Speakman GRAVITYFLO SE-4930 User manual

INSTRUCTIONS FOR MODELS

92-SE-4930-01

For additional assistance or service please contact:

SPEAKMAN®Company

400 Anchor Mill Road

New Castle, DE 19720

800-537-2107

customerser[email protected]

www.speakman.com

SE-4930

SE-4930

GRAVITYFLO™

Freeze Protected Jacket

3 Year Limited Warranty

Additional warranty information can be found at:

www.speakman.com

WARRANTY

MAINTENANCE

Be sure to wear eye protection during assembly and

mounting.

SAFETY TIPS

Always disconnect power while servicing the unit andAlways disconnect power while servicing the unit and

allow the unit to cool down before filling with water.allow the unit to cool down before filling with water.

Occasional cleaning and disinfection is recommended.

To clean the inside of the unit, add 1/2 cup (4 fluid

oz.) of Clorox (liquid bleach) to a full tank of potable

water. Allow the mixture to penetrate for 15 minutes.

Drain tank, and rinse thoroughly several times with

potable water. Take care to not overtighten drain cap

as damage may occur. For further information about

Clorox, call toll-free at 1-800-292-2200. Follow

refilling instructions in this manual and place the tank

back in service. Should any repair part be required,

use only genuine SPEAKMAN parts for repair or

replacement. See available replacement parts in this

document, to order parts call 1-800-537-2107.

As part routine inspection, the unit shall be checked for

adequate water level. (Within 5" of the top cap)

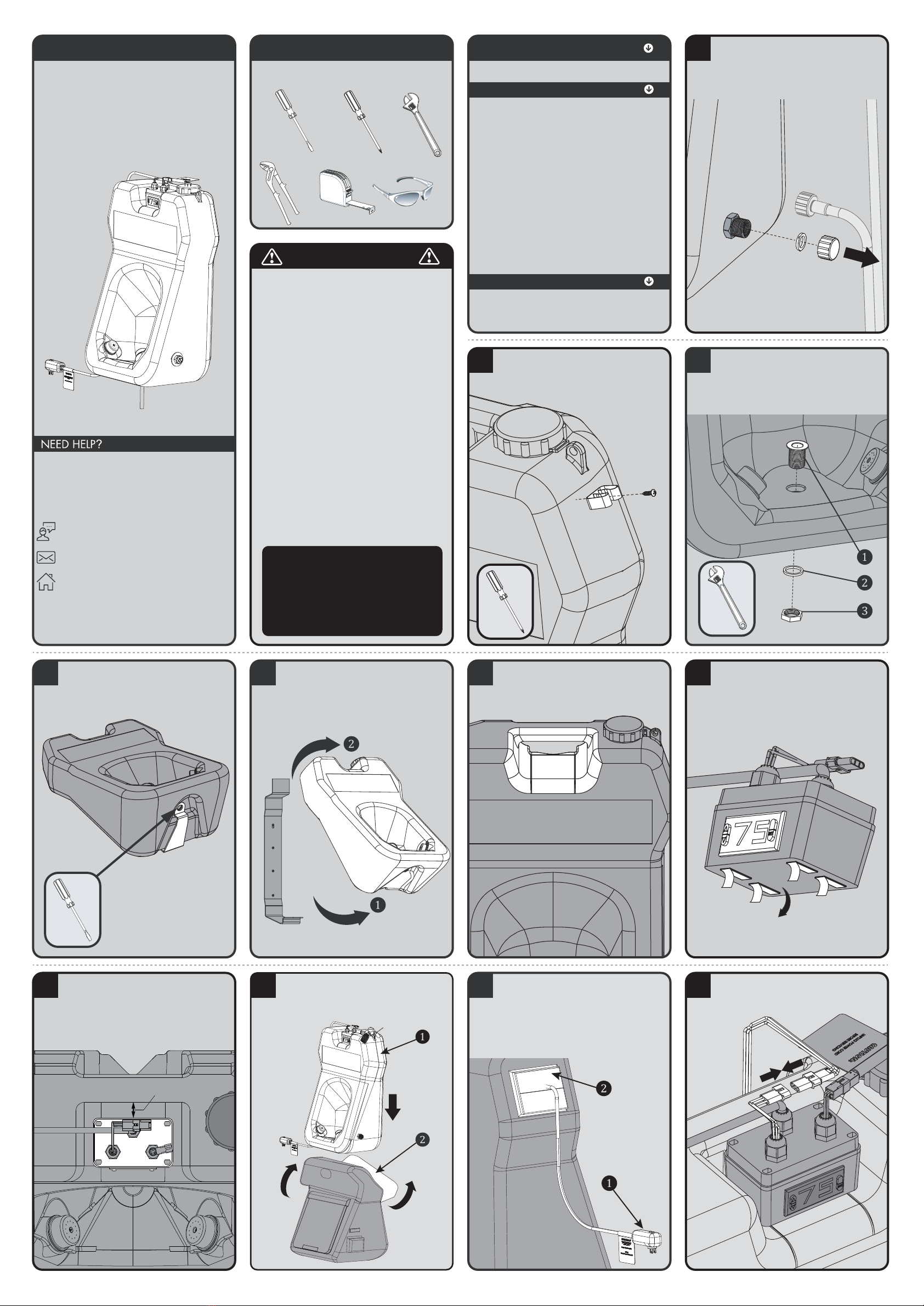

TOOLS AND SUPPLIES

Flat Tip

Screwdriver

Adjustable

Wrench

Measuring

Tape

Safety

Glasses

Slip Joint

Wrench

Phillips

Screwdriver

1Remove the Drain Plug or Drench Hose (if

equipped) and drain the unit completely.

2If your unit has as Hose Clip installed,

remove it at this time. Reinstall the self

tapping screw to seal hole.

3

Disassemble drain parts from unit. Remove

Drain Nut (3) with wrench. Remove Drain

Washer (2) from threading of the Drain

Fitting. Remove Drain Fitting (1) through

openings in the Tank and Wall Bracket.

4Using a screwdriver, pry the lower

portion of the Wall Bracket away from

the recess on the Tank.

5Remove the empty Tank from the Wall

Bracket completely. Unsnap the Wall

Bracket from the recess of the bottom of

the Tank (1). “Unhook” the top of the

handle of the Tank from the Wall Bracket

(2).

6Thoroughly clean and ensure the top area

of the tank is free of dirt and debris before

adhering Electronic Controller Box to

handle area.

7Remove Tape Release Liner (x4) on bottom

of Controller Box to expose tape.

8Ensure Digital Read Out Interface is facing

forward. The control box should be placed

1 - 11/2” from the handle to allow for

clearance of the mounting bracket.

1-1½”

9Slide Tank Assembly (1) into Heated

Jacket (2) and assure the heating pad is

not folded and lying against the tank.

10 Place Power Supply Cable (1) inside of

Tank Jacket. Pass the AC cord through

the Jacket Access Panel (2) located on

the upper left side panel. Verify AC plug

adapter is fully extended through the

Jacket (2). Velcro Jacket Access Panel

closed.

11 Connect 3 Pin Wiring Harness from Jacket

to Controller.

IMPORTANT

Product is designed to be used indoorsProduct is designed to be used indoors

and outdoors.and outdoors.

When mounted in outdoor conditions, product must beWhen mounted in outdoor conditions, product must be

in a covered area and not directly exposed to outdoorin a covered area and not directly exposed to outdoor

elements such as rain and snow.elements such as rain and snow.

ANSI Z358.1 requires that all self-contained eyewash

shall be visually inspected weekly, unless the product

is placed in environments with extreme conditions that

may affect the form, fit, or function of the unit

(temperature, dirt, etc.). If this is the case, then the

inspection should be conducted more often as the end

user deems necessary. Speakman Company furnishes

a testing record tag (91-0635) with each unit. On this

tag, the date of inspection and the inspectors’ initials

should be noted. ANSI Z358.1 specifies that the

height of the spray heads is to be between 33” - 45”

from the floor. The SE-4330 unit weighs approximately

185 lbs filled. Ensure the mounting surface (wall, etc.)

and mounting hardware can safely hold a minimum

vertical load of 300 lbs. Be sure to read instructions

thoroughly before beginning installation. Do not

overtighten any connections or damage may occur.

The unit should be full at all times, to achieve the

minimum 15 minute run time as stated by ANSI, in

case of an emergency. Refill the tank to a full level

after each activation. Before refilling tank dry and

clean outside of spray heads, and inside of pull strap

to remove debris, and to assure proper sealing.

WARNING: This units maintains the water

temperature within the tepid range of 60-90 F.

Depending on the water temperature within the tank

and the ambient conditions, it may take up to

24 hours for the water temperature to reach the

tepid range during initial start-up. If noted during

inspection the water temperature is outside that

range, the product should be taken out of service

and the condition troubleshooted.

12 Place Side Drain through access hole in jacket and secure with supplied Support Washer and

Drain Nut (2). Wrench tighten. Take care to not over tighten connection as damage may occur.

Hand tighten Drain Cap (3). Close Flap (1).

13 Install empty Tank to Wall Bracket by first inserting “hook” on the top of the bracket through the

Jacket Slot located at the upper rear of jacket and into the handle of the Tank (1). Lower the Tank

inserting the lower bracket section through the Jacket Slot and under the Tank. Push the Tank

towards the bracket until the Wall Bracket snaps into the recess at the bottom of the Tank (2).

*CROSS SECTION VIEW

HANDLE

WALL

BRACKET

DRAIN

14 Use a flat head screw driver to ensure that the Bracket (1) and the tank's Drain Hole (2) align. The

Front Access Panel will need to be removed for this process.

* VIEW FROM

UNDER THE TANK

15 Insert Drain Fitting (1) through openings in the Tank and Wall Bracket. From below, reaching

between the Jacket and the Tank, install Drain Washer (2) and Drain Nut (3) to threaded portion

of Drain. Wrench tighten. Take care to not over tighten or damage may occur. Retrieve Drain

Hose (4) from parts accessory bag. Slide threaded Drain Hose (4) through hole in Jacket bottom

and secure to Drain Fitting (1). Hand tighten only.

* VIEW FROM UNDER THE TANK

16 Remove the Activation Pull Strap (1) from

the Tank. Secure Activation Pull Strap to

backside of Front Access Panel (2) as

shown below using the Velcro straps.

17 Install the cups of the Activation Pull Strap

over the Spray Heads individually, pressing

firmly until they are fully seated. Ensure that

the Activation Pull Strap is still connected to

the Front Access Panel as shown in previous

step.

18

CERTIFIED TO ANSI/ISEAZ358.1

Realign front removable Panel (1) to Jacket

from the bottom up. Tuck the top edge of

the panel under the Jacket Flap.

IMPORTANT

Self-contained eyewash equipment shall be visually

checked frequently to determine if flushing fluid

needs to be changed or supplemented. Frequency

of these inspections is dependent on environment

conditions, but at a minimum weekly. Failure to

conduct visual checks could lead to further injury.

Customer shall take precautions to help prevent

the growth of potentially harmful bacteria in

eyewash tanks. Either of the following procedures

is recommended.

Procedure 1: Use suitable Bacteriostatic

preservative to help prevent growth of bacteria in

eyewash tank. Eyewash tank should be drained,

flushed and refilled with clean potable water and

Bacteriostatic preservative added as directed by

the preservative’s manufacturer.

Procedure 2: Drain, flush and refill units with

clean potable water at least once every week

unless site conditions require more frequent

changing. Thoroughly cleanse tank at least once

every month. See “Maintenance” Section for

further information of cleaning unit.

19 Remove existing Fill Cap. Fill the Tank with potable water (approximately 20 gallons). Failure to use

potable water can result in emergency units producing impure or contaminated water, possibly

causing further injury. Install new thermocouple feed tube and Tank Fill Cap Assembly. Pull back top

corner of Activation Panel Flap and inspect Spray Head (1) area for leaks. Inspect Side Drainage

Plug (2) for leaks.

H20

20 Secure Fill Cap to Tank with Tamper Evident Seal Tie. Connect Wiring Harness to Controller.

Update and secure the Maintenance Tag to the Tank in a location where it can be easily checked.

21 Zip up open portion of Jacket (1). Verify all wiring is within Jacket and not kinked. Verify

AC Plug Adapter is fully extended through the Jacket (2). Velcro close the flap.

ACTIVATION INSTRUCTIONS

STEP 1: Follow instructions shown on the

front of the jacket Access Panel.

CERTIFIED TO ANSI/ISEA Z358.1

STEP 2: To activate the flow of water,

firmly remove the front panel as shown.

Fully removing both covers from the Spray

Heads.

22 Plug the unit into the power supply.

AC Electrical Supply

The Ground Fault Circuit Interrupter (GFCI) plug

is to be used in accordance with appropriate

electric codes and regulations. Use this device

with a grounded circuit receptacle rated at

120VAC, 15A.

The GFCI device protects against current

leakage caused by ground faults only. It does

not protect against over current or short circuits.

TEST INSTRUCTIONS

1. Plug device into receptacle.

a. AUTO-RESET devices: Pilot light goes ON.

2. Press TEST button – Pilot light must go OFF.

3. Press RESET button and release – Pilot light

must go ON for use.

CAUTION: Do not use this device if above test

fails. Test unit before each use.

FOR DRAINING AND MAINTENANCE

To periodically drain the unit, Lift Flap (1) and velcro in place. Remove the Drain Plug (2). Once

all water is removed, reinstall the Drain Plug and hand tighten into position. Take care to not over

tighten or damage may occur.

See Maintenance Section for further detail.

See Maintenance Section for further detail.

When the thermostat is disconnected or open

circuit is detected, “LL” (1) is displayed and alarm

LED (2) will flash.

TROUBLESHOOT

Confirm wiring connectors from heater pad to

controller are mated properly.

Confirm wiring connectors from thermostat to

controller are mated properly.

SPEAKMAN®

SE-4930 CONTROLLER INTERFACE

LL

LL

SET

+

°F

FAILURE INDICATOR DISPLAY

FLASHING ALARM INDICATOR

Default Settings:

SET Point = 75° F

Lower Limit = 60° F

Upper Limit = 90° F

Turn unit on: Current / Actual water temperature

will be displayed (1).

Temperature units to be in Fahrenheit (°F) (3).

Heating function indicator displayed means heater

is on (4).

69.5

SET

+

°F

CURRENT WATER TEMPERATURE

TEMPERATURE SET BUTTON

TEMPERATURE UNITS

HEATER ON INDICATOR

Heater Temperature Controller Model ED330

NOTE: During initial startup, the water temperature may

not be in the tepid range (60-90 F). Once plugged in, the

heating unit will warm the temperature up to the tepid

range. Depending on the water temperature within the

tank and the ambient conditions, it may take up to 24

hours for the water temperature to reach the tepid range.

AC Electrical Supply

The Ground Fault Circuit Interrupter (GFCI) plug is to be used in

accordance with appropriate electric codes and regulations. Use this

device with a grounded circuit receptacle rated at 120VAC, 15A.

The GFCI device protects against current leakage caused by ground

faults only. It does not protect against over current or short circuits.

TEST INSTRUCTIONS

1. Plug device into receptacle.

a. AUTO-RESET devices: Pilot light goes on.

2. Press TEST button – Pilot light must go off.

3. Press RESET button and release – Pilot light must go ON for use.

CAUTION: Do not use this device if above test fails. Test unit before

each use.

* CONTROLLER SETTINGS ARE PRE-SET FROM FACTORY *

NORMAL DISPLAY MODE FAILURE MODE

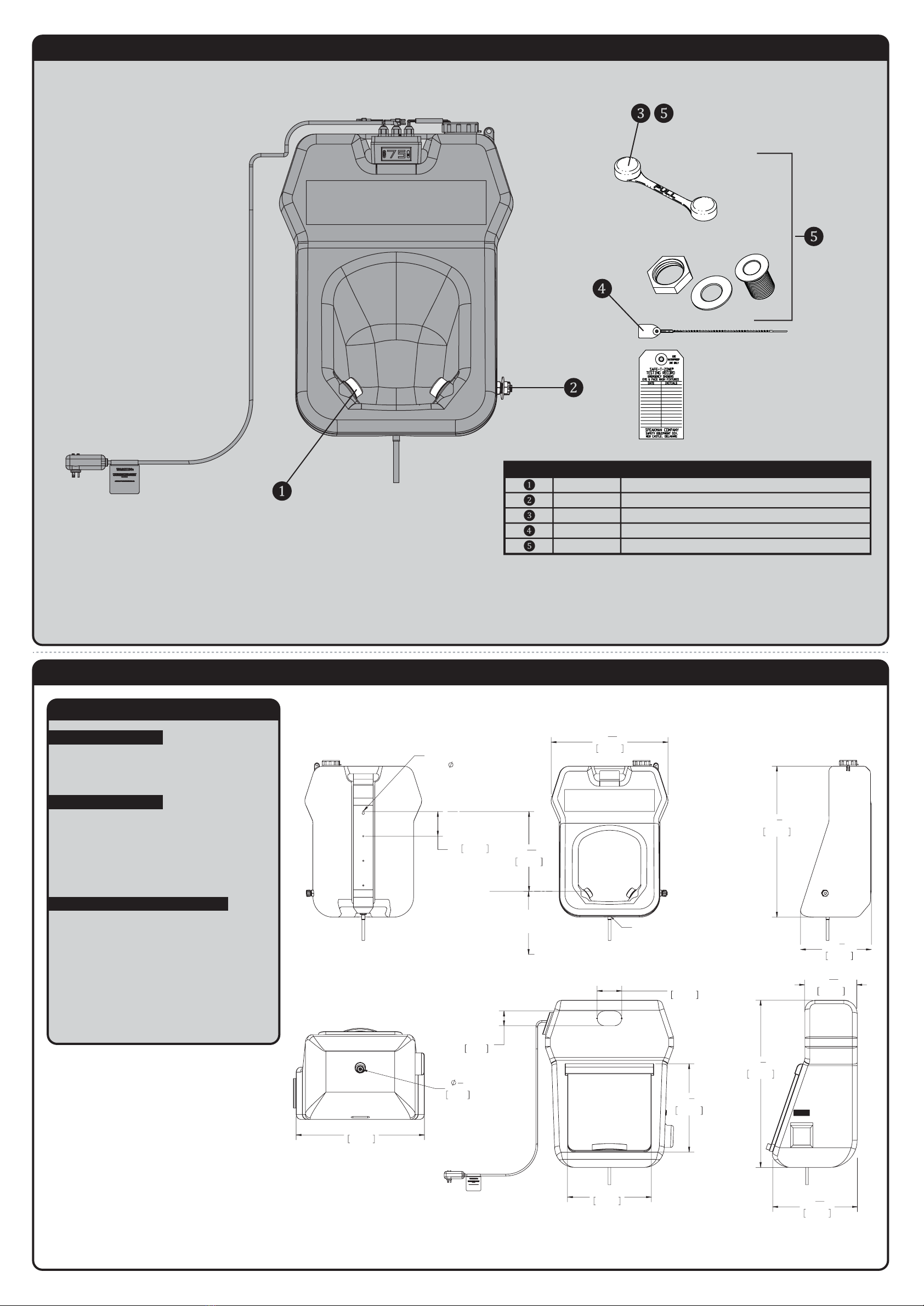

SE-4930 REPAIR PARTS SPEAKMAN®

RPG38-0433 (2) SPRAY HEAD ASSEMBLIES

08-105614 1/2" NPT MALE PLUG

RPG56-0039 PULL STRAP ACTIVATOR

RPG05-0935 (3) 12" TAMPER EVIDENT SEAL TIES

RPG05-0901 PULL STRAP ACTIVATOR & DRAIN BULKHEAD FITTING

ITEM NO. PART NO. DESCRIPTION

SE-4930 ROUGH-IN DIAGRAM SPEAKMAN®

DIMENSIONS SUBJECT TO CHANGE WITHOUT NOTICE.

NOTES:

COMPLIANCE:

FLOW DATA:

ANSI Z358.1

MAX ELECTRICAL RATINGS:

120VAC, 60Hz.

15A, 220W

RUN TIME (FULL TANK):

15 MINUTES (minimum)

FLOW RATE IN gpm (L/min):

.4 (1.5) MINIMUM

Contractor to supply necessary inlet

connections.

3"

76mm

17"

432mm

17 7

8

"

455mm

5"

127mm

33 7

8

"

861mm

10 9

16

"

269mm

17 3

16

"

436mm

3

4

"

18mm

26"

660mm

23 11

16

"

602mm

3/4in GHT MALE DRAIN OUTLET

(UNDERSIDE OF TANK)

33-45in

[833-1143mm]

TO FLOOR

5"

127mm

(TYP. 3 PLACES)

16 3

16

"

411mm

WALL BRACKET MOUNTING

HOLES

1/4" THRU HOLE

(TYP. 4 PLACES)

30 5

8

"

777mm

14 3

8

"

365mm

Other Speakman Personal Care Product manuals

Popular Personal Care Product manuals by other brands

SEVERIN

SEVERIN HG 7713 datasheet

VS Sassoon

VS Sassoon VS2014/2A Instruction booklet

Conrad

Conrad 55 60 21 operating instructions

Orliman

Orliman Lumbitron LT-283 Use and maintenance instructions

Bangtang Network Technology

Bangtang Network Technology Femometer FM-IVY-101 manual

Ruck

Ruck 3011901 Instructions for use