Advanced Diagnostics AD100 User manual

OPERATING & APPLICATIONS MANUAL

OPM100

AD100

Operating Manual Section 1

Citroen Manual Y Section 2

Daewoo Manual N Section 3

FordManual N Section4

General Motors Manual Y Section 5

Hyundai Manual Y & N Section 6

Jaguar Manual N Section 7

Kia Manual Y & N Section 8

Land Rover Manual N Section 9

Mitsubishi Manual N Section 10

Nissan Manual Y & N Section 11

Peugeot Manual Y Section 12

Renault Manual Y Section 13

RoverManual N Section14

SuzukiManual N Section15

VAG Manual Y Section 16

Key Fob Programming Section 17

Tips&Hints Section18

PIN CODE

REQUIRED

OPM100

AD100

Advanced Diagnostics Ltd cannot accept any legal liabilities for

innacuracies within this publication or for any work carried out using the

AD100. Advanced Diagnostics Ltd reserve the right to alter specifcations

without notice.

No part of this publication may be reproduced, stored in a retrievel

system, or transmitted in any form, or by means, electronic, mechanical,

photocopying, recording or otherwise, without the prior permission of

Advanced Diagnostics Ltd.

CERTAIN MATERIAL CONTAINED IN THE MANUALS IS INCLUDED WITH THE THANKS

TO SIMON ASHBY OF DIAGNOSTIC TECHNIQUES

WWW.DNTN.CO.UK

OPM100

CONTENTS

1.1

2.1

3.1

4.1

5.1

PAGE

AD100

PRECAUTIONS

INTRODUCTION

GENERAL OPERATION

FAULT CODES

SOFTWARE UPDATES

Version 3.0 07/01

LIVE DATA 6.1

ACTUATORS

ECU CODING

7.1

8.1

SPECIFICATION 9.1

1.1

PRECAUTIONS

1. The AD100 is an electronic piece of equipment, and although designed for hostile

environments it should not be exposed to excessive sunlight, high temperatures or

immersed in liquids.

2. Return unit to carrying case when not in use.

3. Observe normal health and safety precautions when using this equipment.

4. When performing road tests, use a second person to operate the AD100.

5. Keep clear of all moving objects when near engine compartment.

6. When connecting to vehicle connectors, probe from the back.

7. Ignition circuits generate high voltages, extra precautions and care should be observed

when diagnosing these systems.

8. Incorrect connections may damage sensitive electronic devices fitted to the vehicle.

9. Switch off the vehicle ignition when making or breaking connections.

10. Keep the unit away from spark plugs and coil leads to avoid measurement errors.

11. DO NOT disconnect any wiring harnesses or electronic component while ignition is

ON.

12. DO NOT disconnect battery while engine is running.

13. Before any work is carried out, consult the Vehicle Manufacturers recommended

procedures to ensure any work is carried out in accordance with their instructions.

14. Before any work is carried out, consult the Vehicle Manufacturers warranty

specifications to ensure any work is carried out in accordance with their instructions.

2.1

INTRODUCTION

PRODUCT DESCRIPTION

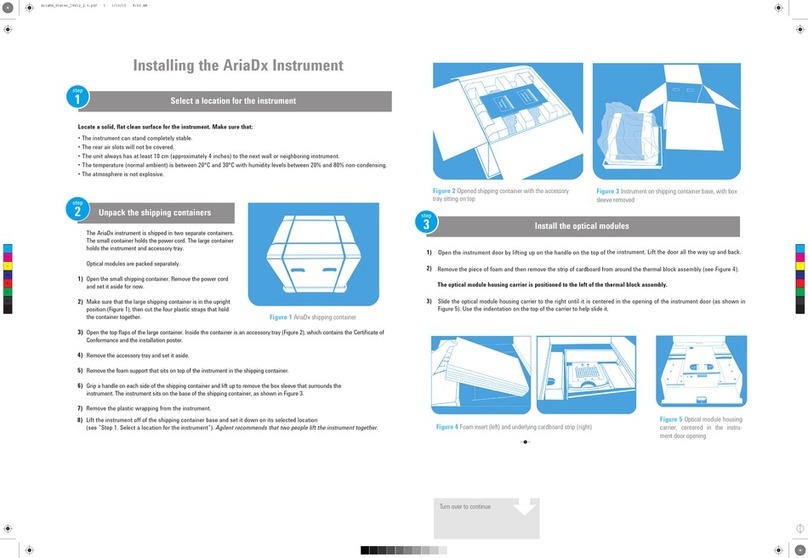

The AD100 is an Advanced Serial Diagnostic system which has been designed and

developed to offer the most advanced diagnostic capabilities.

The AD100 can be used as a hand held portable diagnostic system, and is equipped with

64MB of RAM which is used for the application data, and 4MB of Flash for the protocol

handling system. In addition to this it has a RS232 interface connection for transferring

application data from a PC and printing.

The unit has a 128x64 Dot Matrix Back Lit LCD TFT display along with membrane keypad.

The unit is capable of reading fault codes, clearing fault codes, displaying live data,

performing special functions, and recording live data both statically and on the road.

The unit is powered from the vehicle battery, and connects to the serial diagnostic

connector through a 25way D-Type cable system.

POWER CONNECTION

The unit is powered by the vehicle 12 volts battery which is connected to the diagnostic

socket. If no power is available through the vehicle diagnostic socket then the adapter

cable will have the vehicle battery connections.

VEHICLE CONNECTION

The master cable AD110 is used to connect the equipment to the various adapters

available for the different vehicle connector types.

This system enables the equipment to be kept up to date with the various diagnostic

connectors at a reasonable cost.

LCD BACKLIGHT

The LCD BACKLIGHT is automatically switched on when the unit has power. This cannot

be switched off or adjusted. If the unit is not used for a period of time the LCD backlight

will automatically switch off, and as soon as any key is pressed it will switch back on

again.

3.1

GENERAL OPERATION

KEYPAD OPERATION

FIG 2

FIG 3

FIG 4

Key is use for ENTER and CONTINUE operations

Key’s used for UP and DOWN

movement of selection.

Key is used for EXIT and going

BACKWARDS selections.

Number keys for entering

codes and number selection.

FIG 5

3.2

GENERAL OPERATION

PASSWORD OPERATION

To stop unauthorised access the unit is fitted with a password system which is required to

perform certain operations such as Immobiliser programming etc. Additionally the

protection system is also used to protect unauthorised copying of update software. If there

are any problems with password operation or with software update, then the unit must be

retruned to Adavanced Diagnostics.

MASTER CABLE & ADAPTOR CABLE CONNECTIONS

The unit is supplied with a range of cables to cover various manufacturers. The smaller

adaptor cables use the ADC100 Master Cable, which connects to the AD100. These

adaptor cables can then be connected depending on which system is being tested.

_ _ _ _ _ _

FIG 6

FIG 7

3.3

GENERAL OPERATION

INITIAL OPERATION

After the correct cables and adaptor has been connected to the vehicle the AD100 will

power up and the intial screen will be the contrast adjust. The screen will cycle between

dark and light, and will stop as soon as a key is pressed.

Us the UP and DOWN arrows to adjust the contrast, then press the ENTER key.

The following sceen will be displayed.

Using the UP and DOWN arrows select the required manufacturer, and then press the

ENTER key.

NOTE : For further information and operation refer to the specific applications manual

> FORD

GM

LDV

ROVER

VAG

DIAGNOSTIC MENU

PRESS ENTER KEY

FIG 8

FIG 9

4.1

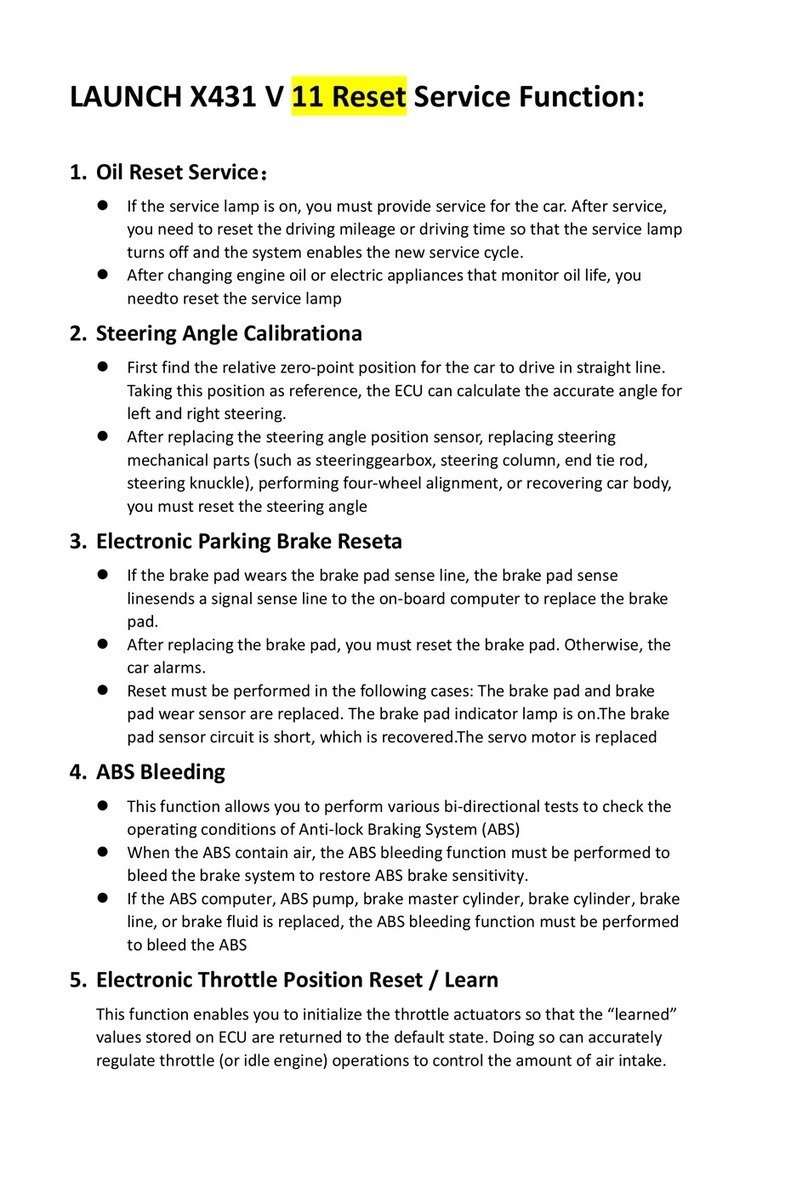

SOFTWARE UPDATE’S

SOFTWARE UPDATES

PROCEDURE

1. CONNECT TRANSFER LEAD ADC126 OR ADC121 TO PC AND AD100 AS

SHOWN BELOW.

2. CONNECT PLUG TO MAINS

POWER.

3. CONNECT 25 WAY D-TYPE TO

AD100.

4. INSERT 6 digit PASSWORD ON

AD100 SO THAT SCREEN DIS-

PLAYS THE MAIN MENU SELEC-

TION SCREEN.

5. CONNECT 9 WAY D-TYPE TO

COM1 OF PC.

6. INSERT CDROM, AND USING

FILE MANAGER OR MYCOMPUTER

SELECT THE FILE LOADER.EXE

AND DOUBLE CLICK TO RUN.

7. SELECT LOAD BUTTON

8. TYPE IN AD100 SERIAL NUM-

BER. NOTE : DO NOT LEAVE A

ZERO IN FRONT OF NUMBER. SE-

RIAL NUMBER CAN BE FOUND ON

REAR OF AD100.

9. SOFTWARE WILL NOW ERASE

OLD APPLICATION.

NOTE : IF THE INCORRECT

SERIAL NUMBER IS USED OR FILE

NAMES ARE CHANGED THEN THE

AD100 WILL BE

RENDERED USELESS.

4.2

SOFTWARE UPDATE’S

SOFTWARE UPDATES

10. THE LOADER PROGRAM WILL

START TO LOAD THE NEW APPLI-

CATION.

11. AFTER SUCCESSFUL LOADING

THE SCREEN WILL DISPLAY

DOWNLOAD COMPLETE.

12. PRESS OK AND DISCONNECT

FROM PC AND CHECK TESTER

HAS LOADED CORRECT SOFT-

WARE AND PIN NUMBER.

5.1

FAULT CODE OPERATION

READING FAULT CODES

Depending on how many fault codes are set, will depend on how many screens are

displayed, however two examples are shown below.

ECU IDENTIFICATION

FAULT CODES

LIVE DATA

ACTUATORS

SPECIAL FUNCTIONS

DIAGNOSTIC MENU

SPECIAL FUNCTIONS

READ FAULT CODES

CLEAR FAULT CODES

DIAGNOSTIC MENU

PRESS ENTER KEY

FAULT CODE :1176

KEY

SIGNAL TOO LOW

CURRENT FAULT

DISPLAY FAULT CODES

PRESS ENTER KEY

FAULT CODE :1176

DOOR SWITCH FAULTY

INTERMITTENT

DISPLAY FAULT CODES

PRESS ENTER KEY

Using the UP and DOWN keys select

the FAULT CODES selection.

Then press the ENTER key.

Using the UP and DOWN keys

select the READ FAULT CODES

selection.

Then press the ENTER key.

NOTE : THE FAULT CODES CAN EITHER BE CURRENT, HISTORIC OR INTER-

MITTENT, AND WILL INDICATE THESE STATES DEPENDING ON WHETHER THE

FAULT IS STILL THERE.

5.2

FAULT CODE OPERATION

READING FAULT CODES (Contd)

CLEARING FAULT CODES

READ FAULT CODES

CLEAR FAULT CODES

DIAGNOSTIC MENU

PRESS ENTER KEY

NO FAULTS FOUND

DISPLAY FAULT CODES

PRESS ENTER KEY

PROCEDURE COMPLETE

CLEAR FAULT CODES

PRESS ENTER KEY

If there are no fault codes recorded,

then the following screen will be

displayed.

Using the UP and DOWN keys

select theCLEAR FAULT CODES

selection.

Then press the ENTER key.

If all the fault codes have been

cleared the screen will display

PROCEDURE COMPLETE.

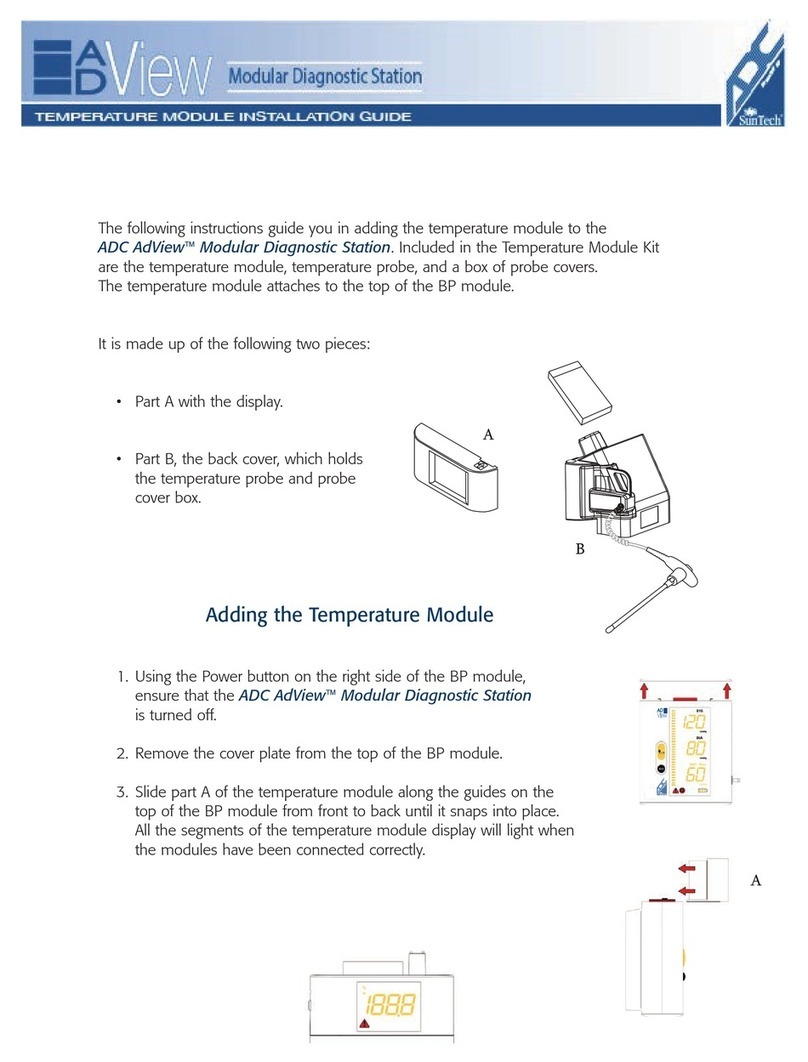

6.1

SPECIAL FUNCTIONS

LIVE DATA

ECU IDENTIFICATION

FAULT CODES

LIVE DATA

ACTUATORS

SPECIAL FUNCTIONS

DIAGNOSTIC MENU

PRESS ENTER KEY

IGN STAT ON

PASS DOOR OPEN

DRV DOOR CLOSED

RRH DOOR OPEN

TP KEY1 PROG

PLIP 1 PROG

LIVE DATA

From the DIAGNOSTIC MENU select the

LIVE DATA function.

Using the UP and DOWN arrows the

additional LIVE DATA parameters will be

displayed.

Additional parameters are shown on the

screen below.

DOOR.CL.R OFF

DOOR.OP.R ON

ENG ECU LOCKED

LO.SP.REL. ON

HI.SP.REL OFF

DR.BUT.IP YES

PASS.BUTT. PULLED

LIVE DATA

7.1

ACTUATORS

ACTUATOR OPERATION

Select ACTUATORS from the main

menu.

A list of actuators for the vehicle will be

listed. Using the UP and DOWN arrows

select the required actuator and press

the ENTER key.

The BUZZER as an example will sound

for a short period of time and then stop.

Press the BACK arrow to exit the func-

tion.

NOTE : Other actuators will operate for

various lengths of time before stopping.

ECU IDENTIFICATION

FAULT CODES

LIVE DATA

ACTUATORS

SPECIAL FUNCTIONS

DIAGNOSTIC MENU

PRESS ENTER KEY

R.H.IND

L.H.IND

HAZ.W.LAM

SCRN.WIP.SLOW

SCRN.WIP.FAST

BUZZER

DE-ICING

ACTUATORS

BUZZER

ACTUATOR ON/OFF

PLEASE CHECK OUTPUT

PRESS BACK TO EXIT

8.1

ECU CODING

ECU CODING OPERATION

Select SPECIAL FUNCTIONS from the

main menu and then RECODE ECU from

SPECIAL FUNCTIONS.

Follow on screen instructions to re-

code ECU.

IMPORTANT NOTE : After coding, TURN

IGNITION to OFF position and discon-

nect AD100.

Wait 1 minute and then test for correct

operation.

.

ECU IDENTIFICATION

FAULT CODES

LIVE DATA

ACTUATORS

SPECIAL FUNCTIONS

DIAGNOSTIC MENU

PRESS ENTER KEY

9.1

SPECIFICATIONS

DESCRIPTION SPECIFICATION

OPERATING SUPPLY 12 VOLTS DC

DISPLAY 128 x 64 GRAPHIC DOT MATRIX

LED BACKLIT

COMMUNICATION PORT CAN, J1850, ISO9141

REVERSE POLARITY YES

SIZE 230 mm x 115 mm x 80 mm

WEIGHT 400 gms

MEMORY 512KB RAM

8MB FLASH

64KB ROM

STORAGE TEMPERATURE 0°C to +50°C

OPERATING TEMPERATURE +5°C TO +40°C

CURRENT CONSUMPTION 200 mA

SERIAL PORT RS232

TECHNICAL TIPS & HINTS FAX BACK FORM

NAME :

COMPANY :

DATE :

VEHICLE :

YEAR :

CONNECTOR LOCATION :

PROBLEMS :

SOFTWARE : Version :

TIPS :

THANK YOU FOR YOUR TIME.

Table of contents