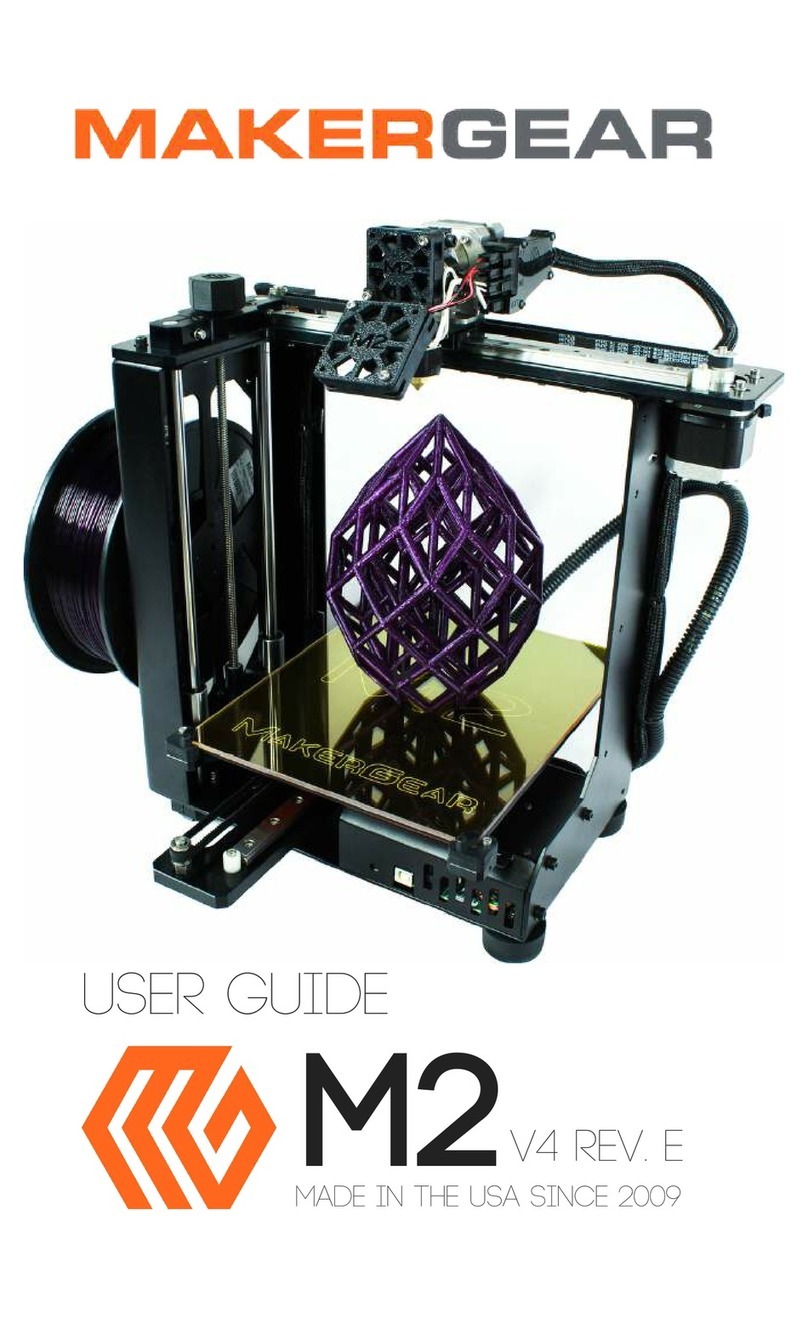

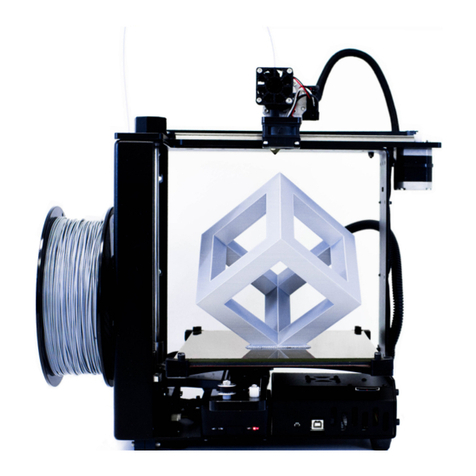

Step 1: Using the QuickStart App, print “hexa.g” from the included SD

card, which we have sliced for you using Simplify3D software. This

should take about 15 minutes to print and will serve as a comparison to

your sliced version of the same model.

Step 2: Remove your SD card from the card reader on your M2 and in-

sert it into your computer’s card reader — this will enable signicantly

faster transfer of les between you computer and the SD card. For com-

puters that do not have an SD card reader, external card readers that

connect to your computer via USB are available.

8

Slicing Files

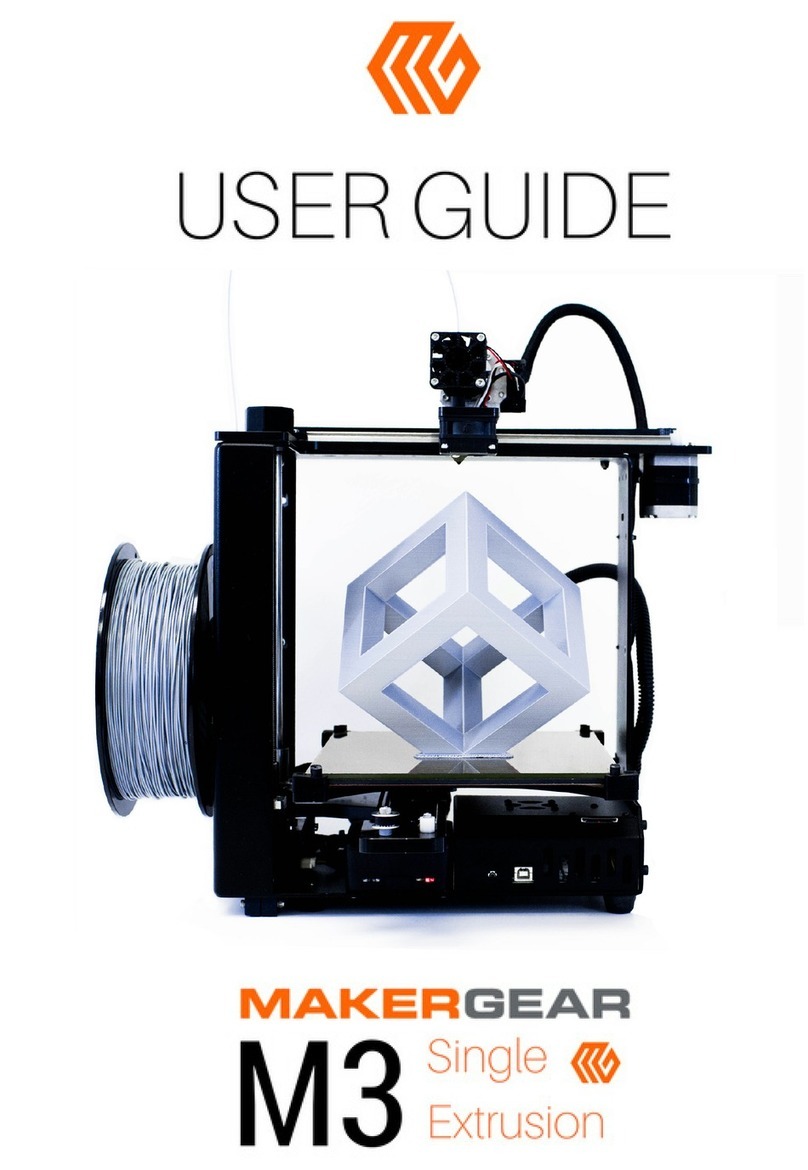

If you try to dowload and print a le from the internet, you’ll notice its

format is either .STL or .OBJ, which your M2 is unable to read. In order

to print these les, you must use special software designed to“slice”

them into“.g” or “.gcode” format — this le format, known as G-Code,

gives your M2 step-by-step commands for where/how to extrude ma-

terial. The steps listed below will help you set up your slicer settings to

slice a .STL le stored on your SD card into .g format.

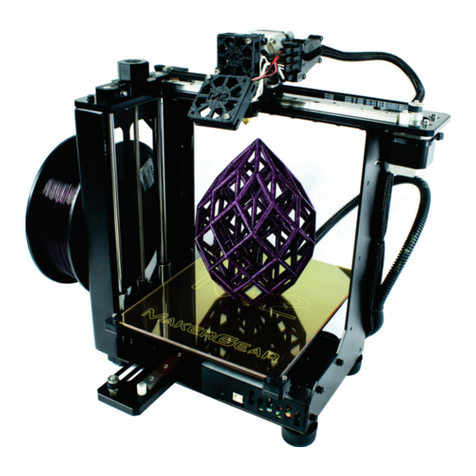

Step 3: Download the most recent Slic3r from slic3r.org. Your slicer

settings will be incorrect. To correct them, click “Load Cong Bundle”

under “File”and select the “cong.ini” le available on your SD card.

Step 4: Import “hexa.stl” into your slicing software, slice the le (i.e.,

click export in .g format), and then name it “hexa2.g”. Transfer this new

.g le to your SD card, eject the card from your computer, and then

insert it back into the card reader on your printer.

Step 5: Use your printer control software (e.g., Printrun by Pronterface,

available at http://www.pronterface.com/#download) to instruct your

M2 to print hexa2.g from your SD card.