Space-Ray SD-EC User manual

®

INSTALLATION MANUAL

1. General 3

1.1 Descripon 3

1.2 Funcon 3

1.3 Warnings 3

1.4 Warranty

2. Technical Data 3

2.1 Table with technical data 3

2.2 Dimensional data 4

3. Installaon 4

3.1 Suspension 4

3.2 Calculang number of fans required 4

3.3 Posioning 4

4. Electrical Connecons 5

4.1 230VacSupply 5

4.2 Connecon opons 5

4.2.1 Connecon without speed controller 5

4.2.2 Connecon with speed controller 5

5. Seng, Operaon and Maintenance 5

5.1 Seng the thermostat 5

5.2 Operaon 5

5.3 Maintenance 5

6. Wiring Diagrams 6

6.1 SD Destracaon fan with Speed Controller 6

6.2 SD Destracaon fan with ed thermostat only 7

7. CE Declaraon and Disposal 7

7.1 CE declaraon 7

17INSTALLATION MANUAL AIR HEATER TYPE EH

11 Disposal and recycling

The meaning of the symbol on the material, its accessory or packaging indicates that this

product shall not be treated as regular waste. Please, dispose of this equipment at your

applicable collection point for the recycling of electrical and electronic equipments waste.

In the European Union and Other European countries which there are separate collection

systems for used electrical and electronic product. By ensuring the correct disposal of this

product, you will help prevent potentially hazardous to the environment and to human health,

which could otherwise be caused by unsuitable waste handling of this product. The recycling

of materials will help conserve natural resources. Please do not therefore dispose of your old

electrical and electronic equipment with your regular waste.

12 Declaration of conformity

Winterwarm Heating Solutions B.V.

Industrieweg 8

7102 DZ, Winterswijk

The Netherlands

Declares that air heater types:

• EH5, EH10, EH15, EH20, EH25, EH30 & EH40

Are in accordance with the essential requirements of the relevant EU directives, being:

• 2014/35/EU (LVD) relating to the electric safety of appliances

• 2014/30/EU (EMC) relating to electromagnetic compatibility of appliances

• 2006/42/EG (MD) relating to the safety of machinery

Goods should be installed and used in accordance with our instructions and with the applicable local and international rules.

Installation should be done by an authorized, qualified and competent installer.

Winterswijk, December 15th 2020

Ir. M. Fiselier

Director Operations

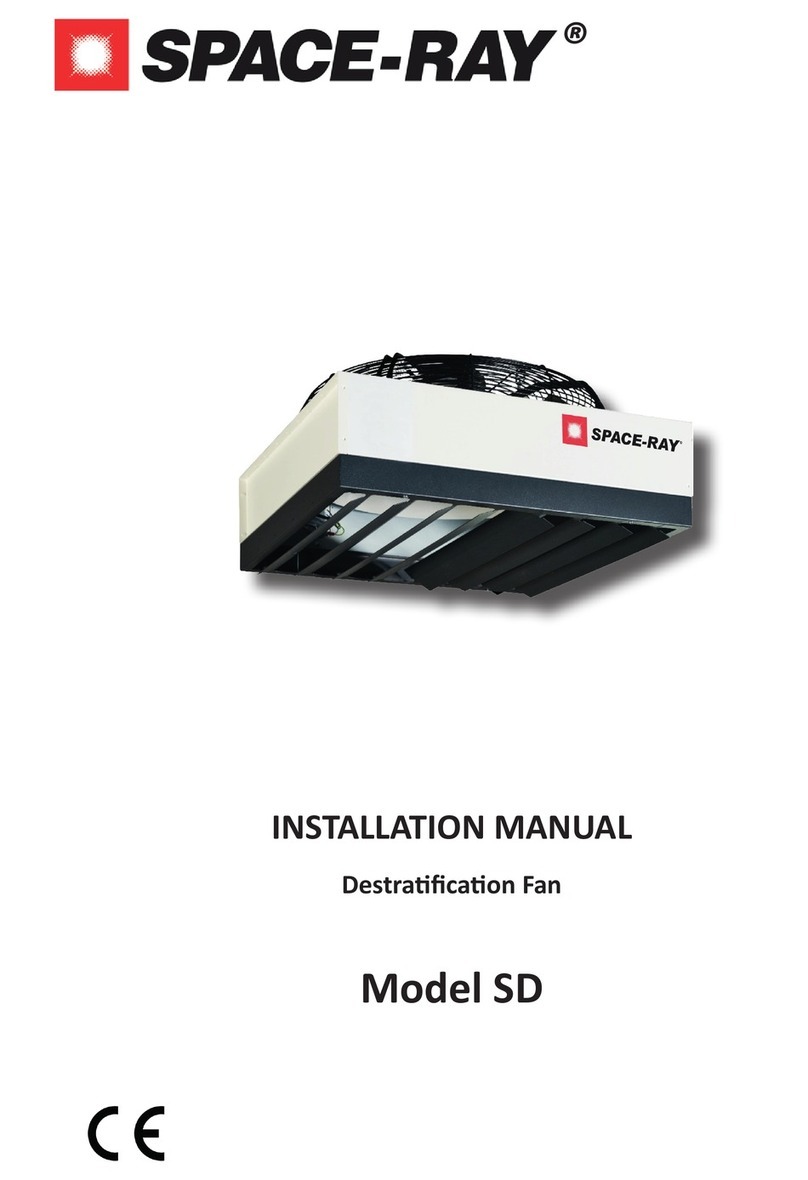

This user’s guide is meant for the installer and if necessary

for the user. It’s a reference to operaon and installaon

of the SD-EC destracaon fan. For the sake of safety

and to guarantee proper funcon, it is vital that you read

this manual thoroughly before starng the installaon, in-

cluding all ps and warnings.

Keep this manual with the appliance and see to it that it is

included when the appliance is moved or sold, to ensure

that during its life, all persons have been informed about

the use and safety aspects of the device.

The SD-EC destracaon fan consists of a metal casing

with a bladed fan & motor ed within a fan guard. There

is an outlet grille with adjustable louvers on the oppo-

site side, which enables the airow to be directed in the

desired direcon. A ed thermostat allows automac

operaon.

The SD-EC destracaon fan is designed to be ed

within the roof space of a building to recirculate e soluon

to achieving this is by ng destracaon fans. These

fans recirculate the, otherwise wasted, warm air gather-

ing within the roof space, to low level. The ed thermo-

stat (SD models) automates this process.

i.e If the room thermostat is set at 25°C, it will switch the

fan on as soon as this temperature is achieved at ceiling/

roof level. The fan will stop when the thermostat detects

a reducon in temperature of approx 1.5°C.

The fan speed can be controlled by:

• 0-10V regulator GA3955

• External power source (0-10V d.c.)

The installaon of a correctly sized destracaon

system, pays for itself quickly due to the signicant energy

savings achieved

This appliance may only be installed and maintaind by a

qualied and competent person.

• The minimum suspension height is 2.7meters. That

is because of safety reasons on touching rotang

parts.

• Disconnect the appliance from the power supply

before performing maintenance on this appliance.

• Cauon, this appliance can start automacally!

• Take care of a safe area when working on this

appliance

• Use cered access equipment.

• Take care of your personal safety. Use safety

gloves and safety shoes.

• This fan can be used by children aged 8 years and

above and by persons with reduced physical, sen-

sory or mental capabilies or lack of experience

and knowledge, if they are supervised or instructed

concerning use of the appliance in a safe way and

understand the hazards involved.

• Children may not play with the fan

• Children may not clean and maintain this fan with-

out supervision.

Operaon/installaon of appliances not in accordance

with this manual will render warranty void. It is not per-

mied to change the specicaons or to make modica-

ons of any kind, to this appliance.

3 3,300 5,700 7,000 10,000

350 450 500 630

0.35 0.45 0.50 0.65

5 to 9 7 to 11 8 to 12 12 to 15

230V 1 Phase N & E - 50Hz

136 490 685 550

1.45 1.3 4.4 4.3

1530 1300 1500 1050

33 to 55 33 to 61 33 to 59 37 to 61

11 18 18 43

• The products used for suspension should be t for

purpose.

• The minimum suspension height is 2.7m. .

• Install the appliance with 2 persons, keep in mind,

working on height and the weight of the appliance.

• Take care of a safe area when working on this ap-

pliance

• Use cered access equipment.

• Take care of your personal safety. Use safety

gloves and safety shoes.

The unit has been applied with 4 suspension eyes for use

with chains or steel wire (not included). Ensure the appli-

ance has an uninterrupted supply of air on both inlet &

outlet, a minimum clearance around the air inlet of 0.5m

should be observed. For exact distance for each specic

unit consult the technical data.

A rule of thumb, choose one fan per 300m2 oor surface.

A more accurate method is on basis of circulaon short-

age.

This is easy to calculate:

Calculate the volume of the space in m3, mulply this by 2.

The resulng gure is the volume in m3/h needed by the

SD-EC destracaon fans.

Select the SD-EC model based upon air output, throw of

the unit and height of the room. Then simply take the ca-

lulated air volume and divide by the air volume produced

by your selected SD-EC model. The resulng gure is the

qty needed for your applicaon.

Selecng an SD-EC model with the highest air vol-

ume is not nessecarily the best soluon. It is important

to achieve uniform air distribuon throughout the space,

for maximum comfort and reduced running costs.

Occasionally it will be nessecary to install more SD-EC

fans that calculaons indicate to achieve uniform air dis-

tribuon. In these scenarios, where possible, reduce the

model size and increase the quanty.

Always ensure the model of fan is capable

of being installed at the height you propose.

Posion the destracaon fan preferably towards the

end of the throw or area that is not directly served by the

heaters throw.

In general, a higher number of fans provides beer air dis-

tribuon.

We suggest that one fan is used per 150 to 300m2 square

of oor surface, taking into account mounng height and

model.

Each SD-EC fan should be ed approx. 1.0m beneath the

roof or ceiling, but not closer than 0.35m. The distance

between oor and fan may not exceed the length of the

fan’s throw as this will prevent the warm air from reaching

the low level. Ensure that the fan is not mounted lower

than the minimum throw to avoid dras and oor dust

from being disturbed.

Even with the louvres set at maximum deecon, there

will be a severe dra when the unit is suspended too low.

Do not place the SD-EC fans above plant machinery or

high obstacles.

Locaon examples:

Fig.1 SD Destracaon fan main components

A

A. Fan & motor assembly

B. Suspension eyebolts x 4

C. Thermostat

D. Outlet louvre frame assembly

D

470 600 600 800

470 600 600 800

289 319 328 438

340 375 375 740

A

A

NOTE

IMPORTANT

Before starng installaon ensure that the

electrical circuit you are working on has been shut o.

The appliance must be earthed!

Power supply to this appliance must be made by wiring

into the terminals within the fan motor. See diagrams in

chapter 6.

The installaon must comply with all applicable local and/

or naonal standards i.e. NEN 1010.

There should be a suitable electrical circuit with a main

fuse. There is an electrical diagram further on in this guide.

The power supply is 230Vac (50 Hz) with earth.

The fan must to be equipped with a 230Volt isolaon

switch or power plug. This switch should disconnect phase

and neutral (not earth) and have a 3mm contact opening

at least. Switches or power plugs must be accessible at all

mes.

The SD-EC is equipped with an on/o thermostat. This

thermostat is connected with the 0-10V control of the

motor. The thermostat measures the temperature near

the fan and switches on the motor when the set temper-

ature has been reached. For correct seng of tempera-

tures, see paragraph 5.1

Besides seng the temperature, the fan speed has to be

set. This van be done in the following ways:

1. Maximum speed only

2. Speed regulator

3. External via 0-10V d.c.

The maximum speed can be set by installing a wire be-

tween the contacts [T2] (Out) and [S3] (In) on the 6-pole

connector. The fan will always run at the maximum speed.

See chapter 6, diagram 3.

On contacts [T1], [T2] and [S3] of the 6-pole connector,

the oponal speed regulator GA3955, or a 3 wire poten-

ometer can be used. Please make sure that the resistance

of the potenometer has a value of 10kΩ. See chapter 6,

diagram 4.

On contacts [T1] and [S3] of the 6-pole connector an ex-

ternal voltage can be connected to control the speed. See

chapter 6, diagram 5.

Aenon The SD-EC needs 2 signals in order to run.

The thermostat contact on the WCU has to be closed and

the speed seng has to be made. If one of these signals is

missing, the motor will not run.

Before starng maintenance make sure that

the electrical circuit you are working on has been isolat-

ed.

The appliance must be earthed.

Set the thermostat of the SD unit approx. 4 to 7°C above

the ambient temperature desired at 1.5m above oor

level. The smaller the dierence between the room ther-

mostat seng and that of the SD destracaon fan, the

longer the unit will be operave.

The SD does not need manual control, it is automac.

Generally temperature seng has to be done by

the installer. The user is allowed to do following sengs:

• Set the temperature at which the fan should ven-

late.

• Turn ON/OFF main switch

• Change fan speed by adjusng the speed regulator

Aenon: Do not set the louvres at an angle greater

than 20°. This will reduce the air volume and in turn the

throw.

In areas where heavy dust is present, it may be necessary

to clean the fan & guard with compressed air once a year.

If the guard is covered with severe dust, the fan will not

provide opmal performance.

Check if the appliance turns ON and OFF as it should on

the thermostat.

Pay aenon on:

• The ON and OFF switching from the thermostat

• The smooth rotaon of the fan

• Remove the dust from the appliance

• Check that the fan does not have severe vibraon

because of unbalance on the fan blades

WARNING!

WARNING!

ATTENTION!

ATTENTION!

BI_WCU_EN_05 Page 6/8

6 Example diagrams

Diagram 1 WCU-EC without internal connections on the motor (WCU 40).

Diagram 2 WCU-EC with internal connections on the motor (WCU60, 80 and 100).

Diagram 3 Connection with fixed maximum speed:

Connect the 230V supply in the 6-pole connector.

Connect a wire between terminals T2 enS3, see diagram below.

WCU

Mount wire between 10V and IN in the 6-pole connector.

L1

N

T1

T2

S3

2

1

3

T

10V

GND

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

2

1

3

T

24V

10V

GND

D1

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

L1 PE N 0V 10V IN

Installation

M1

BI_WCU_EN_05 Page 6/8

6 Example diagrams

Diagram 1 WCU-EC without internal connections on the motor (WCU 40).

Diagram 2 WCU-EC with internal connections on the motor (WCU60, 80 and 100).

Diagram 3 Connection with fixed maximum speed:

Connect the 230V supply in the 6-pole connector.

Connect a wire between terminals T2 enS3, see diagram below.

WCU

Mount wire between 10V and IN in the 6-pole connector.

L1

N

T1

T2

S3

2

1

3

T

10V

GND

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

2

1

3

T

24V

10V

GND

D1

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

L1 PE N 0V 10V IN

Installation

M1

BI_WCU_EN_05 Page 6/8

6 Example diagrams

Diagram 1 WCU-EC without internal connections on the motor (WCU 40).

Diagram 2 WCU-EC with internal connections on the motor (WCU60, 80 and 100).

Diagram 3 Connection with fixed maximum speed:

Connect the 230V supply in the 6-pole connector.

Connect a wire between terminals T2 enS3, see diagram below.

WCU

Mount wire between 10V and IN in the 6-pole connector.

L1

N

T1

T2

S3

2

1

3

T

10V

GND

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

2

1

3

T

24V

10V

GND

D1

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

L1 PE N 0V 10V IN

Installation

M1

BI_WCU_EN_05 Page 6/8

6 Example diagrams

Diagram 1 WCU-EC without internal connections on the motor (WCU 40).

Diagram 2 WCU-EC with internal connections on the motor (WCU60, 80 and 100).

Diagram 3 Connection with fixed maximum speed:

Connect the 230V supply in the 6-pole connector.

Connect a wire between terminals T2 enS3, see diagram below.

WCU

Mount wire between 10V and IN in the 6-pole connector.

L1

N

T1

T2

S3

2

1

3

T

10V

GND

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

2

1

3

T

24V

10V

GND

D1

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

L1 PE N 0V 10V IN

Installation

M1

BI_WCU_EN_05 Page 6/8

6 Example diagrams

Diagram 1 WCU-EC without internal connections on the motor (WCU 40).

Diagram 2 WCU-EC with internal connections on the motor (WCU60, 80 and 100).

Diagram 3 Connection with fixed maximum speed:

Connect the 230V supply in the 6-pole connector.

Connect a wire between terminals T2 enS3, see diagram below.

WCU

Mount wire between 10V and IN in the 6-pole connector.

L1

N

T1

T2

S3

2

1

3

T

10V

GND

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

2

1

3

T

24V

10V

GND

D1

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

L1 PE N 0V 10V IN

Installation

M1

Wire the 230V supply into the 6-pole connector, Connect a wire link between terminal T2 & S3 as shown below

BI_WCU_EN_05 Page 6/8

6 Example diagrams

Diagram 1 WCU-EC without internal connections on the motor (WCU 40).

Diagram 2 WCU-EC with internal connections on the motor (WCU60, 80 and 100).

Diagram 3 Connection with fixed maximum speed:

Connect the 230V supply in the 6-pole connector.

Connect a wire between terminals T2 enS3, see diagram below.

WCU

Mount wire between 10V and IN in the 6-pole connector.

L1

N

T1

T2

S3

2

1

3

T

10V

GND

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

2

1

3

T

24V

10V

GND

D1

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

L1 PE N 0V 10V IN

Installation

M1

BI_WCU_EN_05 Page 6/8

6 Example diagrams

Diagram 1 WCU-EC without internal connections on the motor (WCU 40).

Diagram 2 WCU-EC with internal connections on the motor (WCU60, 80 and 100).

Diagram 3 Connection with fixed maximum speed:

Connect the 230V supply in the 6-pole connector.

Connect a wire between terminals T2 enS3, see diagram below.

WCU

Mount wire between 10V and IN in the 6-pole connector.

L1

N

T1

T2

S3

2

1

3

T

10V

GND

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

2

1

3

T

24V

10V

GND

D1

E1

L1

N

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

EC Motor

Thermostat

Connector

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

L1 PE N 0V 10V IN

Installation

M1

Fied thermostat

Installaon

Control seng via speed regulator GA3955, connect the 230V supply in the 6-pole connector. Connect the speed

regulator as shown in the diagram below:

BI_WCU_EN_05 Page 7/8

Diagram 4 Connection with variable speed

Control setting via speed regulator GA3955:

Connect the 230V supply in the 6-pole connector.

Connect the speed regulator as stated in the diagram below:

WCU

Diagram 5 Connection with variable speed via external power source

WCU

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector Speed regulator 10kΩ

L1 PE N 0V 10V IN

Installation

M1

L1 PE N 0V 10V IN

Installation

M1

0-10V GND

L1

N

T1

T2

S3

23

0

V

A

C

GND (0V)

1

0V

(OUT)

0-1

0V

(

IN )

C

o

n

n

e

c

t

or

External source 0-10V d.c.

6-Pole connector

BI_WCU_EN_05 Page 7/8

Diagram 4 Connection with variable speed

Control setting via speed regulator GA3955:

Connect the 230V supply in the 6-pole connector.

Connect the speed regulator as stated in the diagram below:

WCU

Diagram 5 Connection with variable speed via external power source

WCU

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

Speed regulator 10kΩ

L1 PE N 0V 10V IN

Installation

M1

L1 PE N 0V 10V IN

Installation

M1

0-10V GND

L1

N

T1

T2

S3

23

0

V

A

C

GND (0V)

1

0V

(OUT)

0-1

0V

(

IN )

C

o

n

n

e

c

t

or

External source 0-10V d.c.

Fied thermostat

6-Pole connector

We hereby declare that our products sasfy the applicable European direcves, decisions

and regulaons, as well as the requirements stated in the referenced standards.

BI_WCU_EN_05 Page 7/8

Diagram 4 Connection with variable speed

Control setting via speed regulator GA3955:

Connect the 230V supply in the 6-pole connector.

Connect the speed regulator as stated in the diagram below:

WCU

Diagram 5 Connection with variable speed via external power source

WCU

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

Speed regulator 10kΩ

L1 PE N 0V 10V IN

Installation

M1

L1 PE N 0V 10V IN

Installation

M1

0-10V GND

L1

N

T1

T2

S3

23

0

V

A

C

GND (0V)

1

0V

(OUT)

0-1

0V

(

IN )

C

o

n

n

e

c

t

or

External source 0-10V d.c.

External 0-10V

DC supply

BI_WCU_EN_05 Page 7/8

Diagram 4 Connection with variable speed

Control setting via speed regulator GA3955:

Connect the 230V supply in the 6-pole connector.

Connect the speed regulator as stated in the diagram below:

WCU

Diagram 5 Connection with variable speed via external power source

WCU

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

Connector

Speed regulator 10kΩ

L1 PE N 0V 10V IN

Installation

M1

L1 PE N 0V 10V IN

Installation

M1

0-10V GND

L1

N

T1

T2

S3

23

0

V

A

C

GND (0V)

1

0V

(OUT)

0-1

0V

(

IN )

C

o

n

n

e

c

t

or

External source 0-10V d.c.

6-Pole connector

0-10V GND

If more than one SD-EC needs to be connected to one speed controller, please make sure that the 10V supply of the

dierent units are NOT connected to each other. All SD-EC’s must get their 0-10V supply (10V out, T2) from one

SD-EC. See SD-EC 1, on the diagram below.

BI_WCU_EN_05 Page 8/8

Diagram 6 Several WCUs controlled by 1 speed regulator

If more than one WCU needs to be connected to one speed regulator, please make sure that the 10V supply of the

different units are NOT connected to each other. So all WCUs get their 0-10V supply (10V out, T2) from one WCU. In

the diagram below this is WCU No. 1.

L1

N

T1

T2

S3

230V AC

GND (0V)

0-10V ( IN )

WCU 3

L1

N

T1

T2

S3

230V AC

GND (0V)

0-10V ( IN )

WCU 2

L1

N

T1

T2

S3

230V AC

GND (0V)

10V (OUT)

0-10V ( IN )

WCU 1

Speed regulator 10kΩ

FACTORIES: IPSWICH, ENGLAND - CHARLOTTE, N.C, U.S.A

Gas Fired Products (UK) Ltd

Chapel Lane

Claydon

Ipswich

Suolk, IP6 0JL

Tel: +44(0)1473 830 551

Fax: +44(0)1473 832055

www.spaceray.co.uk

info@spaceray.co.uk

®

SD-EC Manual May 2023

Table of contents

Other Space-Ray Fan manuals

Popular Fan manuals by other brands

TriStar

TriStar VE - 5930 instruction manual

Ebmpapst

Ebmpapst W4D300-CP28-30 operating instructions

Super Vac

Super Vac 716WT user guide

Ebmpapst

Ebmpapst G2E140-AG02-78 operating instructions

System air

System air Villavent VR-400 E installation instructions

HAMPTON BAY

HAMPTON BAY GAZEBO III Use and care guide