Nitto Kohki DLV8100 Series User manual

Other Nitto Kohki Power Tools manuals

Nitto Kohki

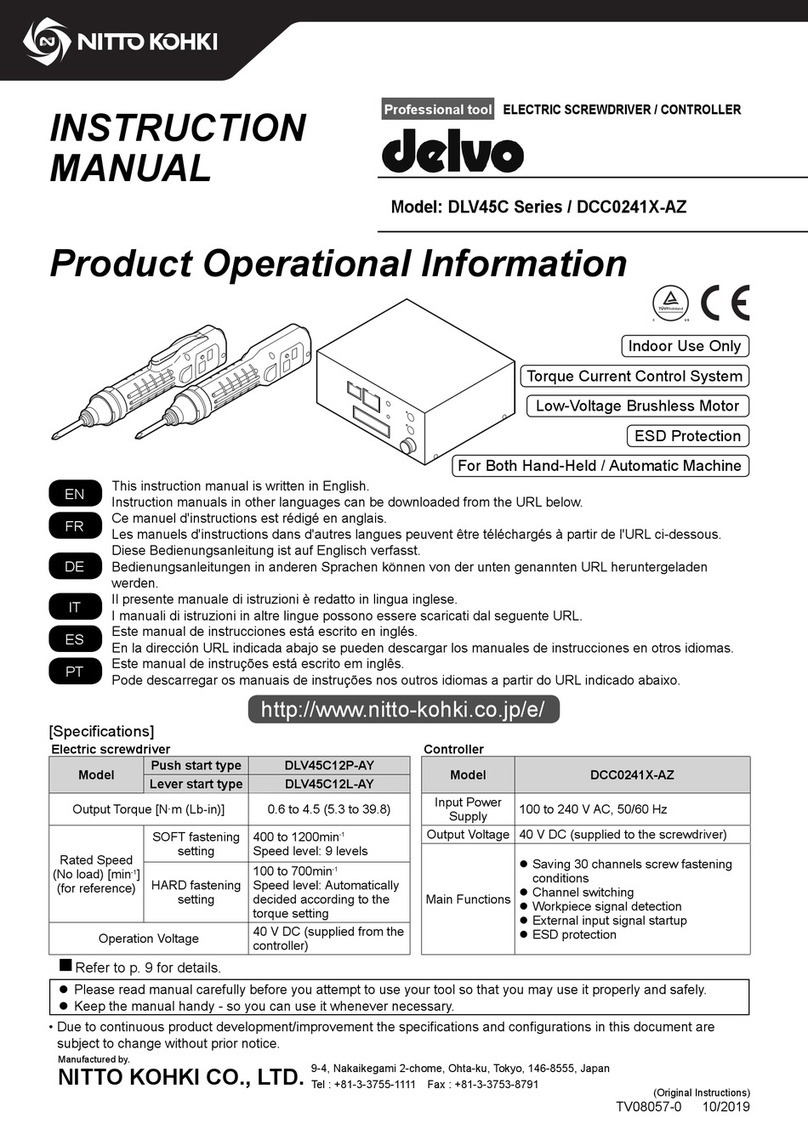

Nitto Kohki delvo DLV45C Series User manual

Nitto Kohki

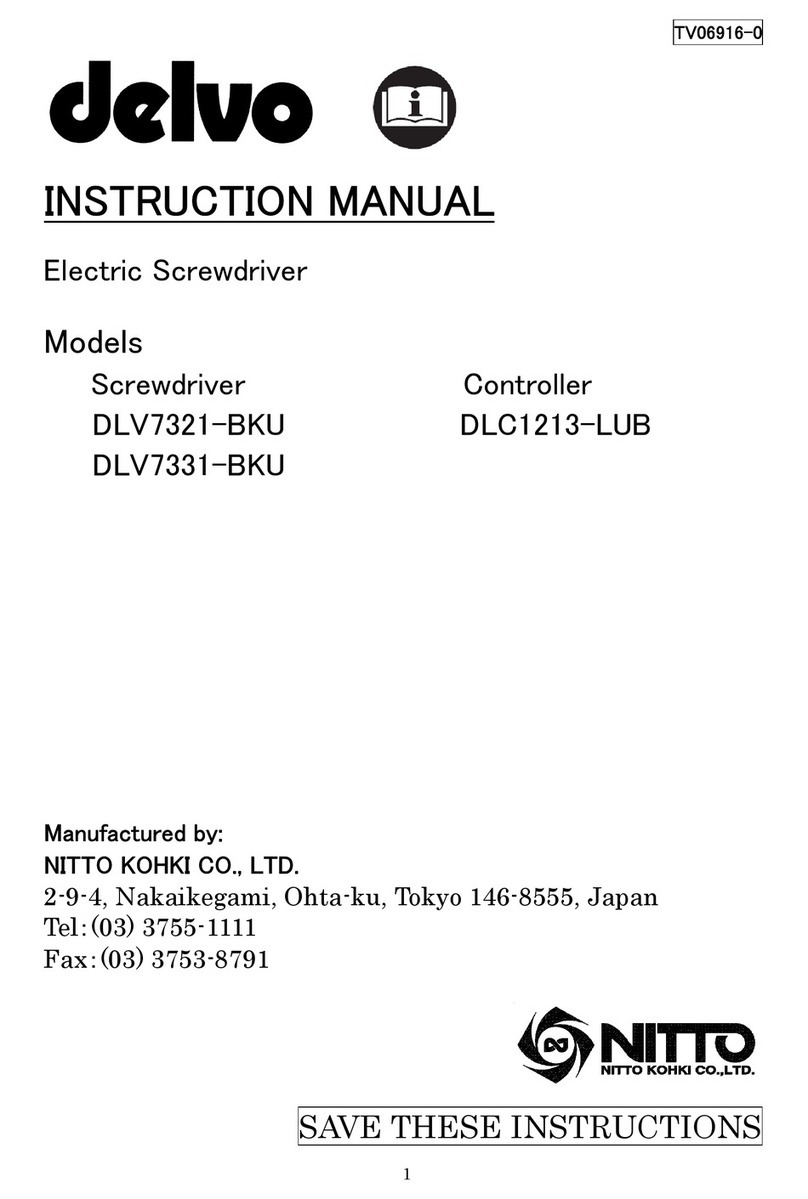

Nitto Kohki Delvo DLV7321-BKU User manual

Nitto Kohki

Nitto Kohki DLV30A User manual

Nitto Kohki

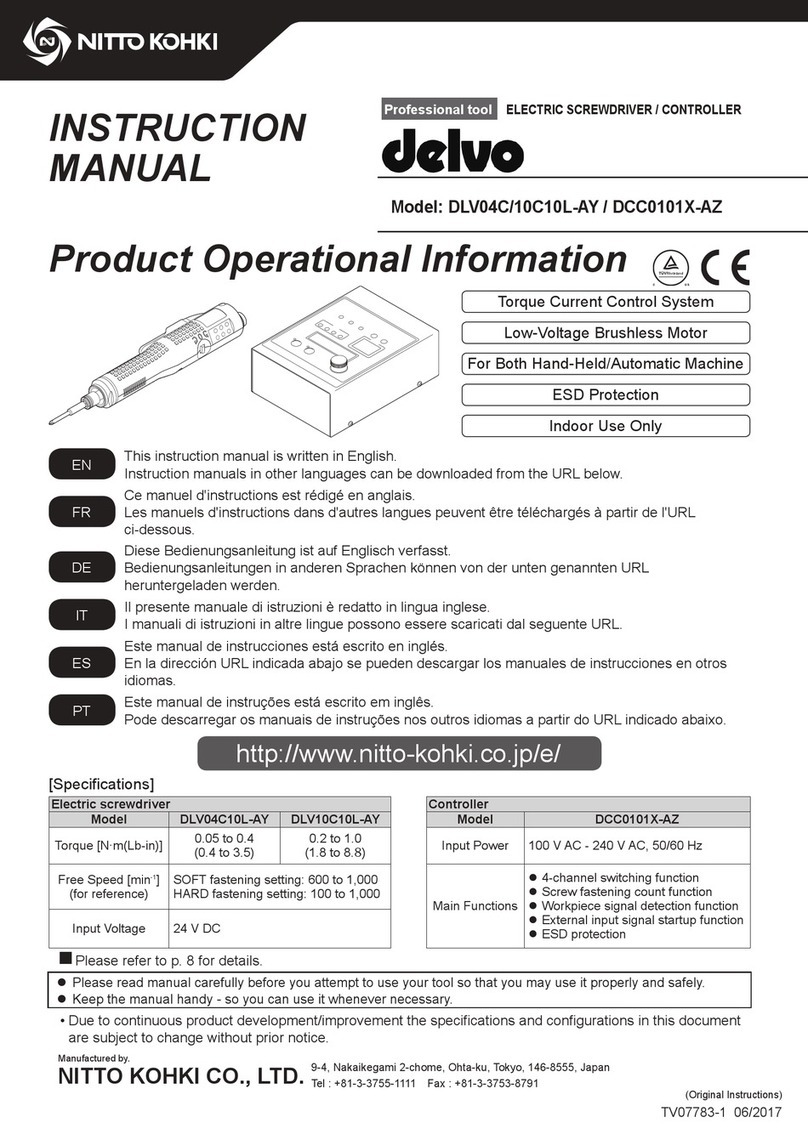

Nitto Kohki DLV04C10L-AY User manual

Nitto Kohki

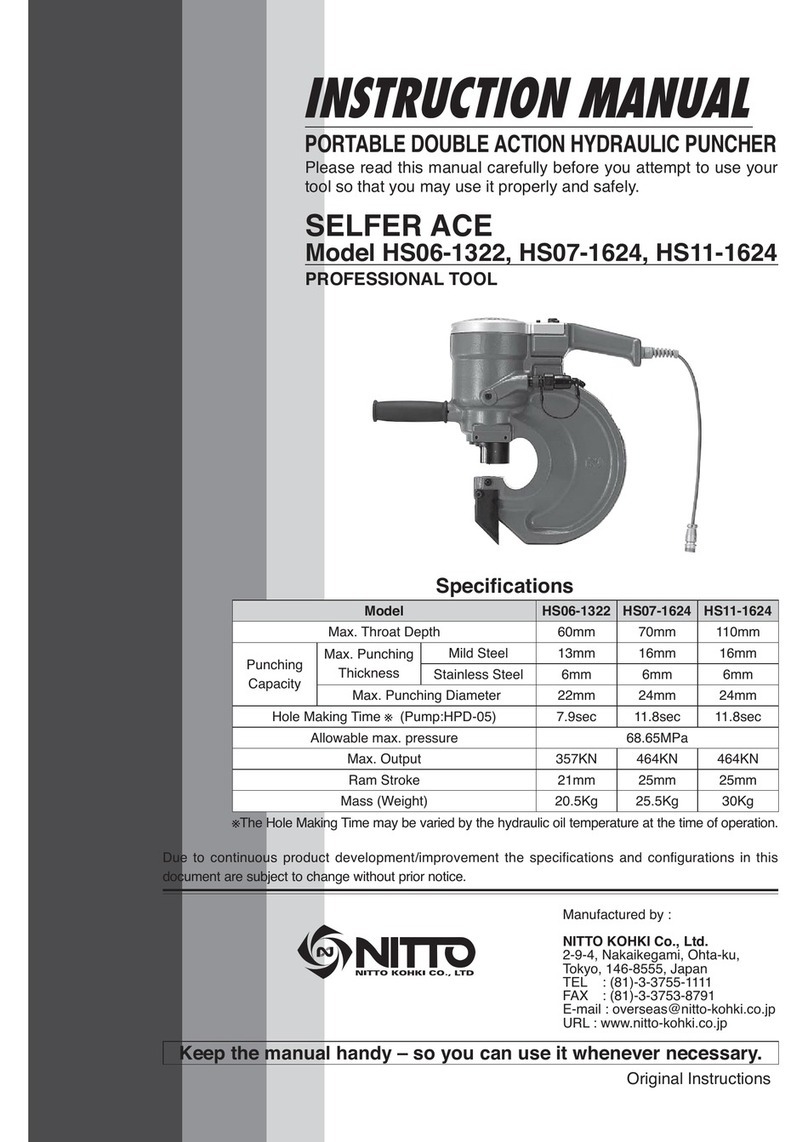

Nitto Kohki SELFER ACE HS06-1322 User manual

Nitto Kohki

Nitto Kohki SELFER ACE HS06-1322 User manual

Nitto Kohki

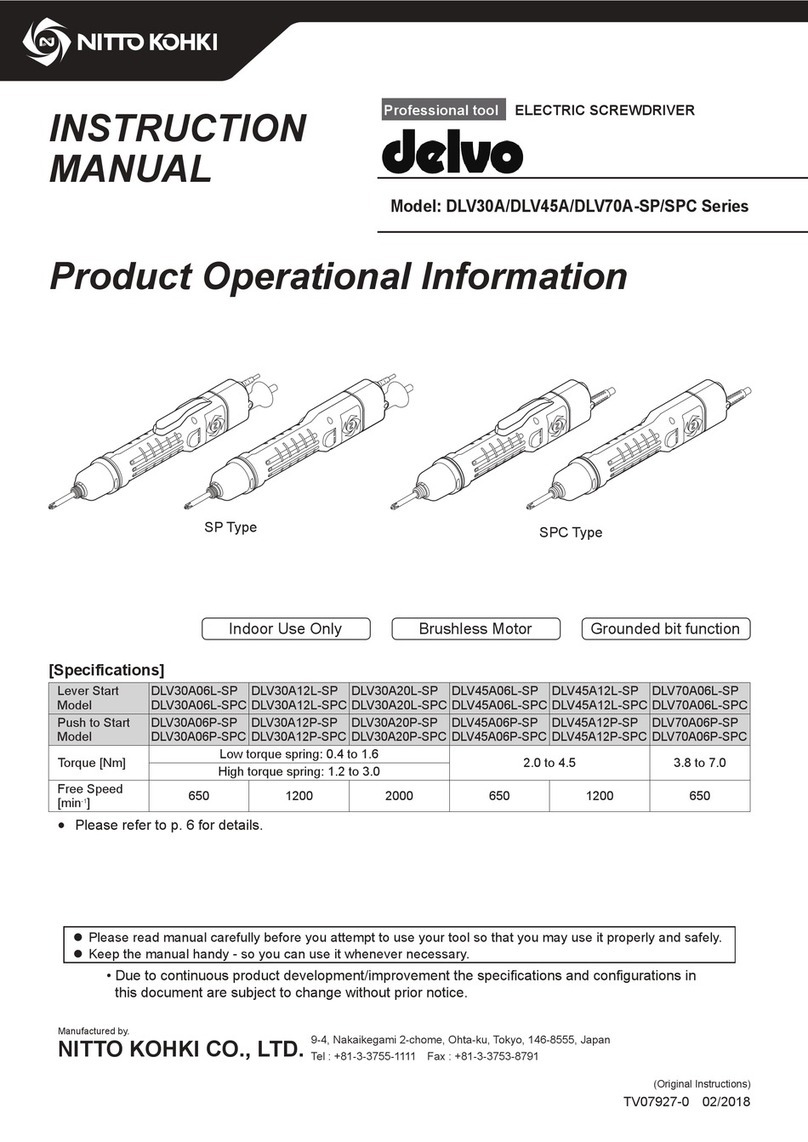

Nitto Kohki DLV30A06L-SP User manual

Nitto Kohki

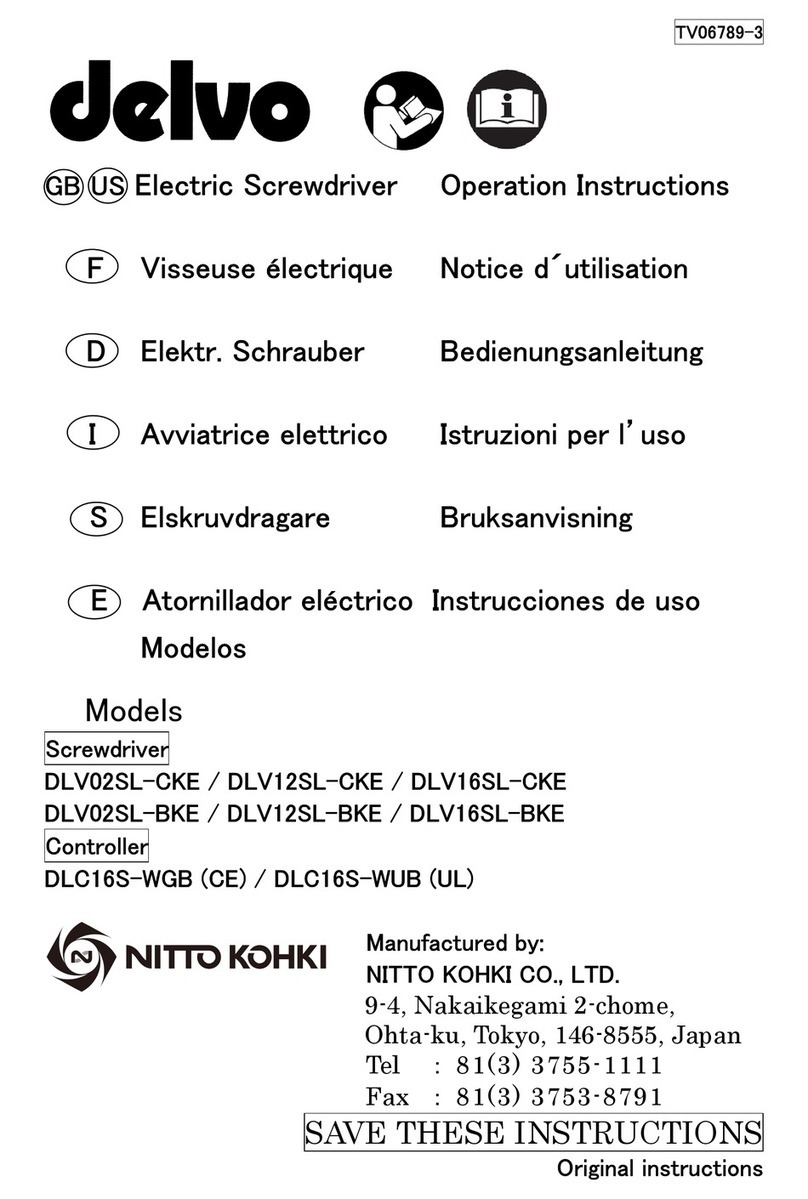

Nitto Kohki delvo DLV02 Series User manual

Nitto Kohki

Nitto Kohki EMB-0307C User manual

Nitto Kohki

Nitto Kohki CB-01 User manual

Nitto Kohki

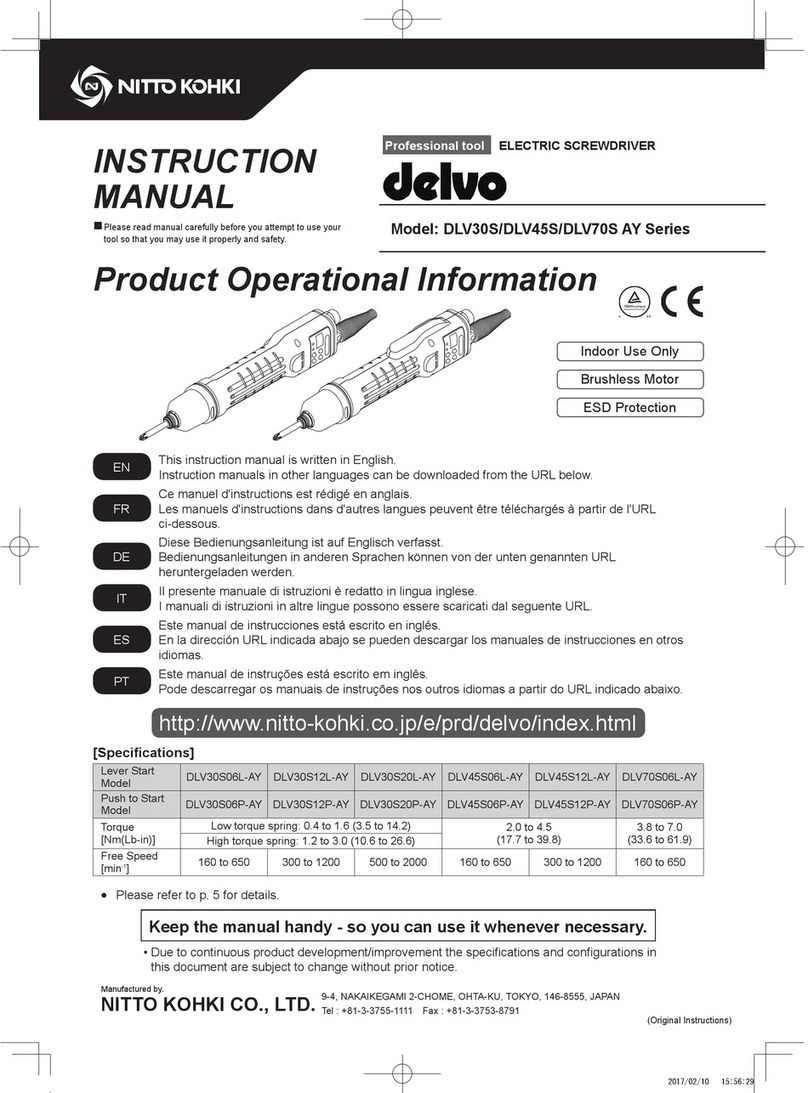

Nitto Kohki DLV30S06L-AY User manual

Nitto Kohki

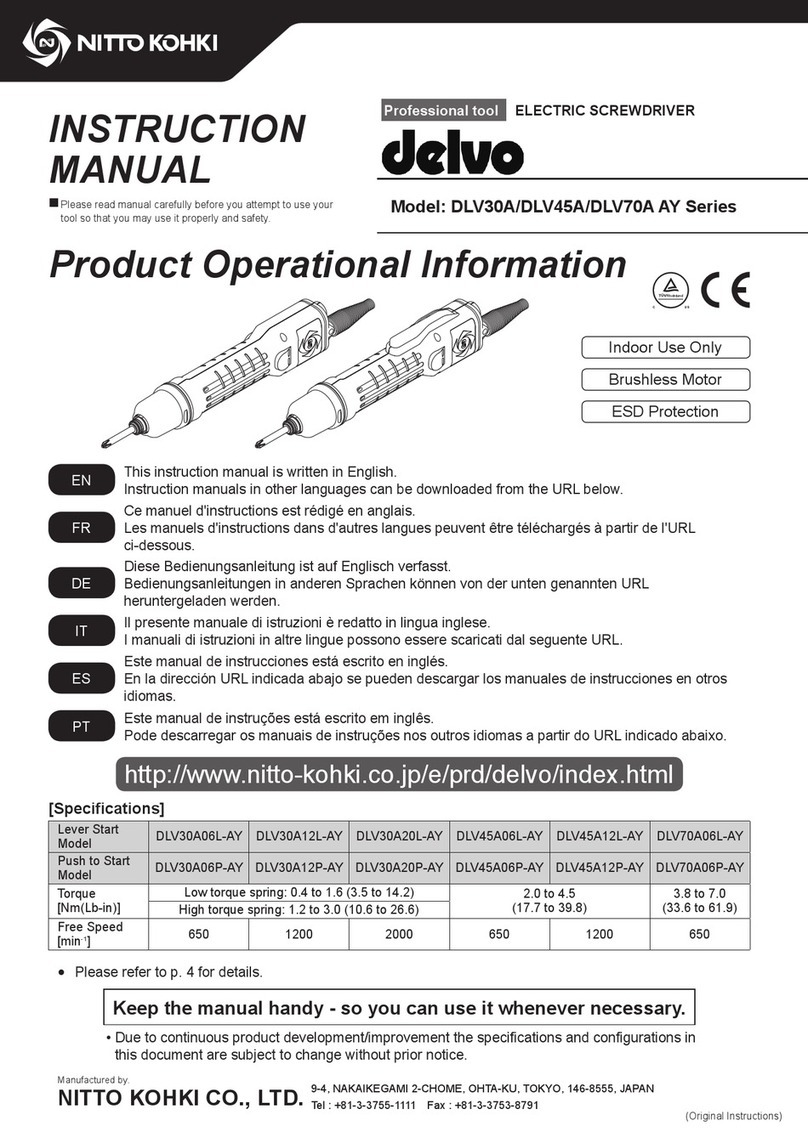

Nitto Kohki DLV30A User manual

Nitto Kohki

Nitto Kohki DLV30S12P-AY Original instructions

Nitto Kohki

Nitto Kohki EJC-32A User manual

Nitto Kohki

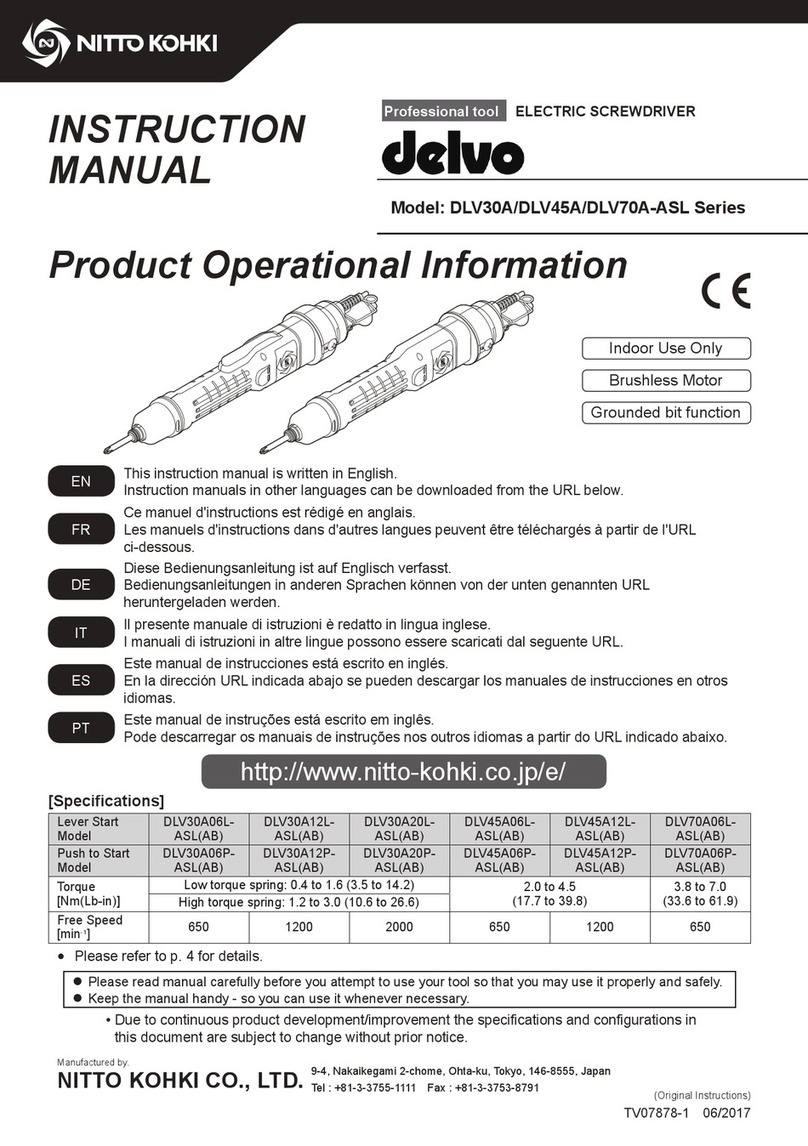

Nitto Kohki Delvo DLV70A-ASL Series User manual

Nitto Kohki

Nitto Kohki delvo DLV5800U Series User manual

Nitto Kohki

Nitto Kohki delvo DLV04C/10C10L-AY User manual