Triangle key for safety lock release

1 Connector pipe for water outlet

1 Elbow pipe for water outlet

1 Outlet hose 2 m,

for connection to external cooling unit

1 Hose clamp, 70-90 mm

1 Instruction Manual set

Remove the bolts from all of the transport brackets that secure

the Discotom to its transport pallet.

Remove the brackets.

Checking the Contents

of the Packing Box

Unpacking Discotom

Discotom-100 /-10

Instruction Manual

4

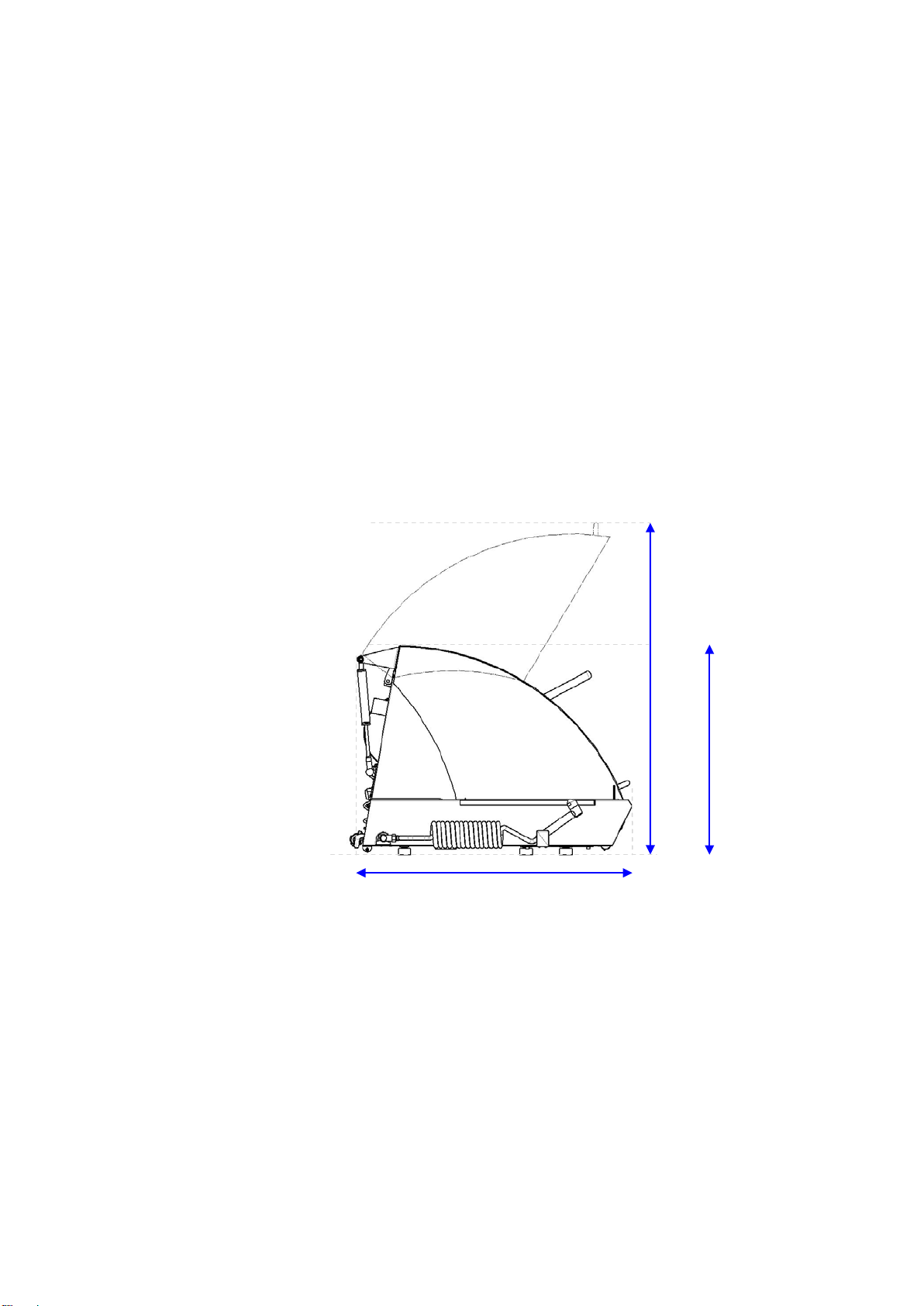

Discotom should be placed on a table strong enough to support a

minimum of 200 kg/ 440 lbs.

Struers recommends the use of the Table Unit, which is designed for

use with Discotom machines, see “Accessories”.

Discotom-100/-10 is recommended to be placed on a table unit (with

a compartment for recirculation cooling unit) with the dimensions:

Width: 920 mm / 36.2”

Depth: 900 mm / 35.4”

Height: 800 mm / 31.5”

(A table unit designed for Struers’ table top cut-off machines is

available as an accessory Cat. No. 06266101)

Make sure there is enough room behind the table for the inlet and

outlet hoses and for the cover to be opened fully (see illustration).

Placing Discotom

Space required

890 mm / 35”

685 mm / 27”

1080mm mm / 42.5”

Discotom-100 /-10

Instruction Manual

5

Discotom-100/-10 may be placed against a wall.

If an external exhaust system is connected to the unit via the fitting

on the rear, ca 17 cm / 7” of space is required for the hose.

Recommended space at the front: 100 cm / 40”.

The recirculation cooling unit can be placed in the table unit

compartment and does not require extra space.

Footprint:

97.7 cm / 38.55”

89 cm / 35”

Discotom-100 /-10

Instruction Manual

6

A crane and 2 lifting straps are required to lift Discotom-10/-100 off

the shipment pallet.

Before lifting Discotom into position:

Carefully open and remove the sides and the top of the packing

crate.

Remove the brackets securing Discotom to the pallet (a torque

bit T30 key is required to remove the coach bolts that secure the

transport brackets).

Place the two lifting straps under Discotom.

− Position the straps under Discotom, so that they are on the

outer side of the feet/ rollers.

− Use straps which are long enough so that they do not place

stress on the glass window (use straps of approx. 3-3½ m in

length).

A lifting bar is recommended so that the two straps are kept

apart below the lifting point.

Lifting Instructions

With a crane

Position straps here

Position straps here

With lifting bar

Without lifting bar

Discotom-100 /-10

Instruction Manual

7

Lift Discotom onto the table.

Lift the front of Discotom and carefully move into place using the

rollers.

A forklift truck can be used to lift Discotom off the shipment pallet.

Before lifting Discotom into position:

Carefully open and remove the sides and the top of the packing

crate.

Remove the brackets securing Discotom to the pallet (a torque

bit T30 key is required to remove the coach bolts that secure the

transport brackets).Lift Discotom from the pallet using a forklift

truck.

Position the forks so that the centre of mass is between the forks

– see illustrations.

Lift Discotom onto the table.

Lift the front of Discotom and carefully move into place using the

rollers.

With a Fork lift

Discotom-100 /-10

Instruction Manual

8

Take a moment to familiarise yourself with the location and names of

the Discotom’s components.

Control panel

Cutting arm

Turn /Push Knob

Joystick for table movement

Flushing gun

Two-hand operation button

Access hole for safety lock release

Getting Acquainted

with Discotom

Front View

Note!

The cover on Discotom can only be opened when the machine is connected

to a power supply and the main power switch is on.

To open the cover when the power is not connected, insert the triangle key

through the access hole at the front to release the safety lock.

Remember to re-activate the safety lock release

before operating Discotom.

Discotom-100 /-10

Instruction Manual

9

Emergency stop

Main power switch

The main switch is located on the right hand side of Discotom.

Turn clockwise to switch on the power.

Cooli unit connection

Service socket (RS232)

Power supply cable connection

Water inlet

Water outlet flange

Flushing hose

Exhaust connection

Side view, right

Rear View

Discotom-100 /-10

Instruction Manual

10

When moving the cut-off wheel whilst the cover is open, the button

on the front of Discotom must be pressed and held just before the

joystick is operated.

Approx. 67 dB (A) measured at idle running, at a distance of

1.0 m/39.4” from the machine.

Two-handed Operation

Noise Level

Press and hold the button,

then move the joystick.

Discotom-100 /-10

Instruction Manual

11

Open the electric connection box and connect a 4-lead or 5-lead

cable* in the following way:

PE: earth

N: neutral (not used)

L1: phase

L2: phase

L3: phase

EU cable UL cable

L1 Brown

L2 Black

L3 Black or grey

Earth Yellow/ green

Neutral Blue (Not used)

L1 Black

L2 Red

L3 Orange/ turquoise

Earth Green (or Yellow/ green)

Neutral White (Not used)

The other end of the cable can be fitted with an approved plug or

hard-wired into the mains, according to the electrical

specifications and local regulations.

*Please see the section on Technical Data at the rear of the

Instruction Manual for recommended cable specifications.

Power Supply

IMPORTANT

Check that the mains voltage corresponds to the voltage stated on the type

plate on the side of the machine.

Discotom-100 / -10

Discotom-100 /-10

Instruction Manual

12

Check that the cut-off wheel rotates in the direction indicated by

the arrow on the cut-off wheel guard. If the direction of rotation is

incorrect:

EU cable UL cable

Switch two of the phases Switch phases L1 and L2

Both requirements refer to the European standard EN 50178 /

5.2.11.1. Similar standards apply in North America.

Direction of the Cut-off Wheel

(Discotom-10 only)

Important:

For Electrical Installations with Residual Current Circuit Breakers

For Discotom-100 connected to electrical installations with residual current

circuit breakers, a residual current circuit breaker,

type B time delayed, 30 mA is REQUIRED

(ref. EN 50178 / 5.2.11.1).

For Electrical Installations without Residual Current Circuit Breakers

The equipment must be protected by an insulation transformer

(double-wound transformer)

Please contact a qualified electrician to verify which option is suitable for the

local installation setup.

Discotom-100 /-10

Instruction Manual

13

Struers recommends the use of an exhaust system, as workpieces

may emit harmful gases when cut. The exhaust system will also

reduce the level of water condensation on the sides of the cover.

To connect the Discotom to an exhaust system:

Mount an exhaust hose from your local exhaust system onto the

flange (50 mm (approx. 2") dia.).

Connection to an External

Exhaust System

Important

If no exhaust is connected, damp air (produced by the cutting process) may

escape from the cutting chamber and penetrate into other areas of the

cabinet. This may cause damage to components and shorten the lifetime of

the machine.

Exhaust connection

Discotom-100 /-10

Instruction Manual

14

To ensure optimal cooling, Discotom must be fitted with a

recirculation cooling unit. Cooling System 4 is a configuration

designed for use with Discotom.

To connect the Discotom to a Recirculation Cooling Unit:

Plug the Cooli control unit’s communication cable into the

Discotom’s control socket.

Connect the water inlet hose to the Cooli pump using the quick

coupling (A).

Connect the other end of the hose to the Discotom water inlet.

Mount the 90° elbow pipe on the straight connector pipe in

the water outlet on the back of Discotom. Lubricate the sealing

ring with grease or soap to facilitate insertion.

Mount the outlet hose onto the elbow pipe and clamp using a

hose clamp.

Check that the outlet hose slopes downwards when connected. If

necessary adjust the length of the hose.

Insert the other end of the hose into the mounting hole in the

bracket on top of the Cooli filter unit (B).

Connect the cooling unit to the mains power supply.

Connecting a Recirculation

Cooling Unit

Note:

Cooling System 4 includes a static filter.

For intensive use, and for materials generating a lot of swarf,

a bandfilter such as Coolimat-200 is recommended.

Note

Before connecting the cooling unit to the Discotom,

follow the instructions in the Cooling Units Instruction Manual

to prepare it for use.

IMPORTANT

Before connecting, check that the mains voltage corresponds to the voltage

stated on the type plate on the side of the machine.

A

B

Other manuals for Discotom-100

1

This manual suits for next models

1

Table of contents

Other Struers Cutter manuals