Spartus WRC310 User manual

User’s manual

Welding water cooler SPARTUS®

WRC400WRC310

WELDING EQUIPMENT SUITABLE FOR TODAY’S NEEDS

Thank you for purchasing our product!

You have made a right choice. Plasma welding and welding processes are

carried out in difficult conditions that expose welding equipment to extreme

tests of its strength. Only high quality equipment can ensure required reliability

and performance during realization of the above-mentioned processes. SPAR-

TUS® products are characterized by precisely such features: they are primarily

reliable and durable, but they are also versatile.We listen carefully to clients’

needs.Therefore, our offer covers such a wide assortment of products.Thank

you very much for your trust in our company. We would like to invite you to

familiarize yourself with the remaining products and offer at www.spartus.

info or directly at alocal distributor of SPARTUS® products.

Before using this product, read the instruction manual in its entirety, with understanding.

Keep the instructions for quick reference to it if necessary. Pay special attention to safety

instructions provided for your protection. In the event of any points of misunderstanding

instructions, contact your supplier or supervisor.

IMPORTANT!

TABLE OF CONTENTS

1.

SAFE USE – HAZARDS ASSOCIATED WITH ARC WELDING AND PLASMA CUTTING

.............. 2

1.1 General safety rules ............................................................................................................................................................... 2

1.2 Electric shock can kill ............................................................................................................................................................ 2

1.3 Welding arc radiation can be dangerous ..................................................................................................................... 3

1.4 Vapours and gases can be dangerous .......................................................................................................................... 3

1.5 Noise can be harmful ........................................................................................................................................................... 4

1.6 Fire or explosion hazard ...................................................................................................................................................... 5

1.7 Other hazards .......................................................................................................................................................................... 6

1.8 Other informations ............................................................................................................................................................... 6

1.9 Symbols used in instructions ............................................................................................................................................ 7

2.

ELECTROMAGNETIC FIELD (EMF) ............................................................................................................ 7

3.

ELECTROMAGNETIC COMPATIBILITY (EMC) ........................................................................................ 7

3.1 General informations ........................................................................................................................................................... 7

3.2 Assesment of area ................................................................................................................................................................. 8

3.3 Methods of reducing emmisions .................................................................................................................................... 8

4.

CONFORMITY WITH STANDARDS ........................................................................................................... 8

4.1 CE marking ............................................................................................................................................................................... 8

4.2 Rating plate .............................................................................................................................................................................. 8

5.

GENERAL DESCRIPTION ............................................................................................................................. 8

5.1 Purpose of use ......................................................................................................................................................................... 9

6.

TECHNICAL SPECIFICATIONS .................................................................................................................... 9

6.1 Operation, storage and transport ................................................................................................................................... 9

6.2 Technical parameters of device ..................................................................................................................................... 10

7.

INSTALLATION AND USE ......................................................................................................................... 10

7.1 Proper cooling ....................................................................................................................................................................... 10

7.2 Movement and handling .................................................................................................................................................. 10

7.3 Description of construction ............................................................................................................................................. 11

7.4 Connecting to power supply .......................................................................................................................................... 12

7.5 Connecting the device ....................................................................................................................................................... 12

8.

MAINTENANCE ........................................................................................................................................... 13

9.

ENVIRONMENTAL PROTECTION ........................................................................................................... 13

9.1 Liquid coolant ....................................................................................................................................................................... 13

10.

TROUBLESHOOTING ................................................................................................................................. 14

USER’S MANUAL EN

2

Arc welding and plasma cutting are processes

that can pose hazards for the operator and per-

sons in his vicinity. The operator and his close

surroundings are exposed, among others, to

the risk of fire, explosion, electric shock, bur-

ning, as well as the risk of getting injured by

moving parts of the device.

Once proper safety measures are provided,

electric welding and plasma cutting are rela-

tively safe processes. For this reason, it is cru-

cial to strictly follow the valid OSH principles

during welding operations.

The informations provided below do not re-

lease the operator from the obligation to follow

the OSH rules that are binding in his plant/

workplace.

1.1 GENERAL SAFETY RULES

Welding operators and persons working in

the vicinity of the welding process should be

made aware of the following hazards associa-

ted with arc welding. They should be made

aware of protective measures as specified in

relevant international and national standards

and regulations.

1.1.1 Equipment condition

and maintenance

• Check the technical condition of the device

and accessories before starting to weld/

plasma cutting. It is forbidden to use equi-

pment that is unserviceable.

• Equipment damaged or defective should

be immediately repaired or removed from

service.

1.1.2 Operation and carrying

• Apply appropriate protective measures in

the space around the zone, where welding

operations are expected to be carried out.

• All equipment should be placed so that it

does not present a hazard in passageways,

on ladders or stairways, etc.

• Falling objects can cause injuries or kill.

Protect device before accidentally falling.

• Welding equipment may be heavy (e.g. wire

feeder fitted with spool and harness). Care

shall be taken during manual handling.

• To handle heavy elements, use hoists/

trucks/transport equipment designed

especially for this purpose. Make sure

the weight ofequipment to be handled

does not exceed the admissible maximum

lifting capacity of used hoist/truck/transport

equipment.

• It is forbidden for unauthorized persons,

especially children, to be in the vicinity of

the device during its use.

•

The device is not suitable for pipe defrosting.

• Device use non-compliant with its intended

purpose is forbidden.

1.1.3 Training

• Only professionally trained and qualified

personnel may install, operate, maintain

and repair the device.

• For operators and their supervisors training

is essential in: the safe use of the equipment;

the processes; the emergency procedures.

1.2 ELECTRIC SHOCK CAN KILL

• Before starting to weld and during the wel-

ding process, the operator should insulate

himself from the ground and the environ-

ment by means of dry and undamaged

protective clothes. It is forbidden to work

on wet ground.

• It is forbidden to touch SK sockets ( „+” and/

or „-”) when the device is in operation (con-

nected to a power supply source).

• It is forbidden to touch live electric compo-

nents of the device.

1. SAFE USE – HAZARDS ASSOCIATED WITH ARC WELDING AND

PLASMA CUTTING

USER’S MANUAL

EN

3

• Power supply must never be connected

before the accessories of SK sockets/con-

nectors are properly installed in the device.

• Use dry and undamaged welding gloves

and protective clothing, in order to ensure

proper insulation of the body. It is forbidden

to touch with a bare hand any elements that

are parts of an electric circuit.

• The operator must always make sure that

there is a good electric connection of the

return conductor to the element to be wel-

ded. The connection should be located as

close to the welding zone as possible.

• Maintain the electrode grip, the welding

torch, the chassis ground clamp, welding

cables and the welding machine in proper

technical condition that ensures safe ope-

ration. Damaged cable insulation should be

replaced with new insulation.

• Never dip an electrode into water, to cool

it down.

• When working above the floor level (at

aheight), use a safety harness to protect

yourself against falling, in the case of po-

tential electric shock.

• Exercise special caution, when using the

device in small rooms or in rooms with

elevated humidity levels.

1.3 WELDING ARC RADIATION CAN BE

DANGEROUS

The arc generates:

• ultraviolet radiation (can damage skin and

eyes);

• visible light (can dazzle and impair vision);

• infrared (heat) radiation (can damage skin

and eyes).

Such radiation can be direct or reflected from

surfaces such as bright metals and light colo-

ured objects.

1.3.1 Eye and face protection

• Use welder’s helmet/shield with an appro-

priate filter to protect you face and eyes

against sparks and welding arc radiation.

• The shield / helmet should provide eye and

face protection against injuries that may

result in welding spatters.

• Welding helmet/shield should be made in

accordance with applicable standards.

1.3.2 Body protection

• The body should be protected by suitab-

le clothing in accordance with applicable

standards.

• Use appropriate protective clothing made

of durable and fire-resistant material, to

ensure proper skin protection.

• The use of neck protection can be necessary

against reflected radiation.

1.3.3 Protection of persons in the vicinity

of an arc

• Protect the remaining personnel present

in the vicinity of welding works against

negative impact of arc radiation and wel-

ding splatters. Warn them about the hazard

resulting from exposure to the welding arc.

In the vicinity of an arc, non-reflective cur-

tains or screens should be used to isolate

persons from the arc radiation. A warning,

e.g. a symbol for eye protection, should

refer to the hazard of arc optical radiation.

Welder’s assistants should also wear

appropriate protective clothing.

1.4 VAPOURS AND GASES

CAN BE DANGEROUS

USER’S MANUAL EN

4

Arc welding and allied processes produce wel-

ding fume which may pollute the atmosphere

surrounding the work. Welding fume is a vary-

ing mixture of airborne gases and fine particles

which, if inhaled or swallowed, constitute a

health hazard.

The degree of risk is depend on:

• the composition of the fume;

• the concentration of the fume;

• the duration of exposure.

A systematic approach to the assessment of

exposure is necessary, taking into account the

particular circumstances of the operator and the

ancillary worker who can be exposed.

Welding fume may be controlled by a wide

range of measures, e.g. process modifications,

engineering controls, methods of work, personal

protection and administrative action.

First it is necessary to consider whether ex-

posure can be prevented by eliminating the

generation of welding fume altogether. Where

this cannot be done, measures for reducing the

quantity of welding fume generated should be

investigated, after which the control of welding

fume at source should be considered. The use

of respiratory equipment should not be con-

templated until all other possibilities have been

eliminated. Normally, respiratory protective

equipment should be used only as an interim

measure. However, there cannot be a situation

in which, in addition to ventilation, the use of

personal protection is necessary.

1.4.1 VAPOURS AND GASES.

ADDITIONAL PRECAUTIONS

• Welding operations can involve generation

of vapours and gases that are hazardous

to health. Inhaling the vapours should be

avoided. Keep your head away from vapours

during welding operations. Ensure proper

ventilation and/or mechanical welding ex-

haust draught to keep vapours and gases

away from the breathing zone.

• When welding is carried out in a confined

space, operators should only be permitted

to weld when other persons, who have

been instructed and who are able to react

in case of an emergency, are in the imme-

diate vicinity.

• In closed rooms or in certain circumstances

during outdoor operations, it may be re-

quired to use individual equipment for the

protection of the welder’s airways, e.g. a re-

spirator. Additional safety measures are also

required when galvanized steel is welded.

• Welding operations must not be performed

in the vicinity of chlorinated hydrocarbons

generated during degreasing, cleaning or

spraying. Heat and radiation generated

by the arc may enter into a reaction with

vapours of solvents, which may lead to the

formation of phosgene – ahighly toxic gas.

• The shielding gas used during arc welding

may force the air out of a room. This may

lead to a health hazard or even death. Pro-

per ventilation, especially in closed rooms,

should always be provided, to ensure appro-

priate amount of air that is indispensable for

safe breathing.

1.5 NOISE CAN BE HARMFUL

In the welding environment, damaging levels of

noise can exist. Continued exposure to a high

noise level on the unprotected ear is injurious.

The noise levels should be reduced to the lo-

west practicable level.

High levels may be tolerated for very short

periods by wearing adequate ear protection in

accordance with the national or local regulation.

In case of doubt, checks by an expert should be

made to establish noise levels in any particular

environment, and, if these are in excess of the

prescribed limit, one of the following alterna-

tives may apply:

a) insulation of the noise source as far as po-

ssible, e.g. by fitting silencers or sound proof

enclosures,

b) insulation of the operator from the noise

USER’S MANUAL

EN

5

source,

c) effective maintenance of sound protection

devices,

d) indication as „ear protection areas” where

applicable,

e) restriction of entry to these„ear protection

areas”to authorized persons,

f) protect your hearing with appropriate per-

sonal protection measures, e.g. earplugs or

hearing protectors.

1.6 FIRE OR EXPLOSION HAZARD

Arc welding and allied processes can cause fire

and explosions. Precautions should be taken

to prevent these hazards.

1.6.1 Fire hazard

• Before setting to perform welding opera-

tions, ensure that elements involving fire

hazard are removed from the zone where

welding operations will take place. If it is

impossible, protect all flammable elements

against the impact of sparks. Remember

that sparks and hot metal may penetrate

through small cracks and openings into the

adjacent area.

• Avoid welding in the vicinity of hydraulic

conduits.

• The welding arc throws sparks and splatters

out. Welders should wear clean and dry

protective clothing (staining with oil should

be avoided in particular) such as welding

gloves, welder’s apron, welder’s trousers,

welder’s boots, protective hood/cap, etc.

• When welding operations are not carried

out, make sure that no part of the electrode

comes into contact with the workpiece or

protective earthing. Accidental contact may

lead to overheating and create a fire hazard.

• The fire extinguisher should be ready for use

and located in an easily accessible place.

• The surroundings of the work should be

observed for an adequate period after its

termination.

• „Hot spots” and immediate surroundings

should be observed until their temperature

has dropped to normal.

1.6.2 Explosion hazard

It is forbidden to heat up, cut or weld tanks,

barrels or containers that contained toxic or

flammable materials. For there is an explosion

hazard, even if the containers have been emp-

tied and cleaned.

1.6.3 Use of cylinders with shielding gas

In case compressed gases are used in the work

place, apply special safety measures to prevent

dangerous situations.

• Use gas cylinders with appropriate shielding

gas, foreseen for a particular process. Addi-

tional equipment (pressure regulator, hoses,

connectors) should be in good technical

condition. A gas cylinder and accessories

should have the required valid attestations

and approvals for use.

• Gas cylinders should always be stored in

vertical position, fixed to an undercarriage

or permanent support.

• Gas cylinders should be placed far away

from areas, where they could be exposed

to the risk of being overthrown or suffering

physical damage.

• Ensure gas cylinders are at a safe distance

from places where electric welding or cut-

ting operations are to be performed, away

from other sources of heat, sparks or flames.

• Care shall be taken to prevent gas cylinders

in the vicinity of the workpiece becoming

part of the welding circuit.

• Never allow the electrode, electrode holder

or any other live electric part to get in con-

tact with the gas cylinder.

• Keep your face and head away from the

USER’S MANUAL EN

6

cylinder valve socket when the valve is

being opened.

• Special valve shield should always be in-

stalled during cylinder transportation or

when the cylinder is not used.

1.7 OTHER HAZARDS

Arc welding and allied processes carrying other

hazards not listed before.

1.7.1 Burns

• Never touch hot parts with bare hands.

• Before handling an element, wait until it

cools down.

• Use appropriate tools to grip and handle hot

elements and wear special welding gloves

and clothing that protects against burns.

1.7.2 Plasma arc is dangerous

Highly concentrated plasma arc poses a ha-

zard for health and life. It is forbidden to aim

plasma arc at people.

1.7.3 Welding wire can cause injuries

Accidental pressing of the button on the wel-

ding torch can cause welding wire to advance

in an uncontrolled manner. The welding wire

tip may be sharp.

Never aim the burner tip of the welding torch

at your face, eyes or other people.

1.7.4 Moving elements can be dangerous

All protective elements and device housing

should be in place and in good technical con-

dition. Keep your hands, hair, clothes and tools

away from gear wheels, fans and other moving

parts during their operation.

Do not bring your hands close to fan motors.

It is forbidden to stop a fan by pressing its axis.

1.7.5 HF – high frequency ignition may

cause interference

As welding by the TIG method or plasma cut-

ting involves high frequency ignition, it can

interfere with mobile phones, radio equipment,

TV equipment or improperly protected compu-

ters and industrial robots, which leads to total

disabling of such devices.

1.8 OTHER INFORMATIONS

When performing welding work, you must

apply equally to the health and safety requi-

rements contained in the current normative

acts, applicable in your country.

USER’S MANUAL

EN

7

WARNING!

The maximum voltage of 15kV. Accidental pressing of the microswitch

results in unintentional arc ignition. Never bring a bare hand close to the

electrode, when the device is connected to a power source.

1.9 SYMBOLS USED IN INSTRUCTIONS

We use this symbol to pay your attention about important information.

2. ELECTROMAGNETIC FIELDS (EMF)

Electric current flowing through any conductor causes localized electric and magnetic fields

(EMF). All welders should use the following procedures in order to minimize the risk associated

with exposure to EMF from the welding circuit:

• Route the welding cables together – secure them with tape when possible.

• Place your torso and head as far away as possible from the welding circuit

• Never coil welding cables around your body.

• Do not place your body between welding cables. Keep both welding cables on the same

side of your body.

• Connect the return cable to the workpiece as close as possible to the area being welded.

• It is forbidden to sit or lean on power source while working.

• Do not weld whilst carrying the welding power source or wire feeder.

WARNING!

The electromagnetic field (EMF) generated during welding (and allied processes) may interfere

with the operation of implanted medical devices for example: cardiac pacemakers. Persons with

implanted medical devices such as cardiac pacemakers are obliged to consult a doctor before

starting to weld/plasma cutting and to exercise special caution during work. It is forbidden for

such persons to be present in the vicinity of the place where welding/plasma cutting processes

are realized without previous consultation of a doctor.

3. ELECTROMAGNETIC COMPATIBILITY (EMC)

WARNING!

This Class A equipment is not intended for use in residential locations where the electrical

power is provided by the public low-voltage supply system. There can be potential difficulties

in ensuring electromagnetic compatibility in those locations due to conducted as well radiated

radio-frequency disturbances.

3.1 GENERAL INFORMATIONS

The user is responsible for installing and using the arc welding equipment according to the

manufacturer’s instructions. If electromagnetic disturbances are detected, then it shall be the

responsibility of the user of the arc welding equipment to resolve the situation with the tech-

nical assistance of the manufacturer. In some cases this remedial action may be as simple as

earthing the welding circuit. In other cases, it could involve constructing an electromagnetic

screen enclosing the welding power source and the work complete with associated input fil-

ters. In all cases electromagnetic disturbances shall be reduced to the point where they are no

longer troublesome.

Welding and plasma cutting processes may emit additional interferences. User is

responsibility for the interferences caused by welding and plasma cutting.

USER’S MANUAL EN

8

3.2 ASSESMENT OF AREA

Before installing arc welding equipment, the user shall make an assessment of potential elec-

tromagnetic interferences in the surrounding area. The following shall be taken into account:

a) other supply cables, control cables, signaling and telephone cables, above, below and adja-

cent to the arc welding equipment,

b) radio and television transmitters and receivers,

c) computer and other control equipment,

d) safety critical equipment, for example guarding of industrial equipment,

e) the health of the people around, for example the use of pacemakers and hearing aids,

f) equipment used for calibration or measurement,

g) the immunity of other equipment in the environment. The user shall ensure that other equi-

pment being used in the environment is compatible. This may require additional protection

measures.

h) the time of day that welding or other activities are to be carried out.

The size of the surrounding area to be considered will depend on the structure of the building

and other activities that are taking place. The surrounding area may extend beyond the boun-

daries of the premises.

3.3 METHODS OF REDUCING EMMISIONS

Methods of reducing electromagnetic interference are listed in detail in the standard

EN 60974-9 –„Arc welding equipment – Part 9: Installation and use”.

4. CONFORMITY WITH STANDARDS

The SPARTUS® WRC310 / WRC400 water coolers are in conformity with the relevant Union har-

monization legislation:

LVD 2014/35/UE Low Voltage Directive

harmonized standards:

EN 60974-2 Arc Welding Equipment – Part 1: Liquid Cooling Systems

4.1 CE MARKING

CE marking is placed on the nameplate of device and/or on the front panel of device.

4.2 RATING PLATE

Rating plate and serial number are located on the device case.

USER’S MANUAL

EN

9

5. GENERAL DESCRIPTION

SPARTUS® WRC310 / WRC400watercoolers

The SPARTUS® WRC310 / WRC400 water coolers are designed to cool welding torches. It is cha-

racterized by high performance. The large-capacity coolant vessel is equipped with a coolant

level gauge. The machines are mains powered from single phase 230V source power.

SPARTUS® WRC310 / WRC400 water coolers are compatible with most of the branded welding

torches, thanks to the use of quick coupler (standard 21) on the inlet and outlet.

SPARTUS® water cooler that high quality, maintenance-free unit, guarantees tightness.This is de-

pendable and irreplaceable source of cooling systems.

5.1 PURPOSE OF USE

The SPARTUS® WRC310 / WRC400 water coolers are designed to cool welding torches in which

the handle and burner are cooled by liquid.

When the welding torch is connected with water cooler – the cooler and the welding torch

form a closed cooling circuit.

6. TECHNICAL SPECIFICATIONS

6.1 OPERATION, STORAGE AND TRANSPORT

Conditions during operation, storage and transport

Range of ambient air temperature

during operation

-20°C to +60°C

Relative humidity of the air up to 50% at +40°C

up to 90% at +20°C

Ambient air free from abnormal amounts of dust, acids,

corrosive substances etc. other than those

generated by the welding process

Base of the welding power source inclined no more than 10°

Range of ambient air temperature

during storage and transport

-20°C to +60°C

Height above sea level ≤1000 m

Duty cycle (def.)

Duty cycle is the time during which You can weld or cut at a certain load without causing overload.

Itis expressed in percent for period of complete cycle which equals 10 minutes. For example: 60% duty

cycle means that for 6 minutes device can operate at given load, after that required 4 minutes time

break (no-load operation).

The device has a degree of protection IP21. Which means that it is intended to be used in closed and

covered areas and suitable for use outdoors. However it is not designed to be used outdoor during

precipitation if it is not covered.

USER’S MANUAL EN

10

6.2 TECHNICAL PARAMETERS OF DEVICE

SPARTUS® water cooler

WRC310 WRC400

Input 1 ~ 230V ± 10% 50 / 60 Hz

Engine power 120W 111W

Max. pump efficiency 5.3l/min 5l/min

Tank capacity* 10l 9l

Max. coolant pressure 3 bar 4.2 bar

Protection class IP 21

Dimensions 570 x 330 x 333mm 470 x 250 x 310mm

Weight (empty tank) 20 kg 14 kg

* Recommended coolant for use with coolers: based on propylene glycol – 69.8% demineralised water, 30%

propylene glycol, 0.2% Benzotriazole.

7. INSTALLATION AND USE

WARNING!

SPARTUS® WRC water coolers are intended for professional and industrial applications.

Installation and use of the device may only be carried out appropriately trained professionals.

Qualified person (def.)

A person who has gained the relevant technical education, training took place and / or gained

experience to perceive the risk and avoid hazards during use of the product (IEC 60204-1).

7.1 PROPER COOLING

The unit should be placed stable on a dry and flat surface. Avoid too much slope and slippery

surfaces. Check regularly that the vents (inlet, outlet) are not covered. The minimum distance

between the cooler vents and walls should be 50cm.

7.2 MOVEMENT AND HANDLING

When moving the unit please take extra care. The device should be moved by using specially

designed transport lugs. If transport handle is damaged, then it needs to be repaired at an

authorized service center.

USER’S MANUAL

EN

11

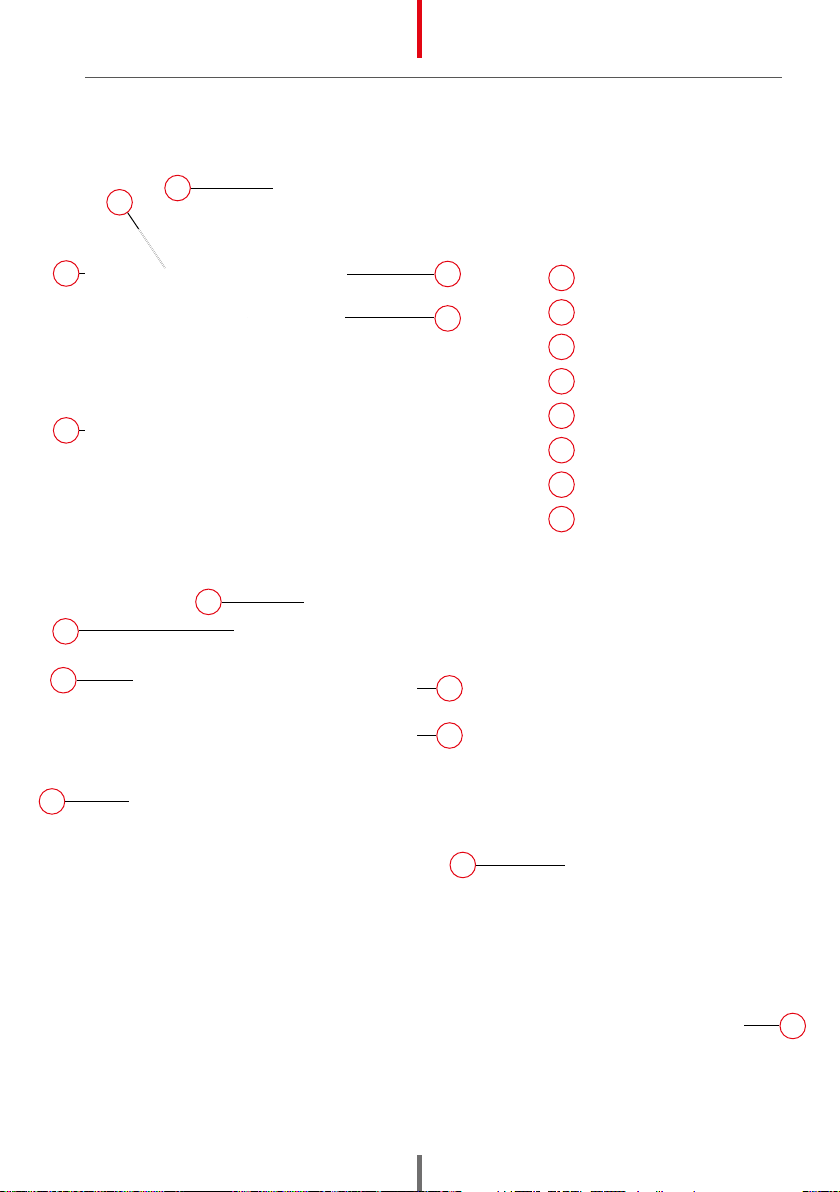

7.3 DESCRIPTION OF CONSTRUCTION

1Transport handle

2Coolant in

3Water level indicator

4Inlet (hot water)

5Outlet (cold water)

6Power switch

7Power cord

8Vents

1

3

8

6

6

2

2

5

7

4

1

3

5

4

USER’S MANUAL EN

12

7.4 CONNECTING TO POWER SUPPLY

Requirements for power network parameters (voltage, permissible range of mains voltage

fluctuations etc.) are given in the table with technical parameters of device and on the rating

plate of welding machine.

Before connecting the unit to the power source:

• Check whether the parameters comply with the requirements for unit.

•

Check: mechanical condition of the power cord and plug. The connection status of the power

cord with plug and unit (loose not allowed). If the power cord or plug is damaged or loose

connection is between them, it is forbidden to connect the device until fault has been rectified.

• The water cooler can be connected to the network only when the power socket is properly

grounded.

7.5 CONNECTING THE DEVICE

Before connecting equipment to the device, make sure that the device is disconnected from power

source and switch 6is in the OFF position.

7.5.1 Liquid – filling the tank

Cooling liquid must meet the requirements of the manufacturer of the welding torches.

It is forbidden to use a coolant (liquid) not intended for use in welding. Cooling liquid should be: non-

flammable, antifreeze, non-conductive.

It is forbidden to operate the water cooler when the tank is empty and/or there is no liquind in the

cooling circuit. The pump can’t operate without liquid.

1. Unscrew the filler cap 2.

2. With aprropriate precautions pour the tank with cooling liquid. Remember to take care of

right liquid level in tank. Control it according to water level indicator.

3. Screw the filler cap.

7.5.2 Connecting the welding torch

SPARTUS® WRC410 water cooler has built-in quick couplings. It is the most popular standard 21.

Welding torch should be equipped with water hoses armed in type 21 couplings (male plug).

1. Connect (hot water hose) into inlet coupler 6.

2. Connect (cold water hose) into outlet coupler 7.

3. Turn on the water cooler, check there is no leakage. Check the liquid circuit.

USER’S MANUAL

EN

13

8. MAINTENANCE

WARNING!

Before performing any maintenance or repairing of device, disconnect welding machine from

the power source and wait at least 5 minutes. The voltage accumulated in capacitors should

be discharged at this time to a safe level. But even after that operation you should be careful.

Maintenance and repair work may be performed only by qualified personnel with the appropriate per-

missions. Regular maintenance provides adequate service life and trouble-free operation of the device.

Routine maintenance (daily: before use/installation):

• Perform a visual inspection of the housing.

• Inspect (visual inspection) the power cord and power plug. Check the insulation of the cable.

• Check if cooling fan is working properly.

• Make sure that all vents are not obstructed.

• Check the level of coolant in the tank.

• Check the tightness of the connections.

At least once a month:

• Regularly remove dust from inside of the machine. Use for this compressed air. The pressure

should be sufficiently low so as not to damage small components inside the machine. If in

the workplace, dust levels are high. You should clean machine often.

• Perform inspection of connection of internal electrical components. If anywhere the joints

are loose, tighten them.

Once a year:

• You should send device to an authorized service center for an interim review.

Liquid coolant:

• The frequency of replacement of the coolant with the new one should be in accordance with

the requirements of the safety data sheet.

9. ENVIRONMENTAL PROTECTION

The product must not be disposed of into an ordinary waste container. It is totally

forbidden to dispose of electric or electronic equipment marked with a crossed-

-out trash can symbol by throwing it into ordinary waste containers. According

to the WEEE directive (directive 2012/19/UE), binding within the European Union,

such products should be disposed of according to local regulations.

USER’S MANUAL EN

14

9.1 LIQUID COOLANT

Replacement of the coolant and its subsequent disposal should be carried out in accordance

with the requirements of the safety data sheet and the laws of the country of use.

10. TROUBLESHOOTING

Not all problems with functioning of the device, are the evidence of failure. You can independently carry

out an analysis in search of probable failure. In case of doubt, please contact to SPARTUS® dealer or

authorized service center.

During the warranty period all repairs should be carried by authorized service center. Repairs carried

out by unauthorized persons will void the warranty.

PROBLEMS WITH THE DEVICE

Whe the power switch is on,

the water cooler doesn’t work.

Power switch is damaged.

No input power.

No liquids in circuit.

The circuit is aerated.

No liquid in the tank.

Water pump is damaged.

Water ow is too slow. Water pump is damaged.

Clogged hose.

The fan does not work. Fan is damaged.

Wrong input.

04.2023

Notes

Notes

Simple solutions and an attractive price – these are

the features of SPARTUS® Easy series devices. Our

equipment has been designed with ease of use and

ergonomics at work in mind.

A masterly combination of high quality production,

excellent parameters and ergonomics – these are fea-

tures of the SPARTUS® Master series of devices, which

were created with demanding welding jobs in mind.

Precision, functionality, excellent parameters and

resistance to high workloads – these are the features

of the SPARTUS® Pro industrial series of devices. This

series consists of specialised solutions which will

satisfy even the most demanding users.

Videopresentation of products

Subscribe to the channel SPARTUS.INFO

This manual suits for next models

1

Table of contents

Popular Water Dispenser manuals by other brands

Kinetico

Kinetico 2020c installation instructions

BWT

BWT AQA drink 1 installation manual

Scotsman

Scotsman SCW 8 LBP Service manual

Whirlpool

Whirlpool HD1000XSW8 Installation Instructions and Use & Care Guide

InSinkErator

InSinkErator Indulge Modern F-HC3300 Specifications

WaterLogic

WaterLogic 4 Firewall user manual