Spartan 300 User manual

PRODUCT MANUAL

Model 300

© 2020 Spartan Tool LLC

Part #44292800 (Rev. F) 2020-00

Spartan Tool LLC |1618 Terminal Road |Niles, MI 49120

order by phone 800.435.3866 order online SpartanTool.com

2

WARNINGS ............................................................................................................ 4

INTRODUCTION........................................................................................................5

Service Information.............................................................................................................5

SPECIFICATIONS AND FEATURES........................................................................................6

SAFETY INSTRUCTIONS ................................................................................................7

300 with Dial-A-Cable Power Cable Feed ...................................................................................... 10

MACHINE FEATURES ..................................................................................................10

ASSEMBLY INSTRUCTIONS ............................................................................................11

Joining Cables ................................................................................................................ 11

Assembly..................................................................................................................... 11

Disassembly .................................................................................................................. 11

Loading Cable Into Machine .................................................................................................. 11

Assembly of Blades to Cable .................................................................................................. 13

Blades........................................................................................................................ 13

Optional Tools ................................................................................................................ 14

Optional Accessories.......................................................................................................... 14

OPERATION...........................................................................................................15

OPERATING THE POWER CABLE FEED ..................................................................................17

SPECIAL APPLICATIONS PROCEDURE ..................................................................................18

Cleaning Lines Through a Manhole ............................................................................................ 18

Rodding Farther than 75' (5/8" Cable*). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Sewer or Septic Tank Overrun............................................................................................ 18

Contents

3

MAINTENANCE INSTRUCTIONS ........................................................................................19

Instructions for Splicing or Repairing Cable .................................................................................... 19

Splicing Cable (Standard Single Wound Cable)................................................................................. 19

Splicing the .55 Magnum Cable and Installing New .55 Couplings .............................................................. 19

Changing Motor Brushes...................................................................................................... 21

Caring for Cables ............................................................................................................. 21

How to Install 5' Drum Anchor Cable .......................................................................................... 22

Machine Storage ............................................................................................................. 22

PARTS & ACCESSORIES ................................................................................................23

Model 300 (04221458) ........................................................................................................ 23

Model 300 Drum Complete (44129300)........................................................................................ 24

External Drum Assembly (02875900) .......................................................................................... 25

Clutch Assembly (04203300) .................................................................................................. 26

Model 300 Internal Drum (02875300).......................................................................................... 27

Model 300 Frame Assembly (04217000) ....................................................................................... 28

Wiring Diagram............................................................................................................... 30

PM Motor with Gear Box 300 (44290200) ...................................................................................... 31

300 Electrical Box Detail (04221458) ........................................................................................... 32

Assembly, Universal Anchor .55 (44292700).................................................................................... 32

5/8" Cable .................................................................................................................... 33

Universal Anchor Cable Assembly, .55"- 5/8" (44292700) ....................................................................... 33

.55" Magnum Cable........................................................................................................... 34

Air Bulb & Hose Assembly (44225800) ......................................................................................... 35

Optional Compact Lift (02884900)............................................................................................. 35

Optional Model 100 Drum Adapters........................................................................................... 36

Tool Box and Accessory Kit .................................................................................................... 38

Pneumatic Tire Upgrade Kit (44250700). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Spartan Accessory Blades ..................................................................................................... 41

WARRANTY INFORMATION ............................................................................................42

4

Warnings

• Read the safety and operating instructions before using any Spartan Tool products. Drain and sewer cleaning can be dangerous if

proper procedures are not followed and appropriate safety gear is not utilized.

• Before starting unit, be sure to wear personal protective equipment such as safety goggles or face shield and protective clothing

such as gloves, coveralls or raincoat, rubber boots with metatarsal guards, and hearing protection.

• Drains and sewer can carry bacteria and other infectious micro-organisms or materials which can cause death or severe illness. Avoid

exposing eyes, nose, mouth, ears, hands, and cuts and abrasions to waste water or other potentially infectious materials, wash hands,

arms and other areas of the body, as needed, with hot, soapy water and, if necessary, flush mucous membranes with water. Also,

disinfect potentially contaminated equipment by washing such surfaces with a hot soapy wash using a strong detergent.

• For any questions, contact the company at the address shown below.

CALIFORNIA PROP. 65

This product may contain an

extremely small amount of lead in the

coating. Lead is a material known to

the State of California to cause cancer

or reproductive toxicity.

CONTACT US

Spartan Tool LLC

1618 Terminal Road

Niles, MI 49120

800.435.3866

SpartanTool.com

5

Introduction

The Spartan Model 300 electric drain and sewer cleaning machine has been designed and manufactured with high quality materials

and care in workmanship. The instructions in this manual have been prepared to ensure that, when followed, the Spartan Model 300 will

provide long and efficient service.

WARNING: It is the responsibility of the operator to read and understand the Product Manual

and other information provided and use the correct operating procedure. Machines should

be operated only by qualified operators. Failure to do so can result in personal injury, death, or

machine damage.

Read the entire manual before the initial start-up of the machine. It is important to know the correct operating procedures of the

machine and all safety precautions to prevent the possibility of property damage and/or personal injury.

NOTE: Information in this manual is current at the time of printing. Spartan Tool reserves the right

to make changes and improvements to its products at any time without notice or obligation.

SPARTAN MODEL 300

Unit Model Number

CONTACT US

Spartan Tool LLC

1618 Terminal Road

Niles, MI 49120

800.435.3866

SpartanTool.com

SERVICE INFORMATION

All requests for information, service, or parts should include machine serial number.

Additional copies of this Product Manual can be downloaded free of charge from

www.SpartanTool.com.

Unit Serial Number

6

Specifications and Features

Drum Capacity 75' of ⁄" cable or 100' of .55 Magnum cable

Cleaning Capacity up to 250'

Recommended Line Size 3" to 6" diameter

Motor

Permanent magnet; 115 volt AC (rectified);

1.25 amps (DC) @ 300 rpm (no load); 4.6 amps

(DC) 155 in-lb torque @ 160 rpm

Weight 101 lbs for a 300 Dial-A-Cable machine with 5'

anchor cable

Height 30" to top of handle (retracted)

41" to top of handle (extended)

Width 18"

Length 29" with Dial-A-Cable power feed

Drum Speed 300 rpm with no load

Cable Feed Spartan Dial-A-Cable Power Cable Feed

Frame Extra strength aluminum/magnesium alloy

• Heavy duty permanent magnet motor with reverse capability.

• Inner drum rotates independently of outer drum, virtually eliminates cable kinking, buckling, and controls torque buildup.

• Outer drum keeps dirt inside, off operator and work area.

• Air foot switch with cord assembly keeps both hands free for safe, easy operation.

• Compact, portable design.

• Extra-strength aluminum and magnesium alloy construction.

• Integral continuous belt stair skids.

• Retractable "sure-grip" extending handle.

IMPORTANT: FOR YOUR OWN SAFETY—Before assembling and operating this unit, read this

product manual carefully and completely. Learn the operation, applications and potential hazards

peculiar to this unit.

7

Use of any electrical equipment in a wet or damp environment can cause fatal shock if not properly guarded against by the operator.

1. Know your drain cleaning machine. Read this Product Manual carefully. Learn the operation, applications, and limitations of this

machine.

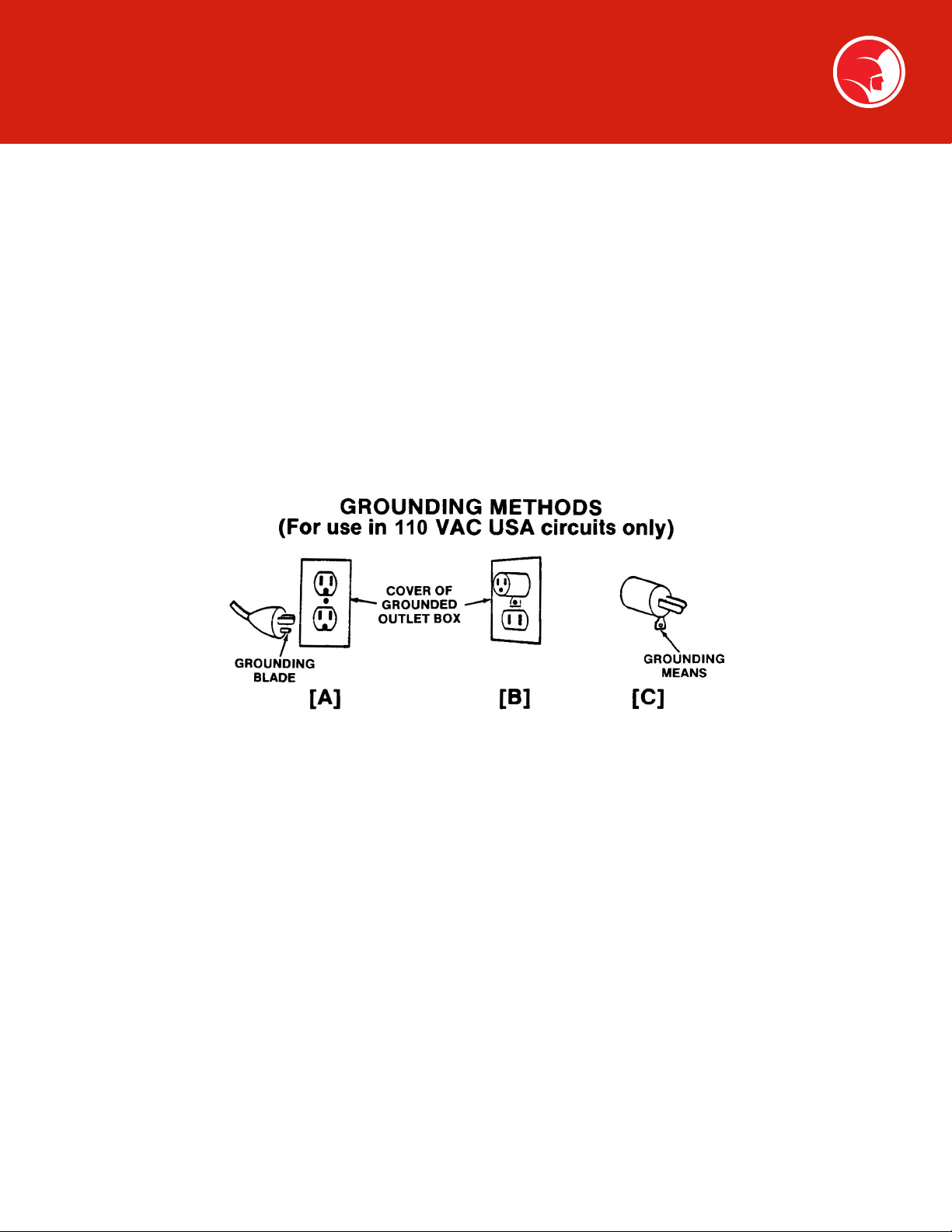

2. Grounding instructions: Before using your Spartan equipment, make sure that a properly grounded, (three hole) electrical outlet

is available. If not, as in older homes, use a three-prong adapter and connect the green pigtail or grounding lug to a known ground,

such as a (metallic) cold water pipe.

This tool should be grounded while in use to protect the operator from electric shock. The tool is equipped with a three-conductor

cored and proper grounding type receptacle. The green (or green and yellow) conductor in the cord is the grounding wire. Never

connect this wire to a live terminal. Units designed for use on less than 150 volts, have a plug that looks like that shown in Fig. 1A.

An adapter (Fig. 1B and 1C), is available for connecting three-prong plugs to two-prong receptacles (except in Canada). If such an

adapter is used, the green colored rigid ear, lug, or the like, extending from the adapter must be connected to a permanent ground

such as a properly grounded outlet box.

Safety Instructions

FIG. 1

This machine is equipped with a Ground Fault Circuit Interrupter (GFCI), which should always be plugged directly into an inspected,

grounded receptacle. Plug the three-pronged plug on the machine power cord with GFCI directly into an inspected grounded

outlet and then test and reset the GFCI.

Never cut off the grounding prong on the power cord for use in a two-hole outlet. Doing so cuts off your protection from shock.

Replace or repair all damaged power cords and components.

8

Safety Instructions

If an extension cord must be used, it must be approved, three-wire construction, equipped with a three-pronged plug, and in good

condition. Replace or repair damaged cords.

Do not use an undersized extension cord. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. Use the following minimum gauges depending upon the length of the extension cord:

• 16 Ga.: for cords of less than 100 feet in length

• 14 Ga.: for cords of 100 feet to 150 feet in length

If in doubt, use the next heavier gauge. (The smaller the gauge number, the heavier the cord.) When the machine is used outdoors,

use only extension cords intended for use outdoors and so marked. Do not allow an extension cord to be exposed to water.

Don't assume that all three-hole outlets are properly installed. Check the outlet and also the adapter, if used, with an outlet testing

device which quickly indicates if a ground is connected. Correct a faulty test indication before proceeding.

4. Don't abuse cord. Never move or lift tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

5. Disconnect power cord. When not in use, before servicing, and when changing accessories, such as blades and cutters.

6. Guard against electric shock. Prevent body contact with grounded surfaces such as pipes, radiators, ranges, refrigerator

enclosures.

7. Avoid accidental starting. Don't move plugged-in tools. Make sure switch is in OFF position before plugging in power cord.

8. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

9. Keep work area clean. Cluttered areas invite injuries.

10. Consider work area environment. Don't expose power tools to rain. Keep work area well lit.

Do not use tool in presence of flammable liquids or gases.

Avoid operating the machine in areas of standing water.

11. Dress properly. Do not wear loose clothing or jewelry. They can be caught in moving parts. Wear protective hair covering to

contain long hair.

Wear standard equipment (Spartan riveted gloves). Never grasp a rotating cable with a cloth or loose-fitting glove, which would get

wrapped around a cable.

Wear rubber boots and wear rubber gloves inside your Spartan cable handling gloves to further insulate yourself.

12. Use safety glasses. Guard against foreign material that might fly off cable.

13. Don't overreach. Keep proper footing and balance at all times.

3. Extension cords

DANGER: Improper use of an extension cord will cause death or severe injury. The GFCI on the

machine's power cord does not protect the operator from electrical shock along the extension cord.

9

Safety Instructions

WARNING: Continued drum rotation in reverse position will cause cable to "jump" out of drum. Possible

operator injury could result.

14. Keep children away. Do not let visitors contact tool or extension cord. All visitors should be kept away from work area.

15. Use recommended equipment and accessories. Use of improper equipment may be hazardous.

Don't force small cable with attachment to do the job of heavy-duty cable.

16. Don't force tool. It will do the job better and safer at the rate for which it was intended.

17. Remove punches and wrenches. Form a habit of checking to see that punches and adjusting wrenches are removed from tool

before turning it on.

18. Keep guards in place. Never operate machine with guard removed.

19. Avoid operating machine in reverse. Operating machine in reverse can result in cable damage and is used only to back tool away

from an obstruction.

20. Do not over torque cables. Excessive and/or continued rotation of the drum once an obstruction has been encountered will over

torque the cable. Kinking or breakage of cable may result. A worn cable can be identified as being very limber, kinked, or having

flattened coils on the outside of cable. Worn cable should be replaced as soon as possible.

21. Maintain tools with care. Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories.

Never use damaged power cords.

Inspect tool cords periodically and, if damaged, repair with proper Spartan replacement parts.

Inspect extension cords periodically and replace if damaged.

Keep handles dry, clean, and free from oil and grease.

22. Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding or moving

parts, breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

Replace defective switches with proper Spartan replacement parts.

Do not use tool if switch does not turn on and off

23. Store idle tools. When not in use, tools should be stored in a dry and locked up place, away from children.

24. Handling cables. Be very careful when cleaning drains exposed to cleaning compounds. Wear protective gloves when handling

cable, and avoid direct contact of skin and especially the eyes and facial areas as serious burns can result from some drain cleaning

compounds.

10

Machine Features

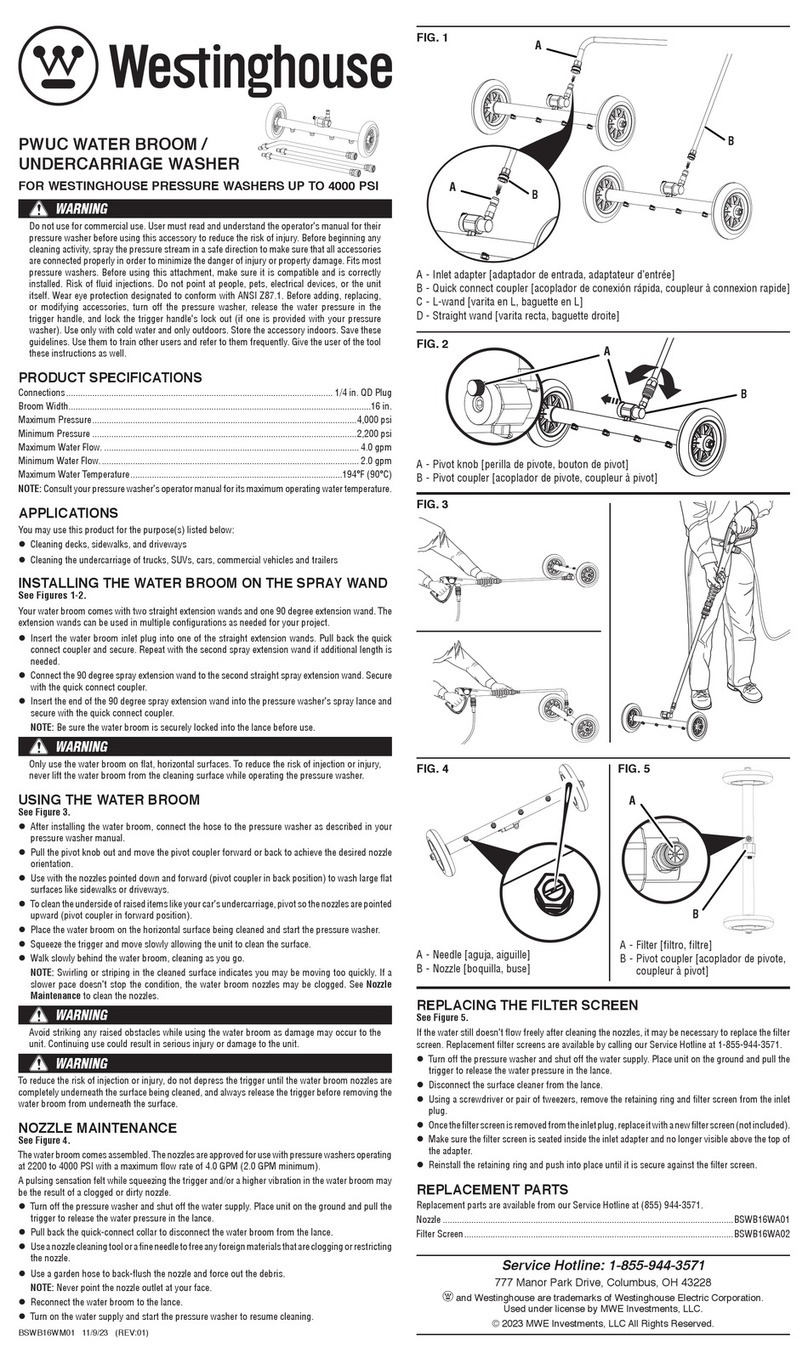

300 WITH DIAL-A-CABLE POWER CABLE FEED

SPARTAN TOOL

NILES, MI 49120

DATE

SIZE SCALE

DRAWN BY ECO

DRAWING NUMBER

SHEET NUMBER

REV

TITLE

THIRD ANGLE PROJECTION

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES

WARNING: THIS DRAWING IS

GENERATED FROM 3D BODY DATA

AND ANY GEOMETRY CHANGES

SHOULD BE CARRIED OUT

IN 3D ONLY.

THIS DOCUMENT CONTAINS

PROPRIETARY INFORMATION AND

SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS FOR ANY

PURPOSE NOR USED FOR

MANUFACTURING PURPOSES

WITHOUT WRITTEN PERMISSION

FROM SPARTAN TOOL L.L.C.

MODEL 300

rwilson 2 of 2

04221458-2020

1/8

B

.XX = ±.01 .XXX = ±.005

FRACTIONS = ±1/64

ANGLES = ±1°

CRITICAL DIMENSION

SPARTAN TOOL

NILES, MI 49120

DATE

SIZE SCALE

DRAWN BY ECO

DRAWING NUMBER

SHEET NUMBER

REV

TITLE

THIRD ANGLE PROJECTION

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES

WARNING: THIS DRAWING IS

GENERATED FROM 3D BODY DATA

AND ANY GEOMETRY CHANGES

SHOULD BE CARRIED OUT

IN 3D ONLY.

THIS DOCUMENT CONTAINS

PROPRIETARY INFORMATION AND

SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS FOR ANY

PURPOSE NOR USED FOR

MANUFACTURING PURPOSES

WITHOUT WRITTEN PERMISSION

FROM SPARTAN TOOL L.L.C.

MODEL 300

rwilson 2 of 2

04221458-2020

1/8

B

.XX = ±.01 .XXX = ±.005

FRACTIONS = ±1/64

ANGLES = ±1°

CRITICAL DIMENSION

Distributor Arm

Dial-A-Cable

Power Feed

Handle Adjustable

Screws

Stair Climber

Air Foot

Actuator

Cord Wrap

Gearmotor

Forward &

Reverse Switch

GFI Power

Cord

FIG. 2

11

Assembly Instructions

STUDY THESE INSTRUCTIONS CAREFULLY BEFORE YOU OPERATE YOUR EQUIPMENT

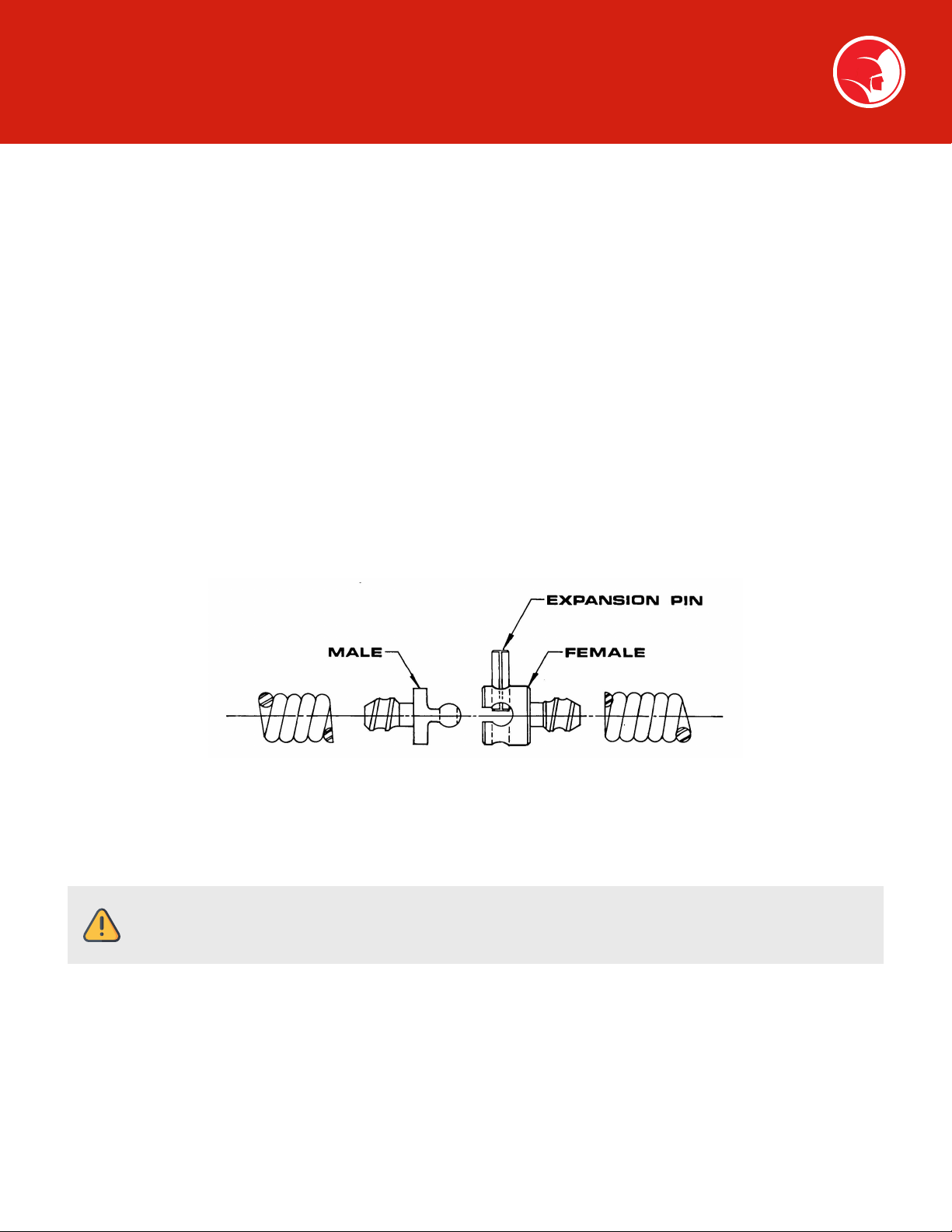

JOINING CABLES

All cables and leaders are coupled together by male and female couplings, and held securely by means of expansion pins as illustrated.

The cable and coupling stand is furnished with the optional tool box to provide a support on which to rest your able when assembling

or disassembling the couplings.

Assembly

Place coupling in groove on top of stand with portion of expansion pin in upright position. Using hammer, drive expansion pin down

flush with coupling. Assembly is complete, cable and machine are ready for use.

Disassembly

Position coupling stand at convenient distance from machine (2-3 feet.) Place coupling in groove, expansion pin up, on top of stand.

Place tip of punch (provided with machine) in expansion pin. Drive expansion pin down with hammer. Note the shoulder on tip of

punch, acts as a stop. Drive the punch until shoulder is flush with the coupling. This is sufficient to permit the male and female portions

of the coupling to be separated but leaves the expansion pin, held securely in one half of the female coupling, in ready position for

reassembly.

LOADING CABLE INTO MACHINE

After uncoiling the cable and laying out flat, attach the male end of the cable to the female end of the 10' anchor in the drum. With

the machine plugged in, depress the foot actuator and check the rotation of the drum. The drum should rotate in a counter-clockwise

direction, as you face the front of the machine. If the drum rotates in the wrong direction, reverse the toggle switch located (refer to

Figure 2) on the motor support and check rotation again. With the drum rotating in the proper direction, start feeding the cable into the

drum.

FIG. 3

WARNING: Due to the amount of initial tension wound into your Spartan cable, care must be taken when

uncoiling the bundle of cable. The cable will spring apart after the wire ties, which secure the cable, are cut.

12

Assembly Instructions

Leave about 2-3 feet of cable out of the machine to allow for attaching the next section of cable. After loading your desired length of

cable, attach either a two foot leader cable or a double male coupling. You are now ready to attach your Spartan cutter blade assembly.

(See Figures 4 & 5 for Cable Connection Diagram).

CAUTION: Always wear your riveted Spartan gloves when handling a rotating cable. Read the section “How

to Operate the Power Cable Feed” before you begin to feed cable into the drum. Feed the cable into the drum

with the drum rotating. This insures proper distribution of cable inside the drum.

FIG. 4

5/8 CABLE

FIG. 5

.55 MAGNUM CABLE

13

ASSEMBLY OF BLADES TO CABLE

Assembly Instructions

Each U-Type Cutting Assembly consists of:

WARNING: Always disconnect power cord before attaching or changing blades.

FIG. 6

Each Three-Blade Cutting Assembly consists of:

FIG. 7

Blades

The optional tool box is furnished with a number of different sizes and shapes of blades for various size sewers and types of cleaning

work. (Additional tools are listed on page 14.)

Your Spartan blades can be attached to either a 2’ leader cable or a double male coupling. To attach a cutter assembly the base of the

blade holder assembly needs to be seated onto the hex part of the leader or double male coupling. Next, the proper blade size is placed

into the blade holder base. After inserting the blade, secure with blade retainer, lock washer and nut. Draw up all blades assemblies

tightly with your T-wrench, otherwise vibrating may cause unnecessary loss of blades. A T-wrench is furnished so you can quickly and

conveniently assemble blades. With the blade assembly attached, your now ready to operate your Spartan machine.`

14

Assembly Instructions

OPTIONAL TOOLS

Part Number Description Use

44006700 Extra Heavy Razor Sharp 2½" Round

Cutter Blade

Used to cut roots and clear blockages in 3", 4", and

6" lines. High water resistance

44052600 Boring Tool Used in 3", 4", and 6" linesfor penetrating major

blockages.

03416600 3" Grease Blade

For cleaning grease or muck lines. Integral

"paddles" act as a scoop and cause a churning

action within the line for quicker, more efficient

cleaning.

03416700 4" Grease Blade

For cleaning grease or muck lines. Integral

"paddles" act as a scoop and cause a churning

action within the line for quicker, more efficient

cleaning.

OPTIONAL ACCESSORIES

Tool box and the following accessories:

• Cable uncoupling stand

• Punch for expansion pin

• T wrench

• 3" and 3½" P-trap blades with blade holder assembly

• Spear blade

• 2" and 2½" blades with blade holder assembly

• 3", 4" blades with blade holder assembly

• Retriever

• Riveted gloves

• Expansion pins, double male, male and female

couplings

• Splicer

• 2' flexible leader

15

Operation

1. Couple the leader or double male coupling, complete with the proper tool, onto working end of the cable. See assembly

instructions.

2. Use a small blade or spear blade on the end of your cable first. Most lateral lines are 4”to 6”in diameter. It is advisable to use a 3”

blade or spear blade first. That enables you to cut the core out of the obstruction, to get the water running. Then remove the 3”

blade, or spear blade. Put on a blade the size of the sewer line to be cleaned, so you can actually scrape the line - thereby giving a

thorough, efficient cleaning job.

a. A good rule of thumb is to use a tool at least 1”smaller than the line to be cleaned. The style of tool is determined by the nature

of job and is left to the discretion of the operator.

b. Flexible trap leaders should be used to negotiate p-traps and severe bends in line.

c. Double male couplings should be used when operating in heavy root build up or severe obstructions.

3. Place your machine as close to the cleanout as possible. Do not allow more than 4 feet of cable between the machine and the

cleanout. Always use the Cable Safety Guide.

WARNING: Never wear loose fitting clothing or jewelry when operating this machine. Always wear your

Spartan riveted gloves when handling cable.

4. Place foot switch, in a comfortable and accessible position in order to have power at all times.

5. Place the switch in the“F” (forward) position. Check by pressing down on footswitch making sure that drum rotates in counter

clockwise direction as you face the drum.

a. Hand-feed the tool into the opening of the line and feed about 6”of cable in before turning machine on.

b. Refer to the section “How to Operate the Power Cable Feed” before proceeding.

6. Exert sufficient downward pressure on the Cable Safety Guide to keep cable in line while depressing foot actuator to start cable

rotating.

a. When using a Dial-A-Cable Power Cable Feed, keep one hand on the Cable Safety Guide halfway between the cleanout and the

power feed outlet. Keep your other hand on the power feed control handle.

7. When your blade meets an obstruction, it will no doubt fail to rotate. A reduction in RPM will be noticed. If RPM of the motor and

drum decrease, quickly pull back on the cable to disengage blade from the root or other obstructions. Thereby releasing torque or

tension on your cable—preventing buckling or kinking of cable.

WARNING: Operator should be thoroughly familiar with the Safety Instructions section before attempting

to operate this equipment.

WARNING: Do not permit blade end to get hung up in an obstruction for more than 2 to 3 seconds. Your

job as an operator of this machine is to keep the cable rotating. Remember, do not operate the machine to the

point where the cable begins to buckle. This practice is dangerous and could damage the cable.

16

Operation

NOTE: Kinkage and breakage of cable is caused solely by one thing: you permit the working end of the

cable to get hung up in an obstruction and you keep on twisting the other end of same with your motor, until

something must give. Remember, the only way you can clean an obstruction from a line, or negotiate a bend

in a line, is when your blades are rotating. Let us repeat: your job is to keep the blades rotating. The design of

your motor is such that as soon as the blade end of your cable gets hung up in an obstruction, your motor RPM

reduces. That reduction in speed is notice to the operator to pull the blade away from the obstruction, thereby

releasing the tension that has been built up in the coil-spring cable. That release of tension prevents buckling,

kinking or breakage of the cable.

8. A good rule to follow for releasing tension on a cable is this: when your blade gets hung up in the obstruction and fails to rotate,

an RPM reduction will be noticeable which indicates it is time to pull the blade away from the obstruction. As you pull it away, all

tension in the cable will be released immediately and your blades will turn at a high speed. As soon as the blade is free, push it back

into the obstruction quickly so as to utilize the built-up power which enables you to clean the line more quickly and efficiently.

WARNING: Do not allow a tool to get hung up in an obstruction. If a tool gets hung up in an obstruction,

a reverse feature is provided on this machine for just this purpose. In the event your blade gets hung up on

an obstruction and you are unable to release it in the normal manner, move the toggle switch to the“OFF”

position, and permit your machine to come to a dead stop. Then, move the toggle switch in the“R”(reverse)

position. Now start your machine slowly. See if you can remove the blade from the root or other obstruction

by this reverse action. When the blade is released, let your machine come to a dead stop again. Then place the

toggle switch in the“F” (forward) position. Make sure that the cable/blade rotates counter clockwise, when

standing in front of the machine, except when reversing it to free cutting tool from obstruction.

WARNING: Do not reverse machine until motor and drum come to a dead stop.

Avoid operating this machine in reverse for any other purpose.

9. When you cut through one group of roots, it is always good to pull back your cable and take another cut. This final cut is what gives

you a thorough cleaning job.

10. When the job is complete, feed the cable back into drum, making sure that your machine is running, so that the distributor arm can

feed and distribute cable in the drum properly.

• KEEP MACHINE RUNNING in the forward direction.

WARNING: Never retract tool from sewer inlet while cable is rotating.

NOTE: It is recommended that a continuous flush of water can be used to clean cable and tool as they

are retrieved.

17

Operation

11. When tool is close to the clean out opening, release foot actuator and allow machine to come to a complete stop.

12. Move toggle switch to the “OFF”position and disconnect machine from power source.

13. Pull remaining cable and tool from the line and hand-feed cable back into the drum.

Operating the Power Cable Feed

1. The adjusting knob on the top controls the tension on the cable. It should be set so that the cable feeds freely in-and-out of the

drum. Tension can be increased by turning handle to the right. Don’t apply too much tension—just enough to keep the cable

moving is sufficient.

2. Cable is fed into the line by putting the handle in forward position. This speed will vary from 0-30 feet per minute depending on

size of the cable and how far forward you push the handle.

3. Cable is brought out of the line by putting the handle in reverse position. You can also vary the speed in reverse.

4. When the handle is straight up, the drive is in neutral position. There is no lateral movement of cable at this point. This enables the

operator to position the blade against the stoppage and chew it away if necessary.

5. Another feature of the Dial-A-Cable Power Cable Feed is its ability to change from FORWARD to REVERSE by simply moving the

handle. The feed reacts immediately.

6. New drive design permits repair right in the field. Entire unit can be taken apart and put back in working order in just ten minutes.

WARNING: (1) Never try to force the cable into the line. Choose a proper feeding speed that gives a smooth

cutting action. (2) Refer to operating and maintenance instructions for proper maintenance.

18

Special Applications Procedure

CLEANING LINES THROUGH A MANHOLE

1. Position your machine at top and about 1' away from manhole.

2. Use a length of 1½" pipe with 45° elbow screwed there to (the depth of the manhole determines the proper length of pipe to be

used).

3. Hand-feed your cable, less leader and blade, through proper length of 1½" pipe.

4. Fasten leader or double male coupling with proper size blade to end of cable.

5. Place blade into line by the use of extension pipe. The length of pipe referred to povides a guide for your flexible shaft from the top

of the manhole to the entrance of the line, thereby preventing your cable from buckling or kinking. It likewise enables the operator

to operate the machine in a convenient, comfortable position at the top of the manhole. Never enter the manhole.

RODDING FARTHER THAN 75' (5/8" CABLE*)

The object of the 5' anchor cable is in the drum is this: When you have fed 75' of cable into the line, the female coupling on the end of

the 5' piece will show up at the end of the distributor arm on your machine. You will then know that you have 75' of cable in the line.

Now, let’s suppose that the line you are cleaning requires more than 75'of cable.

This is the procedure to follow:

1. Disconnect the 75' of cable and leave it in the line. Insure that it cannot fall into the pipe beyond the opening.

2. Take the male end of your extension and add it to the 5' piece in the drum, feeding the whole extension piece into the drum.

• NOTE: The machine should be operating in the forward direction.

3. Hook up to the 75' piece in the sewer and resume rodding.

• *NOTE: 100' of .55 magnum cable can fit in the drum at one time.

MAIN SEWER OR SEPTIC TANK OVERRUN

It is very important to know the approximate distance from inlet to main sewer or septic tank. Overrunning cable too far into main

sewer or septic tank can allow cables to knot up and prevent their retrieval.

19

Maintenance Instructions

WARNING: Make sure machine is unplugged from the electrical system before making any adjustment.

INSTRUCTIONS FOR SPLICING OR REPAIRING CABLE

Splicing Cable (Standard Single Wound Cable)

1. Square ends of cable to be spliced or repaired by placing each end against a grinding wheel, grinding down so that the shoulder of

splicer or coupling will butt squarely against the cable ends. (If splicing “INNER-CORE CABLE”, and inner-core protrudes from cable at

point of repair, pull the inner-core out of the cable just far enough to allow for the insertion of the connector. Then cut the inner-

core off and push back into cable.)

2. Put cable in vice and open ends slightly with drive punch so that opening is just large enough to allow connector to be inserted.

3. Clean splicer or coupling of rust or grease.

4. Connect cables to splicer, or coupling and draw uptightly to shoulder of connector, as illustrated above.

5. Put cable in vice and open ends slightly with drive punch so that opening is just large enough to allow connector to be inserted.

Splicing the .55 Magnum Cable and Installing New .55 Couplings

FIG. 8

Item Part Number Description

1 44110400 .55 Long Male Coupling

2 44110500 .55 Female Coupling

3 44114500 .55 Splicer

4 44111300 .55 Male Coupling

or 44114300 .55 Leader Male Coupling

5 44291601 Anchor Adapter .55 to ⁄"

NOTE: Couplings and splicer

for the .55 Magnum Cable are not

interchangeable with ½" or ⁄"

Spartan cable connectors.

20

Maintenance Instructions

1. Grind cable square by placing the cable end against a grinding wheel. Care is to be taken to assure the innercore is flush with outer

cable. Grind outer cable and innercore down enough to produce a flat contact surface between the cable and connector (splicer or

coupling).

2. Secure the cable into a vise, making sure innercore remains flush with outer cable.

3. Clean connector and inside of cable from rust or dirt. (Care to be taken on cleaning connector threads.) Also it may be necessary to

deburr inside of cable.

4. Insert connector into innercore in the manner of tightening a right hand threaded screw. Tighten connector enough so that contact

is made between outer cable and the connector face. If required, step two through four should be repeated for the other cable end.

5. Since the coupling and the wire in the cable are of high carbon steel, a special welding process is required. Before welding, use a

propane torch to preheat the area where the weld will be. Hold the torch 4-5" away from the metal surface and heat for 2 minutes.

Immediately, weld with an arc welder, using 3/32" diameter unit rod #70 or equivalent chromium-stainless steel rod. Use a heat

range of 90-100 amps. Be sure weld bead is 1/8”wide and 1/2” long, where each wire end contacts the coupling.

After welding, it will be necessary to stress relieve the welded area. Again, using a propane torch holding 4-5”away from metal

surface, heat up to approximately 5 minutes. Allow to cool and cable will be ready for use.

FIG. 9 FIG. 10

NOTE: Never heat the cable to a cherry red color. This indicates too high a temperature and will weaken

the cable.

Table of contents

Other Spartan Cleaning Equipment manuals