Sovol SV01 Manual

SV01

Guide Book

To make Top-quality 3d printer

V.2.0En

Select the correct input voltage to mach your local mains (220V or 110V).

Not use the printer any way other than described here in order to avoid personal injury or property damage.

Do not place the printer near any heat source or ammable or explosive objects. We suggest placing it in a well-ventilated,

low-dust enviroment.

Do not expose the printer to violent vibration or any unstable enviroment, as this may cause poor print quality.

Before using experimental or exotic laments, we suggest using standard laments such as ABS or PLA to calibrate and test

the machine.

Do not use other power cable except the one supplied. Always use a grounded three-prong power outlet.

Do not touch the nozzle or printing surface durint operation as they may be hot. Keep hands away from machine while in

use to avoid burns or personal injury.

Do not wear gloves or loose clothing when operate the printer. Such cloths may become tangled in the printer moving parts

leading to burns. Possible bodily injury, or printer damage.

When cleaning debris from the printer hotend, always use the provided tools. Do not touch the nozzle directly when heated.

This can cause personal injury.

Clean the printer frequently. Always turn the power off when cleaning, and wipe with a dry cloth to remove dust, adhered

printing plastics or any othe material off the frame, guide rails, or wheels. Use glass cleaner or isopropyl alcohol to clean the

print surface before every print for consistent results.

Children under 10 years of age should not use the printer without supervision.

1

2

3

4

5

6

7

8

9

10

11

Notes

Preface

This Guide is designed for Sovol users to start their

printing journey.

We still recommend that please read this guide even if

you are familiar with the 3d Printing technology, as

there are lots of important information about the sovol

for you get a better 3d experience.

In this guide there are links to video tutorials and

downloads, use the Qr-codes or Click to access.

Additional resources and information:

(1) Quick start Guide

Quick start user guide or video found on the Micro Sd

card.

(2) Ofcial website: www.sovol3d.com

Find out all the latest news which contains the

up-to-date information concerning software, rmware,

device maintenance and so on.

3) Sovol Ofcial User Group on Facebook.

Be a part of the Sovol community sharing your projects

and helping each other.

Index

Index

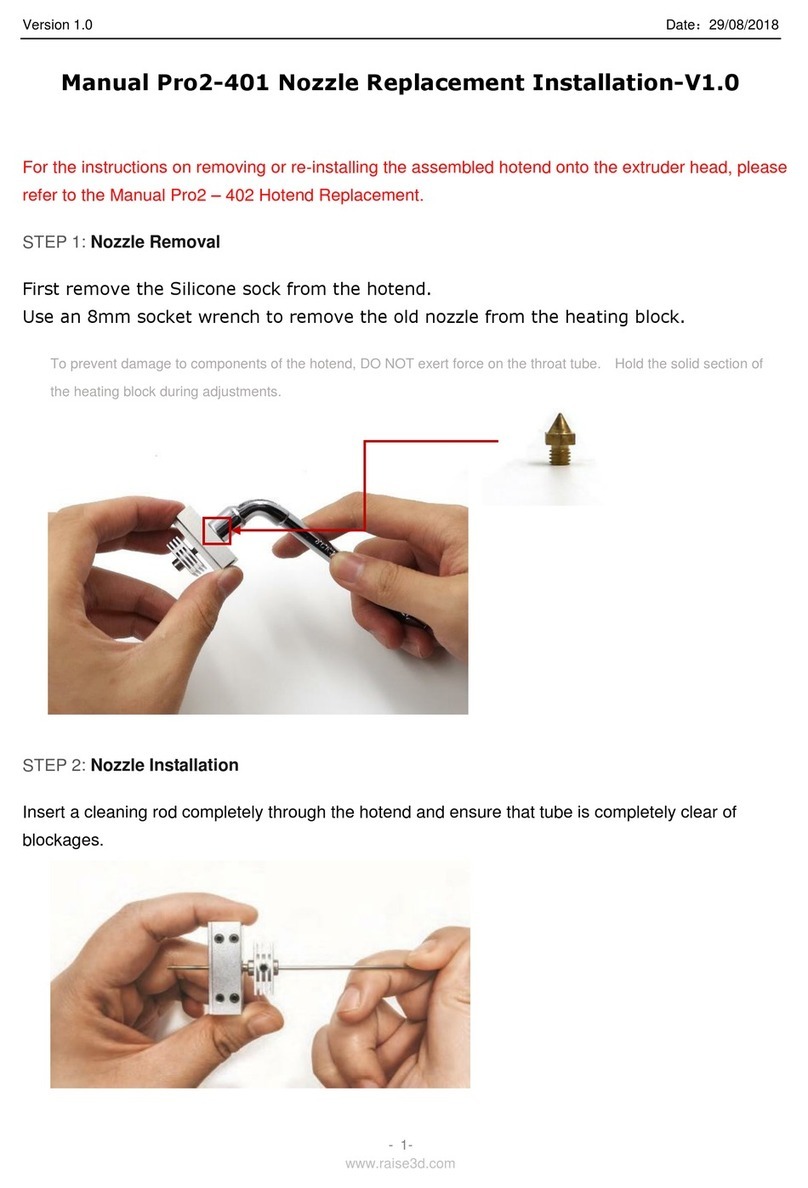

02 Printer Parts

03 Box Contens

04 Assembly

08 Cable Connection

09 Quality Adjustments

10 Screen Information

11 Bed Leveling

12 Loading Filament

13 Software Installation

14 Preparing to Print

15 Conection Diagram

16 BLTouch Installation

17 After-Sales Service

01

02

1

2

3

4

5 6

7

8

9

10

11

12

13

14

15

16

Printer Parts

1. X Axis Motor

2. Main control box

3. Hot bed

4. TF Card and Usb

5. Display screen

6. Button knob

7. Nozzle kit

8. Extrusion kit

9. Filament holder

10. Filament sensor

11 Couplers

12. Y Axis Motor

13. Foot pad

14. Z Axis Motors

15. Power switch

16. Leveling nut

1

2

3

4

5

6

7

8

9

10

11

12 13 14

Box Contens

03

1. Gantry

2. Base with hot bed

3. Filament holder

4. Display Screen

5. Usb cable

6. Z Axis switch limit plate

7. Screws, T-Nuts and extra nozzle

8. Micro SD card and Reader

9. Power cable

10. Filament (200gr.)

11 Pliers

12. Spatula

13. Tool set

14. Nozzle cleaner (0.4mm)

Assembly Steps 1-2

4

M5x25 + WASHERS (4 Units)

Front

A

1

Remove the parts from the box.

Note that the base and gantry are

connected at the factory. If possible,

perform this operation with the help

of another. Remove any tape and

padding from the parts. Inspect the

parts to make sure they were not

damaged in shipment.

Install the gantry (A) to the base (B).

a) On the gantry frame make sure

the nozzle assembly is in to the

front, and the long vertical leads

screws is in to the back.

b) On the base frame, make sure

the black belt tensioner is on the

front, and the stepper motor is on

the back.

Use the M5x25 screws (4) with their

washers. Lift the base frame. Install

the screws through the base frame

into the threaded holes in the gantry

frame. Tighten with an Hex key

(Allen). Do not exceed tightening to

avoid deformations in the frame.

1

2

2

B

04

Front

4mm

33Install the lament spool holder.

Secured in the screw hole of the

lament holder with M4x8 (2)

and M4 T-Nut (2). Loosen the

T-nuts by hand and turn them so

they will t inside the grooves on

the frames.

You want the nuts to be loose so

that when you tighten the bolts,

the nut will rotate 90° and grab

onto the inside of the groove.

Tighten with an Hex key (Allen).

Assembly - Step 3

05

M4x8 + T-NUTS (2 Units)

2.4mm

4

5

4Install the lament sensor.

The plate with the lament sensor is

installed in the upper rear part of the

frame. The correct direction is indicated by

an arrow on the sensor housing. Fixing to

the frame is similar to the method used

previously. Use the M4x8 (2) screws with

M4 T-Nut (2). Loosen the T-nuts by hand,

when you tighten the screws, the nut will

rotate 90° and grab onto the inside of the

groove.

Install the Lcd screen.

The screen is mounted on the right front of

the base frame. Use the M5x20 (2) screws

provided with their washers. Install the

screws throught the Screen plate into the

threaded holes in the bottom frame.

In another step, we will explain how to

make screen connections

5

06

M5x20 + WASHERS

(2 Units)

M4x8 + T-NUTS (2 Units)

Assembly - Steps 4-5

2.4mm

4mm

07

Assembly - Step 6

6

6Install the Z limit switch

This device sets the starting height of the

Z axis, which is responsible for the up and

down movement of the print head.

It is placed next to the left Z stepper motor

and xed to the edge of the vertical frame

using the included T-nuts.

Loosen the T-nuts, place a card or slightly

thick paper in the bottom frame and rest

the sensor plate on the top. This will

provide the correct minimum height,

slightly above the horizontal prole. Tighten

the screws and connect the 2-wire

connector labeled "Z".

M4x10 + T-NUTS (2 Units)

3mm

X

EXP1

EXP2

Z

E

4-WIRE CONNECTORS

X Y Z

2-WIRE CONNECTORS

ZZ EYX

FD

Y

Z

ZY

X

Make connections

The cables are provided with

labels, observe them and the type

of connector for proper

identication.

Make the connections being

careful not to bend the connector

pins.

The display board has three

identied inputs. Connect the

Exp1 and Exp2 cables in their

corresponding place leaving the

Exp3 input empty..

Cable Connection

08

IMPORTANT

Do not forget to place the voltage selector in the position

corresponding to your local mains (220V or 110V).

Use a grounded electrical outlet.

Quality Adjustments

09

Sovol printers are pre-assembled at the

factory, however, to obtain the best print

quality, some adjustments must be made.

Eccentric nut adjustments.

In each movement group there are some

wheels provided with eccentric nuts.

You must adjust them to get enough

rmness and smooth movement at the

same time. Properly adjusted, you should

be able to turn the wheels with your

ngers with a little force.

The adjustment of the wheels that guide

the Z axis also helps to have a

synchronized movement of both sides of

the horizontal prole and the correct

leveling of them.

Belt adjustments.

The X and Y axis are moved by belts.

At the end of each axis there is a

tensioner that can be adjusted. Check

regularly that the belts have enough

tension.

3mm

1 3

542

6

7

10

11

8

9

1. SET TEMPERATURE NOZZLE

3. SET TEMPERATURE HOT BED

5. LAYER FAN SPEED (%)

7. PRINT SPEED (%)

9. PRINT PROGRESS

11. BUTTON KNOB

> PRESS: Conrm/Enter Sub Menu ROTATE: Move/Change value

2. CURRENT TEMP. NOZZLE

4. CURRENT TEMP. HOT BED

6. CURRENT LOCATION NOZZLE

8. PRINT TIME

10. PROMPT MESSAGE

Screen Information

10

Prepare

Control

No Card/

Print TF

Disable

Steppers

Move Axis

Auto Home

Not Printing (Sovol ready)

Menu Sub Menu

Moving X, Y, Z axis

or Extruder by imputing

Close motors and move X, Y, Z

axis by hands

Return to Zero

Explanation

Temperature

Heats hotend and bed, fan speed

or set the preset Pla/Abs preheat

entering a value

Store

Settings

Save the modied

conguration in memory

Initialize

EEPROM Restore factory settings

No card in the printer /

Print from TF card

Cooldown Turn off the heaters

Preheat Pla

Preheat Abs

Preheat hotend, bed or both

at the preset temperature

Tune

Pause

Stop

Speed

Nozzle

Bed

Fan Speed

Flow

PRINTING

Menu Sub Menu

It allows to modify:

print speed, fan speed,

nozzle temperature,

bed temp. and lament ow

while printing

Explanation

Pause printing, resume

Stop printing

Bed Leveling

11

1.Prepare > Auto Home

2.Prepare > Disable Steppers

3.Prepare > Preheat PLA > Preheat PLA Bed

Run the sequence to level

1. Auto Home - The nozzle will move to the

zero point on the XYZ axes.

2. Disable Steppers - The motors are

released to allow manual movement.

3. Preheat Pla Bed - Optional, but

recommended to recreate the printing

temperature conditions.

Slide a paper between the bed and nozzle

If necessary, adjust the bed so that the

paper can be placed in the rst corner.

Level the four corners of the bed

Adjust each of the four thumbscrews under

the bed until the piece of paper slides, with

just a tiny bit of drag, in all locations on the

build plate.

When nished, cool the bed, if heated, using

the menu Prepare>Cooldown

Tip: The Z axis motors are also disabled. So

you should handle the print head gently

keeping it at during the leveling process. If

you put too much pressure, you will lose the

initial Z position obtained with Auto Home

getting an invalid leveling.

TOO FAR

The lament can not

adhere to the platform.

CORRECT DISTANCE

Filament are extruded evenly

just sticking on the platform

TOO CLOSE

Filament are not extruded

enough, even scraping the platform

2

4 3

1

1

2

3

Loading Filament

12

Prepare > Preheat PLA > Preheat PLA End

-

Prepare > Preheat ABS > Preheat ABS End

METHOD 1

Control > Temperature

> Nozzle > 200°

METHOD 2

Printing: Cut the lament in use near the extruder, feed slowly with the new lament

until the extruder takes it.

Not printing: Preheat the nozzle at least to the melting temperature of the lament

that is installed. Pull the lament to remove it, insert the new lament and feed until

it comes out of the nozzle.

TIP: HOW TO REPLACE THE FILAMENT ?

Heat the nozzle

Method 1: Use the printer's Preheat

presets to heat Pla or Abs temperature

according to the temperature range of

the lament you are going to use.

Method 2: Set the temperature

manually in the printer menu Control

Pass the lament through the sensor

Insert the lament into the extruder

When the nozzle is hot, press and hold

the extruder lever, and insert the

lament through the small hole of the

extruder until it comes out of the

nozzle.

When nished, cool the nozzle, using

the menu Prepare>Cooldown

1

2

3

Software Installation

13

Cura.exe

Install Cura

There is a Cura installer on

the MicroSd card included

with the printer.

To download the latest

version visit the website of

Ultimaker

Open Cura and add a New

Printer

Choose Creality Cr-10 as

the base prole and change

the name to Sovol Sv01.

Adjust the size

Enter 280mm, 240mm and

300mm as the printer size

for X, Y and Z.

Congure retraction

The main difference

between Sovol Sv01 and

Cr-10 is the Direct Drive

Extruder. Retraction

distance values of ~ 3mm

and ~ 50mm/s as

retraction speed are

suitable.

1

2

3

4

Load a model in Cura

On the SD card you will nd a

calibration cube so you can

perform an initial test.

Choose settings

Cura has a menu with basic

print settings. If you want

advanced settings, click

Custom.

Make the Slice

Cura will perform the

necessary calculations and

generate a gcode le with the

paths and parameters for the

printer.

Save the gcode le to the card

Use the USB reader provided

with the printer.

Print the model

Insert the SD card upside

down in the printer, select the

gcode le in the menu and

print.

1

2

3

5

4

Install Cura

There is a Cura installer on

the MicroSd card included

with the printer.

To download the latest

version visit the website of

Ultimaker

Open Cura and add a New

Printer

Choose Creality Cr-10 as

the base prole and change

the name to Sovol Sv01.

Adjust the size

Enter 280mm, 240mm and

300mm as the printer size

for X, Y and Z.

Congure retraction

The main difference

between Sovol Sv01 and

Cr-10 is the Direct Drive

Extruder. Retraction

distance values of ~ 3mm

and ~ 50mm/s as

retraction speed are

suitable.

Preparing to Print

14

xyz-cube.stl

> Print from TF > xyz-cube.gcode

BLTouch Installation

16

BLTouch is an optional device for

automatic leveling. Installation

requires the disassembly of the

printer base and the rmware

update.

BLTouch device assembly

Watch the linked videos for a

detailed guide.

Download Firmware

On our website you will nd an

updated Firmware for BLTouch,

pay attention to download the

correct version.

sovol3d.com/pages/download

Update the Firmware from Cura

Open Cura, connect the printer to

your computer using the Usb

cable and load the Firmware from

Printer Preferences into the Cura

software. Wait without

disconnecting until the process is

nished.

In our video tutorials you will nd

an alternative method.

1

2

3

DON’T YOU HAVE A BLTOUCH?

Go to sovol3d.com and get yours.

SOVOL VIDEO

youtu.be/s_Bh4_cOWXY

SOVOL VIDEO

youtu.be/BTCXNLIzrz8

After-Sales Service

17

Service

1.The printer can be returned within seven days, 15 days replacement, one-year warranty, lifetime maintenance.

Every machine is assembled and tested by our expert staff before departing our facilities.

Replacement requirement

1. The appearance of the product is intact, without damage, cracks, deformation, etc.;

2. Machine is complete including all parts, tools, original box, and foam padding;

3. Provide a valid purchase invoice, product numbers should be the same.

Warranty coverage

1. The following accessories are not included in the warranty coverage ( unless damaged by transportation): platform sticker;

platform forming plate; acrylic cover; card reader and TF card; platform glass; USB cable; lament; rack and tools, etc.

2. Prole: Small blemishes in the black paint due to testing or shipping are not covered in the premise that the blemish does not

affect normal use;

3. Nozzle assembly (nozzle, heating block, throat pipe , heat sink, Teon tube, etc.) warranty period is 3 months. If damage occurs

after the warranty expires, you will be responsible for replacement;

4. 12 Month Warranty on the motherboard, LCD display, power supply, heated bed. The free warranty maintenance is provided by

the original factory over the warranty period. After Warranty expires, original factory maintenance is available, but the customer is

responsible for shipping and maintenance costs;

Not included in warranty coverage:

1. It will be difcult to provide an effective warranty service if you can not provide a correct serial number;

2. The whole machine and components exceed the warranty period;

3. Equipment failure or damage caused by unauthorized modication of the equipment (private modication includes:

a) modication of the nozzle assembly; b) modication of the machine structure; c) use of third-party components;

d) use of third-party rmware procedures or change the original Factory rmware program, etc.);

4. Equipment failure or damage due to incorrect installation and use;

5. Equipment failure or damage caused by use in a non recommended working environment specied by this manual

(Unstable, dusty, moisture);

6. Equipment failure or damage due to improper use (beyond workload, etc.) or maintenance;

7. Equipment failure or damage due to the use of other branded components or other inferior consumables.

Table of contents

Other Sovol 3D Printer manuals

Popular 3D Printer manuals by other brands

Hello Bee Prusa

Hello Bee Prusa DIY 3D PRINTER KIT user manual

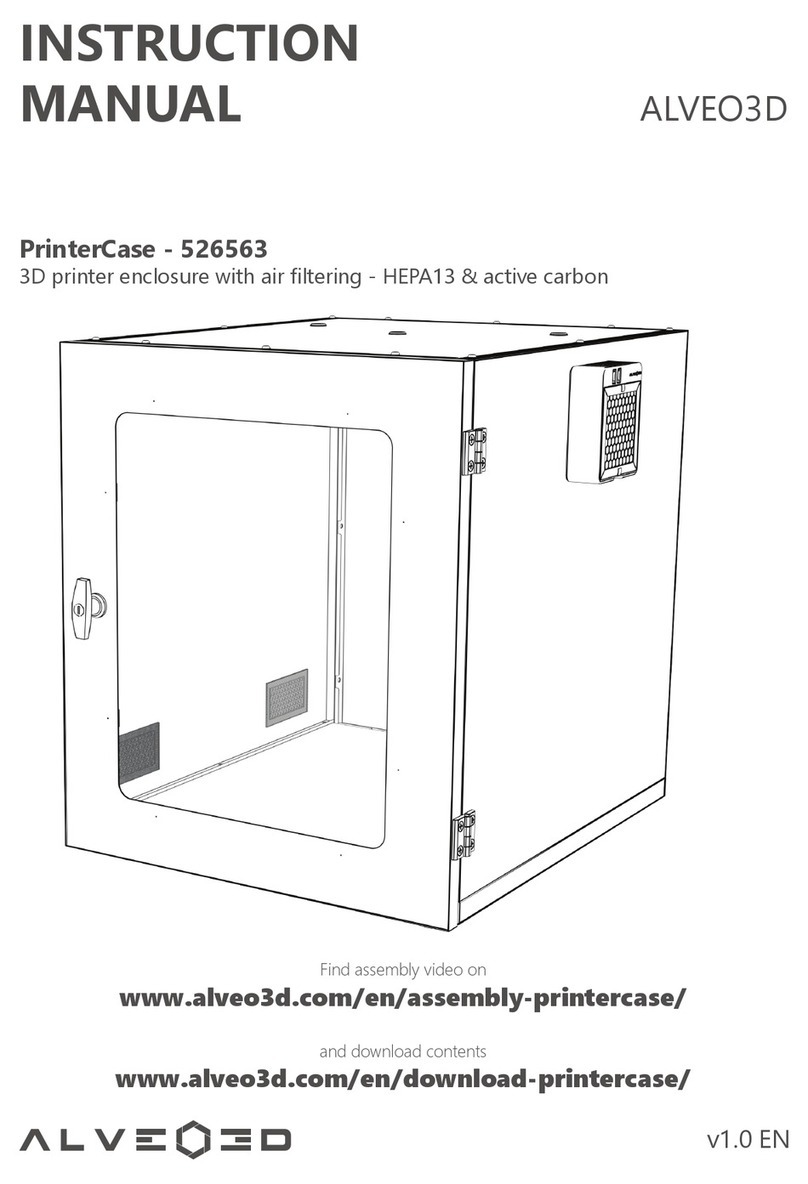

ALVEO3D

ALVEO3D PrinterCase instruction manual

Mingda

Mingda Magician X Instructions for assembly

TUKKARI

TUKKARI TS Acrylic Assembly instructions

Blackbelt 3D BV

Blackbelt 3D BV BLACKBELT 3D Printer Installation & user manual

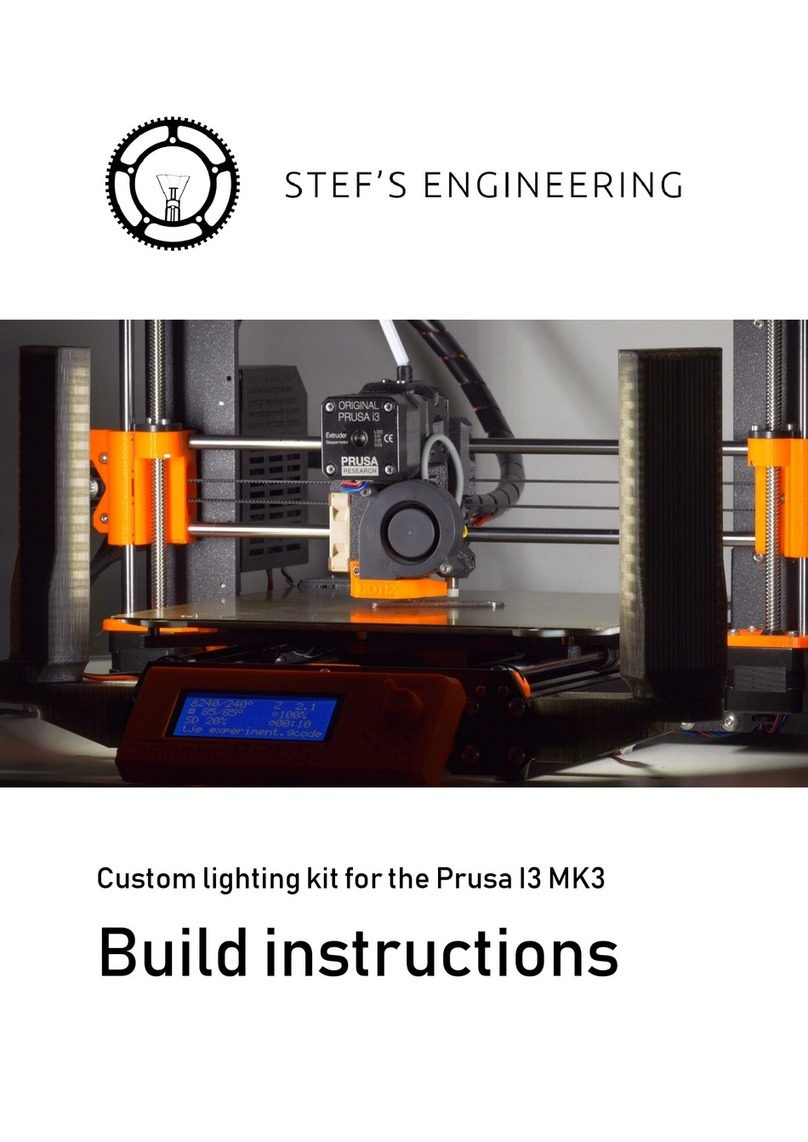

Stef's Engineering

Stef's Engineering Prusa I3 MK3 Build instructions