8

– Ensure that ventilation openings are kept clear when

working in dusty conditions, if it should become

necessary to clear dust, first disconnect the tool from

the mains supply (use non metallic objects) and avoid

damaging internal parts;

– Always use eye and ear protection. Other personal

protective equipment such as dust mask, gloves, helmet

and apron should be worn;

– Pay attention to the wheel that continues to rotate after

the tool is switched off.

– Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

– Never disassemble the rechargeable battery and

charger.

– Never short-circuit the rechargeable battery.

Shortcircuiting the battery will cause a great electric

current and overheat. It results in burn or damage to the

battery.

– Do not dispose of the battery in fire. If the battery is burnt,

it may explode.

– Do not insert object into the air ventilation slots of the

charger. Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical shock

hazard or damaged charger.

– Bring the battery to the shop from which it was purchased

as soon as the post-charging battery life becomes too

short for practical use. Do not dispose of the exhausted

battery.

ADDITIONAL SAFETY WARNINGS

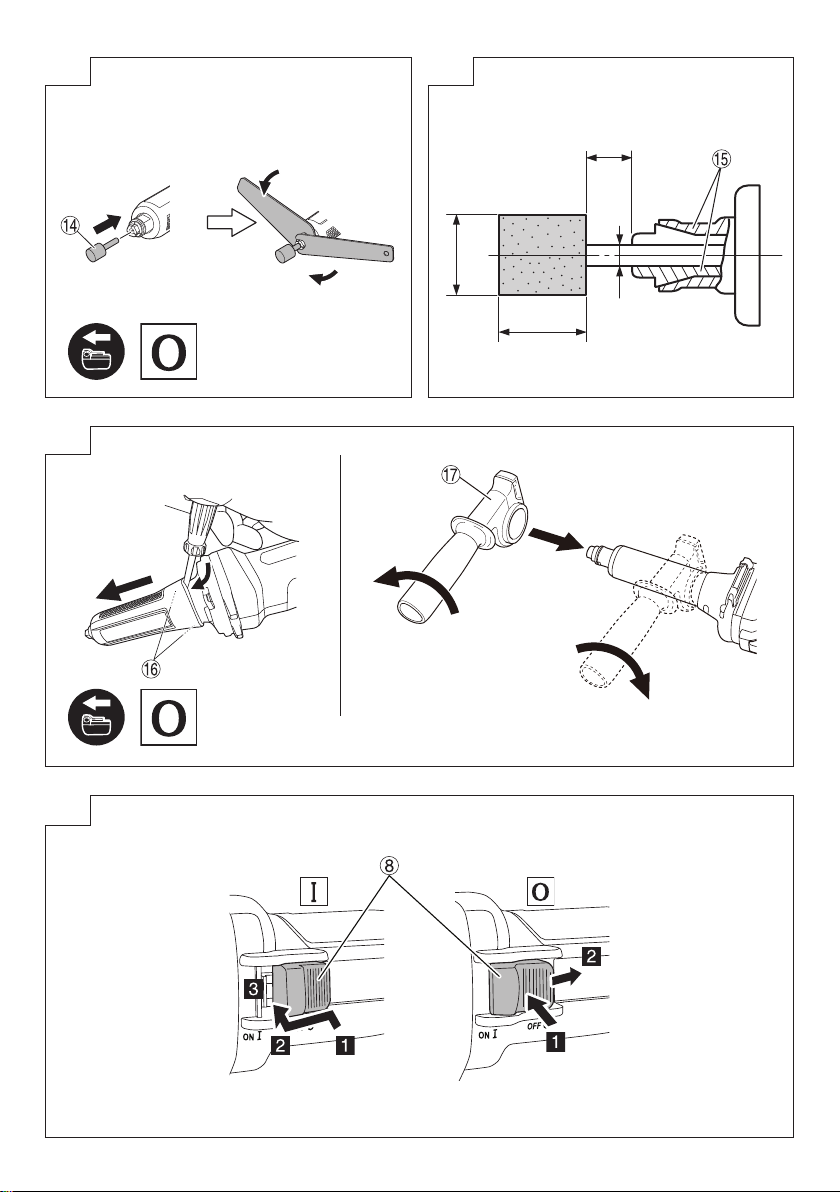

1. Ensure that the wheel to be utilized is the correct type

and free of cracks or surface defects. Also ensure that

the wheel is properly mounted and the collet chuck is

securely tightened.

2. To prolong the life of the machine and ensure a first

class finish, it is important that the machine should not

be overloaded by applying too much pressure. In most

applications, the weight of the machine alone is sufficient

for effective grinding. Too much pressure will result in

reduced rotational speed, inferior surface finish, and

overloading which could reduce the life of the machine.

3. The wheel continues to rotate after the tool is switched

off.

After switching offthe machine, do not put it down until

the wheel has come to a complete stop. Apart from

avoiding serious accidents, this precaution will reduce

the amount of dust and swarf sucked into the machine.

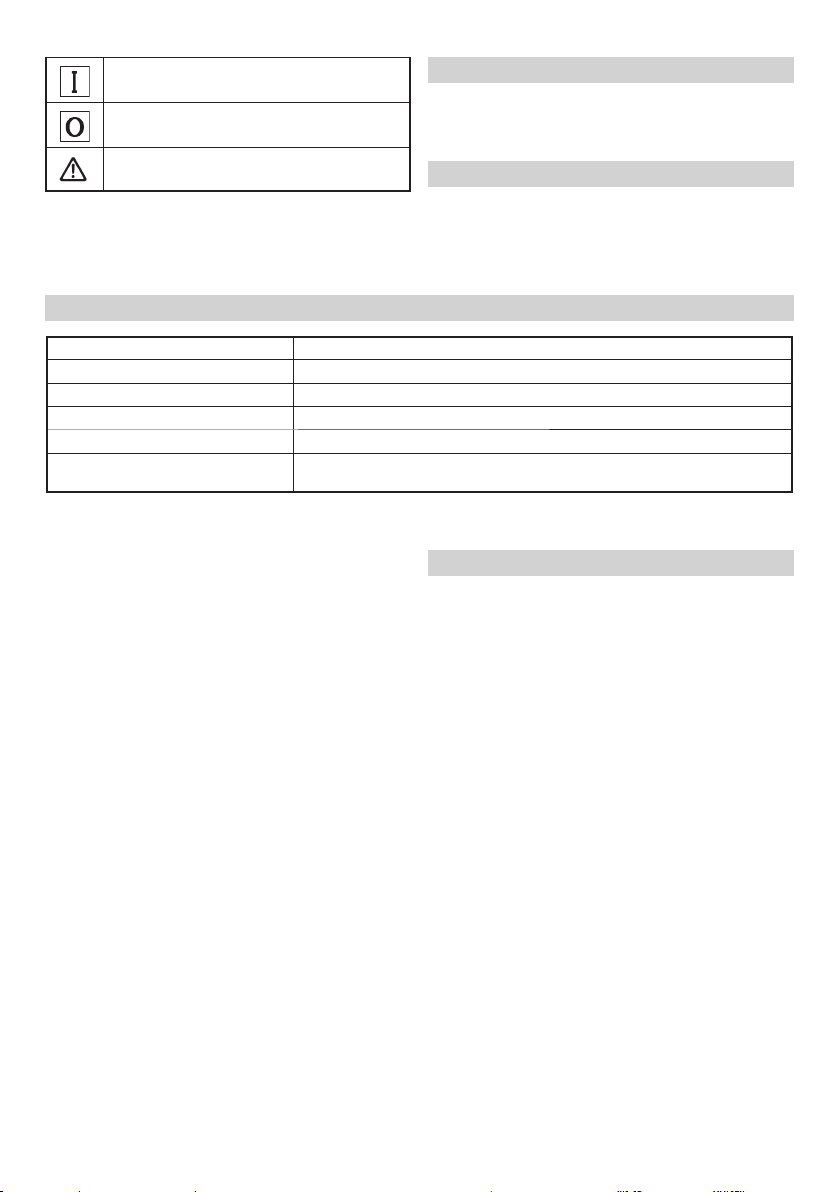

4. Be careful of brake kickback.

This cordless die grinder features an electric brake that

functions when the switch is released. As there is some

kickback when the brake functions, be sure to hold the

main body securely.

5. Do not use the product if the tool or the battery terminals

(battery mount) are deformed.

Installing the battery could cause a short circuit that

could result in smoke emission or ignition.

6. Keep the tool’s terminals (battery mount) free of swarf

and dust.

○Prior to use, make sure that swarf and dust have not

collected in the area of the terminals.

○During use, try to avoid swarf or dust on the tool from

falling on the battery.

○When suspending operation or after use, do not leave

the tool in an area where it may be exposed to falling

swarf or dust.

Doing so could cause a short circuit that could result in

smoke emission or ignition.

PRECAUTIONS FOR BATTERY AND

CHARGER

1. Always charge the battery at an ambient temperature of

-10–40°C. A temperature of less than -10°C will result in

over charging which is dangerous. The battery cannot be

charged at a temperature greater than 40°C.

The most suitable temperature for charging is that of

20–25°C.

2. Do not use the charger continuously.

When one charging is completed, leave the charger for

about 15 minutes before the next charging of battery.

3. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

4. Never disassemble the rechargeable battery or charger.

5. Never short-circuit the rechargeable battery.

Short-circuiting the battery will cause a great electric

current and overheat. It results in burn or damage to the

battery.

6. Do not dispose of the battery in fire.

If the battery is burnt, it may explode.

7. Using an exhausted battery will damage the charger.

8. Bring the battery to the shop from which it was purchased

as soon as the post-charging battery life becomes too

short for practical use. Do not dispose of the exhausted

battery.

9. Do not insert objects into the air ventilation slots of the

charger.

Inserting metal objects or flammable into the charger air

ventilation slots will result in an electrical shock hazard or

damage to the charger.

CAUTION ON LITHIUM-ION BATTERY

To extend the lifetime, the lithium-ion battery equips with the

protection function to stop the output.

In the cases of 1 to 3 described below, when using this

product, even if you are pulling the switch, the motor may

stop. This is not the trouble but the result of protection

function.

1. When the battery power remaining runs out, the motor

stops.

In such a case, charge it up immediately.

2. If the tool is overloaded, the motor may stop. In this

case, release the switch of tool and eliminate causes of

overloading. After that, you can use it again.

3. If the battery is overheated under overload work, the

battery power may stop.

In this case, stop using the battery and let the battery

cool. After that, you can use it again.

Furthermore, please heed the following warning and caution.

WARNING

In order to prevent any battery leakage, heat generation,

smoke emission, explosion and ignition beforehand, please

be sure to heed the following precautions.

1. Make sure that swarf and dust do not collect on the

battery.

○During work make sure that swarf and dust do not fall on

the battery.

○Make sure that any swarf and dust falling on the power

tool during work do not collect on the battery.

○Do not store an unused battery in a location exposed to

swarf and dust.

○Before storing a battery, remove any swarf and dust that

may adhere to it and do not store it together with metal

parts (screws, nails, etc.).

2. Do not pierce battery with a sharp object such as a

nail, strike with a hammer, step on, throw or subject the

battery to severe physical shock.

3. Do not use an apparently damaged or deformed battery.

4. Do not use the battery in reverse polarity.

00BookGP18DAUK.indb800BookGP18DAUK.indb8 2021/03/0415:38:102021/03/0415:38:10