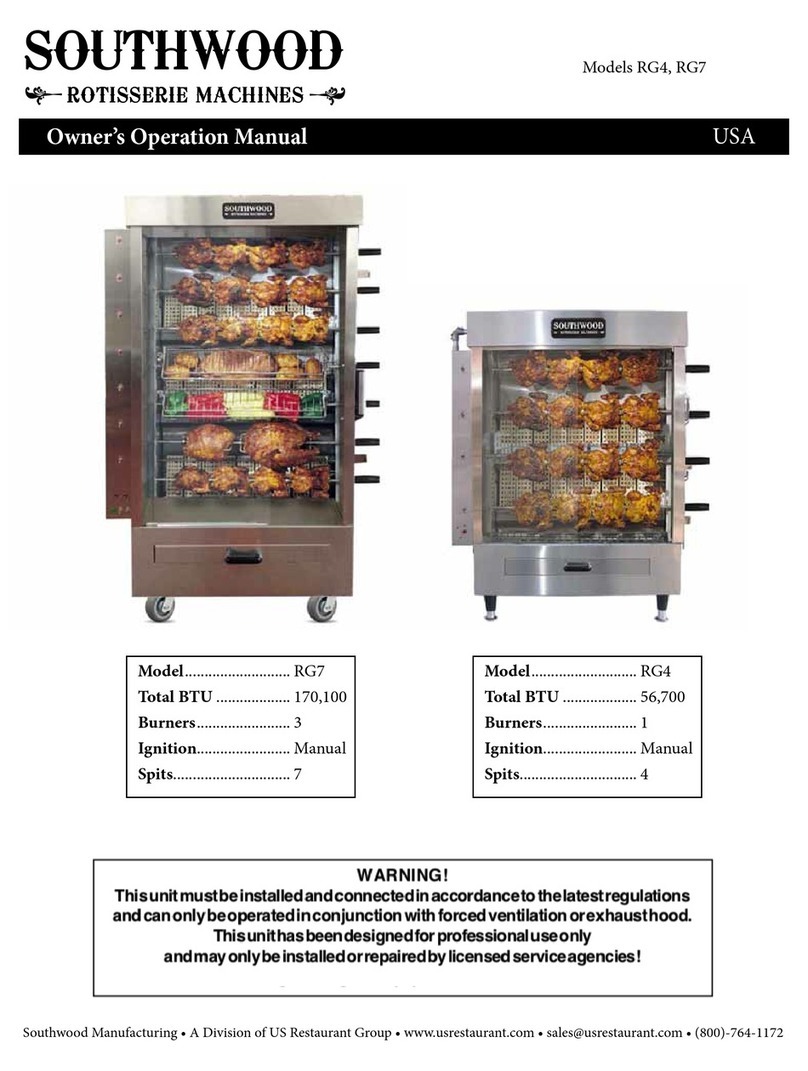

Southwood RG4 Manual

MODEL RG4 -RG7

RG4 AND RG7

INSTALLTION AND MAINTENANCE

WARNINGS

1. In all cases a qualied and licensed electrician and/or plumber must install the rotisserie machine.

2. In the event a user smells gas, instructions for procedures to follow must be placed in a prominent location. is information should

be obtained by containg your local gas supplier or professional.

3. Improper installation, adjustments, alterations, or service can cause property damage, serious injury, or death. Do not attempt to

install or service this machine unless you are a professional.

4. Place the machine in an area that is free of dra and open for accesible for proper maintenance and use.

5. Keep this machine free and clear from combustibles. Do not store or use gasoline or other amables in the vicinity of this machine

6. Do not obstruct the ow of combustion and the ventilation of air. Steps must be taken to ensure machine has adequate air supply

7. Gas Machines use 110V electric for the moror. Do not attempt to connect to 220V

8. Units may only be operated in conjuction with a canopy type exhaust hood or a direct ue vent.

MAINTENANCE & REPAIR

1. Disconnect the power supply during cleaning and servicing.

2. At the end of each day the water pan and cabinet should be cleaned with stainless steel cleaner.

3. All repairs or service must be done by a professional. Do not attempt yourself. Should Gas system need maintenance or repair, call a

plumber or gas professional.

CLEANING

1. A daily cleaning program should be maintained and executed.

2. For stainless steel surfaces, use a cleaning cloth and non abrasive cleaner such as Bon Ami or Noxon

3. Do NOT use SOS or Brillo Pads or any abrasive cleaner. Do NOT use Ajax, Comet, or comparable.

4. Turn the unit o before cleaning. Do not clean while unit is hot.

5. Monthly, remove the ceramics and use a paper clip to clean any debris from the burner openings.

6. Every 6 Months inspect glass doors for chips. If chips found, replace doors as soon as possble. Replace with Tempured glass from

local glass manufacturer.

Southwood Manufacturing • A Division of US Restaurant Group • www.usrestaurant.com • sales@usrestaurant.com • (800)-764-1172

MODEL RG4 -RG7

RG4 AND RG7

GENERAL INFORMATION

EQUIPMENT INTRODUCTION

1. is machine is made of high quality stainless steel. Benets include high temperature resistance, corrosion resistance, high thermal

eciency, and fuel consumption saving.

2. e primary purpose of this machine os for the roasting of chicken, ducks, and other poltry. However these machines are oen used

for a variety of other product such as ribs, pork loin, sucking pigs, and more.

3. ese models have 4 or 7 spits. Each spit is capableof holding 4-5 chickens, depending on size.

4. ese models are designed to be used in properly ventilated areas. Please take care to make sure your installation follows all local

health code and re department guidelines.

5. Keep this machine free and clear from combustibles. Do not store or use gasoline or other amables in the vicinity of this machine.

WORKING PRINCIPLES

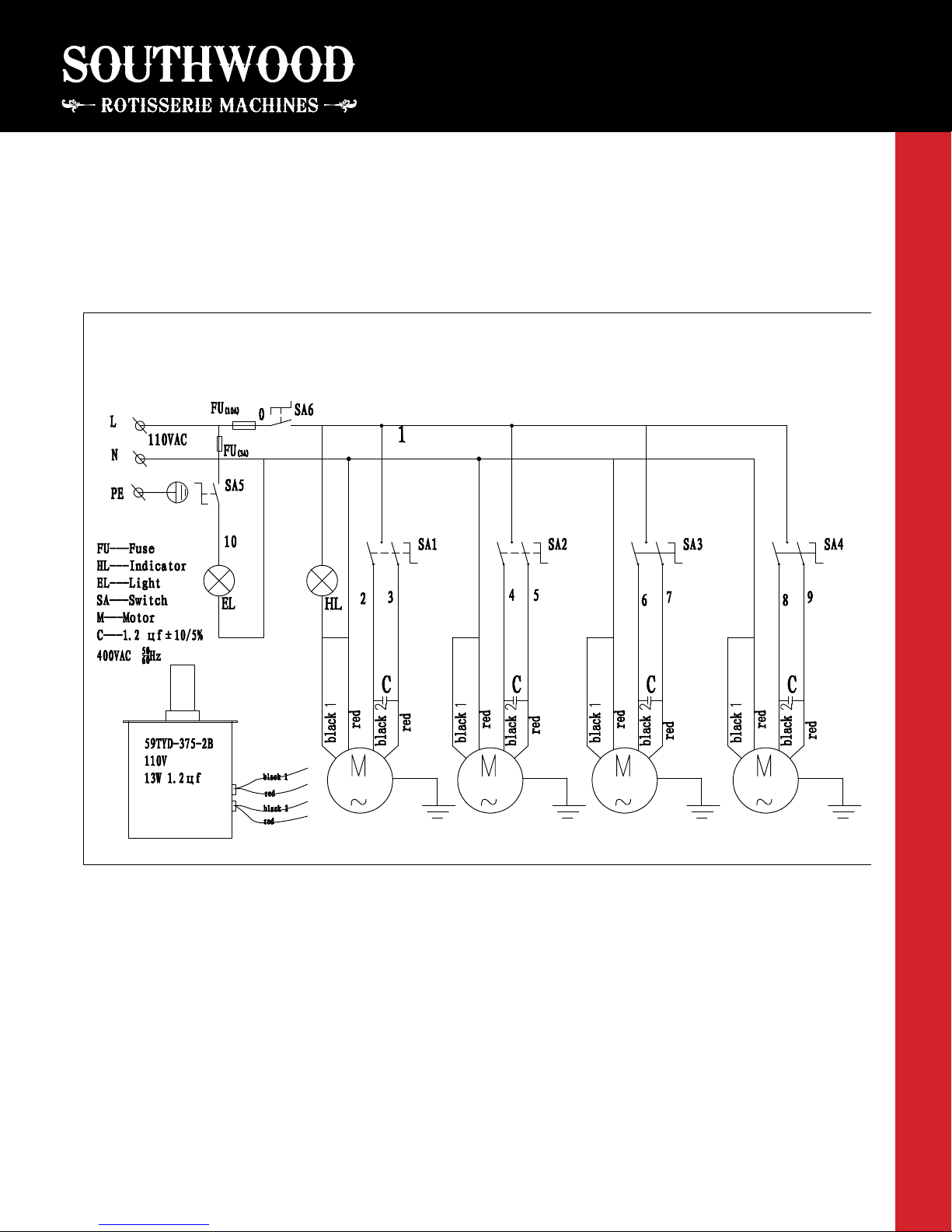

How it works: Each spit is cindependently controlled by a small motor. Each motor has its own switch for easy control. Each burner

should hold ceramic bricks, placed 1” to 1.25” apart, for even roasting.

Structure: e equipment includes the electrical control system, mechanical transmission system, the Skeletal System, burner heating

system.

TECHNICAL DATA

Gas Type LNG LPG

Heat Value 8500-9000Kcal/m³ 20000-22000Kcal/m³

Gas Consumption 6-9 m³/H .5-4kg/H

Pressure Reducing Valve (Trac) 25 m³/H 25kg/H

Static Pressure 2000±400Pa 2800±600Pa

Min. Pressure 1600Pa 2200Pa

MODEL RG4 RG287

EXT. DIM (LDH”) 47×22×54 47x22x71

VOLTAGE 110V, 1PH, 8A, 55W 110V, 1PH, 8A, 100W

FREQUENCY Hz 60 (50 Available) 60 (50 Available)

TEMPERATURE 68-572 °F 68-572 °F

Southwood Manufacturing • A Division of US Restaurant Group • www.usrestaurant.com • sales@usrestaurant.com • (800)-764-1172

RG4 AND RG7

INSTALLTION AND MAINTENANCE

INSTALLATION AND TESTING

According to the specication requirements, congure leakage protection circuit breaker.

Open the packing and then clean up. Push the machine to the place planned. Check to make sure the surface is smooth and even top

prevent vibration while functioning.

Install glass door and wheels

Start the machine, and check that if the machine is working well;

To check for any potential leaks the general method is to apply soap foam to all pipe connections and then ll pressure gas pipeline

with the 4000Pa compressed air. If you see air bubbles materialize please check for a leak. If found, the strengthening or replacement of

the the leaking part should be done by professionals. Aer you have conrmed there is no leakage, proceed to the next step

Complete the above steps, conrm it can idle without any problem, then nish installing.

e equipment can not be used in wet or water leakage place.

Method of operation:

Connect to the electric power, turn on the power switch;

Turn on each motor switch, idle the machine to conrm it can run smoothly;

Puncture the chicken, ducks and other food into the forks. Adjust the distance between the two forks. When nish, shut the side door

and the front glass door.

Observe the product when roasting. Change the direction of rotation of the motor to ensure uniform cooking.

CLEARANCES

e area around the rotisserie must be kept free and clear of all of all combustibles and should never be within public access.

e minimum clearances to construction are as follows:

REAR: 6 INCHES LEFT SIDE: 3 INCHES RIGHT SIDE: 10 INCHES

e rotisserie machines with closed backs may be installed against a wall. e machines with glass on both front and rear are designed

to be installed in a front counter or window area.

• e installation of your rotisserie will inuence your success. e food continually rotates while cooking, creating a colorful display

and aroma. Remember to leave a sucient amount of room to withdraw the spits. ere must also be a space available in front of the

rotisserie for the display and maintenance of the drip pan.

MODEL RG4 -RG7

Southwood Manufacturing • A Division of US Restaurant Group • www.usrestaurant.com • sales@usrestaurant.com • (800)-764-1172

ASSEMBLY

In all cases a qualied and licensed electrician and/or plumber must install the rotisserie machine. Installation must conform to the

local codes of your states, or in the absence, to the National Fuel Gas Code: ANSI Z 223.1-1974 and Addenda, Z223.1a.- 1978 or the

lasted version of the code.

1. Remove all packaging and/or protective vinyl

2. Place the ceramic briquettes inside the unit aer the rotisserie is positioned and the gas lines are installed. Slide the top of the ce-

ramic under the retaining rod and rest the bottom of the ceramic on the pipe. e ceramics must be sitting directly on the burners.

3. e ceramics must not block the burner holes in the pipe. e holes should be at the center of the ceramic openings. Leave 1/2”

between the ceramics.

4. Position the two prongs on the top of the ceramic briquette on the top of the rotisserie and place the bottom section into the groove.

PROBLEM SOLVING

MODEL RG4 -RG7

No Issue Reason Remedy

1. Heats up Slowly A) Gas heat valve or pressure A) Check for proper air ow

is unstable

B) Some burners don’t work B) Repair burner

2. Unit is not working A) Auto Shut down to protect A) Reset

thermal overload

B) Power issues B) Repair power supply

C) Blowout C) Change fuse

D) Spit Turning D) check motor connection to

spit

E) Replace spit motor

3. Spit movement A) Spit placement incorrect A) Reseat Spit

B) Motor connector loose B) Remove and reconnect motor

to transmission

C) Replace motor

Bricks should sit directly on

burner, spaced 1/2” apart.

Southwood Manufacturing • A Division of US Restaurant Group • www.usrestaurant.com • sales@usrestaurant.com • (800)-764-1172

RG4 AND RG7

INSTALLTION AND MAINTENANCE

LIGHTING AND SHUT DOWN

1. To light pilot turn control toward the ON position

2. Light burner with ignition device. If burner does not light, turn o gas and wait 5 minutes before trying again.

5. With Burner lighted, Leave Ball Valve in ON position to cook. Adjustment to ball valve will control strength of burner.

7. To shut o, Turn Ball Valvie to OFF position. Wait 5-minutes before re-lighting

8. If problems persist, please contact a qualied technican

PRODUCT PREP

1. Clean and sanitize the food product

2. Clean and sanitize the spits, skewers, and the thumbscrews 3. Use only authorized sink for raw food products

4. Use only authorized surface for cooked product only

5. Wash hands before and aer handling the raw products

COOKING TIME

e desired temperature in the rotisserie can only be set with the manifold valve knob. As a general rule, the higher the

grilling temperature, the shorter the cooking time.

Aer the unit has been ignited and it has warmed up for at least 15 minutes, load all spits with chicken.

Chicken Cooking Time is 45-60 minutes for a 3.5lb chicken at “On” position

MODEL RG4 -RG7

Southwood Manufacturing • A Division of US Restaurant Group • www.usrestaurant.com • sales@usrestaurant.com • (800)-764-1172

MODEL RG4 -RG7

RG4 AND RG7

INSTALLTION AND MAINTENANCE

Southwood Manufacturing • A Division of US Restaurant Group • www.usrestaurant.com • sales@usrestaurant.com • (800)-764-1172

Other manuals for RG4

1

This manual suits for next models

1

Table of contents

Other Southwood Kitchen Appliance manuals