6

2.1 EXAMPLE OF IDENTIFICATION PLATE

Safety Information Informations Sur La Sécurité

Listed by / Manufactured by:

Spartherm Feuerungstechnik GmbH

Maschweg 38

D – 49324 Melle, Germany

Listée par / Fabriqué par:

Spartherm Feuerungstechnik GmbH

Maschweg 38

D – 49324 Melle, Germany

Appareil de Chauffage a combustion solides

Tested aux Normes: UL-1482-11, ULC-S627-00,

U.S. Enviroment Protection Agency: Certified to comply with 2020

Particulate emission standards using cord wood

Model: Spartherm Cassette 600 Module

Date de Fabrication:

Mois/Année: 11/2019

No de Serie: Stove-600

Solid Fuel Room Heater – For Use with Solid Wood Fuel only

Tested toStandards: UL-1482-11, ULC-S627-00,

U.S. Enviroment Protection Agency: Certified to comply with 2020

Particulate emission standards using cord wood

Model: Spartherm Cassette 600 Module

Date of Manufacture

Month/Year:11/2019

Serial Number Stove-600

TO PREVENT HOUSE FIRES:

Contact local building or fire officials about restrictions and installation

inspection in your area. Install and use only in accordance with manufacturer’s

installation and operating instructions and local codes. In the absence of any local

codes, installation must meet minimum requirements of NFPA 211 in the USA, and

B365 in Canada. Refer to manufacturer´s instructions and local codes for

precautions required for passing a chimney through a combustible wall orceiling.

Inspect and clean chimney system frequently in accordance with manufacturer´s

instruction. Do not connect this stove to a chimney flue serving another appliance.

Do not use grate or elevate fire. Build wood fire directly on hearth. Installation only

with listed UL-103 HTor ULC S 629 chimney diameter 6 or 7 inches.

TO PREVENT CREOSOTE FIRES:

Inspect and clean chimney frequently - under certain conditions of use,creosote

buildup may occurrapidly. Do not use fuels other than firewood.

CAUTION:Only operate the wood heater with the doors fully closed. Replace

glass only with original 4 mm Robax ceramic glass. Areas of the fireplace

incorporating warm or cold air ducts shall be enclosed in accordance with the

manufacturer’s installation instructions. Ifprovided with a hearth extension, the

hearth extension must be installed according to the installation instructions! Air is

needed for fireplace operation! Atleast 14 square inches (90.3 square centimeters)

of outside air must be admitted to the room or directly to the unit through a 5”

(127mm) diameter pipe. Failure to provide this may starve other fuel burning

appliances from an adequate air supply. Do not obstruct air inlet and outlet in any

case. Components used with fireplace must be listed. See manual.

Do not use a fireplace insert or other products not specified for use with this

product.

CAUTION: Gas logs shall be certified for the application. This unit is not designed

to burn with a log set.

This wood heater needs periodic inspection and repair for proper operation.

Consult the owner’s manual for further information. Itisagainst federal regulations

to operate this wood heater in a manner inconsistent with the operating instructions

in the owner’s manual.

POUR EVITER LES INCENDIES DOMESTIQUES:

Contactez les Autorités des bâtiments et les pompiers pour obtenir des instructions concernant les

restrictions et inspections d´installation dans votre région. Installez et utillisez cet appareil

uniquement en respectant les instructions d´installation et d´utilisation du fabriquant. Respectez

également les réglementations locales. En l´absence de réglementations locales, l´installation doit

respecter les normes minimales de NFPA 211 aux Etats-Unis et B365 au Canada. Référez-vous

aux instructions du fabriquant aux réglementations locales pour obtenir des instructions

concernant les précautions nécessaires pour le passage de la cheminée á travers une paroi ou un

plafond combustible. Inspectez et nettoyez le système de cheminée fréquement selon les

instructions du fabriquant. Ne connectez pas ce poêle à un conduit de cheminée utilisé par un

autre appareil. N´utilisez pas de grille et ne faites pas monter le feu. Etablissez le feu de bois

directement dans l´âtre. L'installation doit être faite exclusivement avec le cheminée listé selon la

norue ULC-S604, ULC-S610 ou UL-103 HT de diaméte 6” / 7”.

POUR EVITER LES FEUX DE CREOSOTE : Inspectez et nettoyez la cheminée régulièrement -

Sous certaines condition d´emploi, la creosote peut s´accumuler rapidement. Ne pas utiliser

d´autres combustibles que le bois.

ATTENTION: N'utilisez le poêle que lorsque les portes sont complétement fermées. Remplacer

la vitre uniquement avec du verre Robax céramique de 4 mm.Il faut que les zones du foyer vitré

qui portent les canaux d'alimentation d'air chaud et froid soient conformes à l'instruction de

montage du fabricant. L'approvisionnement en revêtement fait de matériaux ininflammables

devant l'ouverture du foyer vitré doit être installé conforme a l'instruction de montage du fabricant.

L'aération suffisante pour l'utilisation du foyer est nécessaire! Dans l'emplacement du foyer vitré il

faut assurer au moins 14 pouces carée (90,3 centimètres carée) de l'air de dehors ou il faut assurer

l'alimentation en air de combustion directe au foyer vitré par une tube d'un diamètre de 5 pouces

carée ( 127mm). Un manque d’air d’appoint pourrait priver les autres apparells de combustion

d’une alimentation d’air adéquate. Ne pas obstruer les entrés et sorties d’air en aucun cas. Les

composantes utilisées dans l’appareil doivent étre répertoriées. Voir manuel. N'utilisez pas d'insert

de cheminée ou autres produits qui ne sont pas autorisés pour l'usage de ce produit.

ATTENTION: Ce poêle à bois n'est pas conçu pour brûler avec un bûche à gaz.

Ce foyer vitré à bois doit être entretenu et réparé à intervalles réguliers pour assurer un

fonctionnement correct. Veuillez consulter s.v.p. pour de plus amples informations les instructions

du fabricant. Il est contraire aux dispositons de l'autorité d'exploiter ce foyer vitré à bois incompatible

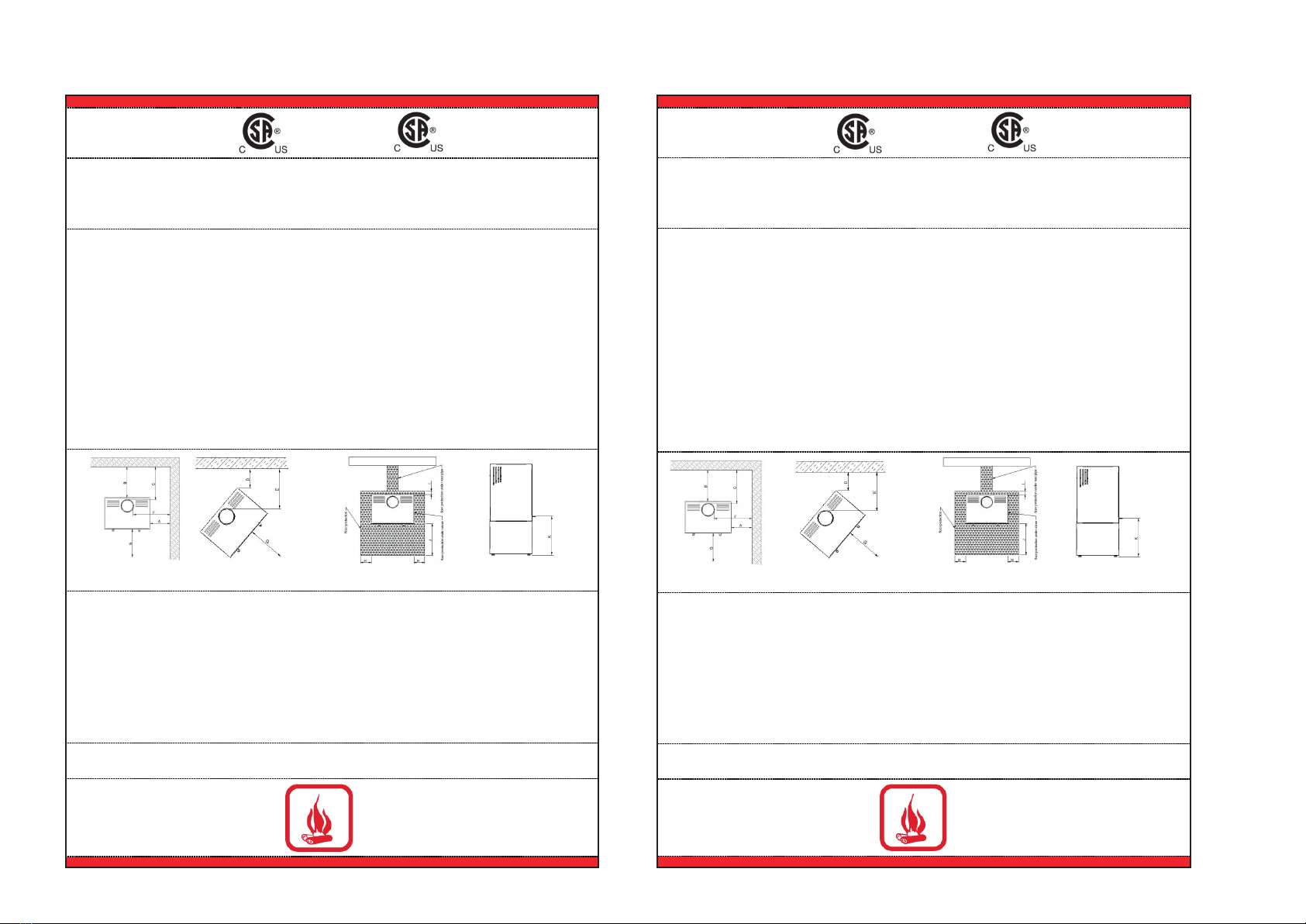

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

Single-wall connector pipe

11” / 279mm

Double-wall connector pipe

11” / 279mm

G.

H.

I.

J.

48” / 1219mm

For Canada 8” / 203mm

For USA 6” / 152mm

8” / 203mm

For Canada 18” / 450mm

For USA 16” / 406mm

48” / 1219mm

For Canada 8” / 203mm

For USA 6” / 152mm

8” / 203mm

For Canada 18” / 450mm

For USA 16” / 406mm

IN FRONT OF UNIT *

Recommend amount of wood:

1,8 kg/hr

ECARTEMENT MINIMUM AUX MATERIAUX COMBUSTIBLES

paroi simple

double paroi

G.

H.

I.

J.

48” / 1219mm

Pour le Canada 8” / 203mm

Pour les USA 6” / 152mm

8” / 203mm

Pour le Canada 18” / 450mm

Pour les USA 16” / 406mm

48” / 1219mm

Pour le Canada 8” / 203mm

Pour les USA 6” / 152mm

8” / 203mm

Pour le Canada 18” / 450mm

Pour les USA 16” / 406mm

Quantité de bois recommandée: 1,8 kg/hr

Min. / Max. sortie (kW): 10,613 – 47,417 BTU/hr

* Not Tested - NFPA Guidelines in the USA, CAN/CSA B365-M91 in

Canada. Floor protection must be minimum 3,8mm non-combustible

material extending beneath the stove, and to the front and sides from door

opening and to the rear as indicated.

*Non testé - Exigences NFPA aux Etats-Unis, CAN/CSA B365-M91 au

Canada. La protection de sol doit avoir une épaisseur de 3,8mm (1 cm), être

d'un matériau non combustible et être placée devant et à côté de la porte ainsi

qu'à l'arrière, comme indiqué.

HOT WHILE IN OPERATION. DO NOT TOUCH.

KEEP CHILDREN AND CLOTHING AWAY.

CONTACT MAY CAUSE SKIN BURNS. SEE NAME PLATE

AND INSTRUCTIONS. KEEP FURNISHINGS AND OTHER

COMBUSTIBLE MATERIALS A CONSIDERABLE

DISTANCE AWAY FROM THE APPLIANCE.

NOT SUITABLE FOR MOBILE HOME INTALLATION.

DO NOT OVERFIRE – IF HEATER OR CHIMNEY CONNECTOR

GLOWS, YOU ARE OVERFIRING.

CHAUD PENDANT LE FONCTIONNEMENT – NE PAS TOUCHER.

TENIR ÉLOIGNÉS LES ENFANTS ET LES VÊTEMENTS –

LE CONTACT PEU CAUSER DES BRULURES. CONSULTEZ

LA PLAQUE D'IMMATRICULATION ET LES INSTRUCTIONS.

TENIR LES FOURNITURES ET AUTRES MATIERES

COMBUSTIBLES À DISTANCE DE L´APPAREIL.

NE PAS INSTALLER DANS UNE MAISON MOBILE.

EVITER DE SURCHAUFFER – SI LE FEU OU LA CHEMINÉE

DEVIENT ROUGE, VOUS SURCHAUFFEZ.

DO NOT REMOVE THIS LABEL NE PAS ENLEVER CETTE ETIQUETTE

Protection de sol pour Canada: 18" (457 mm)

de l´avant de l´appareil au bord de la

Floor protection for Canada: 18" (457mm)

from unit to front of floor protector.

Important: Unit cannot use small base A on non-combustible material –

must be 9 ¼” / 235mm off the floor from bottom of glass or 4 ½“ with R

value 2,957 in Canada or 6 ½” with R value 2,967 in USA.

Important: l’appareil ne peut pas utilizer une petite base A sur un matériau incombustible – doit

être à 9 ¼” / 235mm du sol à partir du bas du verre ou 4 ½” avec une valeur R 2,957 au

Canada ou 6 ½” avec une valeur R 2,957 au USA.

Safety Information Informations Sur La Sécurité

Listed by / Manufactured by:

Spartherm Feuerungstechnik GmbH

Maschweg 38

D – 49324 Melle, Germany

Listée par / Fabriqué par:

Spartherm Feuerungstechnik GmbH

Maschweg 38

D – 49324 Melle, Germany

Appareil de Chauffage a combustion solides

Tested aux Normes: UL-1482-11, ULC-S627 M87,

U.S. Enviroment Protection Agency: Certified to comply with 2020

Particulate emission standards using cord wood

Model: Spartherm Cassette 700 Module

Date de Fabrication:

Mois/Année: 11/2019

No de Serie: Stove-700

Solid Fuel Room Heater – For Use with Solid Wood Fuel only

Tested toStandards: UL-1482-11, ULC-S627 M87,

U.S. Enviroment Protection Agency: Certified to comply with 2020

Particulate emission standards using cord wood

Model: Spartherm Cassette 700 Module

Date of Manufacture

Month/Year:11/2019

Serial Number Stove-700

TO PREVENT HOUSE FIRES:

Contact local building or fire officials about restrictions and installation

inspection in your area. Install and use only in accordance with manufacturer’s

installation and operating instructions and local codes. In the absence of any local

codes, installation must meet minimum requirements of NFPA 211 in the USA, and

B365 in Canada. Refer to manufacturer´s instructions and local codes for

precautions required for passing a chimney through a combustible wall orceiling.

Inspect and clean chimney system frequently in accordance with manufacturer´s

instruction. Do not connect this stove to a chimney flue serving another appliance.

Do not use grate or elevate fire. Build wood fire directly on hearth. Installation only

with listed UL-103 HT orULC S 629 chimney diameter 6 or 7 inches.

TO PREVENT CREOSOTE FIRES:

Inspect and clean chimney frequently - under certain conditions of use,creosote

buildup may occurrapidly. Do not use fuels other than firewood.

CAUTION:Only operate the wood heater with the doors fully closed. Replace

glass only with original 4 mm Robax ceramic glass. Areas of the fireplace

incorporating warm or cold air ducts shall be enclosed in accordance with the

manufacturer’s installation instructions. Ifprovided with a hearth extension, the

hearth extension must be installed according to the installation instructions! Air is

needed for fireplace operation! Atleast 14 square inches (90.3 square centimeters)

of outside air must be admitted to the room or directly to the unit through a 5”

(127mm) diameter pipe. Failure to provide this may starve other fuel burning

appliances from an adequate air supply. Do not obstruct air inlet and outlet in any

case. Components used with fireplace must be listed. See manual.

Do not use a fireplace insert or other products not specified for use with this

product.

CAUTION: Gas logs shall be certified for the application. This unit is not designed

to burn with a log set.

This wood heater needs periodic inspection and repair for proper operation.

Consult the owner’s manual for further information. Itisagainst federal regulations

to operate this wood heater in a manner inconsistent with the operating instructions

in the owner’s manual.

POUR EVITER LES INCENDIES DOMESTIQUES:

Contactez les Autorités des bâtiments et les pompiers pour obtenir des instructions concernant les

restrictions et inspections d´installation dans votre région. Installez et utillisez cet appareil

uniquement en respectant les instructions d´installation et d´utilisation du fabriquant. Respectez

également les réglementations locales. En l´absence de réglementations locales, l´installation doit

respecter les normes minimales de NFPA 211 aux Etats-Unis et B365 au Canada. Référez-vous

aux instructions du fabriquant aux réglementations locales pour obtenir des instructions

concernant les précautions nécessaires pour le passage de la cheminée á travers une paroi ou un

plafond combustible. Inspectez et nettoyez le système de cheminée fréquement selon les

instructions du fabriquant. Ne connectez pas ce poêle à un conduit de cheminée utilisé par un

autre appareil. N´utilisez pas de grille et ne faites pas monter le feu. Etablissez le feu de bois

directement dans l´âtre. L'installation doit être faite exclusivement avec le cheminée listé selon la

norue ULC-S604, ULC-S610 ou UL-103 HT de diaméte 6” / 7”.

POUR EVITER LES FEUX DE CREOSOTE :

Inspectez et nettoyez la cheminée régulièrement - Sous certaines condition d´emploi, la creosote

peut s´accumuler rapidement. Ne pas utiliser d´autres combustibles que le bois.

ATTENTION: N'utilisez le poêle que lorsque les portes sont complétement fermées. Remplacer

la vitre uniquement avec du verre Robax céramique de 4 mm.Il faut que les zones du foyer vitré

qui portent les canaux d'alimentation d'air chaud et froid soient conformes à l'instruction de

montage du fabricant. L'approvisionnement en revêtement fait de matériaux ininflammables

devant l'ouverture du foyer vitré doit être installé conforme a l'instruction de montage du fabricant.

L'aération suffisante pour l'utilisation du foyer est nécessaire! Dans l'emplacement du foyer vitré il

faut assurer au moins 14 pouces carée (90,3 centimètres carée) de l'air de dehors ou il faut assurer

l'alimentation en air de combustion directe au foyer vitré par une tube d'un diamètre de 5 pouces

carée ( 127mm). Un manque d’air d’appoint pourrait priver les autres apparells de combustion

d’une alimentation d’air adéquate. Ne pas obstruer les entrés et sorties d’air en aucun cas. Les

composantes utilisées dans l’appareil doivent étre répertoriées. Voir manuel. N'utilisez pas d'insert

de cheminée ou autres produits qui ne sont pas autorisés pour l'usage de ce produit.

ATTENTION: Ce poêle à bois n'est pas conçu pour brûler avec un bûche à gaz.

Ce foyer vitré à bois doit être entretenu et réparé à intervalles réguliers pour assurer un

fonctionnement correct. Veuillez consulter s.v.p. pour de plus amples informations les instructions

du fabricant. Il est contraire aux dispositons de l'autorité d'exploiter ce foyer vitré à bois incompatible

au manuel du fabricant.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

Single-wall connector pipe

11” / 279mm

Double-wall connector pipe

11” / 279mm

G.

H.

I.

J.

48” / 1219mm

For Canada 8” / 203mm

For USA 6” / 152mm

8” / 203mm

For Canada 18” / 450mm

For USA 16” / 406mm

48” / 1219mm

For Canada 8” / 203mm

For USA 6” / 152mm

8” / 203mm

For Canada 18” / 450mm

For USA 16” / 406mm

IN FRONT OF UNIT *

Recommend amount of wood:

2,1 kg/hr

ECARTEMENT MINIMUM AUX MATERIAUX COMBUSTIBLES

paroi simple

double paroi

G.

H.

I.

J.

K.

48” / 1219mm

Pour le Canada 8” / 203mm

Pour les USA 6” / 152mm

8” / 203mm

Pour le Canada 18” / 450mm

Pour les USA 16” / 406mm

9 ¼” / 235mm

48” / 1219mm

Pour le Canada 8” / 203mm

Pour les USA 6” / 152mm

8” / 203mm

Pour le Canada 18” / 450mm

Pour les USA 16” / 406mm

9 ¼” / 235mm

DEVANT L’APPAREIL *

Quantité de bois reommandée

2,1 kg/hr

* Not Tested - NFPA Guidelines in the USA, CAN/CSA B365-M91 in

Canada. Floor protection must be minimum 3.8mm non-combustible

material extending beneath the stove, and to the front and sides from door

opening and to the rear as indicated.

*Non testé - Exigences NFPA aux Etats-Unis, CAN/CSA B365-M91 au

Canada. La protection de sol doit avoir une épaisseur de 3,8mm (1 cm), être

d'un matériau non combustible et être placée devant et à côté de la porte ainsi

qu'à l'arrière, comme indiqué.

HOT WHILE IN OPERATION. DO NOT TOUCH.

KEEP CHILDREN AND CLOTHING AWAY.

CONTACT MAY CAUSE SKIN BURNS. SEE NAME PLATE

AND INSTRUCTIONS. KEEP FURNISHINGS AND OTHER

COMBUSTIBLE MATERIALS A CONSIDERABLE

DISTANCE AWAY FROM THE APPLIANCE.

NOT SUITABLE FOR MOBILE HOME INTALLATION.

DO NOT OVERFIRE – IF HEATER OR CHIMNEY CONNECTOR

GLOWS, YOU ARE OVERFIRING.

CHAUD PENDANT LE FONCTIONNEMENT – NE PAS TOUCHER.

TENIR ÉLOIGNÉS LES ENFANTS ET LES VÊTEMENTS –

LE CONTACT PEU CAUSER DES BRULURES. CONSULTEZ

LA PLAQUE D'IMMATRICULATION ET LES INSTRUCTIONS.

TENIR LES FOURNITURES ET AUTRES MATIERES

COMBUSTIBLES À DISTANCE DE L´APPAREIL.

NE PAS INSTALLER DANS UNE MAISON MOBILE.

EVITER DE SURCHAUFFER – SI LE FEU OU LA CHEMINÉE

DEVIENT ROUGE, VOUS SURCHAUFFEZ.

DO NOT REMOVE THIS LABEL NE PAS ENLEVER CETTE ETIQUETTE

Protection de sol pour Canada: 18" (457 mm)

de l´avant de l´appareil au bord de la

Floor protection for Canada: 18" (457mm)

from unit to front of floor protector.

Important: l’appareil ne peut pas utilizer une petite base A sur un matériau incombustible –

doit être à 9 ¼” / 235mm du sol à partir du bas du verre ou 4 ½” avec une valeur R 2,957 au

Canada ou 6 ½” avec une valeur R 2,957 au USA

Important: Unit cannot use small base A on non-combustible material – must be 9

¼” / 235mm off the floor from bottom of glass or with R value 2,957 in Canada or 6

½” with R value 2,957 in USA.