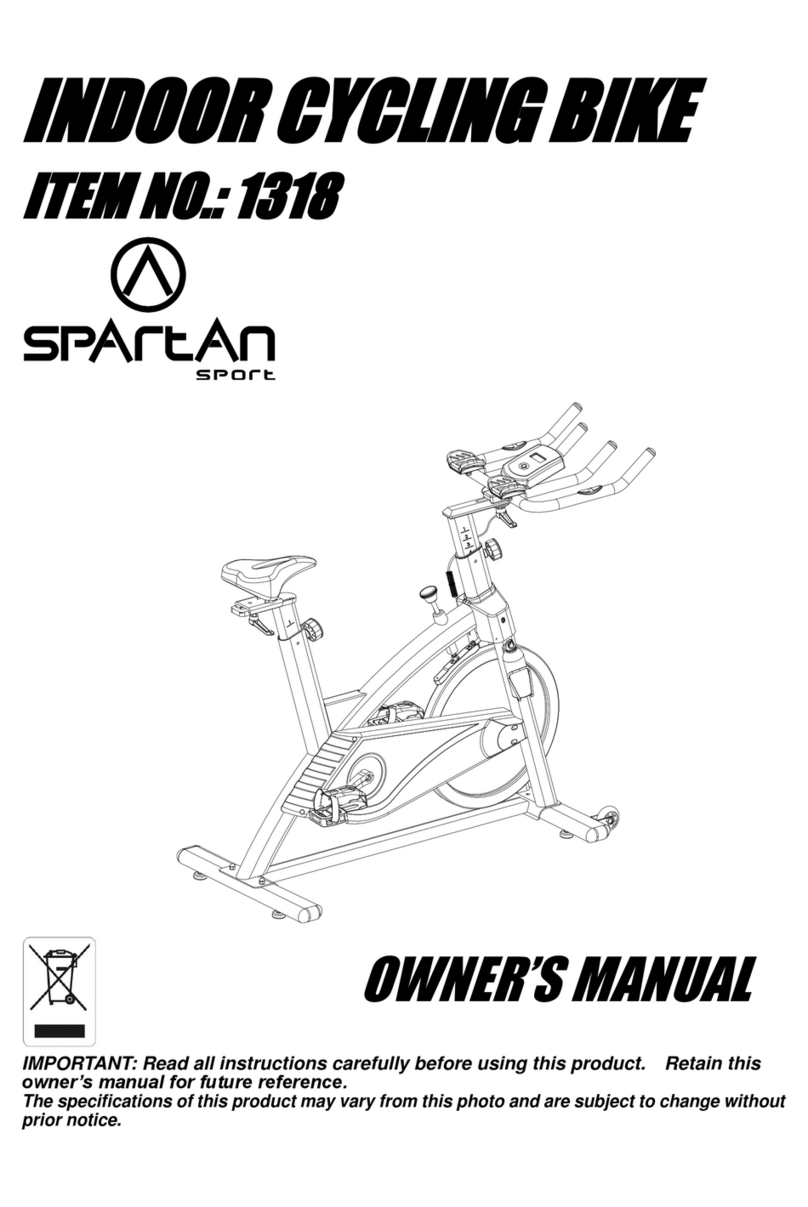

SPARTAN sport Magnetic 50 User manual

1

···

Owner’s Manual

Retain this owner’s manual for future reference

Read and follow all instructions in this owner’s manual

Version A

2

Thank you

Thank you so much for purchasing this product. The product will help you maintain

optimal aerobic fitness. To avoid personal injury, please read the following instructions

carefully before using this product. Please keep this manual for future reference.

Precautions

WARN NG: This upright bike has been designed and constructed to provide maximum

safety. Nevertheless, certain precautions should be taken when using exercise equipment.

Read the whole manual before assembling and using the upright bike. The following

safety precautions should also be observed:

◆t is the responsibility of the owner to ensure that all users of the upright bike are

adequately informed of all precautions. Use the upright bikes only as described in this

manual.

◆Keep children and pets away from this equipment at all times. Do not leave them

unsupervised in the room where place this upright bike.

◆Before using, please confirm that the upright bike has been assembled properly and

the screws in each part have been locked.

◆Place the upright bike on a level surface, with at least 1.0 m of clearance on each side

of upright bike. To protect the floor or carpet from damage, place a mat under the upright

bike.

◆Keep the upright bike indoors, away from moisture and dust. Keep the air flowing

when use it and do not use it in the airless place.

◆Don’t put any sharp objects around the upright bike.

◆Wear appropriate clothes while exercising; do not wear loose clothes that could

become caught on the upright bike. Always wear athletic shoes for foot protection while

exercising.

◆Do not use this product if more than 120kg of weights. Please choose our other series

of upright bikes.

◆Do not put your hands on the moving parts to prevent injures.

◆Keep your pedaling speed in a controlled way.

◆f you find your upright bike works abnormal, do not use it immediately.

◆No more than one person should operate the upright bike at one time.

◆f you feel pain or dizziness while exercising, stop exercising immediately and ask for

a doctor.

3

Safety notice

When you are remedial or have below symptoms, after discussing with your doctor, then

could use this upright bike.

1. Waist paining now and leg, waist, neck hurt before, legs, waist, neck and hand

numbly(The pre-existing disease people who suffer from intervertebral disc,

spondylosis, cervical spine, etc )

2. Have anamorphic arthritis, rheumatic and gout.

3. Have osteoporosis and other abnormality.

4. Have perfunctory system obstacle (heart disease, blood obstacle, hypertension ).

5. Have breath obstacle.

6. Using the manpower pulse adjust machine or insert into the body machine.

7. Have sarcomata.

8. Have thrombus or other symptoms.

9. Have diabetes or be caused by diabetes feeling obstacle.

10. Have skin trauma.

11. Hyperpyrexia caused by sick(38 ℃or over 38 ℃).

12. Abnormal back bone or back bone bending.

13. Pregnant or catamenia.

14. Feel physical abnormality, need convalesce.

15. Body condition is not very well.

16. The aim is to healing.

17. Except the upper symptoms, feel other physical abnormality.

----Maybe cause the accident or the poor body condition.

Before beginning any exercise program, consult your physician. This is especially

important for persons over age 35 or persons with pre-existing health problems. To

reduce the ris of serious injury, read all important precautions and instructions in

this manual and all warnings on your upright bi e before using your upright bi e.

4

Pre-assembly Notes

Make sure to the inventory all the parts that are included in the box. Check the

hardware chart of a full count of the number of parts included for proper

assembly. If any of the parts are missing, contact with the dealer.

Φ8.5×20(31)-7 Φ8.5×R25(33)-2Φ8(30)-7

M8(35)-2 ST4×16(36)-2 M4×10(39)-4

M5×10(38)-4

M8×20(32)-2M8×50(29)-4

M8×65(34)-3

NO. NAME SPECIFICATION QTY

29 Allen C.K.S. half thread screw M8×50×20 4

30 Spring washer Φ8 7

31 Flat washer Φ8.5×Φ20×t1.5 7

32 Allen C.K.S. full thread screw M8×20 2

33 Curved washer Φ8.5×R25×t2.0 2

34 Allen C.K.S. full thread screw M8×65×20 3

5

35 Hex self-locking nut M8 2

36 Philips C.K.S. self-tapping screw ST4×16 2

38 Philips pan head full thread screw M5×10 4

39 Philips pan head full thread screw M4×10 4

Toolkit list

GATHER YOUR TOO S

Before starting the assembly of your unit, gather the necessary tools. Having all the

equipment at hand will save time and make the assembly quick and hassle-free.

C EAR YOUR WORK AREA

Make sure that you have cleared away a large enough space to properly assemble the

unit. Make sure the space is free from anything that may cause injury during assembly.

After the unit is fully asssembled, make sure there is a comfortable amount of free area

around the unit for unabstructed operation.

Name Specification QTY

L Allen wrench 5×35×80S 1

L Allen wrench 6×40×120 1

Open spanner 15#&17# 1

Cross open wrench 1

6

Product instruction

Technical information

Dimension Unfold:1100x530x1400mm

Speed Ratio 8

Flywheel Single way,Φ280/6kg

Up & Down 12 level , 360mm distance

Front & Back 70mm distance

*WE RESERVE THE R GHT TO AMEND THE PRODUCT W THOUT PR OR NOT CE.

Console

Wheel

Front stabilizer

Pedal L

Rear stabilizer

Saddle

Bottle holder

Resistance adjustment knob

Handle bar

Pedal R

7

Step 1

Step 2

ASSEMBLY

INSTRUCTIONS

Attach the front stabilizer (2) to the main

frame (1) with flat washer (31), spring

washer (30) and Allen C.K.S. half thread

screw (29).

Attach the rear stabilizer (3) to the main

frame (1) with flat washer (31), spring

washer (30) and Allen C.K.S half thread

screw (29).

8

Step 3

1. Attach the Upright post decoration strip (46) to the upper right upright post (4), take

the down upright post cover (19) off from the main frame (1) and cover it on the upper

upright post (4).

2. Connect Magnetic sensor wire (12) and console communication wire (13), connect the

resistance adjust knob wire (14) and resistance adjust knob outlet (15).

3. Attach upper upright post (4) to the main frame(1) with curved washer( 33), spring

washer (30), Allen C.K.S. half thread screw (34) and flat washer (31), spring washer

(30), Allen C.K.S full thread screw (32) and flat washer ( 31), Allen C.K.S. half thread

screw (34), Hex self-locking nut (35), curve washer (33), spring washer (30) and

Allen C.K.S. full thread screw (32).

4. Attach upright post cover (19) and upright post decoration strip ( 46) to the main frame

(1).

5. Attach the bottle holder ( 20) to the upper upright post (4) with Phillips C.K.S. full

thread screw (36).

Tip: Put the communication wires and resistance adjust knob wire into the upright post,

and make sure all screws are in the hole before tighten all the bolts.

9

Attention:Hold and

pull up the brake cable

when install it. (As

shown)

10

Step 4

Step 5:

1. Attach the Pedal (L) (5) and Pedal (R)

(6) to the main frame (1), then tighten the

bolts.

1, Loose the Rotary hand bolt (21),

attach the Saddle post (7) to the main

frame (1), then tighten the Rotary hand

bolt

(21)

.

11

Step 6:

Step 7

7

4

38

38

10

9

26

16

Attach the saddle (8) to the saddle post (7), use the handlebar rotary knob ( 22) and

bushing (23) to tighten.

1. Handle pulse connection wire (16) through the upright post (4), and attach the

handlebars (9) to upright post (4), tighten with T-shaped rotary knob (26).

2. Attach console fixed piece (10) to the upright post (4), tighten with Philips Pan

head full thread screw(38).

Tip: Make sure all screws are in the right hole before tighten all the bolts.

6

8

23

7

21

22

12

Step 8

Workout tips

1. User need to put the feet completely inside the pedal, and to adjust the resistance of

magnet control according to the user.

2. Since the machine with double flywheels and it will have huge moment of inertia,

when the user stop before high speed, the user should minimize the resistance and

lower the speed, to avoid hurt the user’s leg by the moment of inertia of left and right

pedal.

3. The machine should be put on the flat floor and have enough space for workout.

1. Connect the console communication

wire (13) and console connection wire

(18), connect the handle pulse

connection wire (16) and console

pulse outlet wire(17).

2. Attach the console (11) to the console

fixed piece (10), tighten with Phillips

C.K.S full thread screw (40) and flat

washer (83).

3. Attach the handlebar cover L (27) and

handlebar cover R (28) through the

handlebars(9) to the upright post (4),

tighten with Philips C.K.S full thread

screw (39).

Tip: Make sure all screws are in the right

hole before tighten all the bolts.

13

Half-drawing for assembly

29

30

31

29

30

31

29

30

31

31 30 32

19

4

15

33

30

34

5

6

7

23

26

38

38

9

10

11

39

27

28

39

17

13

2

3

21

14

16

18

12

1

46

20

36

22

34

35

13

31

32

40

94

8

14

Half-drawing part list

NO. NAME SPECIFICATION QTY

1Main frame 1

2Front stabilizer 1

3Rear stabilizer 1

4Upright post 1

5Pedal L 1

6Pedal R 1

7Saddle post 1

8Saddle 1

9Handlebar 1

10 Console fixed piece 1

11 Console 1

12 Magnetic sensor wire 1

13 Console communication wire 1

14 Resistance adjust knob wire 1

15 Resistance adjust knob 1

16 Handle pulse connection wire 2

17 Console pulse outlet 2

18 Console connection wire 1

19 Down upright post cover 1

20 Bottle holder 1

21 Rotary hand bolt Φ56×M16×P1.5 1

15

22 Handlebar rotary knob 1

23 Bushing Φ10.5×Φ14×10 1

26 T-shaped rotary knob M8×30 1

27 Handlebar cover (L) 1

28 Handlebar cover (R) 1

29 Allen C.K.S. half thread screw M8×50×20 4

30 Spring washer Φ8 7

31 Flat washer Φ8.5×Φ20×t1.5 7

32 Allen C.K.S.full thread screw M8×20 2

33 Curve washer Φ8.5×R25×t2.0 2

34 Allen C.K.S. half thread screw M8×65×20 3

35 Hex self-locking nut M8 2

36 Philips C.K.S. self-tapping screw ST4×16 2

38 Philips pan head full thread screw M5×10 4

39 Philips pan head full thread screw M4×10 4

40 Philips pan head full thread screw M5×10(black) 4

46 Upright post decoration strip 1

83 Flat washer Φ4.5×Φ12×t1.0 4

16

Exploded drawing

65

51

85

32

35

64

51

66

63

35

73

75

76

62

62

63

63

67

69

68

70

72

52

74

84

31

58

47

48

48

2

50

49

47

51 31

30

29 30

29

31

86

29

30

31

29

30

31

3

31 30 32

4

33

30

34

38

38

39

27

28

39

17

18

15

46

19

81

44 81

81

88

89

43

43

44

36

36

36

36

6

7

23

26

80

79

87 87

16

12

13

14

35

51

54

53

56

78

1

59

45

9

21

81

20

36

22

90

93

92

82

55

36

91

31

34

35

32

11

10

40

83

77

77

35

31

8

71

61

57

42

41

42

41

5

37

25

24

60

17

Exploded part list

NO. NAME SPECIFICATION QTY

1Main frame 1

2Front stabilizer 1

3Rear stabilizer 1

4Upright post 1

5Pedal L 1

6Pedal R 1

7Saddle post 1

8Saddle 1

9Handlebar 1

10 Console fixed piece 1

11 Console 1

12 Magnetic sensor wire 1

13 Console communication wire 1

14 Resistance adjust knob wire 1

15 Resistance adjust knob 1

16 Handle pulse connection wire 2

17 Console pulse outlet 2

18 Console connection wire 1

19 Down upright post cover 1

20 Bottle holder 1

21 Rotary hand bolt Φ56×M16×P1.5 1

22 Handlebar rotary knob 1

23 Bushing Φ10.5×Φ14×10 1

24 Locknut t4.0×37×37 1

25 Check ring 1

26 T-shaped rotary knob M8×30 1

27 Handlebar cover (L) 1

28 Handlebar cover (R) 1

29 Allen C.K.S. half thread screw M8×50×20 4

18

30 Spring washer Φ8 7

31 Flat washer Φ8.5×Φ20×t1.5 8

32 Allen C.K.S.full thread screw M8×20 7

33 Curve washer Φ8.5×R25×t2.0 2

34 Allen C.K.S. half thread screw M8×65×20 3

35 Hex self-locking nut M8 9

36 Philips C.K.S. self-tapping screw ST4×16 8

37 Φ45×12 1

38 Philips pan head full thread screw M5×10 4

39 Philips pan head full thread screw M4×10 4

40 Philips pan head full thread screw M5×10 4

41 Crank L 1

42 Crank Φ55×16 2

43 Crank cover 2

44 Philips C.K.S. self-tapping screw ST4×12 4

45 Philips pan head half thread screw M5×55×20 1

46 Upright post decoration strip 1

47 End cap 4

48 Feet pad Φ47×10.5×M10×20 4

49 Allen C.K.S. hollow screw Φ8×33×M6×15 2

50 Wheels Φ55×25.8 2

51 Allen C.K.S.full thread screw M6×15 5

52 Deep groove ball bearing 6203-2RS 1

53 Hex nut M5 2

54 Hex full thread screw M5×80 1

55 Philips C.K.S. self-tapping screw ST4×12 1

56 Saddle post bushing 1

57 Crank co er Φ45×12 1

58 Belt puller Φ263×19 1

59 Flat washer Φ5 1

60 Saddle adjustment 1

61 Washer t3.0×Φ40×Φ24.3 1

Top ring

19

62 Circlip shaft Φ12 2

63 Circlip shaft Φ10 3

64 Tension pulley Φ38×22 1

65 Tension spring 1

66 Brake tension spring 1

67 Deep groove ball bearing 6003-2RS 3

68 Magnetic control fixed axle Φ12×50 1

69 Deep groove ball bearing 6300-2RS 1

70 Flat washer Φ34×Φ25×t1.0 1

71 Crank axle 6.5’’ 1

72 Unidirectional needle bearing Φ35×Φ17×16 1

73 Small belt pulley set Φ30×64 1

74 Deep groove ball bearing 6000-2RS 1

75 Flywheel axle Φ10×109.5 1

76 Flywheel Φ280/6kg 1

77 Sqaure end cap 20×40×t1.5 1

78 Handle pulse set 2

79 Philips C.K.S. self-tapping screw ST4×20 2

80 Round end cap Φ25×t1.5 2

81 Philips C.K.S. self-tapping screw ST4×25 7

82 Fixed magnetic set 1

83 Flat washer Φ4.5×Φ12×t1.0 4

84 Tension pulley fixed set 1

85 Magnetic control set 1

86 Motor belt 440PJ6 1

87 Foam Φ22×t3.0×680 2

88 Motor cover L 1

89 Motor cover R 1

90 Saddle locking piece 1

91 Speed sensor fixed piece 1

92 Allen C.K.S. full thread screw M10×38 1

93 Elastic washer Φ10 1

This manual suits for next models

1

Table of contents

Other SPARTAN sport Exercise Bike manuals

Popular Exercise Bike manuals by other brands

Sunny Health & Fitness

Sunny Health & Fitness SF-B121021 user manual

Monark

Monark 827E instruction manual

Stamina

Stamina 1310 owner's manual

American Fitness

American Fitness SPR-BK1072A owner's manual

Cateye

Cateye CS-1000 (CYCLO SIMULATOR) Service manual

BH FITNESS

BH FITNESS H9158H Instructions for assembly and use