Specac Silver Gate User manual

Silver Gate™Evolution

Single Reflection ATR System

User Manual

2I-10680 Issue 3

Silver Gate™Evolution

Single Reflection ATR System

User Manual

2I-10680 Issue 3

User Manual

2

Silver Gate™ Evolution ATR System

SILVER GATE™ EVOLUTION ATR SYSTEM - P/N GS10680 SERIES

USER MANUAL

1.

I

NTRODUCTION

................................................................................. 4

2.

U

NPACKING AND

C

HECKLIST

............................................................. 6

3.

I

NSTALLATION

V

IA

B

ENCH ARK

™

B

ASEPLATE

................................... 7

4.

A

LIGN ENT

P

ROCEDURE

.................................................................. 8

F

ITTING OF

T

HE

ATR

C

RYSTAL TOP

P

LATE TO THE

O

PTICAL

U

NIT

...... 9

A

LIGN ENT

................................................................................... 11

5.

F

ITTING

A

CCESSORIES TO THE

S

ILVER

G

ATE

™

ATR

O

PTICAL

U

NIT

.. 14

F

ITTING A

P

OLARIZER

.................................................................... 14

B

ENCH ARK

™

P

OLARIZER

R

OTATOR

OUNT

P/N

GS12510 .......... 15

P

URGING THE

O

PTICAL

U

NIT

.......................................................... 16

F

ITTING THE

P

URGE

B

ELLOWS

P/N

GS10707 ................................ 17

6.

A

NVIL OPTIONS

............................................................................... 18

P

ELLET

A

NVIL

P/N

GS10532 ......................................................... 18

S

TAINLESS STEEL

A

NVIL

P/N

GS10567 .......................................... 18

7.

S

A PLING

U

SING THE

S

ILVER

G

ATE

™

A

CCESSORY

......................... 19

G

ENERAL

P

INCIPLES

...................................................................... 19

F

EATURES OF THE

B

RIDGE AND

C

LA P

A

NVIL

A

SSE BLY

................ 19

T

ORQUE

L

I ITER

S

CREW

A

SSE BLY

.............................................. 20

Q

UICK

L

OCK AND

R

ELEASE

ECHANIS

......................................... 21

S

TAY

U

P

D

EVICE

........................................................................... 21

I

PORTANT

N

OTES

F

OR

U

SAGE

..................................................... 21

P

REPARING

T

HE

S

ILVER

G

ATE

™

A

CCESSORY

F

OR

A

NALYSIS

........ 22

C

OLLECTING A

B

ACKGROUND

S

PECTRU

....................................... 22

C

ONTA INATION

C

HECK

O

N

A

NVIL

................................................. 23

C

OLLECTING

ATR

S

PECTRA OF

P

OWDER

S

A PLES

........................ 23

Sil er Gate™ E olution ATR System

3

C

OLLECTING

ATR

S

PECTRA OF

F

LAT

S

OLID SA PLES

..................... 25

C

OLLECTING

ATR

S

PECTRA OF

P

ELLET

/B

EAD

S

A PLES

................. 26

C

OLLECTING

ATR

S

PECTRA OF

F

IBER

S

A PLES

............................. 28

C

OLLECTING

ATR

S

PECTRA

O

F

L

IQUIDS AND

P

ASTE

S

A PLES

........ 29

N

OTES

O

N

C

LEANING

.................................................................... 33

8.

S

ILVER

G

ATE

™

ATR

"B

UBBLE

N

U BER

"

I

DENTIFICATION

L

IST

......... 34

9.

S

ILVER

G

ATE

™

ATR

A

CCESSORY

S

PARE PARTS

............................. 35

10.

S

ILVER

G

ATE

™

ATR

T

ECHNICAL

S

PECIFICATIONS

......................... 36

11.

S

ILVER

G

ATE

™

ATR

S

ERIAL

N

U BERS

........................................ 37

© Apr 2016 Specac Ltd. All rights reserved.

Silver Gate™ and Benchmark™ are trademarks of

Specac Ltd. Other product names that may be mentioned herein

may be trademarks of their respective owners.

User Manual

4

1. Introduction

Thank you for buying a Specac product. We trust it will provide you

with invaluable and excellent service in use.

The Silver Gate™ Evolution Single Reflection ATR is designed for the

quantitative and qualitative analysis of solids, powders, liquids, pastes

and gum-like samples. Sufficient sample is required to cover an ATR

crystal surface of 7mm diameter.

The Silver Gate™ ATR accessory can be configured for use starting

with the optical unit and supplied with or without a bridge and clamp

anvil assembly. There is a choice of zinc selenide (ZnSe), germanium

(Ge) or silicon (Si) flat ATR crystal top plate assemblies and ZnSe or

Ge recessed ATR crystal top plate assemblies to be used on either of

the optical unit assemblies (with or without a bridge.) The ATR crystals

are glue mounted into their respective ATR crystal top plate

assemblies.

A complete Silver Gate™ ATR system consists of an ATR flat or

recessed crystal top plate assembly with a ZnSe or Ge crystal at 45°

incident angle option fitted to an optical unit with a bridge and clamp

anvil assembly. This whole assembly is mounted into a spectrometer

via a Benchmark™ type baseplate for correct positioning of the

accessory to maximize for an optical throughput signal. The ATR

crystal top plate assemblies are interchangeable for placing on a

common optical unit.

The bridge and clamp anvil assembly can be fitted to the Silver Gate™

optical unit as an option if desired. The simplest Silver Gate™ ATR

Accessory configuration is by use of a flat or recessed ATR crystal top

plate assembly on the optical unit without a bridge and clamp anvil

assembly. This combination of parts can be used for the analysis of

liquids and pastes.

For sampling of solids and powders, the bridge and clamp anvil

assembly is fitted onto the Silver Gate™ optical unit. The bridge part

carries a torque limiter screw assembly that provides for a consistent

Sil er Gate™ E olution ATR System

5

and reproducible load to an anvil compression head to enable excellent

close contact of a solid sample with the ATR crystal.

In operation the entire torque screw limiter assembly knob is rotated

until a sufficient load and hence pressure has been applied to the

sample. The torque screw limiter assembly knob will continue to rotate

when the set load is reached, but the drive connection slips and no

more force will be applied. The black colored cover cap with the white

“cross” mark on top of the knob acts as the indicator when the set

applied load is reached in ceasing to rotate. The flat ATR crystal top

plate assemblies are best suited to be used in combination with the

bridge and clamp anvil assembly for solid or powder sample types,

although if the sample is small enough, the recessed ATR crystal top

plate assembly could be used instead.

When using the bridge and clamping mechanism for pressure

application, the compression head anvil does not rotate against the

sample. This ensures that heat is not generated by friction which may

cause changes to the sample, and the sample is not displaced from the

correct sampling position.

The transfer optics unit of the Silver Gate™ ATR consists of mirrors

and optical components to achieve maximum throughput for each flat

or recessed ATR crystal top plate assembly.

As standard a volatiles cover (P/N GS10503) and purge bellows (P/N

GS10707) are supplied with the optical unit without a bridge assembly.

In addition to these parts, a standard stainless steel pressure head

anvil (P/N GS10567) and pellet anvil (P/N GS10532) are also provided

along with the optical unit with a bridge assembly.

User Manual

6

2. Unpackin and Checklist

The Silver Gate™ ATR accessory is provided in its own carry case.

Depending on which Silver Gate™ ATR system has been ordered will

determine the items to check on delivery.

Please check for the following.

1 Silver Gate™ ATR optical unit without bridge and clamp anvil

assembly. - This will include:-

1 Volatiles cover P/N GS10503.

1 Pair of purge bellows P/N GS10707.

1 Silver Gate™ ATR optical unit with bridge and clamp anvil assembly.

This will include:-

1 Volatiles cover P/N GS10503.

1 Pair of purge bellows P/N GS10707.

1 Stainless steel flat anvil P/N GS10567.

1 Pellet anvil P/N GS10532.

With either optical unit assembly:-

1 ATR crystal top plate assembly (choice of ZnSe, Ge or Si flat, or

ZnSe, Ge or Si recessed crystal top plate assembly.

(Any additional ATR crystal top plates ordered with the accessory.)

1 Ball driver 3.0mm

1 Allen key 2.0mm

1 Benchmark™ baseplate for your FTIR spectrometer.

1 Instruction manual for Benchmark™ baseplate installation.

1 Essential Spares Kit of parts (P/N GS10685)

Carefully remove your Silver Gate™ ATR accessory and any ATR

crystal top plates from the carry case in readiness for use.

Sil er Gate™ E olution ATR System

7

3. Installation Via Benchmark™ Baseplate

Figure 1. Sil er Gate™ ATR Accessory – Optical Unit with Bridge and

Clamp An il Assembly and Flat ATR Crystal Top Plate Assembly

The Silver Gate™ ATR is supported on a Benchmark™ baseplate

when installed into a spectrometer. The Benchmark™ baseplate has

three support pillars (one flat support pillar towards the rear and two at

the front with location pins) and a fourth front central pillar into which

the fixing thumb screw (1) of the Silver Gate™ optical unit is tightened.

Note: It is normally best to install the Benchmark™ baseplate in

the spectrometer first before locating the Silver Gate™ ATR

accessory.

Fixing holes and studs in the Benchmark™ baseplate will vary

dependant on the make and model of the spectrometer for which the

Silver Gate™ is to be installed. For details on how to install your

accessory in the spectrometer, refer to the Benchmark™ baseplate

Installation Guide/User anual supplied.

1

User Manual

8

4. Ali nment Procedure

When you have installed the Silver Gate™ ATR accessory into your

spectrometer on its appropriate Benchmark™ baseplate, you should

check for alignment of the accessory. An overall spectral throughput of

between 20% and 55% for ZnSe and Ge ATR flat or recessed crystal

top plate assemblies should be achievable. The Silver Gate™ ATR will

be supplied having a preliminary factory alignment. On installation,

some transmitted energy should be recorded on the spectrometers

energy/light throughput to detector monitoring system, but it will be

necessary to maximize the optical throughput for any specific

spectrometer by adjusting the mirrors in the optical unit of the Silver

Gate™ accessory. To carry out any alignment procedure one of the

Silver Gate™ ATR flat or recessed crystal top plate assemblies must

be fitted to the optical unit.

Fitting of the ATR Crystal Top Plate to the Optical Unit

Six different versions of Silver Gate™ ATR crystal top plate assemblies

can be fitted to the optical unit. They are:-

ZnSe flat crystal top plate assembly, P/N GS10683-1.

Ge flat crystal top plate assembly, P/N GS10683-2.

Si flat crystal top plate assembly, P/N GS10683-3.

ZnSe recessed crystal top plate assembly, P/N GS10684-1.

Ge recessed crystal top plate assembly, P/N GS10684-2.

Si recessed crystal top plate assembly, P/N GS10684-3.

The flat and recessed ATR crystal top plate assemblies are fitted to the

top plate area of the Silver Gate™ optical unit by location holes (2) to

location pins (3) and held in place by magnetic catches (4) to counter

plate fixings (5). (Please see Figures 2, 3, 4 and 5.) Top views of the

flat and recessed ATR crystal top plate assemblies using the ZnSe

crystal as examples are Figures 2 and 3. (Ge and Si top plates are

similar.) The underside view of either the flat or recessed ATR crystal

top plate assembly is shown as Figure 4. The top surface (without

bridge) on the optical unit where to fit the ATR top plates is shown in

Figure 5.

Sil er Gate™ E olution ATR System

9

Figure 2. Top iew of Sil er Gate™ ZnSe Flat ATR Crystal

Top Plate Assembly

Figure 3. Top iew of Sil er Gate™ ZnSe Recessed ATR Crystal

Top Plate Assembly

ATR Crystal

ATR Crystal

User Manual

10

Figure 4. Underside iew of Sil er Gate™ ZnSe Flat or Recessed

ATR Crystal Top Plate Assembly

Figure 5. Top iew of Sil er Gate™ Optical Unit without Bridge

2

4

5

3

6 7

Sil er Gate™ E olution ATR System

11

The flat and recessed ATR crystal top plate assemblies will fit into the

top surface area of the Silver Gate™ accessory in one orientation only.

Align the location holes (2) with the location pins (3). The location slot

(2) must be towards the front of the Silver Gate™ Accessory where the

thumbscrew fixing (1) is located. Allow the three magnetic catches (4)

to engage with their three counter plate fixings (5) to hold the ATR

crystal top plate securely in position. To remove and swap over with

any other ATR crystal top plate assembly, just pull up on the ATR

crystal top plate to release the magnetic catches.

Alignment

With an ATR crystal top plate assembly in position on the optical unit

and when the whole is installed in the spectrometer on an appropriate

Benchmark™ baseplate, the Silver Gate™ Accessory can be finely

aligned. The optical unit cover plate (6) is removed by undoing the

cover plate thumb screws (7) (see Figure 5.) to gain access to the

mirror adjustment screws (8) and (9).

Figure 6. Front iew of Sil er Gate™ with a Flat ATR Crystal

Top Plate and Optical Unit Co er remo ed to show Mirrors

8 9

Mirror

M1

Mirror

M2

User Manual

12

The mirrors M1 and M2 in the optical unit can be adjusted for rotation

and tilt. (See Figure 6.) The 4 cap head screw (8) allows for rotation

of the mirror and the 4 x 12mm grub screw with a cone point (9)

allows for tilt of the mirror, as fixed to its mirror carriage assembly.

The mirror optical set up is symmetrical so it does not matter which

direction the beam passes through the optical unit from source to

detector. (Left to right or right to left as seen from the front of the optical

unit.) However, to align your Silver Gate™ accessory you need to

follow the alignment instructions knowing whether your spectrometer is

a left to right or right to left beam (source to detector) configuration.

The instructions below have been written for a left to right beam

configuration spectrometer.

Tip: If the energy reading on the instrument monitor goes to ero

while making any of the adjustments always bring it back with the

same adjustment before proceeding further. It is always best to

start alignment from the output mirror (the one nearest the

detector). In these instructions it is assumed M2 is the output

mirror. If your output mirror is M1 follow instructions substituting

M1 with M2 (and vice versa.)

1. Using the Ball driver tool in screw (8) of mirror M2 very gently

adjust the rotational movement of the mirror to achieve maximum

energy.

2. Adjust mirror M2 tilt position by inserting the smaller Allen key into

grubscrew (9) and turning to peak the energy.

Important : Turning the Allen key too far anti-clockwise will cause the

grubscrew (9) to dislodge from the back of the mirror (M2).

If this accidentally happens, turn the Allen key a full circle

in the same direction to dislodge the screw further and

free it. (Do not remove it). Next, push the spring mounted

mirror (M2) away from the black anodi ed mirror mount

and turn the Allen key clockwise until the screw is re-set

against the rear of the spring.

Sil er Gate™ E olution ATR System

13

3. aximize the energy by adjusting the rotation and tilt movement

screws (8) and (9) respectively of mirror M1. (See Figure 6.)

4. Repeat the rotation and tilt adjustments as in steps 2 – 4 until

maximum transmission is achieved and then replace the front

cover plate (6) and tighten the cover plate thumb screws (7).

5. If the Benchmark™ baseplate is mounted on a rail or is movable in

the spectrometer, move the Silver Gate™ ATR Accessory on the

Benchmark™ baseplate to find the best position where the

transmission is at a maximum. Now firmly secure the Benchmark™

baseplate in this position.

Note: In some spectrometers it may be necessary to remove the

Silver Gate™ optical unit before securing the baseplate. Where

this is the case, ensure that the Benchmark™ baseplate does

not move when removing the Silver Gate™ optical unit.

User Manual

14

5. Fittin Accessories to the Silver Gate™ ATR

Optical Unit

When the Silver Gate Single Reflection ATR has been installed and

aligned in the spectrometer you have the options of fitting a polarizer

and/or purging the ATR optical unit.

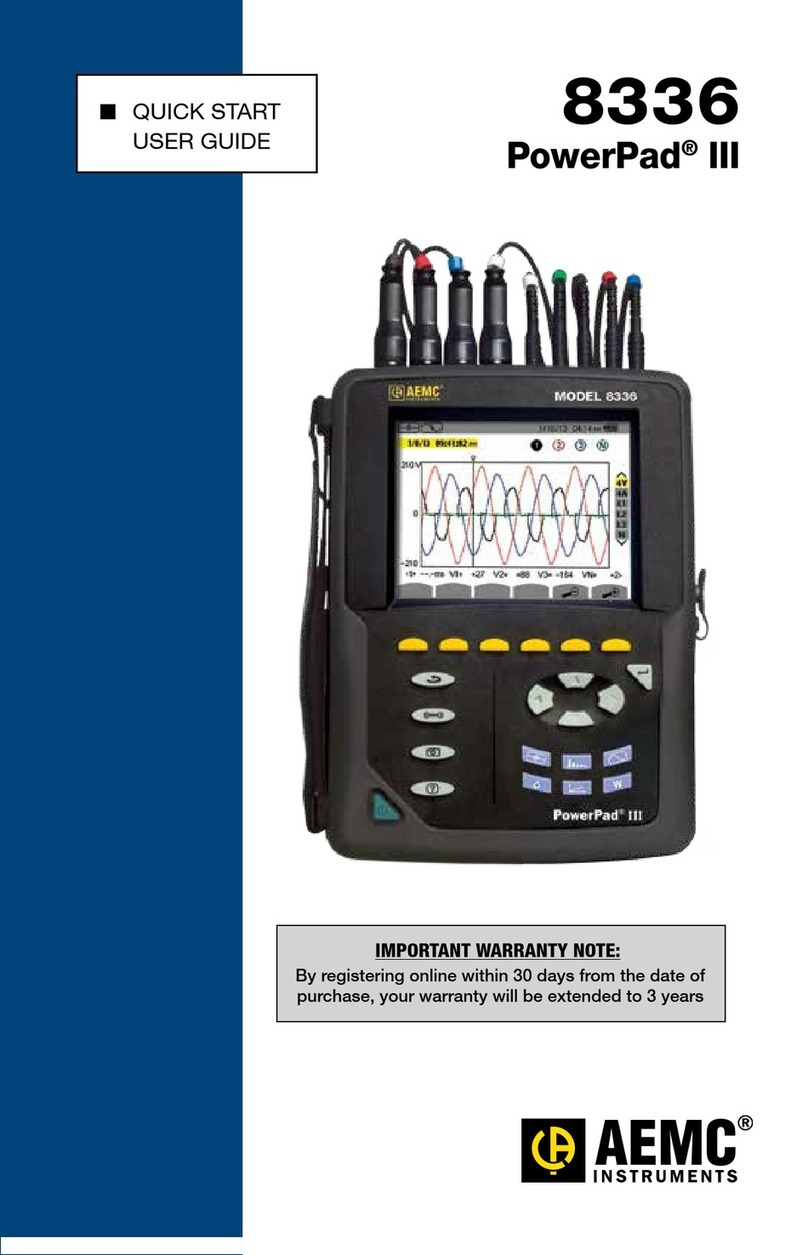

Figure 7. Aperture Ports and Purge Connections on the

Sil er Gate™ Optical Unit

Fitting a Polarizer

Specac P/N GS12000 Series Polarizers can be fitted to the apertures

(10) of the optical unit. The polarizers push fit in these apertures and

can be rotated to the desired angular orientation. The polarizer will

transmit at a maximum (perpendicular component of the polarized light)

when it is mounted so that the notch slot in the polarizer holder ring is

in the vertical plane. Fitting the polarizer to either aperture of the optical

unit will have the same effect.

Note: Fit a polari er where required before purging the system.

11

10

Sil er Gate™ E olution ATR System

15

Benchmark™ Baseplate Compatible Accessory Polariser Rotator

Mount P/N GS12510

In place of the GS12000 Series polariser, a specific Benchmark™

baseplate compatible accessory polariser rotator mount can be fitted to

the aperture ports (10) of the Silver Gate™ optical unit.

The polarizer mount GS12510 is a

rotatable mount that accepts the

Specac range of GS57010 Series,

38mm circular aperture, ring

mounted polarizers. When a

GS50710 Series polarizer has

been installed into the GS12510

mount, it can be rotated for a

particular angular degree of

polarized light by adjustment of an

outer rotating ring on the polarizer

mount itself.

Figure 8. GS12510 Polarizer Mount

The polarizer mount GS12510 can be used when polarized light

experimentation is to be carried out using any Benchmark™ baseplate

compatible accessory, particularly if there is limited space within a

spectrometer sample compartment. The standard aperture ports of the

Benchmark™ baseplate compatible optical units (as item 10 for the

Silver Gate™ optical unit), will accept a GS12000 Series polarizer. To

rotate this type of polarizer, it must be removed from the aperture port

and turned to align with the indicating grooves in the aperture port ring

for either parallel or perpendicular polarization and then re-inserted.

There is a risk of marking the polarizer substrate from fingerprints etc,

whenever placing the polarizer into, or removing it, from the aperture

mounting ports. Therefore, if continual changing of the polarizer

angular orientation is required, use of an appropriate GS57010 Series

polarizer within the GS12510 mount may help to minimize any risk of

marking/damage if using a GS12000 Series polarizer that has to be

removed from the aperture port and rotated by hand.

User Manual

16

Purging the Optical Unit

The Silver Gate™ ATR Accessory is fitted with purge ports (11). The

purge port connections are fitted with rubber caps. To purge the optical

unit the rubber caps are removed and a suitable size of flexible rubber

tubing can be pushed over the ¼” hose connection fittings at the purge

ports to enable the unit to be filled with a purge gas, e.g. Nitrogen.

To enable the optical unit to be purged it is necessary to fit the flexible

purge bellows (12) to the optical unit at the aperture ports (10). (See

Figure 9.) The purge bellows grip fit around the circumference of the

aperture ports and bridge any gap between the optical unit and the

spectrometer sample compartment bulkheads from the source and to

the detector. If the gap/distance between the optical unit and bulkhead

is small, the purge bellows can be cut to size. It is best to cut all the

way around and in between one of the ridged grooves in the bellow

moulding itself.

Figure 9.

Sil er Gate™ ATR Accessory – Optical Unit with Bridge and

Clamp An il Assembly, Flat ATR Crystal Top Plate Assembly

and Purge Bellows

12

Faces of bellows

to be flush fit

with bulkhead

Sil er Gate™ E olution ATR System

17

Tip: It is recommended that purge bellows are fitted during use to

help stabili e the spectrometer/instrument background even if

purging is not to be carried out.

Fitting the Purge Bellows P/N GS10707

1. With the Benchmark™ baseplate secured and the Silver Gate™

Accessory in position, measure the distance between the

spectrometer source and detector bulkhead/side walls and the flat

end faces of the Silver Gate™ Optical Unit. (This is dimension

“‘X”).

2. Using a sharp razor, cut lengths of the flexible purge bellows (12)

which are equivalent to the measured length (“X”) allowing an

additional 10mm for each.

Tip : It is easier to cut the purge tube between the ridged grooves.

3. Unscrew the Silver Gate™ Optical Unit fixing thumb screw (1) and

remove the Silver Gate™ ATR Accessory from the sample

compartment.

Note: Fit a polari er at this stage if required. (GS12000 Series or

GS12510 Benchmark™ Compatible Accessory Polari er Mount)

4. Fit the flexible purge bellows (12) over both end apertures on the

optical unit and compress sufficiently to enable the whole assembly

to fit into the spectrometer.

5. Refit the Silver Gate™ ATR Accessory with the fitted purge bellows

to the Benchmark™ baseplate. Ensure the purge bellows (12) are

not obstructing the optical beam and then retighten the fixing

thumb screw (1) to secure the Silver Gate™ ATR Accessory back

onto the Benchmark™ baseplate.

User Manual

18

6. Anvil Options

Choice of An ils and their Uses

There are two different compression head anvils (13) that can be used

with the Silver Gate™ ATR Accessory when fitted with the bridge and

clamp anvil assembly. The types of anvil and their uses can be

tabulated as follows:-

An il

Description

Sample Type / Use

GS10532 Pellet Polymer beads, softish irregular

shaped solids

GS10567 Stainless steel flat Solids and powders

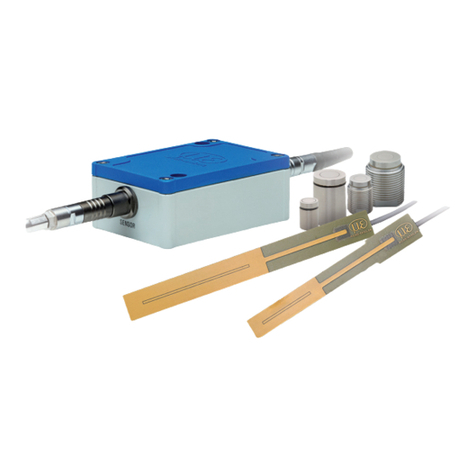

Pellet An il P/N GS10532 (Figure 10.)

This anvil is made of stainless steel and has a

concave recess designed to take round shaped

samples such as polymer beads. Relatively soft

irregular shaped samples can be used with this

anvil on any of the Silver Gate™ ATR crystal

top plate assemblies.

Figure 10

St/Steel Flat An il P/N GS10567 (Figure 11.)

The stainless steel anvil P/N GS10567 should

be used generally for all solid and powder

samples to bring the sample into good contact

with the ZnSe or Ge crystal for any of the ATR

crystal top plate assemblies. Figure 11

Tip: When placing an anvil (13) into position on the end of the clamp

head pressure pin (14) on the bridge, push the hollow depression

of the anvil on with a rotational movement to ensure it makes a

compression fit with the retaining O-ring. Ensure the anvil pressing

face is level and parallel to the bridge (15). (See Figure 12.)

Table of contents