Sovol SV02 Manual

V.1.0

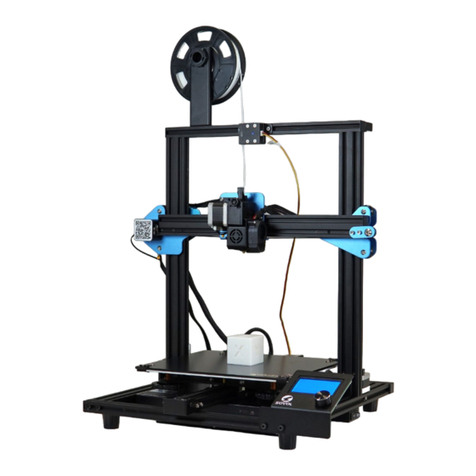

SOVOL-SV02 Printer

Guidebook To:

Constructing Sovol’s Top-quality 3D printer

This guidebook is for Sovol’s SV02 3D printer.

Select the correct input voltage to match your local mains

(220V or 110V).

Please plug the power cord into a three-hole power jack.

Detailed instructions for use are available on the SD card.

Notes

1

2

3

4

5

6

7

8

9

10

Do not use this machine in any way other than described herein. Failure to do so may result in personal

injury and/or damage to property.

Do not place the printer near any heat source or flammable or explosive materials. We suggest placing it

in a well-ventilated, low-dust environment.

Do not expose the printer to violent vibration or any unstable environment, as this may cause poor print

quality.

Before using experimental or exotic filaments, we suggest using standard filaments such as ABS or PLA to

calibrate and test the machine.

Do not use any other power cable except the one supplied. Always use a grounded three-prong power

outlet.

Do not touch the nozzle or printing surface during operation as they may be hot. Keep hands away from

machine while in use to avoid burns or personal injury.

Do not wear gloves or loose clothing when operating the printer. Such cloths may become tangled in the

printers moving parts leading to burns, possible bodily injury, or printer damage.

When cleaning debris from the printer hotend, always use the provided tools. Do not touch the nozzle

directly when heated. This can cause serious burns and injuries.

Clean the printer frequently. Always turn the power off when cleaning, and wipe with a dry cloth to

remove dust, adhered printing plastics or any other material off the frame, guide rails, or wheels . Use

glass cleaner or isopropyl alcohol to clean the print surface before every print for consistent results.

Children under 10 years of age should not use the printer without supervision.

1

Contents

Preface

This Guide is designed for Sovol users and contains vital

information regarding the SV02 to assist in your 3D printing

journey.

We recommend that all users read and understand the

information in this guide, even if you are familiar with 3D

Printing technology.

Additional resources and information:

(1) Quick Start Guide

Quick Start with user guide or view the video on the TF card.

(2) Official Website: http://www.sovol3d.com

Find out all latest news which contains the up-to-date

information concerning software, firmware, device

maintenance and so on.

(3) Sovol User Group on Facebook. Be a part of the Sovol

community sharing your projects and helping each other.

01 ......................... Contents

02 ......................... Introduction

03 ......................... General List

04 ......................... Assembly

06 ......................... Cable Connection

07 ......................... Screen Information

08 ......................... Loading Filament

09 ......................... Bed Leveling

10 ......................... Software Installation

11 ......................... Slicing

12 ......................... Preparing to printing

13 ......................... Circuit Wiring Diagram

14 ......................... After-Sales Service

Filament Holder

Gantry

Assembly

Extruders

Hot end

Hot bed

Touch- Screen

No.

Image

Name

Qty

1

Wrench &

Screwdriver

1set

2

TF Card & Reader

1set

3

Spatula

1

4

Pliers

1

5

0.4mm

Nozzle Cleaner

1

6

Power Cable

1

7

USB Cable

1

8

Spare Parts

1set

on-off control

2

Tool List 1

Gantry Assembly Base

Tool Box

Display screen Filament Holder(*2)

Tool List 2

3

Filament (200g)

No.

Image

Name

Qty

9

M5x25 Black Hex-Bolt and Lock Washer

4

10

Z-axis limit plate assembly

1set

11

M3x4 Screw

4

12

Touch screen support

1

Front

Back

4pcs

M5X25

Gantry Frame Installation

4

1. Carefully remove all parts from the box

and remove any tape or padding from them.

a. Inspect each component and ensure

nothing was damaged during shipment.

Gantry

Base

2. Install the gantry frame (A) to the base frame (B)

a. On the gantry frame, make sure the nozzle assembly is to the front, and

the long vertical lead screw is to the back. On the base frame, make sure

the black belt cover is on the front, and the stepper motor is on the back.

b. Use the M5x25 screws (4) and lock washers (4). Lift the base frame.

Install the screws through the base frame into the threaded holes in the

gantry frame. Tighten with the M5 hex key (Allen) wrench.

Filament Holder Installation

Z-axis limit plate installation

4pcs

M4 T-nut

M4X6

3. Installation of the filament spool holder.

a. Secure the filament holder using two M4*8 screws and

T-nuts. Loosen the t-nuts by hand and align them so

they will fit inside the grooves of the frame. It is

essential that the nuts are loose so that when you

tighten the screws, the nuts will rotate 90° and grab

onto the inside of the groove of the extrusion.

b. Align the round cylinder through the hole of the

filament plate. Turn the large nut to lock in place.

4. Installation of the Z-axis limit plate.

a. The Z-axis limit switch board is installed at the lower

left of the gantry, and the installation method is the

same as that of the filament bracket.

5. Touch Screen Display installation.

a. Attach the bracket to display with M3x4 screws (4)

b. Mount the touchscreen to the front right side of the

frame with M4x6 screws (2) and T-nuts (2).

C

2pcs

M4X10 M4 T-nut

5

Display screen Installation

2pcs

M4 T-nut

M4X6

Y

X

Z

The Y cables go to the motor and

switch at the back of the base frame

that move the build plate.

The Z cables go to the motor and

switch on the left side of the base

frame that raise and lower the nozzle.

The X cable is connected to the

motor and running belt switch

Tip: Try not to bend the

pin connectors as you push

them in. Pay attention to the

working voltage of your

machine

*Plug the power cord into a

three-hole power jack.

6

Select the correct input voltage to match your

local mains (220V or 110V).

Ribbon Cable

Touch Screen Cable

Information Displayed

7

Print Speed

Automatic

Manual

Cooling

Fan

Levelling

Refuel

Moving

Motor

Printer info

Language

Set temperature

of the Nozzle

Current temperature

of the Nozzle

Set temperature

of the Nozzle

Current temperature

of the Nozzle

1. Preheat

Method 1

Method 2

2. Feeding Filament

Press and hold the extrusion clip, insert the filiment from the

inlet to the position with red line above the small pneusmatic

connector.

Tip : How to Replace the Filament ?

1. Preheat the nozzle.

Push and hold extruder arm and feed 5-10mm of filament

by hand, then quickly withdraw the filament.

Using this method helps to avoid pulling liquid filament

through the PTFE tube, potentially causing clogs.

8

1. Tighten the four levelling nuts at the bottom of the platform before

initial levelling.

2. Select Settings→Levelling, click on the number ②

3. Adjust the platform height by turning the knob underneath. Use a piece

of A4 paper (standard printer paper) to assist with the adjustment,

making sure that the nozzle lightly scratches the paper.

4. Complete the adjustment of the screw on all 4 corners.

5. Click the number ① to test whether the middle gap of the platform is

suitable.

6. Repeat above steps 1-2 times if necessary.

7. Slight adjustments can be made while brim

or first layer is printing.

9

5

1

2 3

4

Pro Tip: If the hot bed is not perfectly level

and adjusted, the Z axis compensation

function can be used when printing the first

layer to get a perfect first layer.

10

1. Install the Cura 4.5

2. Add the machine

(How to add the choice of SV02 Machine in Cura, please refer to 'SV02 Machine

Profile guide.docx' in the 'Machine Profile' folder in SD card.)

11

1. Add and merge the models 2. Select custom

3. Select the profile “Draft” 4. Select Enable Prime Tower

1. Save file to SD card

Insert SD card into computer with Reader.

2. Printing

Select “Print from SD”

Select the file to be

printed

Insert the SD card

12

13

Service

1.The printer can be returned within seven days, 15 days replacement, one-year warranty, lifetime maintenance.

Every machine is assembled and tested by our expert staff before departing our facilities.

Replacement requirement

1. The appearance of the product is intact, without damage, cracks, deformation, etc.;

2. Machine is complete including all parts, tools, original box, and foam padding;

3. Provide a valid purchase invoice, product numbers should be the same.

Warranty coverage

1. The following accessories are not included in the warranty coverage ( unless damaged by transportation): platform sticker; platform forming

plate; acrylic cover; card reader and TF card; platform glass; USB cable; filament; rack and tools, etc.

2. Profile: Small blemishes in the black paint due to testing or shipping are not covered in the premise that the blemish does not affect normal use;

3. Nozzle assembly (nozzle, heating block, throat pipe , heat sink, Teflon tube, etc.) warranty period is 3 months. If damage occurs after the warranty

expires, you will be responsible for replacement;

4. 12 Month Warranty on the motherboard, LCD display, power supply, heated bed. The free warranty maintenance is provided by the original factory

over the warranty period. After Warranty expires, original factory maintenance is available, but the customer is responsible for shipping and

maintenance costs;

Not included in warranty coverage:

(1) It will be difficult to provide an effective warranty service if you can not provide a correct serial number;

(2) The whole machine and components exceed the warranty period;

(3) Equipment failure or damage caused by unauthorized modification of the equipment (private modification includes: 1. modification of the nozzle

assembly; 2. modification of the machine structure; 3. use of third-party components; 4. use of third-party firmware procedures or change the original

Factory firmware program, etc.);

(4) Equipment failure or damage due to incorrect installation and use;

(5) Equipment failure or damage caused by use in a non recommended working environment specified by this manual (Unstable, dusty, moisture);

(6) Equipment failure or damage due to improper use (beyond workload, etc.) or maintenance;

(7) Equipment failure or damage due to the use of other branded components or other inferior consumables.

14

SHENZHEN Lian Dian Chuang Technology LTD.

Official Website: www.sovol3d.com

Tel: +86-0755-2107 4700

E-mail: sale@sovol3d.com info@sovol3d.com

Table of contents

Other Sovol 3D Printer manuals