Southworth Powered Dandy PLM 250 User manual

Model# _______________________________

Serial# _______________________________

For equipment manufactured after May 1999.

Powered Dandy Owner’s Manual

PLM 250™

Elevating Powered Helper

September 2016

Southworth Products Corp

P.O. Box 1380/Portland, Maine 04104-1380

Distributed by Ergonomic Partners

Email: [email protected]

Web: www.ergonomicpartners.com

PH: 314-884-8884 | FAX: 800-570-5584

2 PLM 250 — POWERED DANY LIFT

INTRODUCTION

Southworth’s PLM 250 has been designed to take the effort out of lifting and carrying.

The PLM 250 conforms to ergonomic guidelines in order to make them as comfortable

and safe as possible. The battery that powers the platform is sealed for safety and

can be recharged many times.

This manual contains information to acquaint you with the safe, proper use and

upkeep of the PLM 250. You should ensure that this manual is available to personnel

working with the PLM 250.

In the interest of safety please read the entire manual carefully and be familiar with

its contents before you use or service the PLM 250. If you have any questions about

any instructions in this manual, please contact your dealer or Southworth Products

Corporation.

The PLM 250 is tted with an identication plate located on the central cross member

at the base of the actuator. The identication plate is stamped with the model number,

capacity and serial number; this information should be provided when seeking spare

part inquiries or technical support.

PLM 250 — POWERED DANDY LIFT 3

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................................................. 2

RESPONSIBILITY OF OWNERS AND USERS ............................................................................................... 4

SAFETY ALERT SYMBOLS AND SIGNAL WORDS........................................................................................ 5

UNPACKING ................................................................................................................................................... 6

Transit Damage .......................................................................................................................... 6

Hazardous Environments............................................................................................................ 6

High Cycle Applications .............................................................................................................. 6

SPECIFICATIONS............................................................................................................................................ 6

PARTS BREAK DOWN .................................................................................................................................... 6

OPERATION 6

Platform Control.......................................................................................................................... 6

Caster Conguration................................................................................................................... 6

Brake........................................................................................................................................... 6

Direction Lock ............................................................................................................................. 6

Battery......................................................................................................................................... 6

BATTERY LIFE................................................................................................................................................. 7

CONTROL BOX ............................................................................................................................................... 7

ACTUATOR 7

LOAD CAPACITY ............................................................................................................................................. 8

MAINTENANCE ............................................................................................................................................... 8

Monthly ....................................................................................................................................... 9

Annually ...................................................................................................................................... 9

TROUBLE SHOOTING .................................................................................................................................... 9

ORDERING REPLACEMENT PARTS............................................................................................................ 10

RETURN MATERIALS AUTHORIZATION (RMA) ...........................................................................................11

WARRANTY 12

LIST OF FIGURES

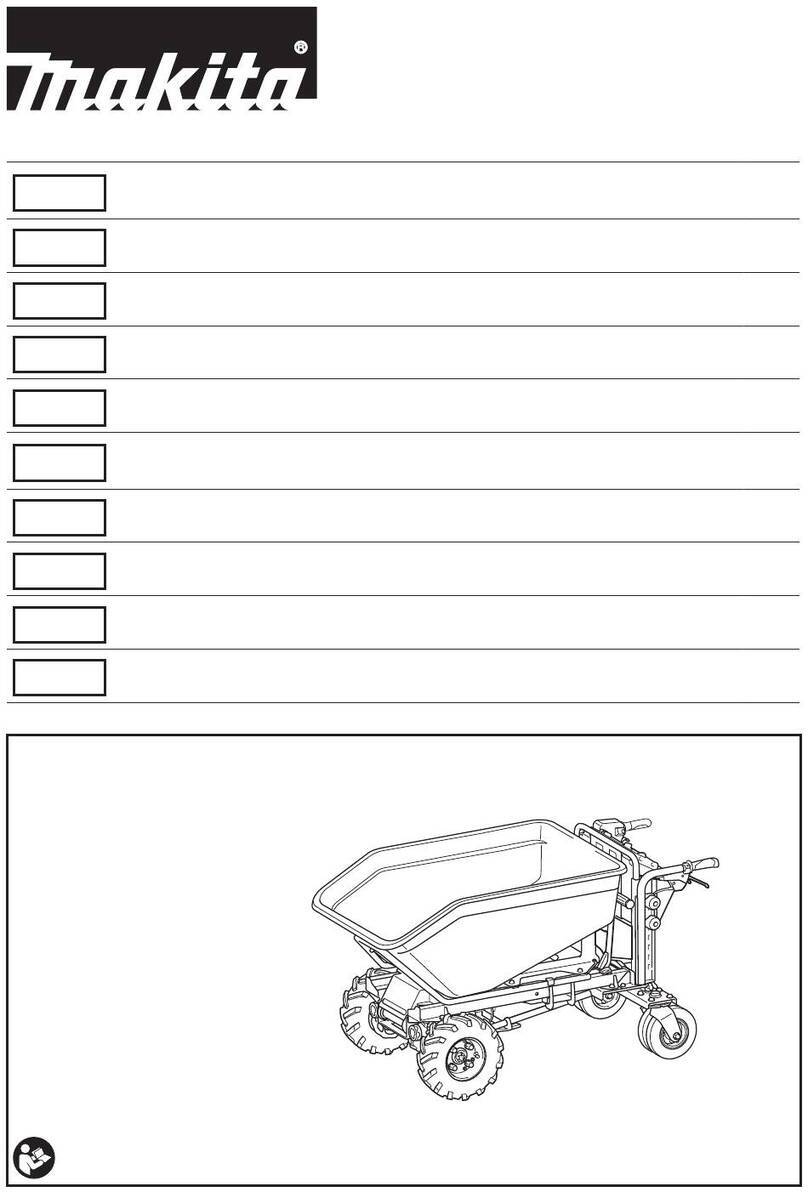

Figure 1 PLM 250...................................................................................................................................... 7

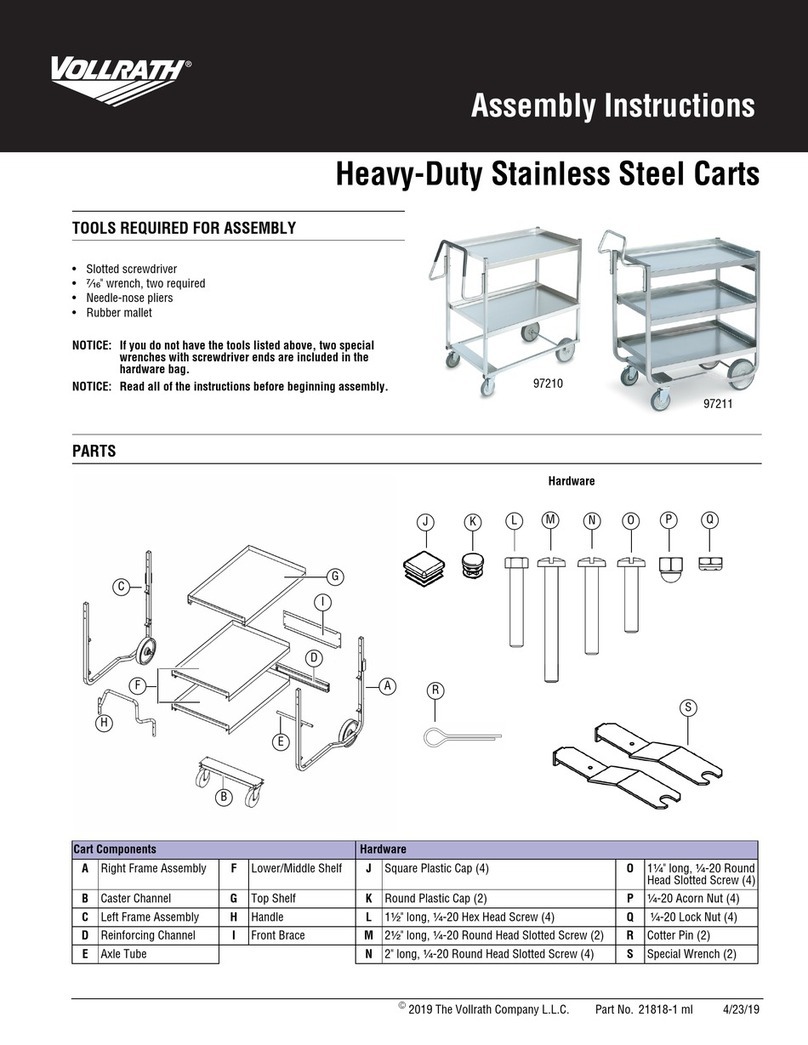

Figure 2 Pinch Points................................................................................................................................ 7

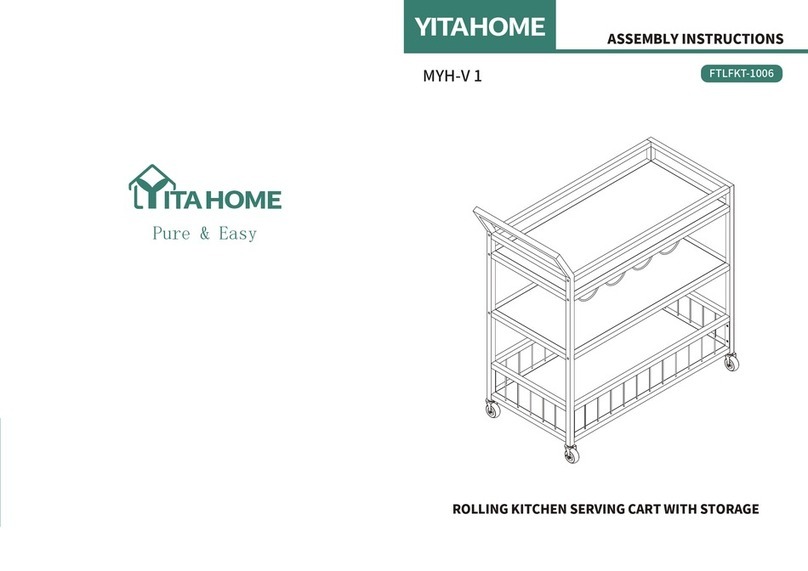

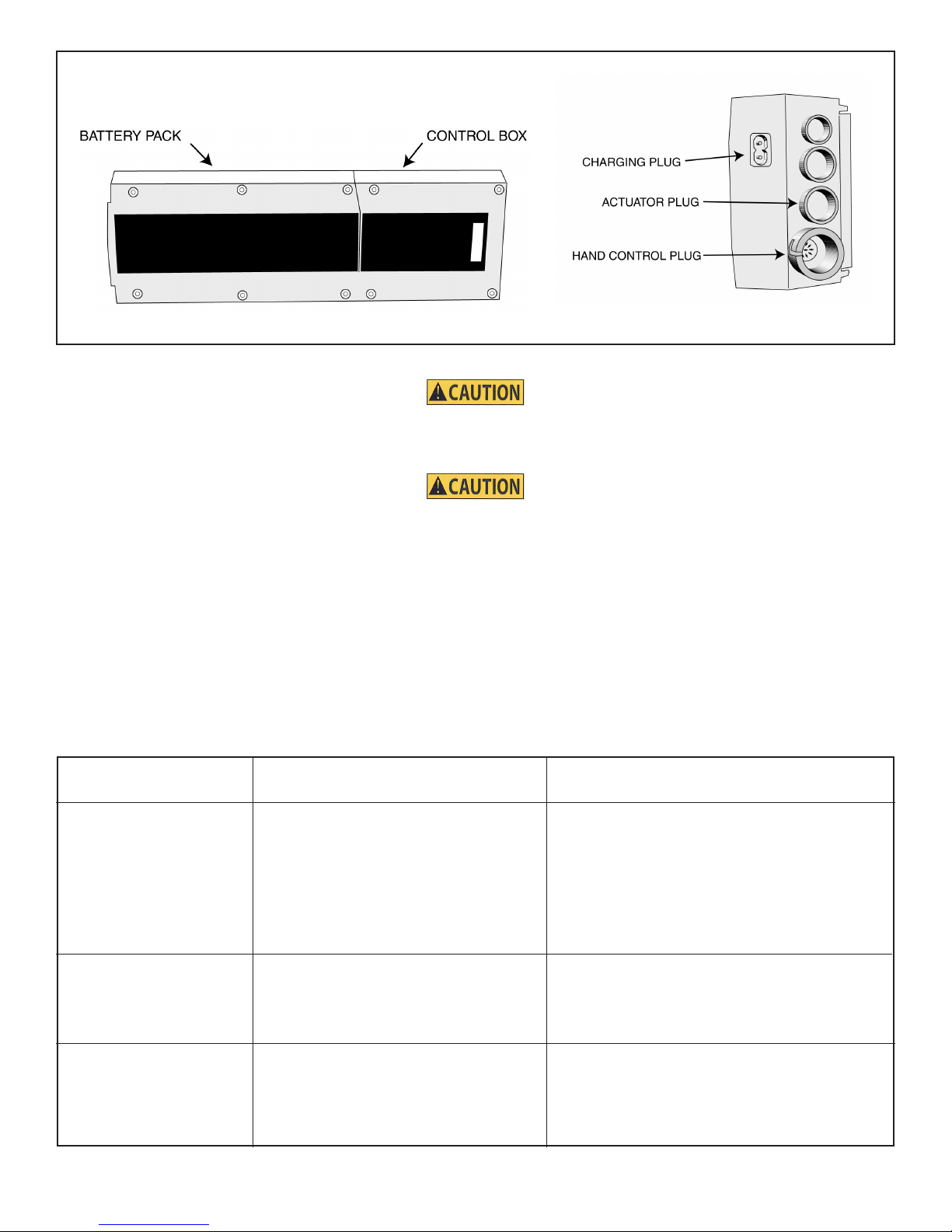

Figure 3 Battery Pack & Control Box ........................................................................................................ 8

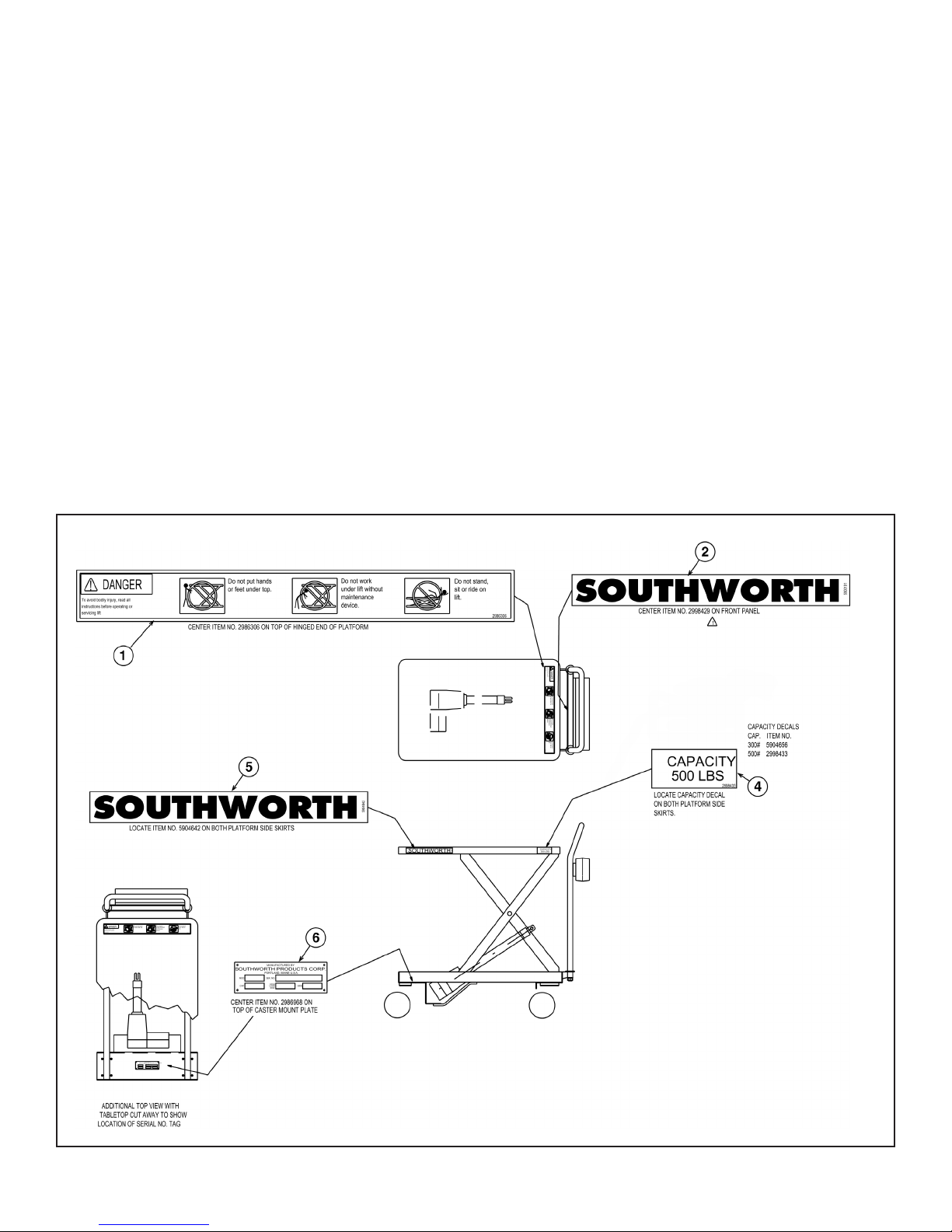

Figure 4 Labels and Precautionary Markings............................................................................................ 9

4 PLM 250 — POWERED DANY LIFT

Responsibility of Owners and Users

Inspection and Maintenance

The device shall be inspected and maintained in proper working order in accordance with

Southworth’s owner’s manual.

Removal from Service

Any device not in safe operating condition such as, but not limited to, excessive leakage,

missing rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed

electric, hydraulic, or pneumatic lines, damaged or malfunctioning controls or safety de-

vices, etc. shall be removed from service until it is repaired to the original manufacturer’s

standards.

Deection

It is the responsibility of the user/purchaser to advise the manufacturer where deection

may be critical to the application.

Repairs

All repairs shall be made by qualied personnel in conformance with Southworth’s instruc-

tions.

Operators

Only trained personnel and authorized personnel shall be permitted to operate the equip-

ment.

Before Operation

Before using the device, the operator shall have:

•Read and/or had explained, and understood, the manufacturer’s operating instruc-

tions and safety rules.

•Inspected the device for proper operation and condition. Any suspect item shall be

carefully examined and a determination made by a qualied person as to whether

it constitutes a hazard. All items not in conformance with Southworth’s specication

shall be corrected before further use of the equipment.

During Operation

The device shall only be used in accordance with this owner’s manual.

•Do not overload.

•Ensure that all safety devices are operational and in place.

Modications or Alterations

Modications or alterations to any Southworth industrial positioning equipment shall be

made only with written permission from Southworth.

PLM 250 — POWERED DANDY LIFT 5

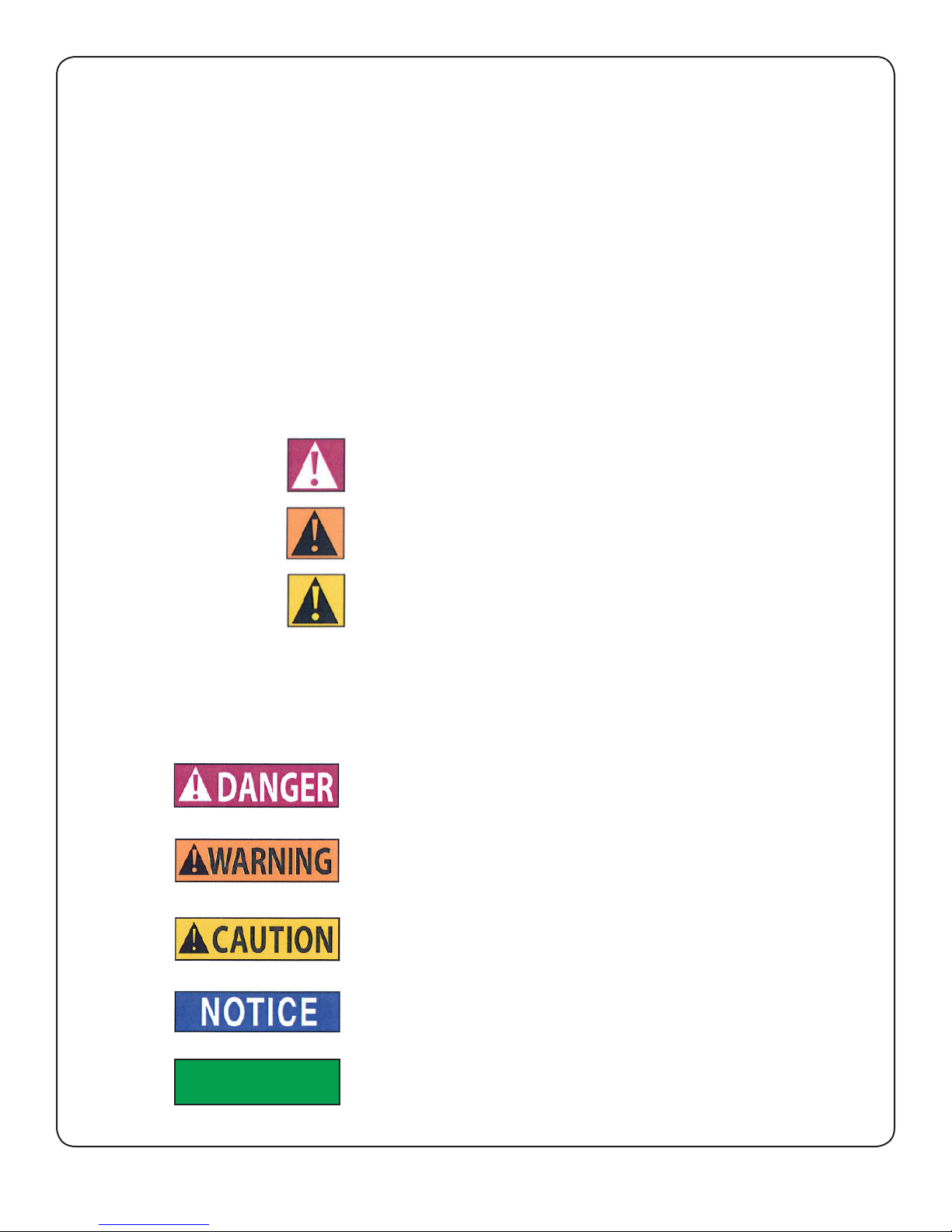

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety of all persons operating, maintaining, repairing, or in the vicinity of this equipment is of paramount concern. This is

a powerful machine with moving parts, and is capable of causing personal injury if proper precautions are not taken. Therefore,

throughout this manual, certain hazards have been identied which may occur in the use of the machine, and there are appro-

priate instructions or precautions which should be taken to avoid these hazards. In some cases, there are consequences which

may occur if instructions or precautions are not followed. Below are the symbols and signal words along with their denitions

referenced from ANSI Z535.4 - Product Safety Signs and Labels.

Safety Alert Symbols

These are the safety alert symbols.. They are used to alert you to potential physical injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

For use with DANGER signal word

(Red Background)

For use with WARNING signal word

(Orange Background)

For use with CAUTION signal word

(Yellow Background)

Signal Words

The meaning of different signal words as dened by ANSI Standard Z535.4 indicates the relative seriousness

of the hazardous situation.

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indi-

cates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices not related

to personal injury.

(Red Background)

(Orange Background)

(Yellow Background)

(Blue Background)

SAFETY

INSTRUCTIONS

SAFETY INSTRUCTIONS (or equivalent) signs

indicate safety-related instructions or procedures.

(Green Background)

6 PLM 250 — POWERED DANY LIFT

UNPACKING AND

SET-UP OF THE

PLM 250

HIGH CYCLE APPLICATIONS

The PLM 250 is designed for intermittent use.

For high cycle operations, the following

should be observed:

1) The PLM 250 is designed to achieve a

minimum life of approximately 10,000

cycles. For intermittent use, this

equates to many years of service.

2) The PLM 250 linear actuator should

not exceed six (6) full cycles per hour.

The recommended duty cycle for the

actuator motor is 10%. This means that

the motor should not be operated for

more than 6 minutes of every hour.

OPERATING

THE PLM 250

PLATFORM CONTROL

The position of the platform is controlled

with a push button switch located on the

hand control. The PLM 250 can be raised

by pressing the UP button on the switch or

lowered by pressing the DOWN button on

the switch.

WARNING!

As the PLM 250 platform moves

up and down, “pinch points” are

created where the scissor legs

cross, where the legs meet the

base and platform and in the

path on which the rollers travel.

When operating the PLM 250,

be careful to ensure that nobody

1) Cut the banding straps and remove the

PLM 250 from the box. (Make sure all

of the parts are included before the box

is discarded. Figure 1.)

2) Attach the handle to the PLM 250 by

sliding the two threaded ends of the

handle into the pockets that are welded

to the base frame. Using the lock

washers and the nuts, secure rmly.

3) Locate the battery control box assembly.

Attach the assembly to the handle using

the 4 self tapping screws, making sure

the control box is to the right and

the battery box is to the left. This

allows the actuator to plug into the

control box.

4) Makeall thecorrect electricalconnections

(gure 3).

TRANSIT DAMAGE

Inspect the PLM 250 for signs of damage

in transit, paying particular attention to

the electrical cabling and connections. If

there is evidence of damage, contact your

Southworth dealer before using the PLM

250.

HAZARDOUS

ENVIRONMENTS

The PLM 250’s electrical equipment is not

suitable for use in ammable or explosive

environments and must never be used

when such hazards exist.

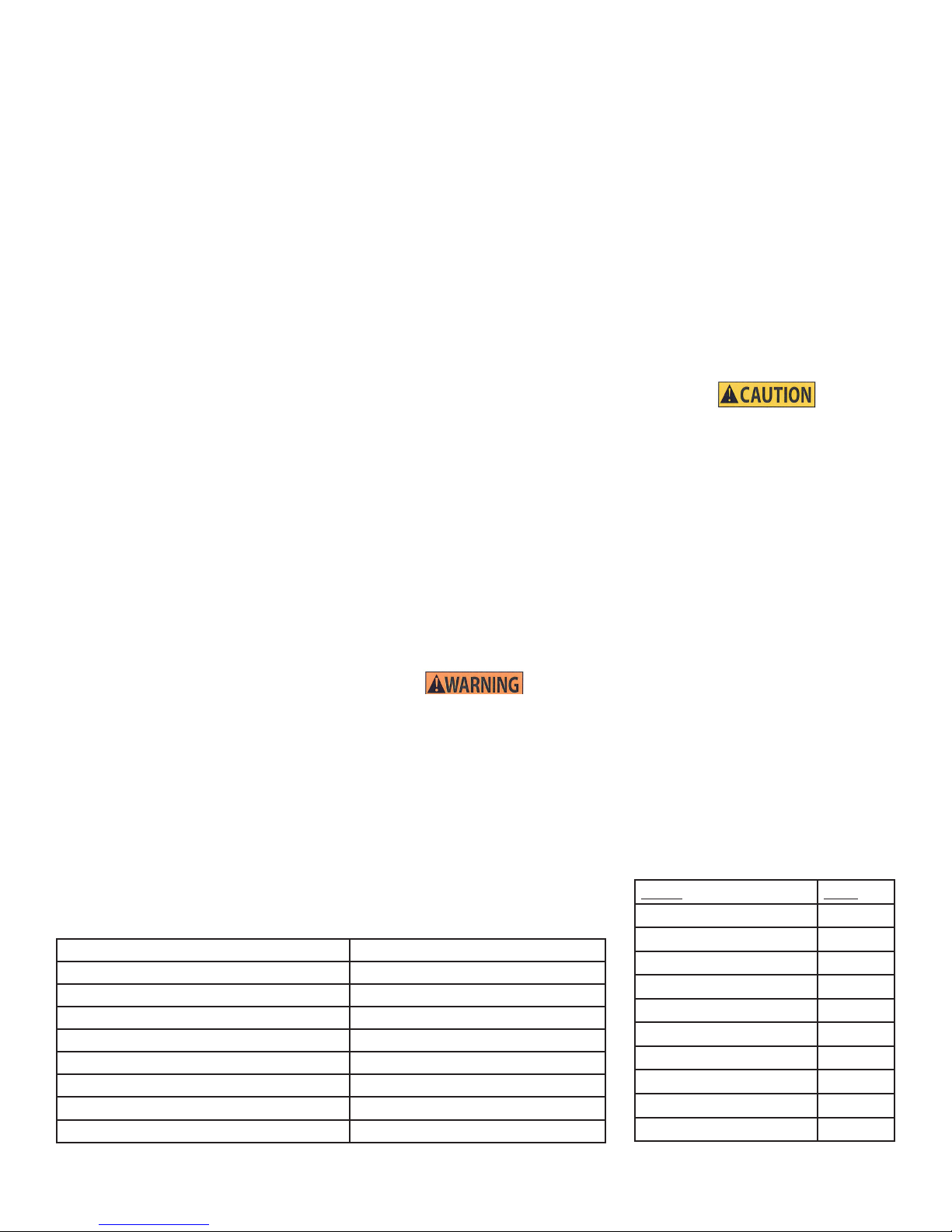

SPECIFICATIONS

Capacity 500 lbs

Platform Size 19-5/8” x 31-1/2”

Lowered Height 14-1/4”

Raised Height 32-1/2”

Vertical Travel 19”

Weight 20 lbs

Dimensions (L x H x W) 38” x 37” x 19-5/8”

Casters 5”

Rise Time 36 Seconds

PARTS BREAK DOWN

PARTS Part #

Platform & Frame 3060649

Directional Caster 5905969

Brake Caster 5905970

Front Caster 5905968

Battery Pack 5905918

Battery Mounting Bracket 5905920

Control Box 5905917

Hand Control 5905958

Actuator 5905916

Decal Kit 3055607

becomes caught in the moving

parts. (Figure 2)

CASTER CONFIGURATION

The PLM 250 is supplied with four swiveling

casters. One of the rear casters is tted

with a brake and the other rear caster has

a direction lock.

BRAKE

The brake prevents the caster from both

swiveling and rolling. Press the lever

located on the top of the caster to engage

the brake.

CAUTION!

The brake is an important safety

device. Please ensure it is

engaged when the PLM 250 is

unattended. Attempt to nd level

ground whenever possible.

DIRECTION LOCK

The direction lock prevents the caster from

swiveling but allows the caster to roll as

usual. Use it when pushing the PLM 250

in a straight line to provide greater stability.

BATTERY

The PLM 250 is supplied with a 24 volt

battery pack which snaps easily on to

the control box. This allows for a quick

exchange of battery packs if needed. The

control box is mounted to the handle of the

PLM 250 for easy access. The control box

PLM 250 — POWERED DANDY LIFT 7

Figure 1. PLM 250

Hand Control

Platform and Frame

Handle

Battery Pack

Control Box

Bottom Pivot

Direction Lock Caster

Brake Caster

Power Lead

Actuator

Center Pivot

Rollers

Lockwasher and Nut

Lockwasher and Nut

includes a quick disconnect hand control,

and an internal charger.

The battery is a VRLA sealed lead acid

battery. It is exempted from DOT Hazardous

Material. VRLA batteries can be shipped by

traditional carriers such as UPS or FEDEX.

WARNING!

The battery contains lead acid and should

not be punctured or damaged. Seek

urgent medical advice if acid contacts

skin or clothing. Ensure that the battery

is disposed of safely and according to

local regulations.

BATTERY LIFE

Because of the batteries self-discharge, over time you

can not expect the battery to be fully charged. When

you receiveyourPLM 250 it is recommended that

you charge the battery immediately. The initial

charge needs to be for a minimum of 24 to 48

hours. After this rst initial charging, there is a

maximum charging time of 6 hours to reach the

batteries full charge capacity.

The life of the battery is determined on the

amount of usage between charging. This is

best explained as follows:

• 100% discharging depth: If the

battery is totally discharged, there is

approximately 180 charging cycles

available.

• 50% discharging depth: If the battery is

50% discharged, there is approximately

400 charging cycles available.

• 30% discharging depth: If the battery is

30% discharged, there is approximately

1200 charging cycles available.

Therefore it is recommended to recharge

the battery as frequently as possible.

Doing this will ensure the longest battery

life available.

CONTROL BOX

Your control box is equipped with some

special features. It has an internal charger

with a 10 ft. charging cord, a soft start and

stop function which eliminates jumping of

the actuator and table. There is a unique

acoustic alarm feature that tells you when

the battery is at 50% capacity. The hand

control, which is clearly marked with UP and

DOWN buttons, comes with a 24” coil cord.

ACTUATOR

The PLM 250’s actuator is one of its best

features. You can hardly tell it’s running

because of its low noise level that’s below

45db. It has built-in end-stop switches

for protection against dead heading or

damaging the actuator. The operating

mechanism is a simple screw jack that’s

driven by an internal DC motor.

Figure 2. PLM 250 Pinch Points

8 PLM 250 — POWERED DANY LIFT

LOAD CAPACITY

The load capacity is stamped into the

identication plate located on the central

cross-member, at the base of the actuator

and capacity stickers on either side of the

table. (figure 4) The PLM 250 contains

an overload protection device that may

cut power to the unit if overloaded. If this

occurs, make sure that the PLM 250 is not

loaded beyond its capacity. The device will

reset within a matter of seconds and power

will be restored. The load capacity is based

on the load applied centrally and uniformly

to the platform.

CAUTION!

Do not overload the PLM 250, as

this may damage the unit.

CAUTION!

Do not let loads significantly

overhang the platform, as this

could result in the platform being

overloaded, and cause the PLM

250 to tip over.

MAINTENANCE

The PLM 250 requires minimal maintenance.

The PLM 250 is designed for a life of

approximately 10,000 cycles after which a

new actuator may be required.

Daily inspection: Make sure there are no

foreign objects in the way of the rollers and

the scissor legs. Make sure all wires are

plugged into the control box.

Figure 3. Battery Pack and Control Box

PROBLEM

PLM 250 will not raise.

PLM 250 is slow to raise or

will not raise to the top.

PLM 250 will not lower.

POSSIBLE CAUSES

1) Power is not supplied to the actuator.

2) Batteries are discharged.

3) An electrical fault may exist or the

actuator may have burned out.

1) Batteries are discharged.

2) A fault may exist with the motor/switch.

1) Power is not supplied to the actuator.

2) Batteries are discharged.

REMEDY

Check whether the power cable is plugged in.

Recharge the batteries.

Contact Southworth Customer Service Dept. 1-800-

743-1000.

Recharge the batteries.

Contact Southworth Service Dept. 1-800-743-1000.

Check whether the power cable is plugged in.

Recharge the batteries.

Quick Check Troubleshooting Chart

PLM 250 — POWERED DANDY LIFT 9

Figure 4. Labels and Precautionary Markings

LABELS AND

PRECAUTIONARY

MARKINGS

#1 2986306 – Danger

#2 2998429 – SOUTHWORTH

#4 2998433 – 500 lb Capacity

#5 5904642 – SOUTHWORTH

#6 2986968 – Name Plate

MONTHLY MAINTENANCE

1) Check all welds, making sure they are

intact, no cracks or broken spots.

2) Turn the PLM 250 on its side and check

that the caster bolts are tight. If the

caster with the direction lock requires

tightening, engage the direction lock

and ensure that the castor is pointing

straight ahead before tightening.

3) Check that the cotter pins on the

actuator pivot bolts are in place.

4) Inspect the cable and plug for signs of

damage.

5) Inspect the battery control box

assembly for obvious signs of abuse.

6) Use a clean rag to wipe the paths along

which the rollers travel.

7) Lubricate (WD-40) pivots and roller

pins.

ANNUALLY OR 3000 CYCLES

1) Dismantle.

2) Lubricate (WD-40) pivots and roller

pins.

3) Clean.

4) Reassemble.

TROUBLE

SHOOTING

The PLM 250 should provide years of

trouble-free service. However, in the event

you experience difculties with the PLM

250, the troubleshooting chart on page 8

may help you identify the problem.

You may, of course, contact Southworth’s

Customer Service Dept. at 1-800-743-1000.

10 PLM 250 — POWERED DANY LIFT

Ordering Replacement Parts

Southworth has carefully chosen the components in your unit to be the best available for the purpose.

Replacement parts should be identical to the original equipment. Southworth will not be responsible

for equipment failures resulting from the use of incorrect replacement parts or from unauthorized

modications to the machine.

Southworth will gladly supply you with replacement parts for your Southworth lift. With your order,

please include the model number and the serial number of the unit. You will nd these numbers on

the name plate.

To order replacement parts, please call the Parts Department at (207) 878-0700. Parts are shipped

subject to the following terms:

• FOB factory.

• Returns only with the approval of our parts department.

• Payment net 30 days (except parts covered by warranty).

• Freight collect (except parts covered by warranty).

• The warranty for repair parts is 30 days from date of shipment.

Parts replaced under warranty are on a “charge-credit” basis. We will invoice you when we ship the

replacement part, then credit you when you return the assumed substandard part, and we verify that

it is covered by our warranty. Labor is not covered under warranty for Parts orders.

Parts Department

Southworth Products Corp

P.O. Box 1380

Portland, ME 04104-1380

Distributed by Ergonomic Partners

Email: [email protected]

Web: www.ergonomicpartners.com

PH: 314-884-8884 | FAX: 800-570-5584

PLM 250 — POWERED DANDY LIFT 11

RETURN MATERIALS AUTHORIZATION

(RMA) PROCEDURES

The Southworth Return Authorization (RMA) Procedure is provided as a courtesy to our custom-

ers in the event a product or a component may need to be returned.

If a customer wishes to return a Southworth product, the rst step in the process is to request an

RMA number from the Customer Service Department. This request must be made on or before

the thirtieth (30th) calendar day following the date of Southworth’s invoice for the merchandise

being returned.

The RMA number must appear on the outside of any packaging material for a return to be

accepted and processed at Southworth manufacturing facility. Customers shipping returns back

to Southworth, from the continental US, Canada or Mexico have thirty (30) days from the effec-

tive date of the RMA to have the merchandise arrive freight prepaid at Southworth. If the RMA

number is missing or expired (beyond 30 days) it may be refused at Southworth. If any RMA is

expired, contact the Customer Service Department before returning to Southworth.

All RMA’s are subject to the appropriate restocking fees. All credits issued are less restocking

fees as applicable, plus any assessed outbound/inbound in-transit damages.

Return addresses: please refer to your RMA for the specic address to which your product

should be returned. Southworth has multiple facilities and returning goods to other than the des-

ignated location will result in goods being refused.

Please contact the Customer Service Department at anytime regarding questions to this proce-

dure.

Southworth Products Corp

P.O. Box 1380

Portland, ME 04104-1380

Distributed by Ergonomic Partners

Email: [email protected]

Web: www.ergonomicpartners.com

PH: 314-884-8884 | FAX: 800-570-5584

12 PLM 250 — POWERED DANY LIFT

Southworth Products Corp warrants this product to be free from defects in material or

workmanship for a period of 1 year of single shift usage from date of shipment, providing

claim is made in writing within that time period. This warranty shall not cover modied

designs for special applications, failure or defective operation caused by misuse,

misapplication, negligence or accident, exceeding recommended capacities, failure to

perform required maintenance or altering or repairing, unless alteration is authorized by

Southworth Products Corp. Except as set forth herein, there are no other warranties,

express or implied, including the warranties of merchantability and tness for a particular

purpose, all of which are hereby excluded.

Southworth Products Corp makes no warranty or representation with respect to the com-

pliance of any product with state or local safety or product standard codes, and any failure

to comply with such codes shall not be considered a defect of material or workmanship

under this warranty. Southworth Products Corp shall not be liable for any direct or conse-

quential damages arising out of such noncompliance.

Southworth Products Corp’s obligation under this warranty is limited to the replacement or

repair of defective components at its factory or another location at Southworth Products

Corp’s discretion. The Southworth Warranty is for product sold with in North America. For

products shipped outside of North America the warranty will be for replacement of defec-

tive parts only. Labor is not included. This is buyer’s sole remedy. Except as stated herein,

Southworth Products Corp will not be liable for any loss, injury or damage to persons or

property, nor for direct, indirect, or consequential damage of any kind, resulting from fail-

ure or defective operation of said product.

This warranty may be altered only in writing by Southworth Products Corp, Portland,

Maine.

SOUTHWORTH PRODUCTS CORP

P.O. Box 1380, Portland, ME 04104-1380

Distributed by Ergonomic Partners

Email: [email protected]

Web: www.ergonomicpartners.com

PH: 314-884-8884 | FAX: 800-570-5584

1 YEAR WARRANTY

Table of contents

Popular Outdoor Cart manuals by other brands

Combi

Combi ANGEL WAGON AW Series Instruction Manual and Inspection Manual

Granite

Granite 97011-4 owner's manual

Oklahoma Sound

Oklahoma Sound MULTI MEDIA CART MMC Product handbook

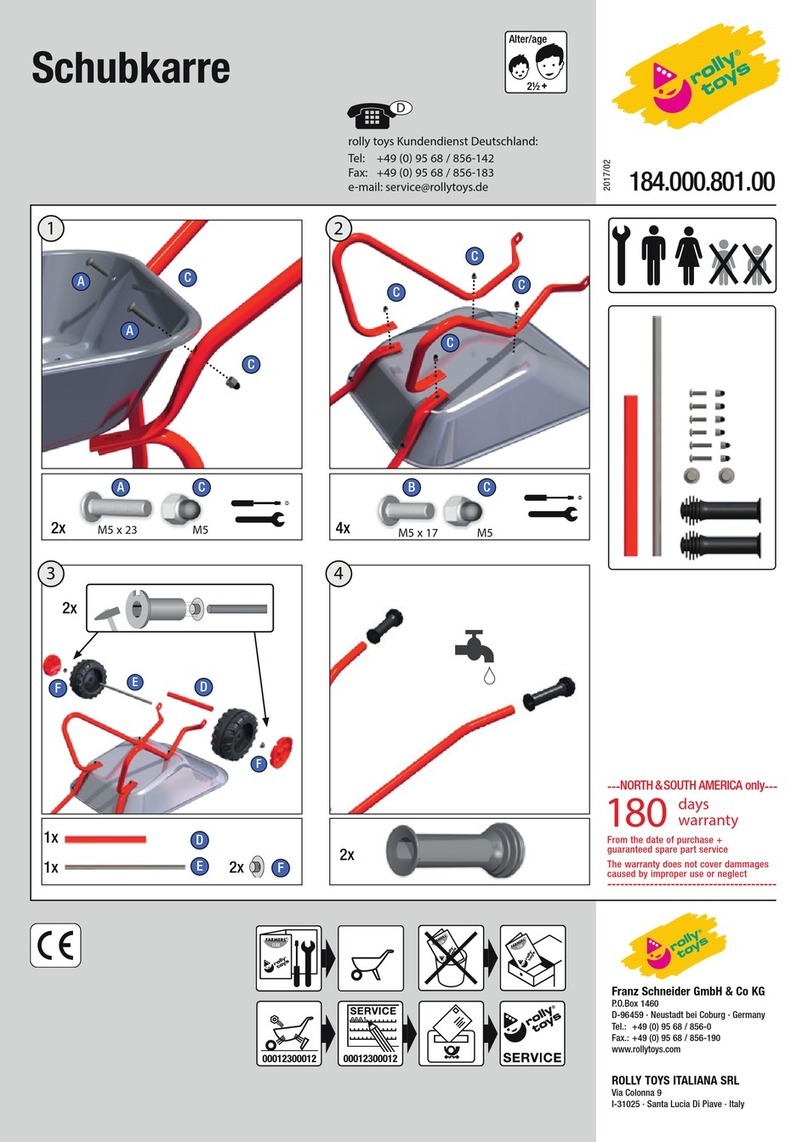

Rolly Toys

Rolly Toys Double Tyre manual

KitchenAid

KitchenAid KFFU271TSS00 parts list

Great Little Trading

Great Little Trading Time for Tea Trolley quick start guide