SpanDeck MANTIS 8010 User manual

REV: DATE:

OPERATOR’S MANUAL

FOR THE

MANTIS™MODEL 8010

40-TON DIESEL-POWERED,

HYDRAULICALLY-OPERATED

CRAWLER CRANE

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

ii

REV: DATE:

TABLE OF CONTENTS

1. OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Operator Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Directional References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Capacity Limits and General Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Lubrication and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. DASH/CONTROL PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Engine Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Swing Right/Left Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Telescope Out/In Control; Auxiliary Winch Control . . . . . . . . . . . . . . . . . . . .9

Main Winch/Boom Hoist Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Travel Controls; Tracks Extend/Retract Switch . . . . . . . . . . . . . . . . . . . . . .11

Auxiliary Equipment Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Other Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3. LOAD MOMENT INDICATOR/ANTI-TWO-BLOCK SYSTEM . . . . . . . . . . . . . .15

Load Moment Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Load Chart Selection & Load Moment Indicator Setting . . . . . . . . . . . . . . .15

Anti-Two-Block (A2B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4. ENGINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Alarm Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Walk-Around Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Electric Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Starting With Jumper Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

After Starting The Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Engine Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

After Stopping The Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5. WINCH/AUGER CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6. BOOM CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7. SWING CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8. TRAVEL CONTROLS; TRACKS EXTEND/RETRACT SWITCH . . . . . . . . . . . .29

9. AUXILIARY WINCH CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

10. TOOL/AUGER OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

iii REV: DATE:

APPENDICES

A. BOOM LOAD CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

B. MAINTENANCE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

C. CAPACITIES & SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

D. FILTER CROSS REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

E. COLD WEATHER OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

F. REEVING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

G. PREPARATION FOR SHIPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

H. COUNTERWEIGHT REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . . . . .49

I. JIB/EXTENSION REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . .51

J. MAIN BOOM REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

K. CRAWLER FRAME REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . . . . .55

L. TERMS & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

iv

REV: DATE:

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

REV: DATE:

The Mantis 8010 is a diesel-powered, hydraulically-

operated crawler crane. Its maximum load capacity is

40 U.S. tons (36.2 metric tons), depending on boom

position and rigging.

The 8010 is operated from the crane operator’s cab.

This main operating station provides for operation

and monitoring of all crane functions, including winch,

boom, swing, and travel controls. All controls for nor-

mal crane operations are arranged in the standard

configuration for crane operation.

DO NOT ATTEMPT TO OPERATE THIS EQUIP-

MENT UNTIL YOU READ AND FULLY UNDER-

STAND ALL OF THE OPERATING INFORMATION IN

THIS MANUAL.

FAILURE TO DO SO WILL CREATE A HAZARDOUS

SITUATION THAT MAY RESULT IN SERIOUS

INJURY, DEATH AND/OR EQUIPMENT DAMAGE.

Although the Mantis 8010 is simple to operate and

care for, the operator must be thoroughly familiar with

its operating controls and methods before starting any

lifting work. Prior to operating the 8010, read and

understand the information in this manual.

This machine uses a number of specialized controls

and operator aids to enhance operation. Some of

these devices may be unfamiliar to you. Your dealer,

as part of his service, can explain any control or

maintenance functions that are not clear.

The way you operate and maintain the Mantis 8010

for its first 100 hours will largely determine its useful

life and freedom from unscheduled maintenance. This

manual contains use and regular maintenance

instructions for the 8010. Keep it handy, preferably in

the operator’s cab, and refer to it often.

MANUAL ORGANIZATION

This manual is organized as follows:

1. Overview - describes the 8010 in general, lists

general cautions for safe crane operation, and

explains the crane’s systems and the way its docu-

mentation is organized.

2. Dash/control panels - describes the operator con-

trols

3. Engine Controls

4. Load Moment Indicator/Anti-Two-Block Control

5. Engine - describes the startup and shutdown pro-

cedures and routine checks necessary to make

sure the engine is operating properly and to keep it

operating reliably.

6. Winching system - Describes the operation of the

lifting winch and proper hoisting procedures for the

8010.

7. Swing System - Describes the swing system and

its operation

8. Boom Controls - Describes the operation of the

boom up/down and telescope in/out systems.

9. Travel - describes the operation of the 8010’s trav-

el controls.

10. Routine Maintenance - details the maintenance

functions the operator usually performs as part of

crane operation.

1

1. OVERVIEW

DANGER!

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

OPERATOR ALERTS

This manual uses a number of alert levels to warn the

operator about certain hazardous conditions. These

alerts are listed below.

NOTE or WARNING

Indicates an operating or fault condition which may

cause equipment damage if not corrected.

Indicates an operating or fault condition which is very

likely to cause equipment or load damage.

Indicates a situation which will cause major equip-

ment damage, operator injury, or death.

DIRECTIONAL REFERENCES

Craning Operations

When the words “right” and “left” designate direction

in craning operations, they refer to the right- or left-

hand side of the 8010 as viewed from the operator’s

cab, no matter which direction the cab is facing.

Travel Operations

When the words “right” and “left” designate direction

in travel operations, they refer to the right- or left-

hand side of the 8010 as viewed with the operator

cab facing forward (boom over the idler end of the

undercarriage). If the cab is facing backward (boom

over the drive end of the undercarriage), all travel

control functions are reversed.

Always use caution when using the 8010’s travel con-

trols as well as any other function.

CAPACITY LIMITS AND

GENERAL CONDITIONS

The MANTIS 8010 Crane as manufactured by

SpanDeck, Inc. meets the requirements of ANSI

B30.5c (1992) when specifically equipped. Structure

and stability have been tested in accordance with

SAE J1063 and SAE J765, respectively. Lifting

capacities as determined by boom length, angle, or

lifting radius apply only to machines as originally

equipped by the manufacturer and in a properly main-

tained condition.

Capacities given are maximum covered by the manu-

facturer’s warranty and are based on a freely sus-

pended load with no allowance for factors such as

out-of-level operation, supporting surface conditions,

hazardous surroundings, experience of personnel,

etc.

The operator shall establish practical working loads

based on prevailing operating conditions such as, but

not limited to, those listed above.

When making lifts where capacities may be within a

zone limited by structural strength, the operator shall

determine that the weight of the load is known within

± 10% before making the lift.

DO NOT lift a load without consulting the Load Chart.

Deductions from rated capacities must be made for

the weight of the hook block, overhaul ball, slings,

spreader bar, or other suspended equipment.

2

REV: DATE:

CAUTION

DANGER!

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

SIDE PULL ON THE BOOM IS EXTREMELY

DANGEROUS AND MUST BE AVOIDED.

DO NOT EXCEED THE MANUFACTURER’S SPECI-

FIED MAXIMUM REEVING.

Load radius is defined as the horizontal distance from

the axis of rotation to the center of the lifting device

after load is applied.

Boom angle is the included angle between the longi-

tudinal axis of the boom base section and the hori-

zontal axis, after lifting the load. The boom angle

before lifting should be somewhat greater than

desired to account for boom deflection.

Boom angle/boom length relationships given in the

load charts are an approximation of the resulting load

radius, which should be accurately measured.

Boom height dimensions are measured from ground

to center of lower boom head sheave.

It is permissible to attempt to telescope the boom

with a load within the limits of rated capacities.

However, boom angle, system hydraulic pressure,

and/or boom lubrication may affect operation.

The 8010 utilizes an LMI/A2B unit which monitors

crane load, boom position and boom angle to deter-

mine whether the 8010 is operating within its limits.

This unit also incorporates an “anti-two-block” control

device to prevent the crane’s lifting block from con-

tacting the boom head sheaves. See Section 3, p.15,

for details of LMI/A2B operation.

LUBRICATION AND MAINTENANCE

Proper and timely lubrication and service are essen-

tial for satisfactory performance of the 8010. Refer to

the sections on lubrication and service in this manual.

Tighten all nuts, bolts, and hydraulic and electrical

connectors on the 8010 after the first 100 hours of

operation, then periodically reinspect them to make

sure that everything remains tight.

At least once a month, do a thorough walk-around

inspection of the crane. Finding and correcting minor

problems before they become serious can prevent

considerable downtime.

Protect against dirt - Before removing inspection cov-

ers, panels, filler caps, etc., from any part of the

8010, clean away all dirt around the opening. Keep

all fuel and lubricants clean; use only fuel and lubri-

cants that you know are clean. Keep all filler caps in

place except when you are actually adding fluid and

then replace them promptly.

If you experience any operating or service problems,

contact your Mantis dealer or the factory immediately.

3REV: DATE:

DANGER!

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

4

REV: DATE:

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

The 8010’s operator controls are grouped into nine

main functional groups as follows:

• Engine Controls

• Swing Right/Left Controls

• Telescope Out/In Control; Auxiliary Winch Control

• Main Winch Lower/Raise Control

• Boom Hoist Raise/Lower Control

• Travel Controls; Tracks Extend/Retract Switch

• Auxiliary Equipment Controls

• Other Operator Controls

• Load Moment Indicator/Anti-Two-Block System

The illustrations on this page show the layout of the

8010’s control panels

2. DASH/CONTROL PANELS

5REV: DATE:

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

ENGINE CONTROLS

Voltmeter

This gauge indicates the condition of the 8010’s elec-

trical system by displaying the battery voltage. Proper

operation is indicated by a reading in the green zone

(12-15 volts). Readings outside this range indicate a

problem with one or more electrical system compo-

nents.

Engine Hour Meter

This meter displays cumulative engine running time in

hours.

Oil Pressure Gauge

This gauge indicates the engine oil pressure. Proper

pressure may vary between 35 and 70 psi (2.4 and

4.8 bar) depending on engine and outside tempera-

ture, load, and engine speed.

Oil Pressure Warning Light

This light illuminates to indicate that the engine oil

presure is too low. If this warning light comes on, the

operator should stop the engine as soon as possible

and determine the cause.

Engine Temperature Gauge

This gauge indicates engine coolant temperature

(water-cooled engines) or cylinder head or oil temper-

ature (air-cooled engines).

For water-cooled engines, this gauge should read

between 160 and 205°F (71 and 96°C) once the

engine has reached operating temperature.

Readings outside this range indicate low coolant level

(water-cooled engines only) or a problem with one or

more cooling system components.

Engine Temperature Warning Light

This light illuminates to indicate that the engine tem-

perature is too high. If this warning light comes on,

the operator should stop the engine as soon as pos-

sible and determine the cause.

Tachometer

This gauge provides a digital readout of engine rota-

tion speed.

Fuel Level Gauge

This gauge indicates the fuel remaining in the 8010’s

fuel tank.

Ignition Off/Operation/Preheat /

Start Switch

This rotary switch controls starting and stopping of

the engine. See Engine Operation, p.17, for starting

and stopping instructions.

Starting Aid Switch

When pressed while the starter motor is engaged,

this pushbutton injects a timed shot of starting fluid

into the engine’s intake manifold to aid starting. The

operator should use this control sparingly and only

when the engine will not start readily in cold weather.

Throttle

This rotary knob sets a constant engine speed for lift-

ing or travel operation. When turned to any position

above idle (full counterclockwise), it sets the engine

speed. The throttle pedal (Other Operator Controls,

p.12) can temporarily override the setting of this con-

trol if desired.

See Engine Operation, p.17, for guidelines on proper

engine speeds under various operating conditions.

Air Filter Warning Light

This light illuminates to indicate that engine air flow is

restricted and the filter needs to be serviced.

12

11

10

9

8

7

6

5

4

3

2

1

6

REV: DATE:

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

REV: DATE:

7

1 2

5

6

7

12

9

8

11

4

3

10

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

SWING RIGHT/LEFT CONTROLS

NOTE: Speed of operation of the Swing System is

directly proportional to engine speed and control lever

displacement

Swing Control/Horn Button

This lever controls the Boom Swing function. Pushing

the lever forward swings the boom right and pulling it

backward swings the boom left.

The button at the top of this control lever sounds the

warning horn when depressed.

Swing Brake Pedal

This pedal engages the swing brake when pushed

forward (toe down) and releases it when pushed

backward (heel down).

DO NOT REST YOUR FOOT ON THE SWING

BRAKE PEDAL.

Swing Brake Switch

This toggle switch engages (ON) or disengages

(OFF) the swing park brake.

NEVER ENGAGE THE SWING PARK BRAKE

WHEN THE SWING IS IN MOTION.

TELESCOPE OUT/IN CONTROL,

AUXILIARY WINCH CONTROL

Auxiliary Winch On/Off Switch

This toggle switch enables (ON) or disables (OFF)

auxiliary winch rotation. When the auxiliary winch is

disabled, the boom telescope function is enabled.

Telescope/Auxiliary Winch Control

When the Auxiliary Winch On/Off Switch is in the off

position, this lever controls the boom telescope func-

tion; pushing it forward extends the boom and pulling

it backward retracts the boom.

When the Auxiliary Winch On/Off Switch is in the on

position, this lever controls the auxiliary winch; push-

ing it forward lowers the hook block and pulling it

backward raises the hook block.

Auxiliary Winch Speed Range Button

This button, at the top of the Telescope control lever,

selects either the low (button not depressed) or high

(button depressed) range of auxiliary winch rotation.

6

5

4

3

2

1

8

REV: DATE:

CAUTION

CAUTION

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

9REV: DATE:

2

3

4

16

5

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

MAIN WINCH/BOOM HOIST

CONTROLS

NOTE: Speed of operation of the Winch and Boom

Hoist Controls is directly proportional to engine speed

and control lever displacement

Main Winch/Auger Control

When the AUGER/VIBRO switch (See Auxiliary

Equipment Controls, P.11) is off, this lever controls

the main winch: pushing it forward lowers the hook

block and pulling it backward raises the block.

Speed Range Button

This button, at the top of the Main Winch/Auger

Control lever, selects either the low (button not

depressed) or high (button depressed) range of

main winch rotation.

Boom Hoist Raise/Lower Control

This lever controls the Boom Hoist function. Pushing

the lever forward lowers the boom; pulling it back-

ward raises the boom

3

2

1

10

REV: DATE:

1

2

3

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

TRAVEL CONTROLS

Left/Right Track Forward /Track

Reverse Pedals

These pedals control the track motion. Pushing either

right or left pedal forward (toe down) moves its track

forward; pushing either pedal backward (heel down)

moves its track backward.

Travel speed is proportional to engine speed and

pedal displacement.

Speed High/Low Switch

This toggle switch selects either high (2.2 mph, 3.5

km/h) or low (1.3 mph, 2.1 km/h) travel speed.

Park Brake On/Off Switch

This toggle switch engages (for crane operation) or

disengages (for crane travel) the travel brake.

OPERATOR CAB ORIENTATION AFFECTS THE

OPERATION OF THE TRAVEL FUNCTIONS. SEE

DIRECTIONAL REFERENCES, P.2.

TRACKS EXTEND/RETRACT

SWITCH

This toggle switch controls the position of the crane’s

tracks. The switch is spring-loaded to the center posi-

tion. When the switch is pushed toward extend, the

tracks move to their wide (17.3 ft, 5.28 m) configura-

tion for lifting. When it is pushed toward retract, the

tracks move to their narrow (10.9 ft, 3.32 m) configu-

ration for travel or transport.

NEVER LIFT LOADS WITH THE 8010 UNLESS THE

TRACKS ARE FULLY EXTENDED.

THE OPERATOR MUST ENSURE THAT NO

PERSONNEL ARE NEAR THE 8010’S TRACKS

BEFORE ENGAGING THE TRACKS EXTEND

FUNCTION.

5

4

3

2

1

11 REV: DATE:

CAUTION

DANGER!

DANGER!

4

3

5

1 2

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

AUXILIARY EQUIPMENT

CONTROLS

Tool High/Off/Low Switch (Option)

This toggle switch selects either high (10 GPM, 37.8

l/min) or low (5 GPM, 18.9 l/min) hydraulic fluid vol-

ume for the optional tool connector ports or turns the

ports off.

Auger/Vibro On/Off Switch (Option)

This toggle switch turns pressure to the auger/vibro

connection ports on or off to control auger/vibro oper-

ation.

Main Winch/Auger Control

When the AUGER/VIBRO switch is on, this lever con-

trols auger operation: pushing it forward rotates the

auger forward and pulling it backward rotates the

auger in reverse.

Speed Range Button

This button, at the top of the Main Winch/Auger

Control lever, selects either the low (button not

depressed) or high (button depressed) range of

auger rotation.

If the 8010 is equipped with a vibro hammer instead

of an auger, this button has no function when the

AUGER/VIBRO switch is on.

Auger Latch Open/Closed Switch

(Option)

This toggle switch engages or disengages the latch

that holds the auger in stowed position.

5

4

3

2

1

12

REV: DATE:

2

3 4

5

1

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

OTHER OPERATOR CONTROLS

Throttle Pedal

This pedal controls engine speed; pushing the pedal

down increases speed, releasing it decreases speed.

This control can override the setting of the throttle

knob (See Engine Controls, P.6) if the operator wish-

es to temporarily speed up the engine.

Level Gauge

This is a dual-bubble device which allows the opera-

tor to determine whether the 8010 is level in both

front-rear and left-right directions.

ANY OUT-OF-LEVEL CONDITION WILL AFFECT

THE 8010’S LIFTING CAPACITY. SEE APPENDIX A,

BOOM LOAD CHARTS FOR DETAILS.

Warning Light Test Switch

This button, when pushed with the engine running,

illuminates all of the operator panel warning lights to

check their function. The operator should check all

warning lights each time he starts the engine.

Fuel Filter/Water Separator

Warning Light

The warning light in this unit illuminates to indicate

that the water separator is nearly full and needs ser-

vice.

Hydraulic Oil Temperature/

Filter Alert Lights

These two warning lights illuminate to warn the oper-

ator that the hydraulic oil is too hot or that the filter

has become clogged. Either condition signals the

operator to cease lifting operations as quickly as pos-

sible and to find and correct the problem.

Hydraulic Cooling System

Auto/Manual Switch

This switch selects between thermostatically-con-

trolled (AUTO) or continuous (MANUAL) operation of

the hydraulic cooling system. Under normal opera-

tion, this switch should be left in Auto. However, the

operator may override this automatic operation at any

time by switching to Manual.

Circulating Fan Hi/Off/Low Switch

This toggle switch selects high or low speed opera-

tion of the circulating fan motor or turns it off.

Heater Fan Off/Low/Hi Switch

This rotary switch selects high or low speed operation

of the heater blower motor or turs it off.

Defrost On/Off Switch

This toggle switch turns the defrost blower motor on

or off.

Heat Control

This push-pull control adjusts the temperature of the

air circulated by the heater fan. Pulling the knob out

raises the temperature; pushing it in lowers the tem-

perature.

Windshield Wiper Control

This rotary switch selects low or high speed operation

of the windshield wiper or turns it off.

Work Lights On/Off Switch

This toggle switch turns the outside work lights on or

off.

12

11

10

9

8

7

6

5

4

3

2

1

13 REV: DATE:

DANGER!

CONTROL LAYOUT SHOWN ON NEXT PAGE

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

14

REV: DATE:

11 12

10

9

8

7

6

5

4

3

2

1

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

THE LMI/A2B IS AN OPERATIONALAID THAT

WARNS THE CRANE OPERATOR OF APPROACH-

ING OVERLOAD CONDITIONS AND ALSO WARNS

OF OVERHOIST CONDITIONS WHICH COULD

CAUSE DAMAGE TO EQUIPMENT AND INJURY TO

PERSONNEL.

THE DEVICE IS NOT, AND SHALL NOT BE, A SUB-

STITUTE FOR GOOD OPERATOR JUDGMENT,

EXPERIENCE, AND THE USE OF ACCEPTED

CRANE OPERATING PROCEDURES.

THE RESPONSIBILITY FOR THE SAFE OPERA-

TION OF THE CRANE SHALL REMAIN WITH THE

CRANE OPERATOR, WHO SHALL ENSURE THAT

HE UNDERSTANDS AND OBSERVES ALL SUP-

PLIED WARNINGS AND INSTRUCTIONS.

PRIOR TO OPERATING THE CRANE, THE OPERA-

TOR MUST CAREFULLY AND THOROUGHLY READ

AND UNDERSTAND THE INFORMATION IN THIS

MANUAL TO ENSURE THAT HE KNOWS THE

OPERATION AND LIMITATIONS OF THE LMI/A2B

SYSTEM AND CRANE.

PROPER FUNCTIONING IS DEPENDENT UPON

PROPER DAILY INSPECTIONS AND UPON

OBSERVATION OF THE OPERATING INSTRUC-

TIONS SET FORTH IN THE LMI/A2B MANUAL.

The Mantis 8010 is equipped with a Load Moment

Indicator (LMI)/Anti-Two-Block (A2B) system which

aids the operator in preventing overload and two-

block conditions. The system is factory set and no

adjustments can be made to it by unauthorized per-

sonnel.

The LMI/A2B unit is programmed with load charts

installed in the machine during load testing at the fac-

tory. Before making a lift, the operator must select the

proper operating mode and set the reeving switch to

the appropriate “parts of line.” See Appendix A and

the LMI/A2B System Operator’s Manual for details.

LOAD MOMENT INDICATOR (LMI)

Boom length and angle are determined by the boom-

mounted reel which contains the length and angle

transducers. Based on these factors, the system

computer determines load radius which is displayed

in the operator cab.

Pressure transducers connected to the boom hoist

cylinder determine boom load by reading the

hydraulic pressure in the cylinder. The system calcu-

lates the “load-moment” based on load and load

radius and alerts the operator if an overload situation

is approaching.

In case of emergency or component failure, the oper-

ator can override the system by turning the console-

mounted key switch in the operator cab.

LOAD CHART SELECTION &

LOAD MOMENT INDICATOR SETTING

Each Load Chart in Appendix A corresponds to a par-

ticular crane configuration. The Load Moment

Indicator system must be set to match the configura-

tion in use. If it is set improperly, the crane may func-

tion poorly or not at all.

The LMI has two switches that correspond to critical

setup factors, as follows:

Counterweight Toggle Switch

This side-mounted switch selects whether or not the

crane is using a counterweight

Dec. Switch

This rotary switch selects the crane operating mode,

or boom configuration.

The chart in Appendix A shows the permissible com-

binations of settings for these three switches, as well

as the proper load charts to use for each mode. No

other combinations are allowed.

NOTE:

If you are certain that a load is within load chart limits

but the crane will not lift it, check the settings of these

two switches, as well as the reeving switch.

3. LOAD MOMENT INDICATOR/

ANTI-TWO-BLOCK (LMI/A2B) SYSTEM

15 REV: DATE:

CAUTION

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

ANTI-TWO-BLOCK (A2B)

The anti-two-block feature aids the operator in pre-

venting the hook block from contacting the point

sheaves (a “two-block” situation). This system will

stop the function(s) being used at the time the block

contacts and lifts the A2B switch weight.

The system consists of switches mounted at the

boom tip and single sheave stand-off (“Rooster”),

extension tip, or jib tip (if used). The switch(es) sup-

port a weight through which the load line passes.

When the hook block or headache ball lifts this

weight, the switch contacts close sending a signal to

a solenoid valve. When the solenoid valve receives

the signal, it shifts to divert the control pressure for

boom lower, boom extend and winch raise circuits,

stopping the functions until the two-block situation is

cleared.

As with the LMI system, in case of component failure,

the operator can override the system with the con-

sole-mounted key switch in the operator cab.

The crane operator must read the LMI/A2B System

Operator’s Manual before operating the system. In

case of a problem, the system console will display an

error code. The operator must then consult the

Troubleshooting Manual, and if unable to rectify the

problem, call the factory or a Mantis dealer for assis-

tance.

Both the Operator’s Manual and Troubleshooting

Manual for the LMI/A2B are included in the documen-

tation package provided with this equipment.

16

REV: DATE:

1. Display

2. Counterweight Toggle Switch

4. Reeving Switch

5. Anti-Two-Block Alarm Light

6. Load Moment Prewarning Light

7. Load Moment Alarm Light and

Horn Off Button

8. Load Indication Button

9. INFO Button

10. Angle Limit Button

11. E Button

12. Key Switch

13. A2B Bypass Switch Position

14. Normal Operation Position

15. LMI Bypass Position

16. Audible Alarm

17. Operating Code (Dec.) Switch

PAT DS-150 OPERATING CONTROLS

See the LMI/A2B System Operator's Manual for complete control descriptions

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Table of contents

Popular Construction Equipment manuals by other brands

probst

probst STS-EASY operating instructions

AMBIC

AMBIC EasiFoamer operating instructions

stellar labs

stellar labs 6000 owner's manual

Titan Attachments

Titan Attachments PHD25 Operator's manual

Broderson

Broderson IC-200-2J Operation and maintenance manual

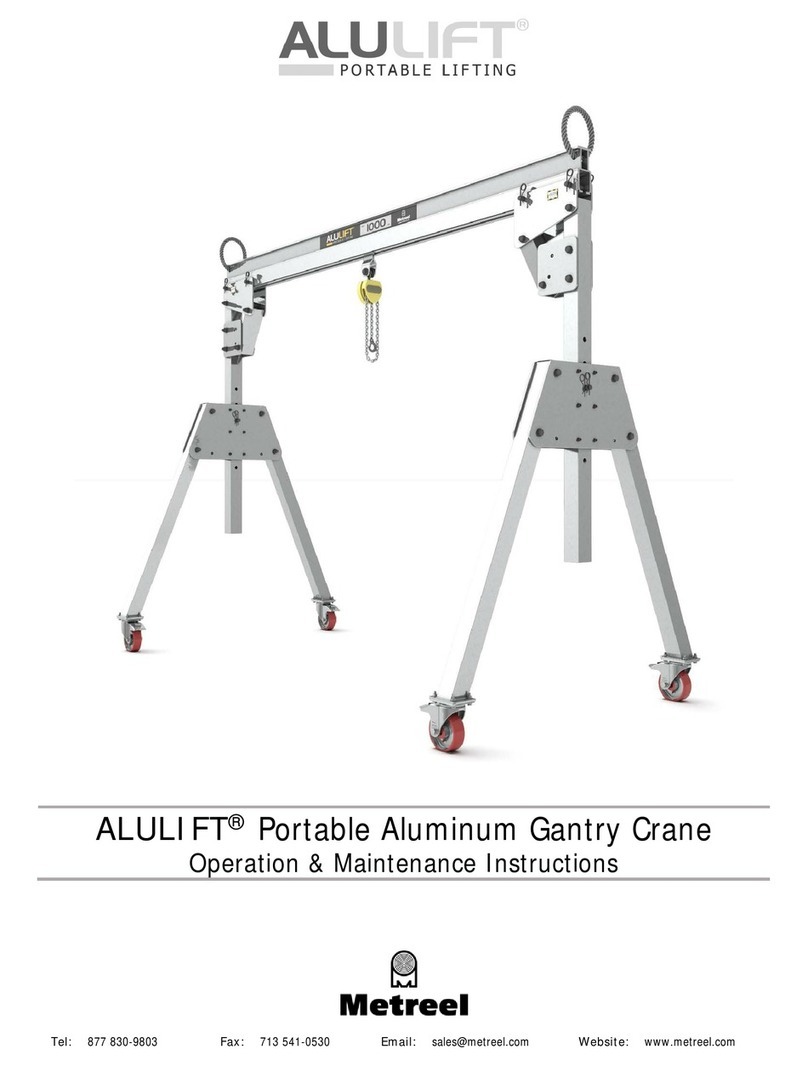

Metreel

Metreel ALULIFT Operation & maintenance instructions