Specialty Saw Clean-Cuts HYDM70-110V User manual

HYDM70-110V

INSTRUCTION MANUAL

Table of Contents

Introduction ........................ 3

Old Method....................... 3

New Clean-Cuts Method .. 3

Operation ........................... 4

Operation Procedure........ 4

Changing the Blade............ 5

Vacuum Port....................... 6

Maintenance....................... 6

Benets .............................. 7

Hose Cutting Blades .......... 7

CAUTION

Use extreme caution. Please read all instructions before

starting machine. Follow all safety guidelines, do not remove

safety guards. Unplug machine prior to servicing.

GLOVES

Proper hand protection should be worn at all times when

working with sharp cutting tools.

SAFETY EYE WEAR

Proper eye protection should be worn at all times when work-

ing with high RPM cutting blades.

INSTRUCTION MANUAL

HYDM70-110V Hydraulic Hose Saw

2

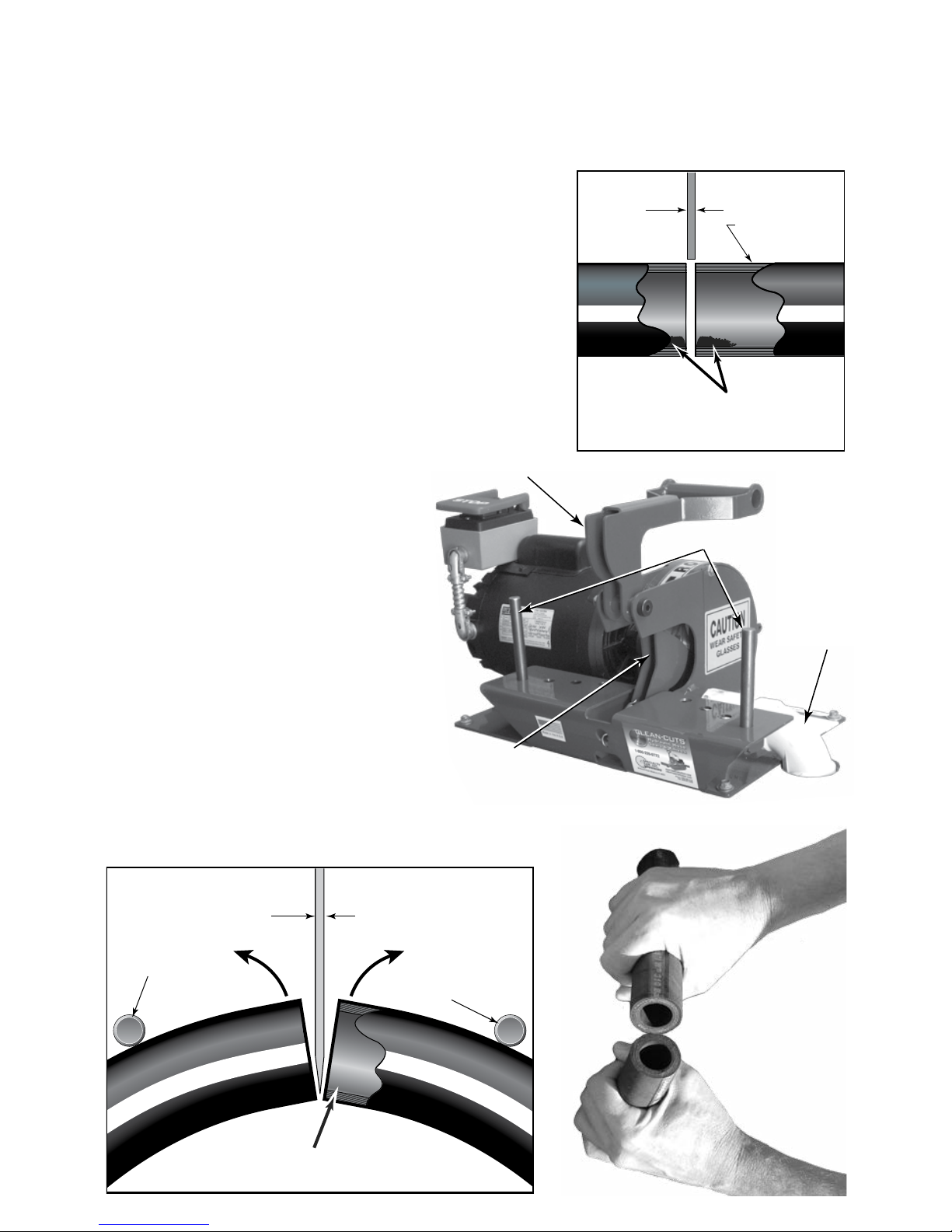

New Improved Clean-Cuts Method

With the Clean-Cuts hydraulic hose

saws the hose is positioned across

two pins (A) and moved into the

blade (C) by a feed foot (B) using

a pulldown handle for better lever-

age on heavy hose. The feed mo-

tion causes the hose to stretch at

the point of contact with the blade,

allowing it to separate as it is cut (see

image at below). This separation al-

lows the hose to pass clear of the saw

blade with NO friction, NO heating and

NO DEBRIS! A vacuum hose (D) is at-

tached to a vacuum port to remove any

tiny amount of debris or smoke during

cutting.

A

B

C

D

NO DEBRIS

1/8” Clean-Cuts Blade

Pin A

Pin A

Hose separates

as blade slices,

no kerf required.

H

y

d

r

a

u

l

i

c

H

o

s

e

|

|

|

|

|

|

|

|

|

|

|

H

y

d

r

a

u

l

i

c

H

o

s

e

|

|

|

|

|

|

|

Introduction

Clean-Cuts hydraulic hose cutting system is break-through technology using a

toothed blade, cutting with the backs of each tooth, so the blade does not take a kerf.

The saw bends the hose into the blade spreading the cut edges to avoid burning and

smoking.

Old Method

The normal sawing method of lowering an abrasive

saw blade onto the hose causes the hose to com-

press and deform. As the blade cuts the compressed

hose expands against the blade causing friction,

heating and burning and much of the debris from the

kerf of the blade is deposited into your hose.

DEBRIS INSIDE

YOUR HOSE!

1/8” Abrasive

Wheel

Hydraulic Hose

Hydraulic Hos

Hydraulic Ho

3

OPERATION

This saw is a rugged and dependable tool when used and maintained properly. Many

of these saws have been in daily service for years and are still in good working order.

As with any tool, good operating procedure is important for tool life and operator

safety.

Operating Procedure

1. Set pin placement for the size hose you are cutting using the following guide:

Hose Size Pin Location*

-4 (1/4”) 1

-6 (3/8”)

-8 (1/2”) 2

-12 (3/4”)

-16 (1”) 3

-20 (1 1/4”) 4

*This guide only “suggests” the best possible pin placement, as there are vari-

ables such as new or used hose, brands of hose, braided or spiral wire rein-

forcement (4 or 6 wire multi-spiral). As an operator you will learn the best pin

placement for the hose you are cutting. Remember that the cut hose should be

square and clean.

2. Start the saw and let the motor come up to full speed. This is most important with

theDCsawsastheytakeamomentto“rampup”.Cuttingbeforethey’reatfull

speed can cause very high amperage draw and shorten the life of the motor.

3. Pushthehoseintothesawwithsteady,evenpressure.Letthebladedoits’jobby

cutting the hose not ripping it. This becomes more important as the hose size be-

comes larger, especially with the 6 wire multi-spiral hose. If there is a lot of smoke

and sparks you may be forcing the hose too fast or the blade may be excessively

dull.

After the hose is cut, be careful as the blade spins down to a stop.

A coasting blade is still dangerous!

4. Examine the hose. Look at the squareness and how clean the cut is. A good cut

goes a long way toward making a strong hose assembly.

4

11

2

2

3

3

4

4

11

2

2

3

3

4

4

Changing the Blade

1. Disconnect the saw from the power

source

2. Remove all the hex nuts from the cover

3. Remove the cover. Note that when the

cover is removed, the blade guard will

spring forward. Remember to place it

behind the cover upon reassembly.

4. Placea1⁄4”rodthroughthearborguard

into the hole in the arbor. This will lock

the arbor in place while the bolt is re-

moved. Please note, the arbor bolt

has reverse threads. To remove it, turn

clockwise while facing it.

5. Remove the old blade and replace with

a fresh one. Be sure the blade direction

is correct. “Clean Cuts Blades” have a

directional arrow on them. The AC saw

turns clockwise when viewed from the

motor shaft end and the DC saw turns

counterclockwise. Some models have

a pin in the arbor, be sure to line up the

blade hole and the washer recess with

that pin.

6. Tightenthearborboltwiththe1⁄4”lock-

ing rod in the arbor to about 20-25 ft/

lbs. It should be snug but

do not over tighten it as it

stresses the motor assem-

bly and is unnecessary.

7. Removethe1⁄4”locking

rod

8. Replace the cover being

sure to put the blade guard

behind it.

9. The pusher pivot bolt

should be greased before

reassembly. Put that bolt

inrstthencompletereas-

sembly with the rest of the

bolts. Note: the pusher

pivotboltis7/16”,thepusherstopboltis1⁄4”andthecoverboltsare3/8”.

10.Tightenallthenutsrmlybutdonotovertighten.Thepusherpivotnutshouldbe

justtightenoughtoallowthepusherhandletopivotsmoothlywithoutbinding. 5

Vacuum Port

Some saw models have a

vacuum port in the cover.

You can attach a 2” shop

vac hose to this port. If the

saw and vacuum “on-off”

switches are wired through

one contactor, the opera-

tor will be able to run both

units simultaneously. A

shop vac attached to the

vacuum port will remove

most of the dust, smoke

and smell while cutting

hose. It is important to

checkthevacuumlterregularlyasitwillplugupwiththenerubberdustthatisas-

sociated with hose cutting.

Maintenance

Examine the blade periodically (blade cover in place) for tooth condition and sharp-

ness. A sharp blade cuts the best but as the teeth wear they will still cut well.

Occasionally pull the blade cover off and perform a closer inspection of the blade

paying attention to any cracks that may have occurred. If cracks are observed, the

blade should be thrown away as it could break while spinning. Cracks are very rare

as these blades are high quality steel and are tempered to the correct hardness for

this application. With the cover off, clean the hose dust that has accumulated inside.

Lubricate the pivot points of the blade guard and pusher with oil on a regular ba-

sis (once a month). Whenever the blade cover is removed, use that opportunity to

grease the pivot points.

Check the condition of the wiring as it may wear over time, especially the DC saws

thatexthewiringfromthehandlemountedswitch.Themotorsrequirelittlemainte-

nance (wipe or blow the accumulated dirt off) as the bearings are sealed.

Keep the area around the saw uncluttered. The DC van saws have high amp con-

nectors with rubber boot protectors. If those protectors wear over time and grounded

metalcomesincontact,itwillsparkandbearehazard!

Speaking of grounding. For proper performance from the DC saws, always have a

good, clean ground connection.

6

Benets

• Cleaner Cuts

• Safer Cuts

• No Smoke

R

O

T

A

T

I

O

N

R

O

T

A

T

I

O

N

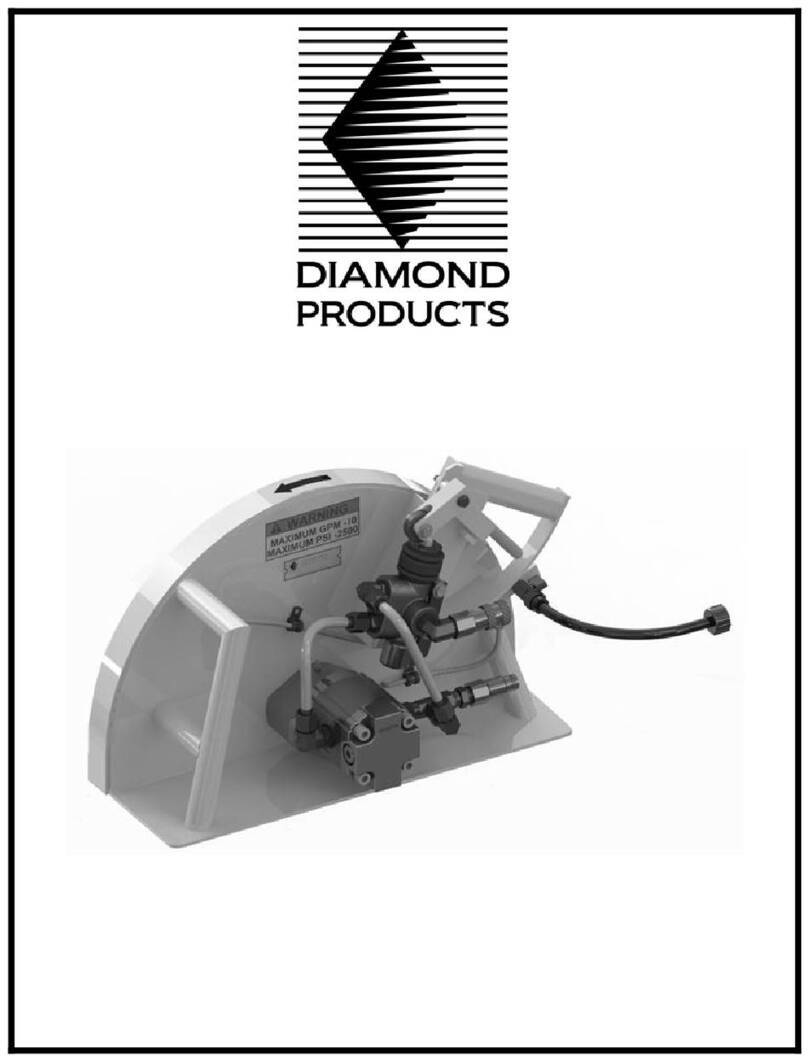

Hose Cutting Blades

The following 5 types of blades are designed

tocuthydraulichose.Ifyou’renotsurewhich

is best suited to your application please call

for our recommendation.

Clean-Cuts blades are manufactured in: M-2,

D-2, M-35, & High Speed Steels.

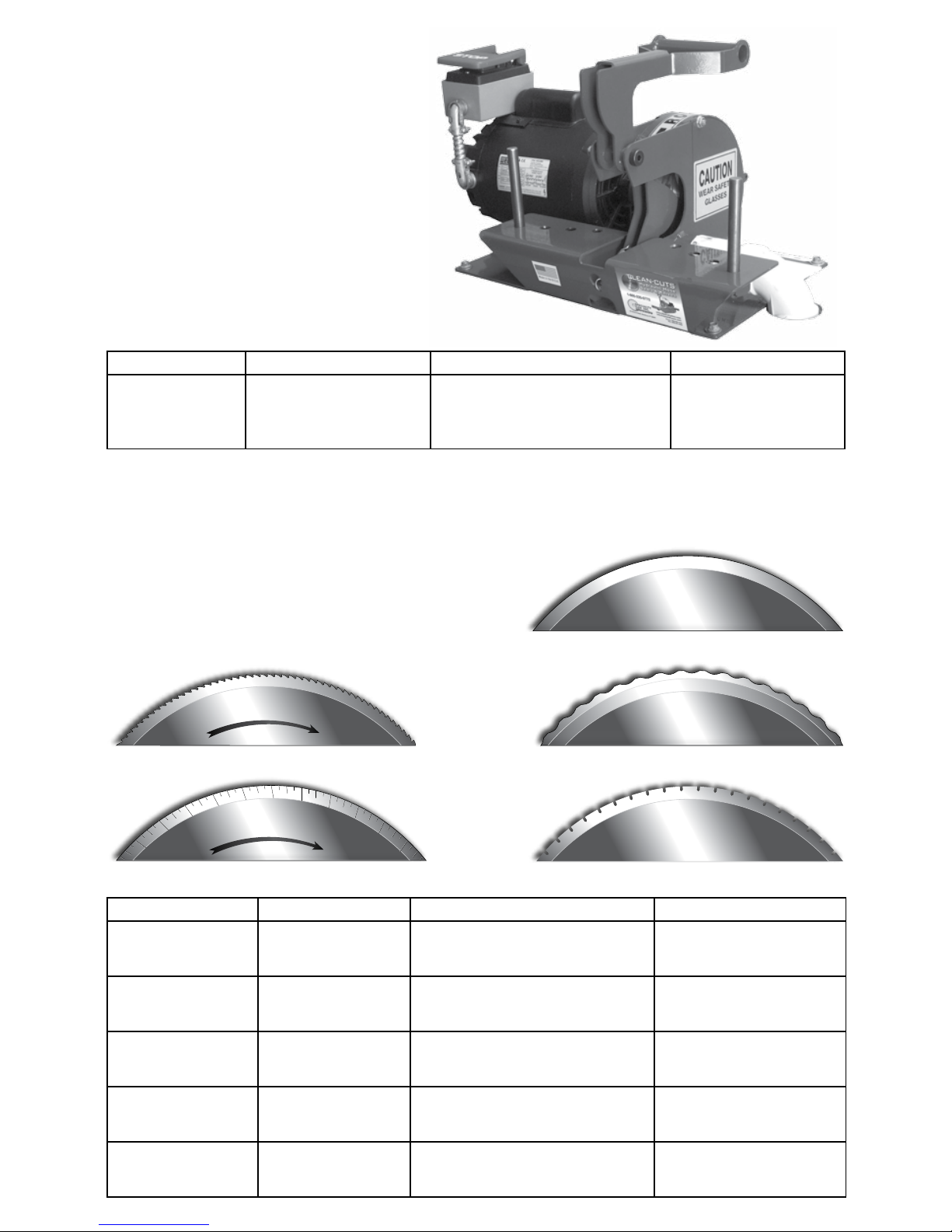

MODEL MOTOR BLADE CUTTING CAPACITY

HYDM70-110V 2 HP, 110 VAC, 1

Phase, 60 Cycle,

3,450 RPM

7" OD x .093 THK X 3/4” arbor 1-1/4″IDx4Wire

Hydraulic Hose

Advanced Scallop Blade Scalloped Blade

Smooth Blade

Micro-Slotted Blade Slotted Blade

MODEL TYPE BLADE SIZE CUTTING CAPACITY

HYD07X093X3/4 Advanced Scallop 7” OD x .093 THK X 3/4” arbor 1-1/4″IDx4Wire

Hydraulic Hose

MSE7X093X3/4 Micro-Slotted 7” OD x .093 THK X 3/4” arbor 1-1/4″IDx4Wire

Hydraulic Hose

CDBK7X093X3/4 Smooth 7” OD x .093 THK X 3/4” arbor 1-1/4″IDx4Wire

Hydraulic Hose

NSK7X093X3/4 Scalloped 7” OD x .093 THK X 3/4” arbor 1-1/4″IDx4Wire

Hydraulic Hose

SSE07X093X3/4 Slotted 7” OD x .093 THK X 3/4” arbor 1-1/4″IDx4Wire

Hydraulic Hose

Specialty Saw, Inc.

30 Wolcott Road

Simsbury, CT 06070 USA

1-800-225-0772

Voice: (860) 658-4419 ~ Fax: (860) 651-5358

Email: info@specialtysaw.com

Website: http://specialtysaw.com

© Specialty Saw, Inc. 2014

Table of contents

Other Specialty Saw Saw manuals

Popular Saw manuals by other brands

DeWalt

DeWalt DW303 instruction manual

Scheppach

Scheppach HM305SL Translation of original instruction manual

Diamond Products

Diamond Products HS-20-F-10 parts manual

ATIKA

ATIKA DKV 400-2 Original instructions

RIDGID

RIDGID MaxSelect R885 Operator's manual

EIBENSTOCK

EIBENSTOCK EDB 480.1 Original instructions