Spectris Servomex OxyDetect User manual

Part Number: 05311001B

Revision: 4

Language: UK English

SERVOMEX OxyDetect

OPERATOR MANUAL

OxyDetect Oxygen Deficiency Gas Detector Contents

05311001B / Revision 4 i

IMPORTANT INFORMATION

Continued safe and reliable operation of this equipment is

conditional on all installation, operation and maintenance

procedures being carried out in accordance with the appropriate

manuals, by personnel having

appropriate qualifications,

experience and training.

Poursuite de l'exploitation sûre et fiable de cet équipement est

subordonné à toutes les procédures d'installation, de

fonctionnement et d'entretien étant effectué en conformité avec les

manuels appropri

és, par un personnel ayant les qualifications

appropriées, l'expérience et la formation.

Failure to observe the requirements of the manual may result in the user being held

responsible for the consequences and may invalidate any warranty.

Servomex will accept no liability for unauthorised modifications to Servomex supplied

equipment.

Servomex has paid particular attention to Health & Safety throughout the manual. Where

special precautions need to be taken due to the nature of the equipment or product, an

appropriate safety icon and warning message is shown. Special attention should be made

to Section 1.2, where all such messages are summarized.

In line with our continuous policy of research and development, we reserve the right to

amend models and specifications without prior notice.

This manual is accurate at the date of printing, but will be superseded and should be

disregarded if specifications or appearance are changed.

Servomexis a registeredtrademarkof Servomex Group Limited. The use ofall trademarks

in this document is acknowledged.

© 2016. Servomex Group Limited. A Spectris Company. All rights reserved.

Contents OxyDetect Oxygen Deficiency Gas Detector

ii 05311001B / Revision 4

CONTENTS

Section

Page

1DESCRIPTION AND DEFINITIONS ............................................................1

1.1 Scope of this manual...................................................................................1

1.2 Safety information .......................................................................................1

1.3 Description..................................................................................................2

1.4 Ordering options..........................................................................................3

1.5 Certification.................................................................................................5

1.5.1 Hazardous area certification...................................................................5

1.6 Markings.....................................................................................................7

1.6.1 Label locations.......................................................................................8

2CERTIFICATION INFORMATION................................................................9

2.1 Hazardous area approval and certification...................................................9

2.1.1 Equipment certification standards...........................................................9

2.1.2 Europe and IECEx..................................................................................9

2.1.3 North America......................................................................................10

2.1.4 Label information..................................................................................10

3SPECIFICATION.......................................................................................12

3.1 General.....................................................................................................12

3.2 Environmental limits ..................................................................................12

4UNPACK THE INSTRUMENT ...................................................................14

5INSTRUMENT USER INTERFACE ...........................................................15

5.1 Introduction...............................................................................................15

5.2 Start-up and measurement screens...........................................................15

5.3 Soft key legends........................................................................................16

5.4 System and measurement status icons......................................................17

5.5 Scroll bars.................................................................................................17

5.6 Menu options/screens and password protection.........................................17

5.7 The menu screen ......................................................................................18

5.8 The settings screen...................................................................................19

5.9 The information screen..............................................................................20

5.10 Editing on-screen data...............................................................................20

6INSTALLATION AND SET-UP...................................................................22

6.1 Mechanical installation...............................................................................23

6.2 Electrical Installation..................................................................................23

6.2.1 Electrical Safety....................................................................................23

6.2.2 Electrical data.......................................................................................26

6.2.3 Connect the electrical supply................................................................28

6.2.4 Analogue output connections................................................................30

6.2.5 Interface Relay connections..................................................................32

6.2.6 Modbus Ethernet connection (option)....................................................33

6.3 Switch on/set-up........................................................................................34

6.3.1 Selecting the security level and password(s).........................................34

6.3.2 Selecting the security level ...................................................................35

OxyDetect Oxygen Deficiency Gas Detector Contents

05311001B / Revision 4 iii

6.3.3 Changing passwords............................................................................36

6.3.4 Adjusting the screen contrast................................................................36

6.3.5 Adjusting the backlight timer.................................................................37

6.3.6 Setting the clock...................................................................................38

6.3.7 Changing regional settings ...................................................................38

6.4 Configuring and using the mA outputs (option)...........................................39

6.4.1 Overview..............................................................................................39

6.4.2 Introduction to the mA output parameters .............................................39

6.4.3 Setting up the mA output parameters....................................................41

6.4.4 Calibrating the mA output.....................................................................43

6.5 Configuring the measurement alarms........................................................44

6.5.1 Alarm modes and levels .......................................................................44

6.5.2 Latching/non-latching alarms................................................................46

6.5.3 Hysteresis levels ..................................................................................46

6.5.4 Viewing the measurement alarm status.................................................47

7CALIBRATION..........................................................................................48

7.1 Connecting the calibration gas cap............................................................50

7.2 Manual calibration.....................................................................................51

8ROUTINE MAINTENANCE........................................................................53

8.1 Inspecting the calibration cap ....................................................................53

8.2 Checking the mA output ............................................................................53

8.3 Checking the relays...................................................................................53

8.4 Cleaning the instrument.............................................................................54

8.5 Preventative maintenance.........................................................................54

9FAULT FINDING.......................................................................................56

9.1 Fault, maintenance required and SIP statuses...........................................56

9.1.1 Status definitions..................................................................................56

9.1.2 Status annunciations............................................................................56

9.2 Viewing messages.....................................................................................58

9.2.1 Active messages ..................................................................................58

9.2.2 View history messages.........................................................................59

9.3 General fault finding..................................................................................59

10 STORAGE AND DISPOSAL......................................................................62

10.1 Storage.....................................................................................................62

10.2 Disposal....................................................................................................62

11 SPARES...................................................................................................63

12 DISPOSAL IN ACCORDANCE WITH THE WASTE ELECTRICAL AND

ELECTRONIC EQUIPMENT (WEEE) DIRECTIVE ....................................64

13 APPENDIX................................................................................................65

A1 PERFORMANCE DATA............................................................................65

A2 FACTORY CONFIGURATION SETTINGS ................................................66

A3 IMPLEMENTATION GUIDE FOR MODBUS ETHERNET

COMMUNICATIONS (OPTION) ................................................................67

Contents OxyDetect Oxygen Deficiency Gas Detector

iv 05311001B / Revision 4

A3.1 Introduction...............................................................................................67

A3.2 References................................................................................................67

A3.3 Supported function codes..........................................................................67

A3.4 Exception codes........................................................................................67

A3.5 Addressing................................................................................................68

A3.6 Floating point numbers..............................................................................68

A3.7 System data mapping................................................................................68

A3.8 Transducer data mapping..........................................................................68

A3.9 System Fault Mapping...............................................................................70

A3.10 Transducer fault and alarm mapping..........................................................71

A3.11 System set-up mapping.............................................................................73

A3.12 Transducer set-up mapping.......................................................................74

A3.13 System control ..........................................................................................75

A3.14 Transducer control.....................................................................................75

A4 CONFIGURING THE MODBUS PARAMETERS (OPTION).......................77

A4.1 TCP (Ethernet) Communications parameters.............................................77

A5 CROSS INTERFERENCE OFFSETS........................................................79

A6 END USER NOTES...................................................................................83

© This manual is copyright, and no part of it may be reproduced without Servomex's written approval.

OxyDetect Oxygen Deficiency Gas Detector 1 – Description and definitions

05311001B / Revision 4 1

1 DESCRIPTION AND DEFINITIONS

1.1 Scope of this manual

This manual provides installation, operation and routine maintenance instructions for

the 05311B1 OxyDetect - Oxygen Deficiency Fixed Gas Detector, abbreviated to

"instrument" or “unit” in the remainder of this manual.

1.2 Safety information

Read this manual and ensure that you fully understand its content before you attempt

to install, use or maintain the instrument. Important safety information is highlighted in

this manual as WARNINGs and CAUTIONs, which are used as follows:

Warnings highlight specific hazards which, if not taken into

account, may result in personal injury or death.

Avertissements soulignent les dangers spécifiques qui, si pas

pris en compte, peut entraîner des blessures ou la mort.

Cautions highlight hazards which, if not taken into account, can

result in damage to the instrument or to other equipment or

property.

Précautions soulignent les dangers qui, si pas pris en compte,

peut entraîner des dommages à l'instrument ou à un autre

appareil ou d'un bien.

This manual also incorporates 'Be aware of' information, which is used as follows:

This highlights information which it is useful for

you to be aware of (for

example, specific operating conditions, and so on).

1 – Description and definitions OxyDetect Oxygen Deficiency Gas Detector

2 05311001B / Revision 4

1.3 Description

The Instrument is a fixed wall mounted gas detector with an integral oxygen sensor

that outputs a linear 4-20mA signal that represents an ambient oxygen concentration.

Additionally, three changeover relays are provided to signal the following detector

statuses.

Measurement alarm level 1 (user configurable)

Measurement alarm level 2 (user configurable)

Instrument Fault and Oxygen measurement >23%

These outputs must be integrated into a gas detection management system as the

instrument gives no direct visible or audible warning or alarm of an oxygen-deficient

environment (internal audible alarm or visual beacon), its function being solely to

measure the ambient level of oxygen. It offers a measurement of ambient oxygen

based on the principles of paramagnetism, a non-depleting and inherently linear

measurement technique.

The instrument is designed to be installed within indoor working environments such

as laboratories, workshops or analyser shelters.

Gas sample measurements are shown on the instrument display, and can be output

as a 4-20mA milliamp (mA) signal and / or gas sample alarm levels indicted by relay

status, to a gas detection management system.

The instrument requires little routine maintenance, other than calibration which is

essential for the accuracy of the gas measurements.

The instrument is not to be used for process control or process

monitoring

L'instrument ne doit pas être utilisé pour le contrôle des

processus ou la surveillance de processus

The OxyDetect is not a medical device as defined in the medical

devices directive 93/42/EEC and is not intended to be used on

human beings for the diagnosis, prevention, monitoring,

treatment or alleviation of disease. Injury or replacement or

modification of the anatomy

Le OxyDetect est pas un dispositif médical tel que défini dans

les dispositifs médicaux de la directive 93/42 / CEE et ne sont

pas destinés à être utilisés sur des êtres humains pour le

diagnostic, la prévention, contrôle, traitement ou atténuation

d'une maladie. Blessure ou de remplacement ou modification de

l'anatomie.

OxyDetect Oxygen Deficiency Gas Detector 1 – Description and definitions

05311001B / Revision 4 3

The safe area version is not to be used in certified or hazardous

locations (potentially explosive atmospheres)

La version de zone de sécurité ne doit pas être utilisé dans des

endroits certifiés ou dangereux (atmosphères explosibles)

The instrument is not suitable for corrosive atmospheres (those

atmospheres where gases and vapours are present in

concentrations high enough to cause corrosion to normal

industrial appliances or where specialised coatings, materials or

finishes would normally be specified to avoid corrosion)

L'instrument ne convient pas pour les atmosphères corrosives

(ces atmosphères gaz et les vapeurs sont présents dans des

concentrations suffisamment élevées pour provoquer la

corrosion des appareils industriels ou normales où devraient

normalement être précisées revêtements spécialisés, des

matériaux ou finitions pour éviter la corrosion)

1.4 Ordering options

For the latest ordering options please contact your local Servomex agent or visit

www.servomex.com.

1 – Description and definitions OxyDetect Oxygen Deficiency Gas Detector

4 05311001B / Revision 4

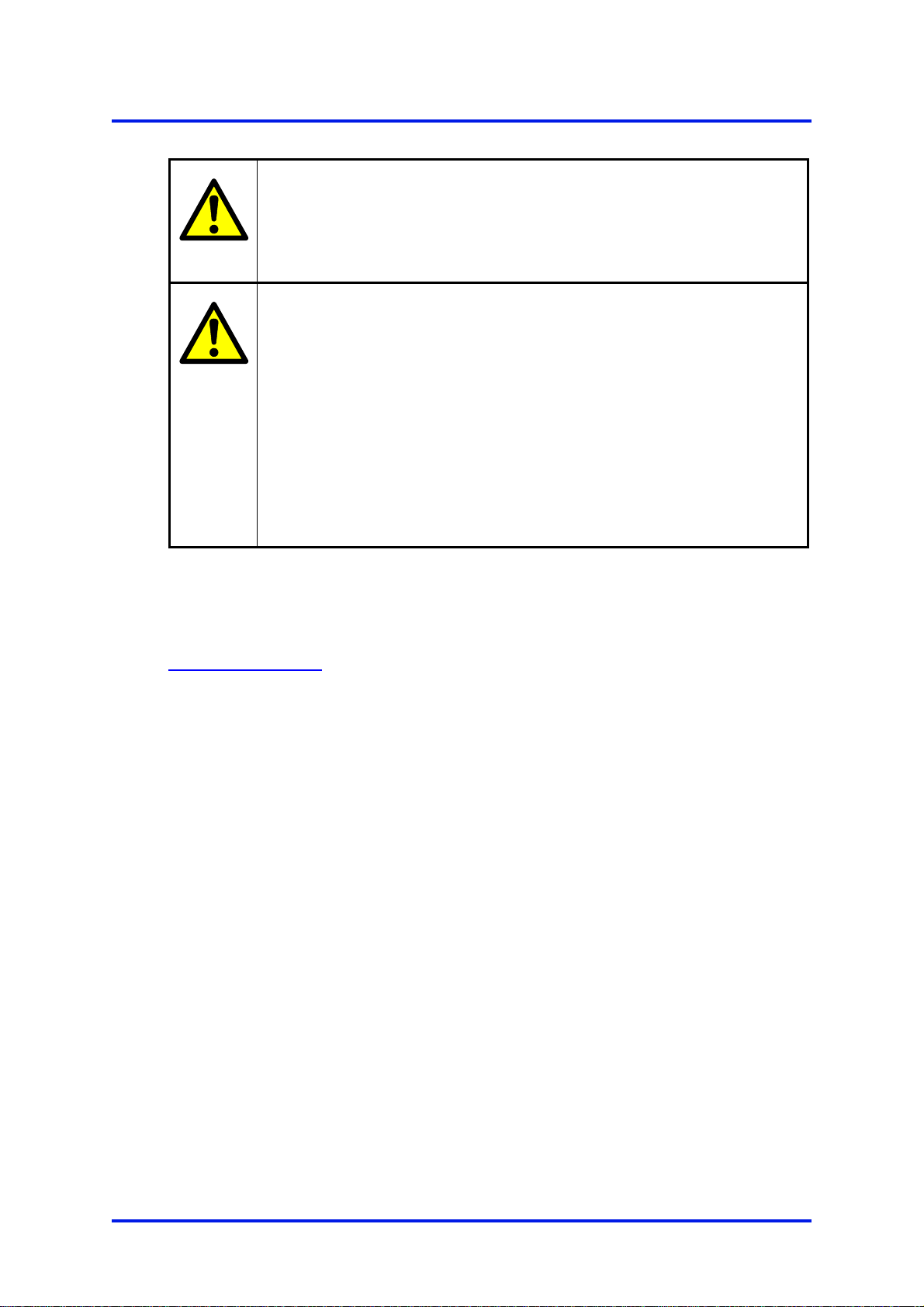

Key Description Key Description

1. 4 x mounting holes for M6 fixings

2. Display

3. 4 x Gland entries holes diameter

22mm

4. Fault LED (amber)

5. Measurement alarm LED (red)

6. Chassis earth

7. Enclosure breather (do not block)

8. Soft key 4, from left to right soft

keys 1, 2, 3 and 4

9. Senor cover and calibration cap

mounting nozzle

Figure 1 - Front of Instrument

1

2

3

4

5

6

7

8

9

OxyDetect Oxygen Deficiency Gas Detector 1 – Description and definitions

05311001B / Revision 4 5

1.5 Certification

1.5.1 Hazardous area certification

Do not modify the unit, either mechanically or electrically, as the

certification of the instrument will be invalidated and it may not

operate safely.

Ne modifiez pas l'unité, soit mécaniquement ou électriquement,

ou la certification de l'instrument sera invalidée et il ne peut pas

fonctionner en toute sécurité.

Hazardous area certification is restricted to the use of the unit in

atmospheres at normal oxygen concentration and normal

atmospheric pressures. The oxygen measurement range for

hazardous area versions is 0 to 21%.

Certification de zone dangereuse est limitée à l'utilisation de

l'appareil dans des atmosphères à la concentration d'oxygène

normale et des pressions atmosphériques normales . plage de

mesure de l'oxygène pour les versions en zone dangereuse est

0 à 21 %.

Exposure to some

chemicals may degrade the sealing

properties of materials used in the following devices.

K1: Relay from Customer Interface Board - Sealed Device

K2: Relay from Customer Interface Board - Sealed Device

K3: Relay from Customer Interface Board - Sealed Device

L’exposition à certains produits chimiques mai dégrader la

fermeture des propriétés des matériaux utilisés dans les appareils

suivants: (Amérique du Nord uniquement).

K1: Relais de Carte Interface HM - Sealed Device

K2: Relais de Carte Interface HM - Sealed Device

K3: Relais de Carte Interface HM - Sealed Device

Substitution of the following components may impair suitability

for Division 2 (North America only).

K1: Relay from Customer Interface Board - Sealed Device

K2: Relay from Customer Interface Board - Sealed Device

K3: Relay from Customer Interface Board - Sealed Device

La substitution de composants suivants peut render ce matériel

inacceptable pour les emplacements de Classe 1, Division 2:

(Amérique du Nord uniquement).

1 – Description and definitions OxyDetect Oxygen Deficiency Gas Detector

6 05311001B / Revision 4

K1: Relais de Carte Interface HM - Sealed Device

K2: Relais de Carte Interface HM - Sealed Device

K3: Relais de Carte Interface HM - Sealed Device

EXPLOSION HAZARD - Substitution of components may impair

suitability for CL I, Div 2. (North America only)

RISQUE D’EXPLOSION – La substitution de composants peut

render ce matériel inacceptable pour les emplacements de

Classe I, Division 2. (Amérique du Nord uniquement)

Make sure that the operating environment is within the limits

specified in the product data (section 3.2).

Assurez-vous que l'environnement d'exploitation est dans les

limites spécifiées dans les données du produit (section 3.2).

Do not open the enclosure if an explosive atmosphere is present.

Ne pas ouvrir en atmosphère explosive.

Do not open the enclosure if the instrument is energized.

Ne pas ouvrir sous tension.

It is a condition of certification that the unit must be installed

following the appropriate national or international legislation or

codes of practice. In particular, you must make sure that the

correct glands are fitted to cable entries and that you do not

compromise the weatherproofing of the enclosure.

C'est une condition de la certification que l'unité doit être

installée en respectant la législation ou des codes de pratique

nationale ou internationale approprié. En particulier, vous devez

vous assurer que les glandes appropriés sont installés aux

entrées de câble et que vous ne compromettent pas l'étanchéité

de l'enceinte.

All of the monitor electrical connections are considered to be

incendive and therefore must only be connected to safe area

equipment.

Tous les moniteurs connexions électriques sont considérés

comme incendiaire et donc ne doit être connecté à l'équipement

des zones de sécurité.

OxyDetect Oxygen Deficiency Gas Detector 1 – Description and definitions

05311001B / Revision 4 7

Only use a soft, clean cloth moistened with water to wipe clean

the outside of the enclosure.

Utilisez uniquement un chiffon doux et propre humidifié avec de

l'eau pour nettoyer l'extérieur de l'enceinte.

The equipment is incapable of passing the dielectric strength

test prescribed by the standards, and so this must be taken into

account during installation.

L'équipement est incapable de passer le test de rigidité

diélectrique prescrite par les normes, et si cela doit être pris en

compte lors de l'installation.

The equipment shall be used in an area not exceeding Pollution

Degree 2 as defined in IEC 60664-1.

L'équipement doit être utilisé dans une zone ne dépassant pas

2 degré de pollution tel que défini dans la norme CEI 60664-1.

1.6 Markings

The instrument includes these external markings. Their details are shown in Section Error!

Reference source not found..

Follow the appropriate safety instructions and be aware of any warnings about potential

hazards.

1 – Description and definitions OxyDetect Oxygen Deficiency Gas Detector

8 05311001B / Revision 4

1.6.1 Label locations

Figure 2 - OxyDetect unit label locations

OxyDetect unit

Certification label

(fitted on hazardous

location versions

only. See Figure 4 &

Figure 5)

OxyDetect unit rating

& serial number label

(Figure 3)

OxyDetect Oxygen Deficiency Gas Detector 2 – Certification information

05311001B / Revision 4 9

2 CERTIFICATION INFORMATION

2.1 Hazardous area approval and certification

2.1.1 Equipment certification standards

The standards to which the equipment has been certified are listed below:

ATEX

EN 60079-0:2012 + A11 :2013

EN 60079-7 :2015

EN 60079-11:2012

EN 60079-15:2010

IECEx

IEC 60079-0:2011 Edition 6

IEC 60079-7 :2015 Edition 5

IEC 60079-11:2011 Edition 6

IEC 60079-15:2010 Edition 4

2.1.2 Europe and IECEx

ATEX II 3G

Coding (ATEX and IECEx) Ex ic ec nC IIC T4 Gc

Ambient Temperature

range -5 °C to +45 °C

Certification number

(ATEX) Baseefa15ATEX0165X

Certification number

(IECEx) IECEx BAS 15.0112X

Conditions of safe use

(ATEX & IECEx)

1. Possible electrostatic risk - clean only with a

damp cloth.

2. The equipment is not capable of passing

the dielectric strength test prescribed by the

standards, and so this must be taken into

account during installation.

3. The equipment shall be used in an area not

exceeding pollution degree 2 as defined in

IEC 60664-1.

4. All cable entries must utilise a suitably

certified cable gland or, in the case of any

unused entries, a suitably certified blanking

element in order to maintain the pollution

degree level and ingress protection IP66 of

the equipment.

2 – Certification information OxyDetect Oxygen Deficiency Gas Detector

10 05311001B / Revision 4

2.1.3 North America

Coding Class I, Division 2, Groups A-D; T4

Class I, Zone 2, Group IIC; T4

Ambient Temperature

range -5 °C to +45 °C

SGS Contract No. 710216

SGS Certificate Reference SGSNA/19/SUW/00043

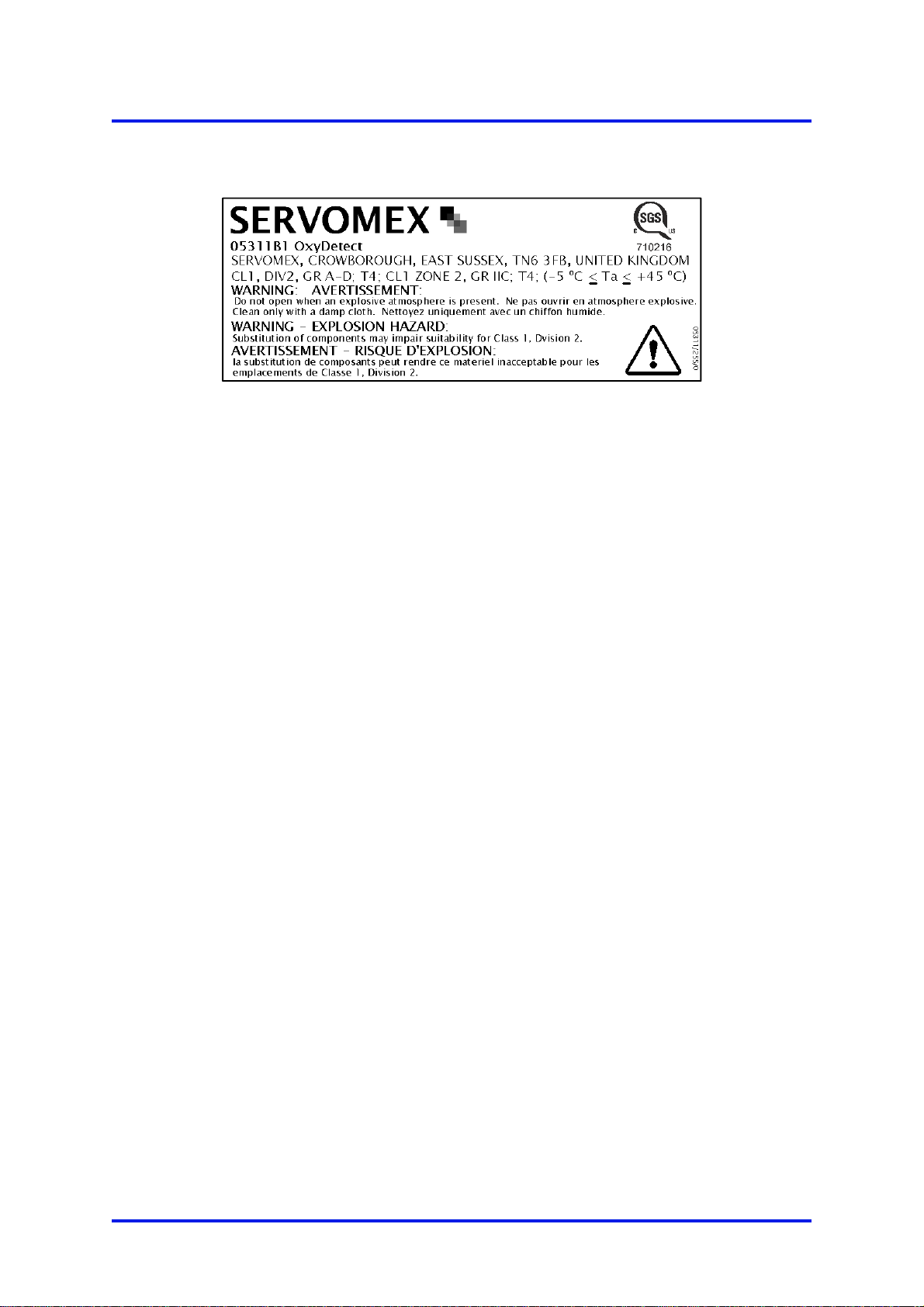

2.1.4 Label information

Figure 3 - OxyDetect Rating Label

Figure 4 - OxyDetect ATEX / IECEx Certification label

OxyDetect Oxygen Deficiency Gas Detector 2 – Certification information

05311001B / Revision 4 11

Figure 5 - OxyDetect North America

CL1 Div 2 Certification label

3 – Specification OxyDetect Oxygen Deficiency Gas Detector

12 05311001B / Revision 4

3 SPECIFICATION

The protection, accuracy, operation and condition of the

equipment may be impaired if the instrument is not installed in

accordance with the requirements of this and subsequent

sections of the manual.

La protection, la précision, le fonctionnement et l'état de

l'équipement peut être altérée si l'instrument n'a pas été installé

en conformité avec les exigences du présent et les sections

suivantes du manuel.

3.1 General

Dimensions:

length x height x width 210 x 200 x 106 mm (8.3” x 7.9” x 4.2”)

Mass <2.5 kg (5.5lbs)

3.2 Environmental limits

Equipment is suitable for indoor use only

Ambient temperature range

Operational

Hazardous location certified

+5 °C to +45 °C (+41 °F to +113 °F)

-5 °C to +45 °C (+23 °F to +113 °F)

Storage -5 °C to +50 °C (+23 °F to +122 °F)

Operating pressure range Ambient

80 to 110 kPa (11.6 to 16 psi) Hazardous

Areas

Operating ambient humidity range 10 to 80% RH, non-condensing

Operating altitude range –500 * to 2000

†

metres

(-1600 * to 6500 †feet)

Ingress protection IP66 (IP40 sensor)

The instrument is rated Pollution Degree 2

* Below sea level.

†Above sea level.

05311001B / Revision 4 13

The OxyDetect enclosure is designed such that it achieves

IP66 ingress protection. However, in operational use

consideration must be made for the protection of the sensor

opening which is rated to IP40. Therefore, the instrument should

not be exposed to washing with liquid jets. The instrument is for

indoor use only.

L'enceinte OxyDetect estconçue de telle sorte qu'elle réalise

IP66 protection d'entrée. Cependant, dans l'utilisation

opérationnelle examen doit être fait pour la protection de

l'ouverture du capteur qui est évalué à IP40. Par conséquent,

l'instrument ne doit pas être exposé à un lavage avec jets de

liquide. L'instrument est destiné à être utilisé en intérieur.

If the ambient temperature falls below 0 °C (32 °F) the instrument

should be recalibrated to ensure correct operation.

Si la température ambiante descend en dessous de 0 °C (32 °F)

l'instrument doit être recalibré pour assurer un fonctionnement

correct.

4 – Unpack the instrument OxyDetect Oxygen Deficiency Gas Detector

14 05311001B / Revision 4

4 UNPACK THE INSTRUMENT

The instrument is delicate and care must be taken when

handling.

L'instrument est délicate et il faut prendre soin lors de la

manipulation.

1. Remove the instrument and any other equipment from its packaging.

It is advisable that the gland entry blanking plugs are only removed

just prior

to product installation.

2. Inspect the instrument and the other items supplied, and check that they are not

damaged. If any item is damaged, immediately contact Servomex or your local

Servomex agent.

3. Check that you have received all of the items that you ordered. If any item is

missing, immediately contact Servomex or your local Servomex agent.

4. If you do not intend to use the instrument immediately:

Refit any protective plastic covers.

Place the instrument and any other equipment supplied back in its protective

packaging.

Store the instrument as described in Section 10.1.

Otherwise, read Section 5 (Instrument user interface), and then continue at

Section 6 onwards to install, set up, and use the instrument.

Retain the shipping documentation and packaging for future use (for example,

return of the instrument to Servomex for servicing or repair).

05311001B / Revision 4 15

5 INSTRUMENT USER INTERFACE

5.1 Introduction

The instrument user interface comprises the following (shown on Figure 1):

Display Shows various screens: see Section 5.2 onwards

Soft keys The function of each of the soft keys depends on the screen

currently being shown on the display: see Section 5.2

Alarm LED On when an alarm condition exists: see Section 6.5

Fault LED On when a fault condition exists: see Section 9.1

5.2 Start-up and measurement screens

When you first switch on the instrument, a 'start-up screen' is displayed while the

instrument carries out a self-test.

The start-up screen shows the Servomex name, a 'self-test time elapsed/remaining'

indicator, and messages identifying the tasks being carried out as part of the self-test.

The screen will initially display the "System Check" task message. The measurement

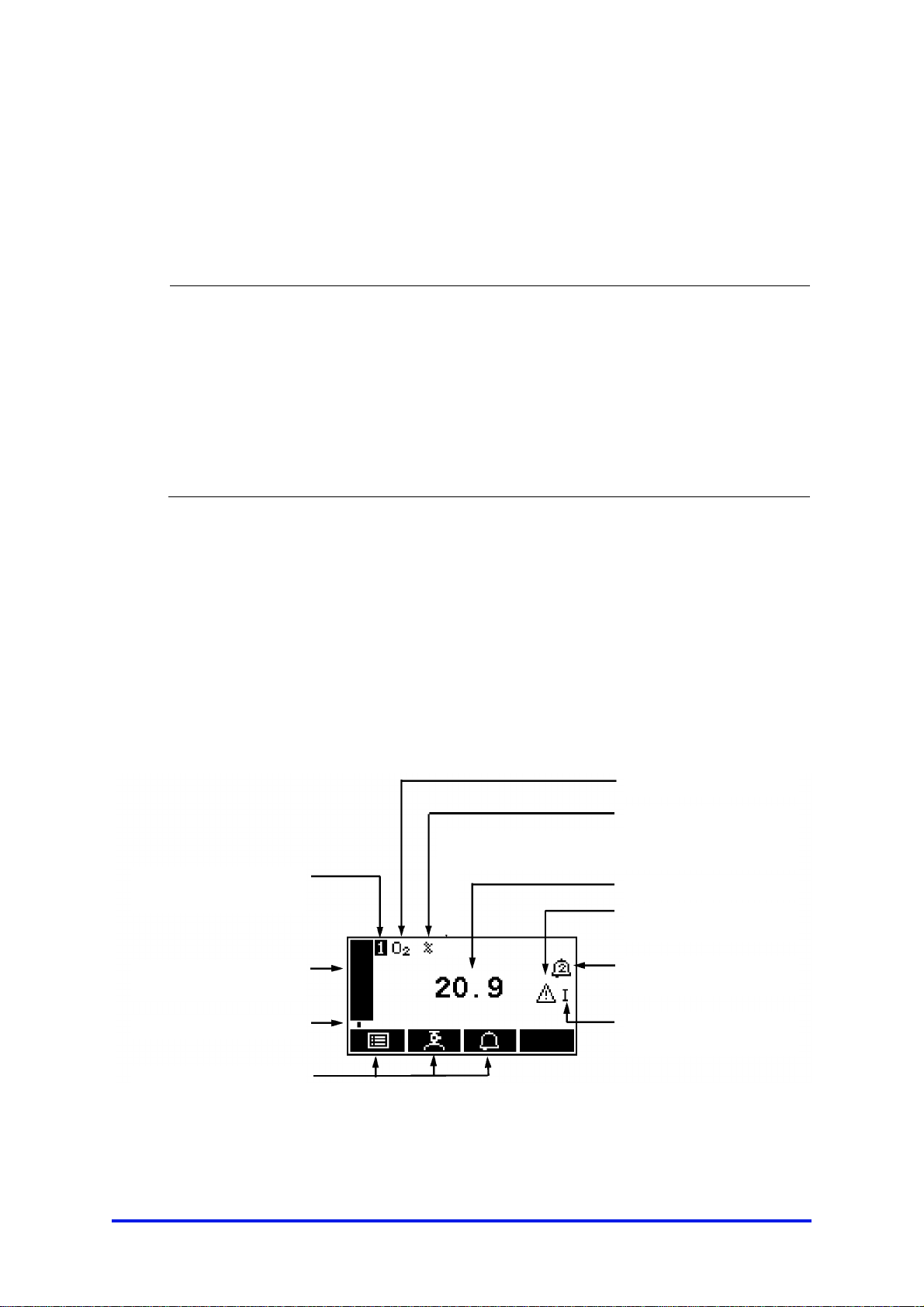

screen is then displayed, as shown in Figure 6 below.

Figure 6 - The measurement screen

Gas being measured

Measurement units

Pressure compensation

indicator *

Current measurement

Alarm icon

(see Section 6.5.1)

mA Range

(see Section 6.4.1)

Icons

(see Section 9.1.2)

Soft key legends

Status icon bar

(see Section 5.4)

Transducer number

("1" always shown)

Software health indicator

This manual suits for next models

1

Table of contents

Popular Gas Detector manuals by other brands

ELRO

ELRO ES46 quick start guide

BEINAT

BEINAT CO922 Guide

Critical Environment Technologies

Critical Environment Technologies LPT-M Operation manual

Beacon

Beacon MEGA Installation, operation and maintenance instructions

Bosean Electronic Technology

Bosean Electronic Technology BH-4M user manual

Duomo

Duomo CellAir user manual

Heath Consultants

Heath Consultants RMLD-CS HPN 105301 Operator's manual

RKI Instruments

RKI Instruments 65-2495RK Operator's manual

Riken Keiki

Riken Keiki SD-1DOX operating manual

MSA AUER

MSA AUER ALTAIR operating manual

Riken Keiki

Riken Keiki GD-84D-EX Series operating manual

CALECTRO

CALECTRO SenseAir A-SENSE Manual for installation