1

TRAK Machine Tools

Southwestern Industries, Inc.

TRAK 3ntr 3D Printers –Printer & MMS Guide

1Introduction

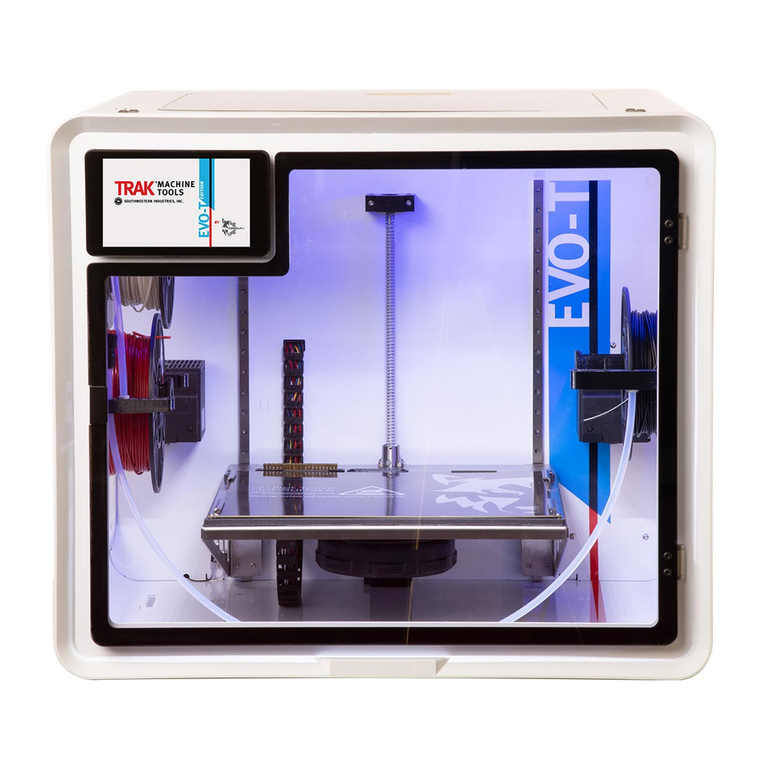

Congratulations! Whether you purchased a TRAK 3ntr A2 or A4, you have an industrial-grade, 3D printer

that will produce high quality, functional parts, using an accurate and repeatable FFF print process, at low

cost per part.

TRAK 3ntr 3D Printers offer:

•An open materials platform enabling selection of a wide range of materials

•Complete flexibility in tailoring/tuning process settings and part characteristics

•Temperature controlled build chambers and printer plates

oNozzles up to 840° F (450°C)

oBed Up to 320° F (160° C)

oChamber up to 194° F (90° C)

•Generous build capacity/volume

oPrint Parts up to 24”x13”x19” for the A2

oPrint Parts up to 12”x7.5”x 8” for the A4

•Simultaneously prints 2 or 3 different print materials

•Integrated camera offering remote web monitoring

•Optional Material Management System to protect expensive environmentally sensitive materials

•KISSlicer software that converts STL files to printer ready g-code programs

•HEPA Filter

1.1 Printer Guide Overview

This Printer Guide covers the following topics:

•Initial printer installation, connection, set-up, and calibrations

•Operating the printer manually from the LCD front panel

•Everyday operating, print job set-up, & maintenance procedures

•Before you print

•Printing parts

•Calibrating the printer

•Maintaining the printer

•Troubleshooting machine/print problems

•Some basic information about print materials

Programming of the TRAK 3ntr 3D printers is not covered within this Printer Guide because programming

is performed with separate slicing software that outputs a printer program file (G-code). The TRAK 3ntr

is supplied with KISSlicer software and associated reference files necessary to make G-Code files for

printing, please consult the appropriate manuals for that software in order to create G-code files for

printing.

NOTE - Despite the best efforts for completeness, the scope and detail of the Printer Guide set-up,

calibration, operation, and maintenance manual contents can be somewhat limited. Where additional

information is required please consult the appropriate manual or contact your dealer.