Space PFB035 Series Installation guide

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

BRAKE TESTER –TEST LANE

CONTROL UNIT:

PFC750

PFC800

PFC750/WALL

ROLLER BRAKE TESTERS:

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6SERIES –SPRT102/7 SERIES

INSTRUCTION OPERATION

AND MAINTENANCE MANUAL

COMPOSIZIONE

COMPOSITION

ZUSAMMENSETZUNG

COMPOSITION

COMPOSICIÓN

70 pagine (copertine

comprese)

70 pages (including

cover pages)

70 Seiten (inkl.

Deckblätter)

70 pages (pages de la

couverture incluses)

70 páginas (incluidas

las portadas)

68 pagine numerate

68 numbered pages

68 numerierte Seiten

68 pages numérotées

68 páginas numeradas

• Per eventuali chiarimenti interpellare il più vicino rivenditore oppure rivolgersi direttamente a:

• For any further information please contact your local dealer or call:

• Im Zweifelsfall ober bei Rückfragen wenden Sie sich bitte an den nächsten Wiederverkäufer oder direkt an:

• Pour tout renseignement complémentaire s’adresser au revendeur le plus proche ou directement à:

• En caso de dudas, para eventuales aclaraciones, póngase en contacto con el distribuidor más próximo ó diríjase

directamente a:

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

SIMBOLOGIA UTILIZZATA NEL MANUALE

SYMBOLS USED IN THE MANUAL

IN DER BETRIEBSANLEITUNG VERWENDETE ZEICHEN

SYMBOLES UTILISES DANS LA NOTICE

SIMBOLOGÍA UTILIZADA EN EL MANUAL

SIMBOLI

SYMBOLS

ZEICHEN

SYMBOLES

SÍMBOLOS

VIETATO!

FORBIDDEN!

VERBOTEN

INTERDIT!

PROHIBIDO!

Obbligo!

Operazioni o

interventi da

eseguire

obbligatoriamente

Mandatory!

Operations or jobs

to be performed

compulsorily

Vorschirift

Obligatorisch

auszuführende

Arbeitsvorgänge

oder Eingriffe

Obligation.

Opérations ou

interventions

obligatoires

Obigación.

Operaciones o

intervenciones que

hay que realizar

obligatoriamente

Pericolo!

Prestare particolare

attenzione

Hazard!

Be especially

careful

Gefahr!

Äusserste Vorsicht

ist geboten

Dager!

Faire trés

attention

Peligro!

Prestar especial

atención

Pericolo: scariche

elettriche

Shock hazard

Gefahr! elektrische

Entladungen

Danger

d’électrocution

Peligro de

descargas

eléctricas

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 1/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

TABLE OF CONTENTS

0. CAUTION .......................................................................................................................3

0.1. Preliminary safety information..........................................................................................3

1. INTENDED USE.............................................................................................................4

2. PERSONNEL TRAINING ...............................................................................................4

2.1. General preventive measures..........................................................................................4

2.2. Indication of outstanding risks..........................................................................................5

2.3. Emergency devices .........................................................................................................5

2.4. Safety devices .................................................................................................................5

2.5. Emergency situations.......................................................................................................5

2.6. Operating precautions......................................................................................................6

3. EQUIPMENT COMPOSITION ........................................................................................7

3.1. Roller assembly...............................................................................................................8

3.1.1. Roller brake tester PFB035 series....................................................................................................9

3.1.2. Roller brake testers SPRT102/4, SPRT102/5, SPRT102/6 and SPRT102/6 series

with weighing equipment: .............................................................................................................. 10

3.1.3. Roller brake testers SPRT102/4, SPRT102/5, SPRT102/6 and SPRT102/7 series

without weighing equipment: ......................................................................................................... 11

3.1.4. Roller brake testers PFB040 series:.............................................................................................. 12

3.1.5. Roller Brake Testers PFB045 series ............................................................................................. 13

3.1.6. Roller brake testers PFB060 series:.............................................................................................. 14

3.2. Console PFC750E000...................................................................................................15

3.3. Console PFC800E000...................................................................................................16

3.4. Console PFC750/WALL.................................................................................................17

3.5. Remote control ..............................................................................................................18

3.6. Control keyboard ...........................................................................................................18

3.7. Pressure-meter pedal SRT047BTH ...............................................................................19

3.8. Brake lever pressure meter with remote control (optional)

only for 3 wheels vehicle and quadricycles ....................................................................19

3.9. Set of carriageable covers (optional) only for the test with 3 wheels vehicles.................20

3.10. Adherence tester (optional)............................................................................................20

3.11. Side-slip test (optional) ..................................................................................................20

4. INSTALLATION OF THE BTS2 SOFTWARE ..............................................................21

4.1. Part 1: Launcher installation...........................................................................................21

4.2. Part 2: Pre-required software installation .......................................................................21

4.3. Parts 3: Installation of the main software........................................................................22

4.4. Update the SW (ONLY for MCTC-Net2 in Italy) .............................................................23

4.5. System Info view............................................................................................................25

5. OPERATING INSTRUCTIONS.....................................................................................26

5.1. Starting and stopping the appliance...............................................................................26

5.2. Smart Card to protect the software ................................................................................27

5.3. Program configuration....................................................................................................28

5.3.1. Inspections (Checks)..................................................................................................................... 29

5.3.2. Test line layout............................................................................................................................... 34

5.3.3. Environnemental conditions .......................................................................................................... 35

6. MCTCNet 2 PROGRAM (ONLY for MCTC-Net2 in Italy). ...........................................36

6.1. RETE mode...................................................................................................................36

6.2. DIR mode ......................................................................................................................37

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 2/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

7. CARS MEASUREMENTS CYCLE................................................................................38

7.1. Enter data......................................................................................................................38

7.1.1. Selecting the type of test ............................................................................................................... 38

7.1.2. Choosing the vehicle category ...................................................................................................... 38

7.2. Side slip procedure........................................................................................................40

7.3. Measuring the weight of the axle or entering the vehicle weight.....................................41

7.4. Adherence test procedure..............................................................................................42

7.5. Brake test procedure......................................................................................................44

8. THREE AND FOUR WHEELS VEHICLES AND

LIGHT QUADRICYCLE MEASUREMENT CYCLE ......................................................49

8.1. Data enter......................................................................................................................49

8.1.1. Select the vehicle........................................................................................................................... 49

8.1.2. Select the category for a tricycle ................................................................................................... 49

8.1.3. Type of three wheels vehicle......................................................................................................... 50

8.1.4. Service commands for the front and the rear axle ........................................................................ 50

8.1.5. Type of braking system: SERVICE and PARKING ....................................................................... 51

8.1.6. Action of the PARKING brake ....................................................................................................... 51

8.1.7. Type of vehicle and entry of the weight of the vehicle for freight transport................................... 52

8.2. Brake test on the front axel............................................................................................53

8.3. Brake test on the rear axel.............................................................................................56

8.4. Parking brake test..........................................................................................................57

8.5. Test graph and final summary........................................................................................57

9. DATA PRINT................................................................................................................59

10. CUSTOMER DATABASE.............................................................................................63

11. BACK-UP and RESTORE............................................................................................64

12. TROUBLESHOOTING..................................................................................................65

13. MAINTENANCE ...........................................................................................................66

14. STORING AND SCRAPPING.......................................................................................66

15. IDENTIFICATION PLATE.............................................................................................67

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 3/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

0. CAUTION

Any damage caused by failure to follow the instructions in this manual or improper machine use

shall relieve SPACE S.R.L. of all liability.

0.1. Preliminary safety information

Before starting the machine:

Read this manual carefully before using the brake tester. This manual forms an integral part

of the product, its purpose is to provide the user with instructions on how to operate the brake

tester.

Keep it throughout the working life of the machine in a well-known and easily-accessible place

where it can be referred to every time doubts arise. All product operators must be in a position

to read this manual.

Assembly and setting instructions, reserved for the fitter (specialized technical staff) are

contained in the specific manual. Masonry works and details on system specifications are

shown on specific drawings available from your SPACE S.R.L. dealer.

Make sure the power supply is in conformity with the specifications shown on the plate.

Make sure the machine is properly positioned on the floor.

Suitably position the machine power cables.

On starting the machine:

During operating program loading, position the vehicle close to the line but not move the front

axle onto the roller, as the system is busy checking the correct operation of these devices.

In emergency conditions and before performing any maintenance:

Isolate the machine from any power sources by means of the machine master switch.

Work environment and machine cleaning:

The work environment must be kept clean and dry and must not be exposed to atmospheric

agents. It must also be well lighted.

Do not clean the machine using strong jets of water and compressed air.

To clean plastic panels or tops, use alcohol (always avoid liquids containing solvents).

SPACE S.R.L. can modify in any moment the models described in this manual for technical or

commercial reasons.

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 4/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

1. INTENDED USE

The product is designed to perform braking tests on front and rear axles of vehicles weighing under

4000 kg when fully loaded.

The model featuring adherence test device is designed to perform tests on the front and rear axles

of vehicles weighing under 4000 kg when fully loaded.

The max acceptable roller assembly and suspension test load per axle is 2500 daN.

Important! Failure to comply with the weight restrictions indicated above could

permanently damage system parts.

Any damage ensuing from failure to comply with the instructions given in this manual or incorrect

machine use shall relieve SPACE S.R.L. of all liability.

2. PERSONNEL TRAINING

The machine must only be used by specially trained and authorized persons. To ensure the

machine is operated in the best possible manner and measurements are properly made, operators

must be correctly trained and be in possession of all necessary information in order to achieve

operating standards in line with the indications provided by the manufacturer. In case of any

doubt concerning use and maintenance of the machine, refer to the instruction manual; if doubts

still remain, contact an authorized after-sales center or the SPACE S.R.L. technical department.

2.1. General preventive measures

During operation and maintenance of this machine, always abide by the safety and

accident-prevention regulations in force.

The machine must only be used by adequately trained and authorized persons.

This machine must only be used for the purpose for which it was expressly intended.

SPACE S.R.L. declines all liability for injury or damage to persons, animals and things

caused by improper machine use.

Accessories and spare parts must be fitted by persons authorized by SPACE S.R.L. and

only original spare parts and accessories must be used

The machine must only be operated in places where there is no danger of explosions or

fire.

Removal or changes made to safety devices, or warning signals on the machine can cause

serious hazards and represents a violation of European safety regulations.

Before doing any maintenance jobs on the system, always disconnect the power supply.

In case of doubt, do not interpret, but contact SPACE S.R.L. technical assistance in order

to obtain instructions suitable for performing operations in total safety.

Do not allow unauthorized personnel to come near the brake tester during the cycle.

Only one operator must work inside the test area and must not exit from the vehicle near

the roller tester. In the event of the operator, for any reason, not being able to exit from

the vehicle, he should ask for the assistance of a second operator who may access the

test area only after operating the emergency device

The workspace must be clean and dry with particular reference to substances made up

of that oil can cause danger; the atmosphere must sufficiently be illuminated.

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 5/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

2.2. Indication of outstanding risks

The machine was designed and manufactured in compliance with applicable regulations. The risks

connected to the use of the machine have been eliminated as far as possible. Other outstanding

risks are described in this manual; the machine also features self-adhesive pictograms (chap 0

and 0 on page 15 and 16) indicating hazard areas. In the event pictograms become illegible, please

order them from a dealer or directly from SPACE S.R.L. and replace them. Please refer to Spare

Parts manuals.

2.3. Emergency devices

In case of an emergency, operate the special device on the rear of the cab as shown at Figure 7

and Figure 6 page 15 and 16 at ref. 8.

2.4. Safety devices

-Safety button: stops and prevents roller start (Button on the front of the cab shown at Figure

7 and Figure 6 on page 15 and 16 at ref. 3).

-Vehicle sensor rollers: these enable the start of the rollers only when they are both pressed.

-Slip/speed control sensor rollers: these stop roller rotation when an anomalous wheel speed

is detected of the vehicle being tested.

-Stop/F1 key: on the functional keyboard and remote control. For stopping roller rotation and

the test under way.

-Cab access doors: these prevent access to energized parts. These must only be opened by

professional and authorized personnel (Figure 7 and Figure 6 at ref. 9).

2.5. Emergency situations

ATTENTION!: In the event of emergency situations, the special device behind the console will

have to be operated (see Figure 7 and Figure 6 on page 15 and 16, at ref. 8), and

consequently, the console should be installed so the emergency device is easily

accessible. The user is responsible for inspecting and maintaining access to the

emergency device free of obstacles or impediments and for periodically checking

its efficiency.

ATTENTION!: Unauthorized persons must not be allowed to enter the test area. Only one

operator must work inside the test area and must not exit from the vehicle near

the roller tester. In the event of the operator, for any reason, not being able to

exit from the vehicle, he should ask for the assistance of a second operator who

may access the test area only after operating the emergency device.

ATTENTION!: The equipment also features a safety device on the front (Figure 7 and Figure 6

on page 15 and 16, at ref. 3); this prevents the rollers starting. This must be

disengaged, by turning clockwise, only after checking that no risk situations

exist. The disconnecting operation must be only executed after to have verified

that the conditions of emergency inside of the test area are respected. The rollers

are normally prevented from being started if the vehicle axle is not on the roller

assembly. Press the STOP key on the remote control or the red key on the

keyboard to stop the rollers; this is necessary if the vehicle brakes are not

working properly and do not allow automatic roller stoppage.

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 6/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

2.6. Operating precautions

IMPORTANT!: During brake testing, the vehicle is sometimes reactively pushed off the

rollers. To prevent this occurring, pull the handbrake, when this does not

affect the axle being tested.

IMPORTANT!: The vehicle must be tested with the motor running so the servo brake

expansion box is loaded. It is important to have the motor running especially

when a vehicle is being tested with hydropneumatic compensation type

suspensions.

The steering lock of the vehicle being tested must not be engaged.

IMPORTANT!: Vehicles with permanent four-wheel drive can only be tested on the REVERSE

version brake tester with 4WD program switched on. This enables the wheels

to be turned in the opposite direction so as to uncouple the differential and

prevent transmitting driving torque to the axle not being tested.

IMPORTANT!: Before performing a test, make sure the brakes are dry and that tire pressure

is correct.

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 7/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

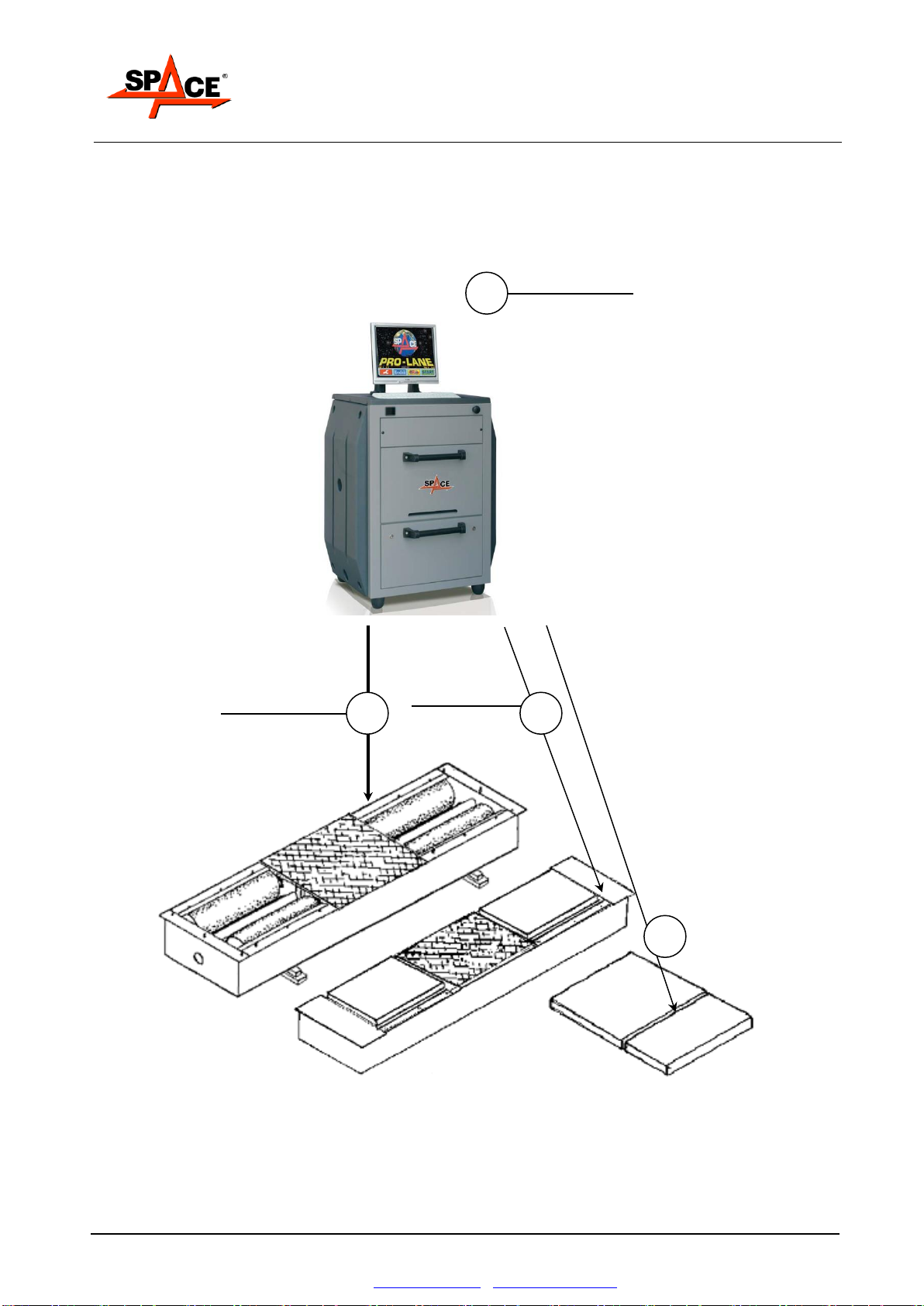

3. EQUIPMENT COMPOSITION

1

CONSOLE

(par.

3.2, 3.3 and 3.4)

2

ROLLER

BENCH

(par. 3.1)

4

Side-slip test

(optional)

par. 3.11

Adherence test

(optional)

Par. 3.10

3

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 8/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

3.1. Roller assembly

The roller assemblies of the SPACE brake tester consist of a folded metal (plate) frame with

reinforcements and “C” sections for supporting and housing the operation and measurement

devices.

The roller drive system consists of a gear motor (one for each pair of rollers) constrained to a load

cell secured to the frame.

During braking, a tangential force is applied on the rollers which creates a torque resistant to the

action of the gear motor. In these conditions, the gear motor would tend to turn around the roller

rotation axis if it were not secured to the load cell.

In actual fact, the resistant torque generated by braking is unloaded on the cell.

The load cell sends a signal to the console which is used to manage result calculation and display.

Each pair of rollers features a proximity switch (called CAR-ON sensor) which indicates the

presence of a vehicle. If the support on which this is mounted is lowered, the sensor no longer

detects the support, the contact closes and an electric signal is sent to the console; this is the

signal for the motors to start.

In the event of even only one of the proximity switches not closing the contact, the console fails to

receive the signal and consequently the test is interrupted. It follows that testing is only possible

with both “rollers” lowered by the axle of the vehicle being tested.

Each pair of rollers also features a proximity switch (called TACHO sensor) that detects roller

speed and consequently vehicle wheel speed. This quantity, which is continuously measured,

when compared with the initial wheel speed, determines the slip condition that causes test stop.

Roller stoppage at the end of the test is therefore determined by the set slide threshold having

been reached. This normally coincides with detection of maximum braking force of the axle being

measured.

In the case of emergencies or special needs, the test can also be stopped by the operator, by the

remote control or keyboard.

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 9/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

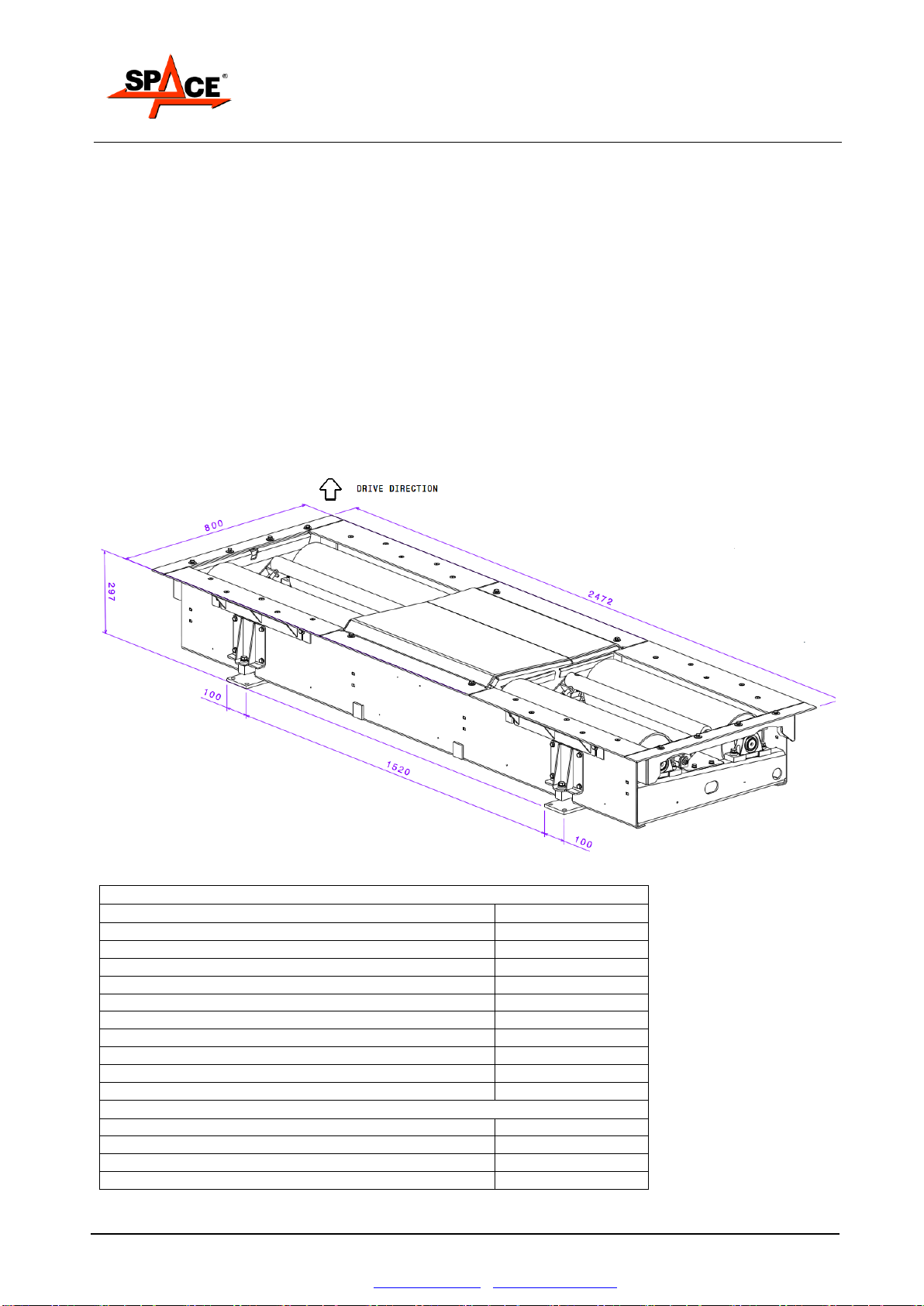

3.1.1. Roller brake tester PFB035 series

The roller brake tester PFB035 series consists of:

roller brake tester PFB035 0000 (can be used together with suspension tester code APF110);

roller brake tester with weighing equipment PFB035 2000 (2 sensor weighing equipment)

The tester is physically separate from the console; the only connections are power connections (to

power the motors) and electronic connections (signaling cables, vehicle presence, rolling speed

and measurement cables).

Figure 1

TECHNICAL SPECIFICATIONS PFB035

Roller dimensions

700 - 205

Roller internal wire distance

800 mm

Roller external wire distance

2200 mm

Max. transit weight per axle

4000 daN

Max measurable braking force

5000 N

Motors

M90 4kW

Empty roller tip speed

5,2 km/h

Grip coefficient

>0,7

Precision measuring chain

≤ ±1%

Weight

382 kg

WEIGHING FRAME TECHNICAL SPECIFICATIONS

Max. transit weight per axle

4000 daN

Max. test weight per axle

2500 daN

Precision measuring chain (2 sensor)

≤ ±3%

Weight

30kg

E.g. Roller brake tester

with weighing equipment:

PFB035 2000

E.g. Roller brake tester

without weighing equipment:

PFB035 0000

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 10/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

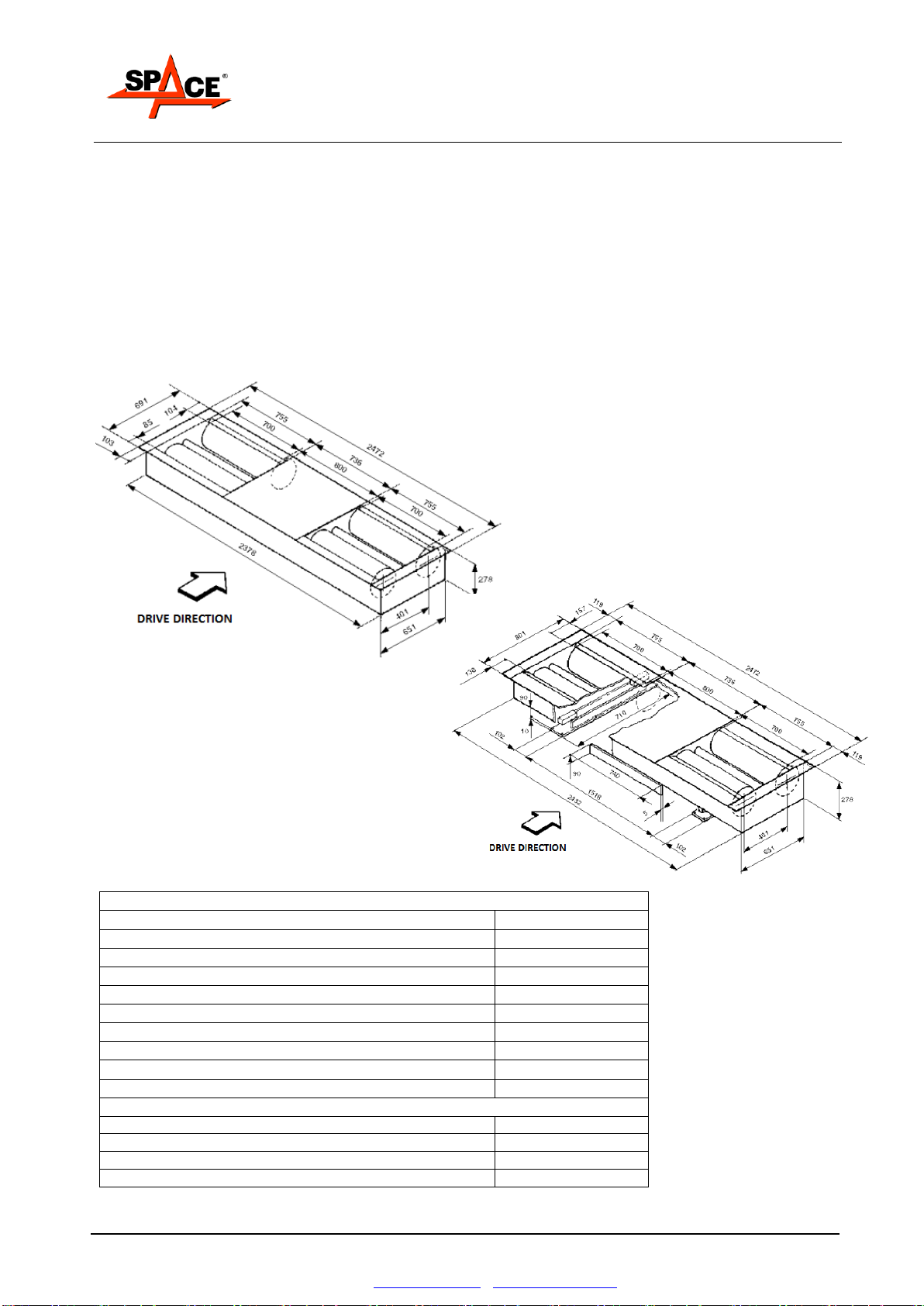

3.1.2. Roller brake testers SPRT102/4, SPRT102/5, SPRT102/6 and SPRT102/6

series with weighing equipment:

The roller brake tester SPRT102/4, SPRT102/5, SPRT102/6 and SPRT102/6 series with weighing

equipment consists of:

roller brake testers SPRT102/4P, SPRT102/5P, SPRT102/6P or SPRT102/7P with weighing

equipment;

roller brake testers SPRT102/4P4, SPRT102/5P4, SPRT102/6P4 or SPRT102/7P4 with 4

sensors weighing equipment;

roller brake testers SPRT102/4PF, SPRT102/5PF, SPRT102/6PF or SPRT102/7PF with

weighing equipment and self-braking motors;

roller brake testers SPRT102/4P4F, SPRT102/5P4F, SPRT102/6P4F or SPRT102/7P4F with

4 sensors weighing equipment and self-braking motors.

The tester is physically separate from the console; the only connections are power connections (to

power the motors) and electronic connections (signaling cables, vehicle presence, rolling speed

and measurement cables).

Figure 2

TECHNICAL SPECIFICATIONS

Roller dimensions

700 - 205

Roller internal wire distance

800 mm

Roller external wire distance

2200 mm

Max. transit weight per axle

4000 daN

Max measurable braking force RT102/4 series

4000 N

Max measurable braking force RT102/5 series

5000 N

Max measurable braking force RT102/6 series

6000 N

Max measurable braking force RT102/7 series

7500 N

Empty roller tip speed

5,4 km/h

Grip coefficient a

>0,7

Weight

385 kg

WEIGHING FRAME TECHNICAL SPECIFICATIONS

Max. transit weight per axle

4000 daN

Max. test weight per axle

2500 Kg

Precision

±2 %

Weight

30kg

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 11/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

3.1.3. Roller brake testers SPRT102/4, SPRT102/5, SPRT102/6 and SPRT102/7

series without weighing equipment:

The roller brake tester SPRT102/4, SPRT102/5, SPRT102/6 and SPRT102/7 series without

weighing equipment consists of:

roller brake testers SPRT102/4, SPRT102/5, SPRT102/6 or SPRT102/7 without weighing

equipment;

roller brake testers SPRT102/4F, SPRT102/5F, SPRT102/6F or SPRT102/7F with self-

braking motors and without weighing equipment;

The tester is physically separate from the console; the only connections are power connections (to

power the motors) and electronic connections (signaling cables, vehicle presence, rolling speed

and measurement cables).

Figure 3

TECHNICAL SPECIFICATIONS

Roller dimensions

700 - 205

Roller internal wire distance

800 mm

Roller external wire distance

2200 mm

Max. transit weight per axle

4000 daN

Max measurable braking force RT102/4 series

4000 N

Max measurable braking force RT102/5 series

5000 N

Max measurable braking force RT102/6 series

6000 N

Max measurable braking force RT102/7 series

7500 N

Empty roller tip speed

5,4 km/h

Grip coefficient a

>0,7

Weight

385 kg

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 12/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

3.1.4. Roller brake testers PFB040 series:

The roller brake tester PFB040 series consists of:

roller brake testers PFB040 0000 without weighing equipment;

roller brake testers PFB040 2000 with four sensors weighing equipment;

roller brake testers PFB040 1000 with self-braking motors and without weighing equipment;

roller brake testers PFB040 3000 with self-braking motors and four sensors weighing

equipment;

The tester is physically separate from the console; the only connections are power connections (to

power the motors) and electronic connections (signaling cables, vehicle presence, rolling speed

and measurement cables).

Figure 4

TECHNICAL SPECIFICATIONS PFB040 SERIES

Roller dimensions

700 - 205

Roller internal wire distance

800 mm

Roller external wire distance

2200 mm

Max. transit weight per axle

4000 daN

Max measurable braking force

6000 N

Motors

M100 4,7kW

Empty roller tip speed

5,2 km/h

Grip coefficient

>0,7

Weight PFB040 2000

415 kg

Weight PFB040 0000

385 kg

WEIGHING FRAME TECHNICAL SPECIFICATIONS

Max. transit weight per axle

4000 daN

Max. test weight per axle

2500 Kg

Precision

±2 %

Weight

30kg

E.g. Roller brake tester

with weighing equipment:

PFB040 2000

E.g. Roller brake tester

without weighing equipment:

PFB040 0000

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 13/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

3.1.5. Roller Brake Testers PFB045 series

The roller brake testers PFB045 series consist of:

roller brake testers PFB045 0000 without weighing equipment;

roller brake testers PFB045 2000 with four sensors weighing equipment;

roller brake testers PFB045 1000 with self-braking motors and without weighing equipment;

roller brake testers PFB045 3000 with self-braking motors and four sensors weighing

equipment;

The tester is physically separate from the console; the only connections are power connections (to

power the motors) and electronic connections (signaling cables, vehicle presence, rolling speed

and measurement cables).

Figure 5

TECHNICAL SPECIFICATIONS PFB045

Roller dimensions

700 - 205

Roller internal wire distance

800 mm

Roller external wire distance

2200 mm

Max. transit weight per axle

4000 daN

Motors

M112 5kW

Empty roller tip speed

5,2 km/h

Grip coefficient

>0,7

Weight PFB045 0000

385kg

Weight PFB045 2000

415 kg

WEIGHING FRAME TECHNICAL SPECIFICATIONS

Max. transit weight per axle

4000 daN

Max. test weight per axle

2500 Kg

Precision

±2 %

Weight

30kg

E.g. Roller brake tester

with weighing equipment:

PFB045 2000

E.g. Roller brake tester

without weighing equipment:

PFB045 0000

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 14/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

3.1.6. Roller brake testers PFB060 series:

The roller brake tester PFB060 series consists of:

roller brake tester PFB060 0000 without weighing equipment;

roller brake tester PFB060 1000 with self-braking motors and without weighing equipment;

roller brake tester PFB060 2000 with two sensors weighing equipment;

roller brake tester PFB060 3000 with self-braking motors and two sensors weighing

equipment.

TECHNICAL SPECIFICATIONS PFB060

Roller dimensions

1000 - 205

Roller internal wire distance

800 mm

Roller external wire distance

2800 mm

Max. transit weight per axle

5000 daN

Motors

M112 5,5kW

Empty roller tip speed

2,5 km/h

Grip coefficient

>0,7

Precision measuring chain (2

sensor)

≤ ±3%

Weight

485 kg

WEIGHING FRAME TECHNICAL SPECIFICATIONS

Max. transit weight per axle

5.000 daN

Max. test weight per axle

4.000 daN

Precision measuring chain

≤ ±3%

Weight

30kg

Figure 6

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 15/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

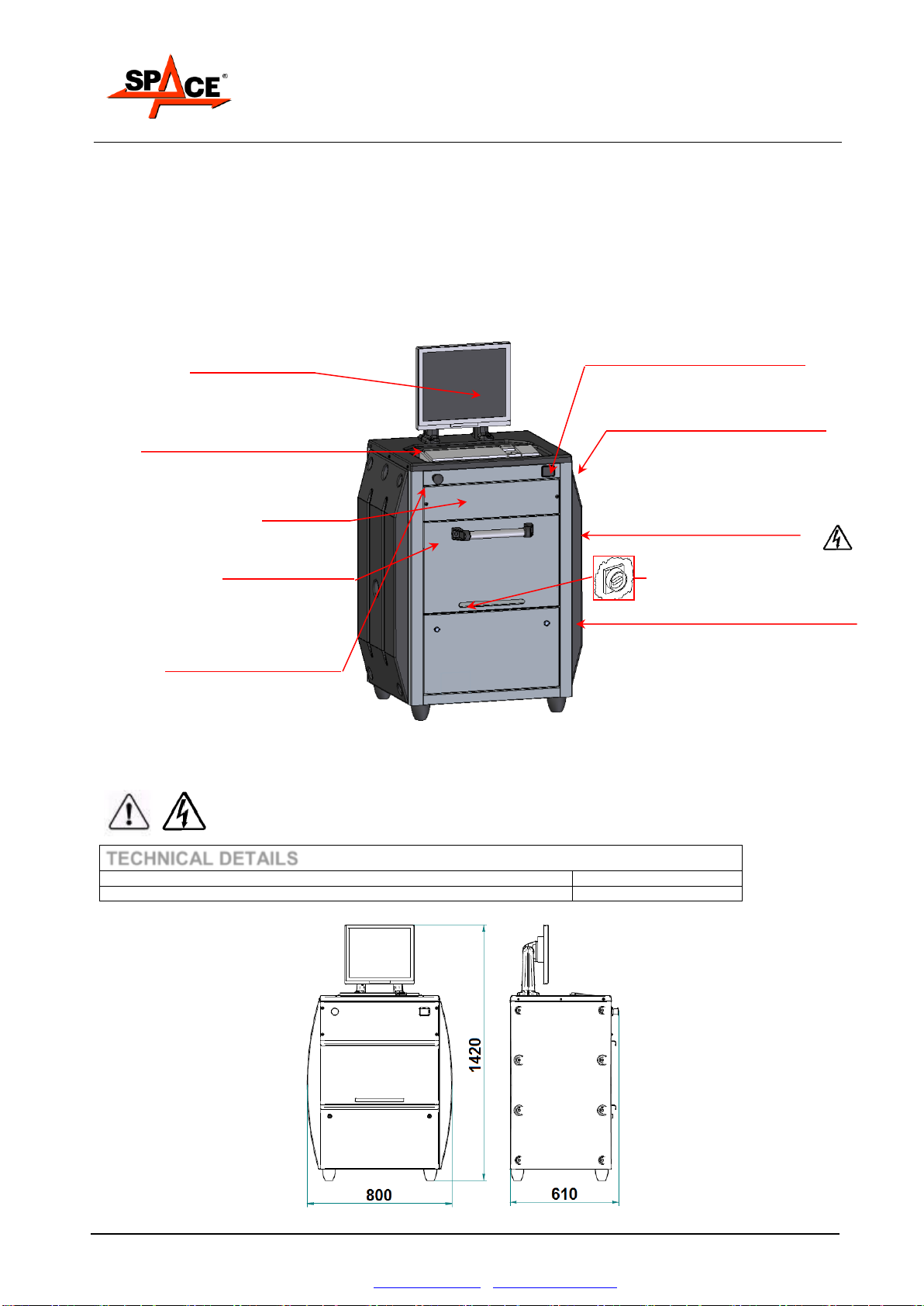

3.2. Console PFC750E000

All brake tester and suspension tester operations expect the use of a console, featuring electronic

and electric components for the processing and management of signals from the tester sensors.

Figure 7

IMPORTANT!: The rear door leading to the switchboard and the front panel leading to the CPU

board and power board can only be opened by authorized personnel; these

compartments contain high-voltage components which can prove hazardous to

unskilled operators.

TECHNICAL DETAILS

Power supply

400V 3ph + neutral

Weight

110kg

1) Monitor for displaying the choice

and sequence of test stages, initial

setting, real-time display of the test

and of the results; monitor size 19”.

Correct luminosity and contrast are

factory set.

2) 102-key PC type keyboard

4) Remote-control infrared receiver

8) Main switch/emergency device

(in the backside)

5) Printer housed behind the central door.

The test results are printed on an ink jet

printer for A4 format sheets.

.

7) On the front is a panel with a lock to key.

Inside the door is a shelf with the CPU board

for managing the signals from the different

measurement devices and the power

supply board.

6) Pictograms affixed to the machine:

Shock hazard

9) On the rear is a door with a lock to key

on which the main switch is present, (part.

8) Inside of which the switchboard is

housed for the powering of the entire

system and the starter of the motors.

3) Roller stop button. Once this has been

pressed, to reset operation, it must be

turned clockwise.

10) An IBM compatible PC can be

accessed featuring HD, an SVGA

graphic card, an RS232 serial port

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 16/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

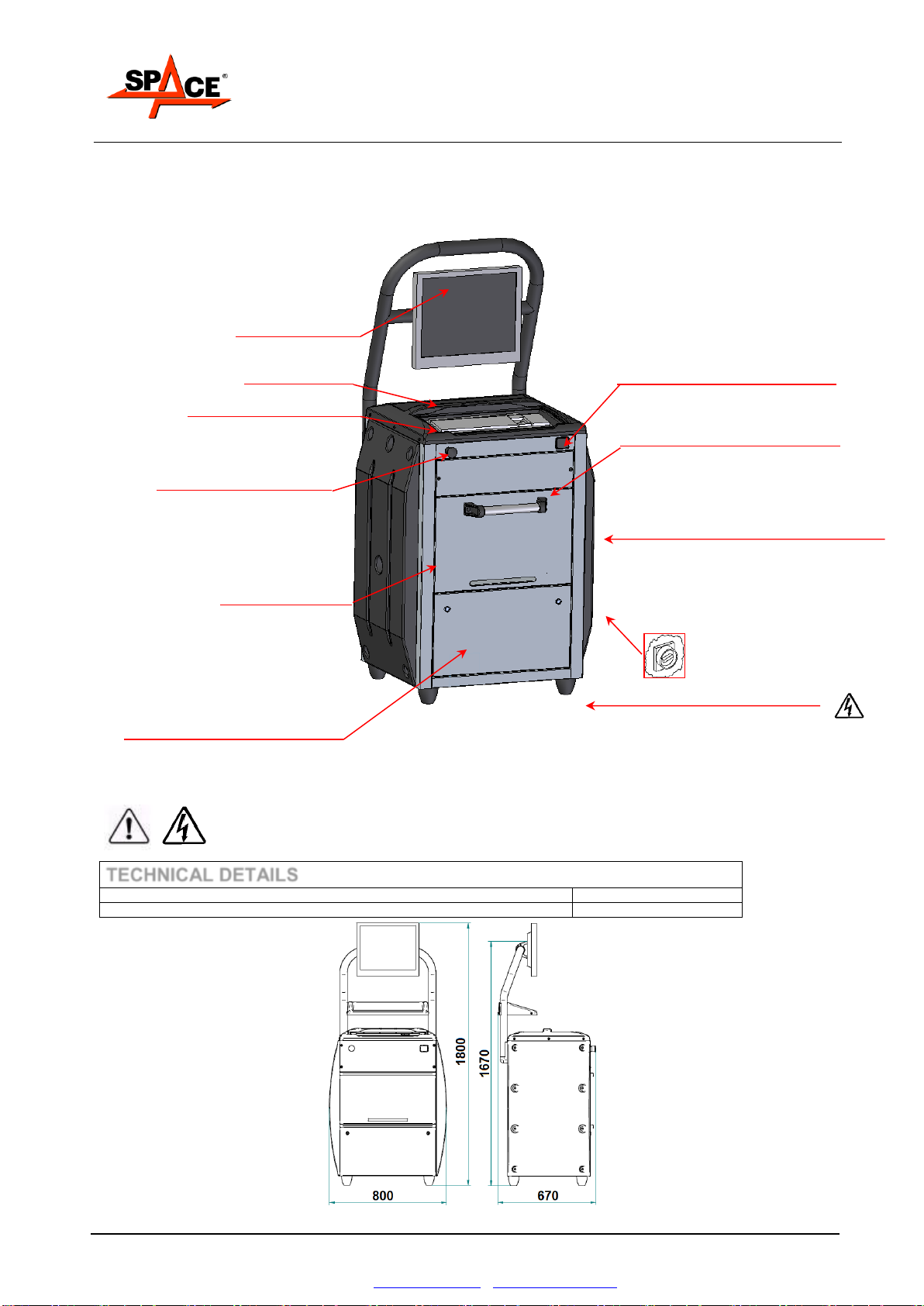

3.3. Console PFC800E000

Figure 8

IMPORTANT!: The rear door leading to the switchboard and the front panel leading to the CPU

board and power board can only be opened by authorized personnel these

compartments contain high-voltage components which can prove hazardous to

unskilled operators.

TECHNICAL DETAILS

Power supply

400V 3ph + neutral

Weight

155kg

1) Monitor for displaying the choice and

sequence of test stages, initial setting,

real-time display of the test and of the

results; monitor size 22”.

Correct luminosity and contrast are

factory set.

2) 102-key PC type keyboard

10) Remote-control infrared receiver

6) Pictograms affixed to the machine:

Shock hazard

9) On the rear is door with a lock to key on

which the main switch is present, (part. 8)

Inside of which the switchboard is housed

for the powering of the entire system and

the starter of the motors.

4) Glove compartment

7) On the front is a panel with a lock to key.

Inside the door is a shelf with the CPU board

for managing the signals from the different

measurement devices and the power

supply board.

8) Main switch / emergency device (in

the back side)

11) An IBM compatible PC can be

accessed featuring HD, an SVGA

graphic card, an RS232 serial port

3) Roller stop button. Once this has been

pressed, to reset operation, it must be

turned clockwise.

5) Printer housed behind the central door.

The test results are printed on an ink jet

printer for A4 format sheets.

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Page 17/68

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

3.4. Console PFC750/WALL

Space saver control unit wall mounted.

It is available with PC, keyboard, 19 SVGA monitor and printer included or not.

Figure 9

IMPORTANT!: The door leading to the switchboard, the CPU board and power board can only be

opened by authorized personnel; these compartments contain high-voltage

components which can prove hazardous to unskilled operators.

TECHNICAL DETAILS

Power supply

400V 3ph + neutral

Precision

±0,5%

Weight

40 kg

User Manual

SPACE s.r.l.

Soc.a socio unico

PFB035 SERIES –PFB040 SERIES

PFB045 SERIES –PFB060 SERIES

SPRT102/4 SERIES –SPRT102/5 SERIES

SPRT102/6 SERIES –SPRT102/7 SERIES

Code M0247 - Ver.1.4

(09/2016)

Page 18/68

SPACE s.r.l. –10090 TRANA (TO) Via Sangano, 48

Tel. (+39) 011/ 934 40 300 –Fax (+39) 011/ 933 88 64

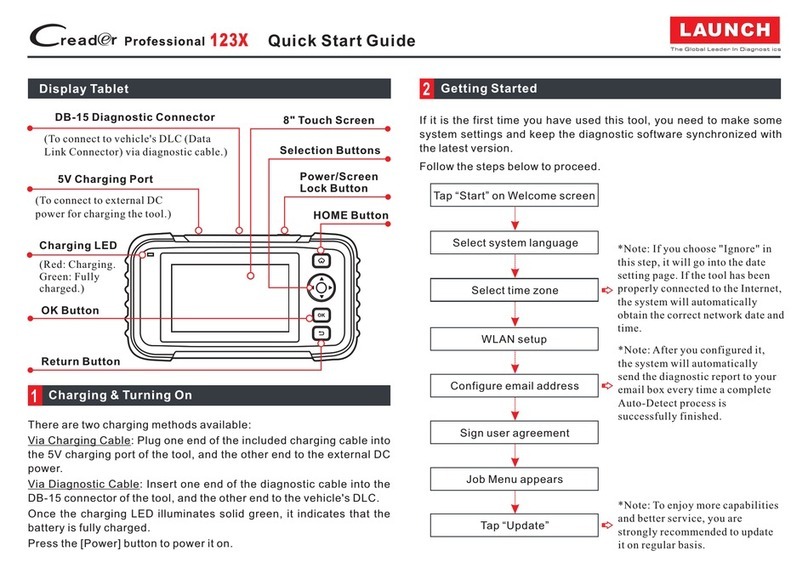

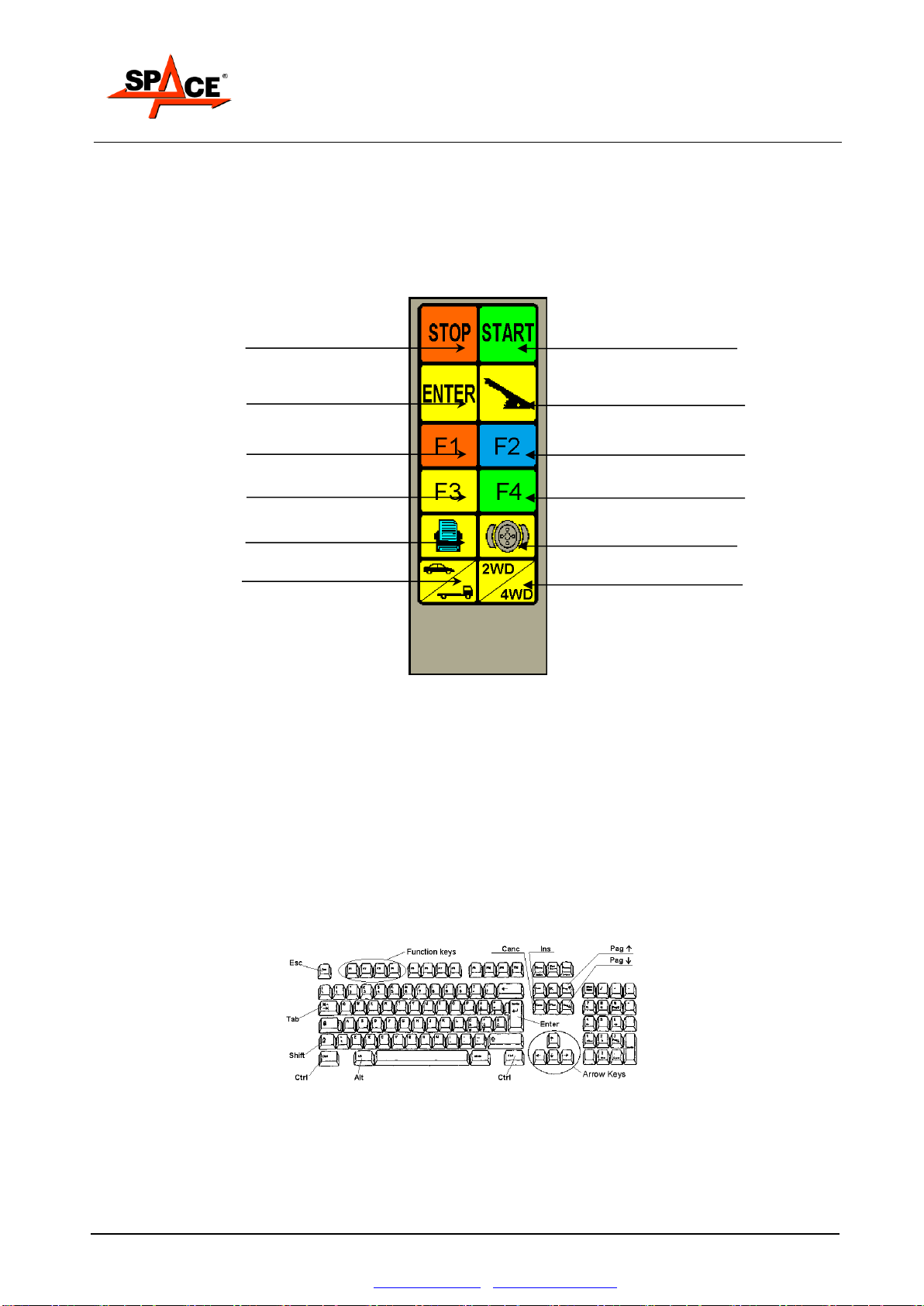

3.5. Remote control

The control interface with the console consists mainly of the 12-key infrared beam remote control.

The entire test procedure can be conducted from the remote control. Thanks to the icons, the keys

are easy to distinguish during the test.

The function keys (F1, F2, F3 and F4) take on different meanings from time to time. Reference

must be made to the graphic representation of such keys on the lower part of the monitor.

Interruption or end of test key

Test start key

Test storage key

Parking brake selection key

Function key F1

Function key F2

Function key F3

Function key F4

Print request key

Brake ovality (out-of-roundness)

procedure selection key

Car /Truck procedure selection

key

2WD / 4WD procedure selection key

Figure 10

3.6. Control keyboard

All models feature a standard 102-key keyboard connected to the PC.

The PC keyboard acts as an interface for entering details of the car, for headings, for first

configuration setting and for entering the maximum parameters acceptable for the measured

quantities.

These parameters can only be changed by qualified users according to acceptability criteria which

can change according to reference norms, specific analyses and studies, etc.

In case of faulty operation of the remote control, the test can be fully performed through the PC

keyboard on the function keys.

Figure 11

This manual suits for next models

33

Table of contents