Application

Page 4 RES-402

operating safety. They are not included in the scope of

supply of the standard control system and are

described in a separate document.

1.5 Line filter

The use of an original ROPEX line filter is mandatory in

order to comply with the standards and provisions

mentioned in section 1.7 "Standards / CE marking" on

page 4. This device must be installed and connected

according to the instructions contained in section 8.3,

"Power supply" as well as the separate documentation

enclosed with the line filter.

1.6 Warranty provisions

The statutory provisions for warranties apply for a

period of 12 months following the delivery date.

All devices are tested and calibrated in the factory.

Devices that have been damaged due to faulty

connections, dropping, electrical overloading, natural

wear, incorrect or negligent handling, chemical

influences or mechanical overloading as well as

devices that have been modified, relabeled or

otherwise altered by the customer, for example in an

attempt to repair them or install additional components,

are excluded from the warranty.

Warranty claims must be examined in the factory and

approved by ROPEX.

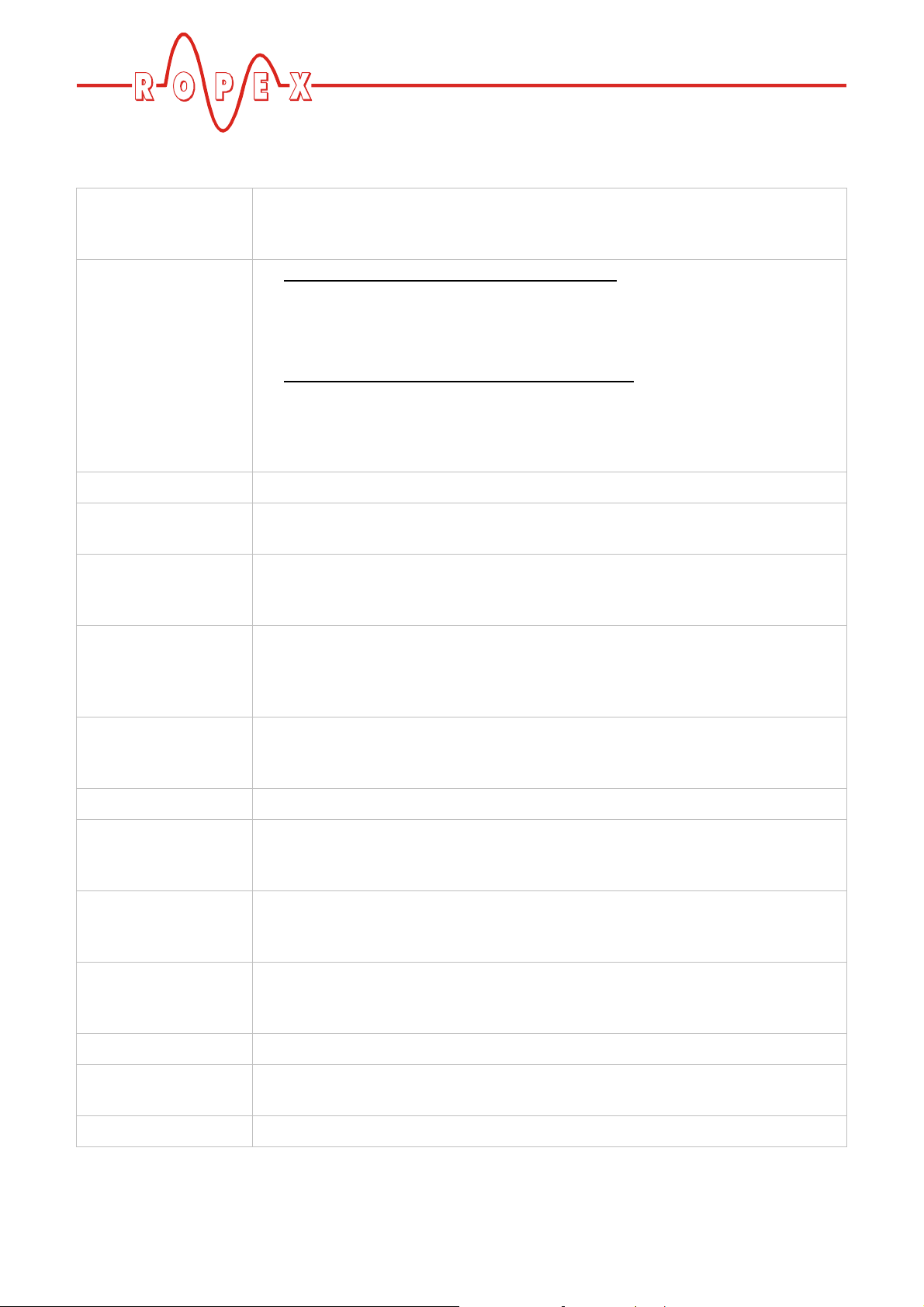

1.7 Standards / CE marking

The controller described here complies with the

following standards, provisions and directives:

Compliance with these standards and provisions is only

guaranteed if original accessories and/or peripheral

components approved by ROPEX are used. If not, then

the equipment is operated on the user's own

responsibility.

The CE marking on the controller confirms that the

device itself complies with the above-mentioned

standards.

It does not imply, however, that the overall system also

fulfils these standards.

It is the responsibility of the machine manufacturer and

of the user to verify the completely installed, wired and

operationally ready system in the machine with regard

to its conformity with the safety provisions and the EMC

directive (see also section 8.3, "Power supply"). If

peripheral components (e.g. the transformer or the line

filter) from other manufacturers are used, no functional

guarantee can be provided by ROPEX.

2 Application

This RESISTRON temperature controller is an integral

part of the "series 400", the outstanding feature of

which is its microprocessor technology. All

RESISTRON temperature controllers are used to

control the temperature of heating elements

(heatsealing bands, beaded bands, cutting wires,

heatsealing blades, solder elements etc.), as required

in a variety of heatsealing processes.

The controller is most commonly used for impulse-

heatsealing PE and PP films in:

• Vertical and horizontal f/f/s machines

• Pouch, filling and sealing machines

• Film wrapping machines

• Pouch-making machines

• Group packaging machines

•L-sealers

DIN EN 61010-1

(VDE 0411-1)

Safety provisions for electrical

measuring, control and laboratory

devices (low voltage directive).

Overvoltage category III, pollution

severity 2, safety class II.

DIN EN 60204-1 Electrical equipment of machines

(machinery directive)

EN 50081-1 EMC interference emissions

according to EN 55011, group 1,

class B

EN 50082-2 EMC interference immunity:

ESDs, RF radiation, bursts, surges.