5. TEMPERATURE DISTRIBUTION CHART

5. TEMPERATURE DISTRIBUTION CHART4. OPERATION

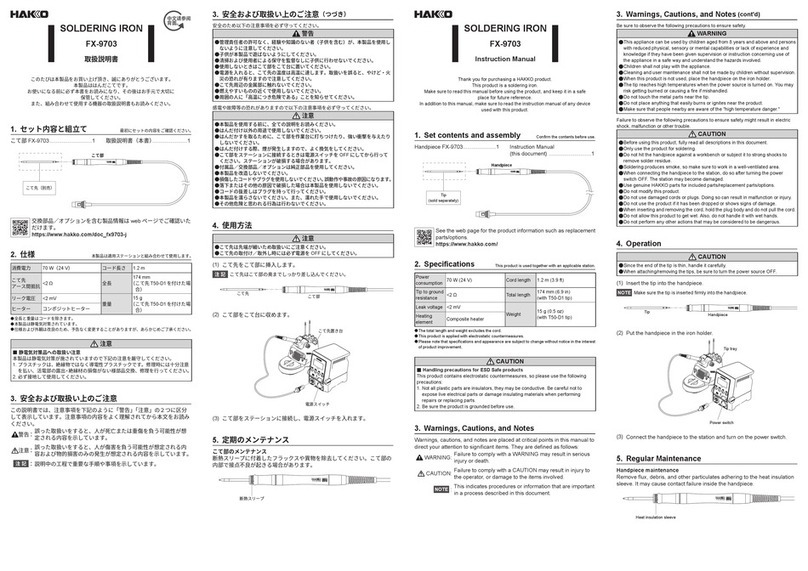

・Examples of use (Including optional parts*)

7. TROUBLE SHOOTING GUIDE

Problem

No air comes out

The temperature does not

increase (or decrease).

Air flow volume cannot

be adjusted.

Problem Cause

Unit is not connected properly

to power outlet.

Heating element burnout.

Motor is broken.

Unit is not connected properly

to power outlet.

Heating element burnout.

The slide button (switch) is set

to "I".

Temperature control knob or PWB

is broken.

Air flow control knob or PWB is

broken.

Procedure

Connect properly.

In case the resistance value for heater terminal (b) shows

an abnormal value, please replace the heating element.

If no air comes out even if there is no abnormality for the

heating element, that means that the motor is out of order.

Please replace the motor.

Connect properly.

In case the resistance value for heater terminal shows

an abnormal value, please replace the heating element.

Turn the slide button (switch) to "II".

Please contact the distributor or the agency.

Please contact the distributor or the agency.

8. PARTS LIST

SpecificationsPartName

Heatingelement/110V

Heatingelement/220V

Heatingelement/230V

Heatingelement/240V

Fanunit/withmotor

Pipecover

Pipe/withmica

PartNo.

A5040

A5041

A5043

A5042

B5154

B5162

B5163

ItemNo.

1

2

3

4

①

②

③④

※If a problem other than those listed above occurs or if the problem continues even after

performing the solution, contact the distributor or the agency from which you purchased

the unit.

スタンド

The temperature and air flow volume are reference values; these values will not be guaranteed.

* Please refer to “8. PARTS LIST”.

Measured at the point 10mm from the pipe. (without nozzle*)

* When the nozzle is attached, the temperature and air flow volume will change.

Please make sure to adjust both of them when using the unit with a nozzle.

Drying painting and putty

Heat shrink tubing

Use of hook type

nozzle and stand

Peeling sticker

Shrinking

Use of spatula type nozzle

Welding PVC sheet

Use of nozzle holder

and spatula type nozzle

along with roller

Curving plastic

material

Use of

nozzle holder and

single nozzle without stand

Stand

Roller

1

120℃

A,B

110℃

A,B

100℃

A,B

90℃

A

85℃

A

2

175℃

A,B,C

165℃

A,B,C

145℃

A,B,C

130℃

A,B,C

115℃

A,B,C

3

295℃

C,D,E

270℃

C,D,E

230℃

C,D,E

205℃

B,C,D,E

190℃

B,C,D,E

4

425℃

D,E

390℃

D,E

320℃

D,E

285℃

C,D,E

270℃

C,D,E

5

530℃

505℃

425℃

380℃

D,E

345℃

D,E

1

(0.15 m3

/min)

2

(0.17 m3

/min)

3

(0.2 m3

/min)

4

(0.23 m3

/min)

5

(0.25 m3

/min)

Examples of use) A: Drying painting and putty B: Peeling sticker C: Shrinking D: Heat shrink tubing

E:

Curving plastic material

0

100

200

300

400

500

600

12345

Temperature control knob

Temp. (℃)

Air flow control knob 1

Air flow control knob 2

Air flow control knob 3

Air flow control knob 4

Air flow control knob 5

Temp.

Air flow

6. MAINTENANCE / INSPECTION

CAUTION

Replacing the heater can be dangerous. When doing so, be sure to unplug the unit and follow the steps below.

A. Removing the heating element

1. Remove the pipe cover by rotating it anti-clockwise for approx. 20 degrees from

the position when seen from the front

2. Remove the four screws securing the pipe, and remove the pipe and the mica.

3. Pull the heating element straight out.

B. Measuring the resistance

of the heating element

Measure the resistance of the terminals

(a) or (b).

(a) The normal value is 13 Ω (±10% 110V), 56 Ω (±10% 220V), 62 Ω (±10% 230V),

70 Ω (±10% 240V). If the resistance is abnormal, replace the heating element.

(b) The normal value is 115 Ω (± 10% 110V), 300 Ω (±10% 220 - 240V).

If the resistance is abnormal, replace the heating element.

Pipe cover

Pipe Heating elementMica

(a)

(b)

C. Attaching the heating element

Please attach the heating element by following the procedure reverse to that for when

removing the heating element.

※Please make sure to attach the heating element by aligning the terminals and the holes

in the fan case.

Fancase

Heating

element

Terminals

After use, the pipe and heating element are

very hot. Please allow them to cool down.

CAUTION

Approx. 20

degrees rotation

●Optional parts

B5166Stand A1115Roller

N70-02

Spatula type

9

62

(Inside

dimension)

N70-01*

Spatula type

213

20

(Inside

dimension)

ø12

(Inside

diameter)

ø12

(Insidediameter)

ø12

(Inside

diameter)

N70-03Hooktype N70-04Hooktype N70-05Nozzleholder

ø12

ø45

20

ø45

40

N70-06Single

*Whentheunitisused

underthecondition

below,ALWAYScool

downafteruse.Failure

tofollowthisprocedure

mayresultinblownfuse.

Temperaturecontrolknob:level5

Airflowcontrolknob:level2orlower

After use, always turn the slide button (switch) to "I" and allow the unit to cool

down for at least 90 seconds.