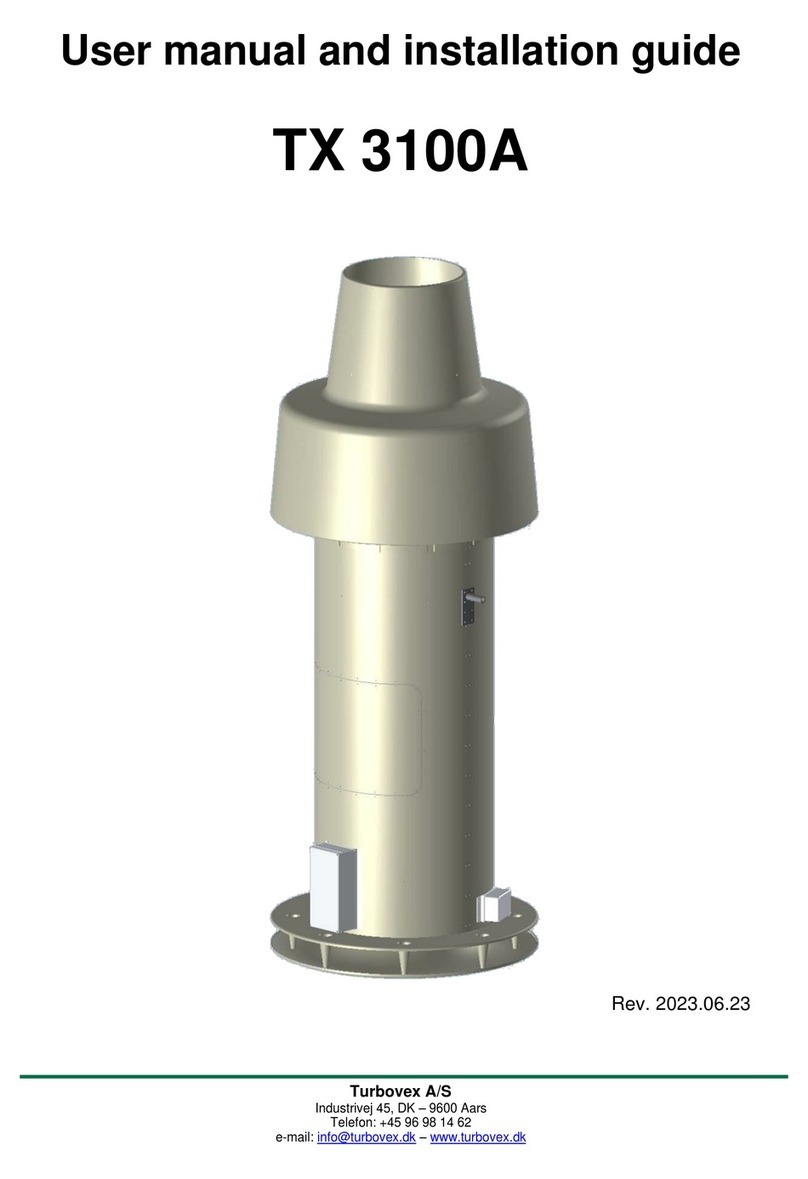

Edge Rebel 80 Configuration guide

Table of Contents Rebel 80

I

General Information

Section Page

1.1 Contents of the Manual ------------------------------------------------------------------------------ 1

1.2 Machine Data Plate ----------------------------------------------------------------------------------- 2

1.2 Technical Support ------------------------------------------------------------------------------------- 2

2. Technical Information

2.1 Description of the Machine ------------------------------------------------------------------------- 3

2.2 Machine Footprint ------------------------------------------------------------------------------------- 3

2.3 Specifications and Capacities ---------------------------------------------------------------------- 4

2.4 Bar stock requirements ------------------------------------------------------------------------------ 4

2.5 Safety ---------------------------------------------------------------------------------------------------- 5

2.5.1 Covers --------------------------------------------------------------------------------------------------- 5

2.5.2 Axial Shifting Switch ---------------------------------------------------------------------------------- 5

2.5.3 Lathe Door Safety ------------------------------------------------------------------------------------- 6

2.5.4 Emergency Stop Buttons ---------------------------------------------------------------------------- 6

3. Transportation and Handling

3.1 Lifting and Moving by Forklift ----------------------------------------------------------------------- 7

3.2 Lifting by Crane ---------------------------------------------------------------------------------------- 8

4. Installation of the Bar Feeder

4.1 Lathe Preparation ------------------------------------------------------------------------------------- 9

4.2 Distance from the Lathe ----------------------------------------------------------------------------- 9

4.3 Axial Shifting Device ---------------------------------------------------------------------------------- 10

4.4 Magazine Attachment --------------------------------------------------------------------------------- 12

4.5 Alignment ------------------------------------------------------------------------------------------------- 14

4.6 Anchoring the Bar Feeder ---------------------------------------------------------------------------- 15

Table of Contents Rebel 102SE

II

4.7 Electrical Connection ----------------------------------------------------------------------------------- 15

4.8 Initial Magazine Finger Adjustment ----------------------------------------------------------------- 15

4.9 Resetting the Home Position ------------------------------------------------------------------------- 18

5. Adjustments and Settings

5.1 Adjustment of Magazine Angle ----------------------------------------------------------------------- 20

5.2 Changing Bar Pushers ---------------------------------------------------------------------------------- 21

5.3 Axial Shifting ---------------------------------------------------------------------------------------------- 22

6. Control Operation and Description

6. Rebel 80 Remote Pendant ---------------------------------------------------------------------------- 23

6.1 Control Pendant Functions ---------------------------------------------------------------------------- 23

6.1.1 Status LEDs ----------------------------------------------------------------------------------------------- 23

6.1.2 Pusher Jog Buttons -------------------------------------------------------------------------------------- 23

6.1.3 V-Tray Up and Down Buttons ------------------------------------------------------------------------- 24

6.1.4 Pre Auto and Automatic/Manual Buttons ----------------------------------------------------------- 24

6.2 Sequence for Manually Changing Bars ------------------------------------------------------------ 24

6.2.1 Unload Bar from Lathe ---------------------------------------------------------------------------------- 24

6.2.2 To Load a New Bar -------------------------------------------------------------------------------------- 25

6.3 HMI (Control Panel) ------------------------------------------------------------------------------------- 25

6.3.1 Starting the Bar Feeder -------------------------------------------------------------------------------- 25

6.3.2 Setting the Measurement Standard to Inches or Millimeters --------------------------------- 26

6.3.3 Manual Screen Functions ------------------------------------------------------------------------------ 26

6.3.4 Passwords ------------------------------------------------------------------------------------------------- 26

6.3.5 Program Storage ----------------------------------------------------------------------------------------- 27

6.3.6 Forward and Reverse Jog Buttons ------------------------------------------------------------------ 28

6.3.7 Bar Off Button --------------------------------------------------------------------------------------------- 28

6.3.8 Bar On Button --------------------------------------------------------------------------------------------- 28

6.3.9 Automatic Button ----------------------------------------------------------------------------------------- 28

Table of Contents Rebel 80

III

6.3.10 Automatic Screen Functions -------------------------------------------------------------------------- 29

7. Setup Wizard

7. Setup Wizard Screens ---------------------------------------------------------------------------------- 30

8. Maintenance

8.1 Periodic Maintenance ----------------------------------------------------------------------------------- 37

8.2 Drive Belt Tension Adjustment ----------------------------------------------------------------------- 38

8.3 Lubrication ----------------------------------------------------------------------------------------------- 39

8.4 Maintenance Screens ----------------------------------------------------------------------------------- 40

9. User Parameters

9. User Parameters 1 through 8

10. Factory Parameters

10. Factory Parameters 11 through 21 ------------------------------------------------------------------ 44

11. Service Technician Parameters

10. Service Technician Parameters 22 through 42 --------------------------------------------------- 53

12. Alarms

Alarms 1 – 4 -------------------------------------------------------------------------------------------------------- 73

Alarms 5 – 13 ------------------------------------------------------------------------------------------------------ 74

Alarms 14 – 19 ---------------------------------------------------------------------------------------------------- 75

Alarms 20 – 23 ---------------------------------------------------------------------------------------------------- 76

Alarms 24 – 26 ----------------------------------------------------------------------------------------------------- 77

Table of Contents Rebel 80

IV

Alarms 27 – 29 ----------------------------------------------------------------------------------------------------- 78

Alarms 30 – 32 ----------------------------------------------------------------------------------------------------- 79

Alarms 33 – 35 ----------------------------------------------------------------------------------------------------- 80

Alarms 36 – 38 ----------------------------------------------------------------------------------------------------- 81

Alarms 39 – 41 ----------------------------------------------------------------------------------------------------- 82

Alarms 42 – 44 ----------------------------------------------------------------------------------------------------- 83

Alarms 45 – 47 ----------------------------------------------------------------------------------------------------- 84

Alarms 48 – 51 ----------------------------------------------------------------------------------------------------- 85

Alarms 52 – 70 ----------------------------------------------------------------------------------------------------- 86

Alarms 93 – 96 ----------------------------------------------------------------------------------------------------- 87

13. Electrical System

Electrical schematic table of contents ----------------------------------------------------------------------- 88

Schematic ----------------------------------------------------------------------------------------------------------- 89

14. Parts

Parts ordering information ------------------------------------------------------------------------------------- 106

Electrical components ------------------------------------------------------------------------------------------- 106

Exploded views --------------------------------------------------------------------------------------------------- 107

1. GeneralInformation Rebel 80

1

1.General Information

Please read and understand the Manual before operating the bar feeder

1.1Contents of this Manual

The bar feeder manufacturer hasprovided this manual as an integral part of themachine.

Adherence to the instructions ofthe manual will help prevent injuryto the operator and

damage tothemachine as well as helpingto realize the maximum potential of the bar

feeder andmachine tool. Particularlyimportant points ofinformationare preceded by

the followingsymbols and text:

Warning Indicates a potential danger to life or risk ofpersonal injury. Exercise

extreme caution.

Caution Indicatesa possible hazardous condition. Take precautions accordingto the

instructions followingthese warnings to help prevent injuryto personnel or damage to the

equipment.

ImportantInformation precedes special or technical information. Additional

information can be locatedbyusingthe table ofcontents ofthis manual.

Skilled Denotes operations that must be carried out byqualifiedand skilled personnel.

Other operations may be performed byqualified personnel or trained operators.

1. GeneralInformation Rebel 80

2

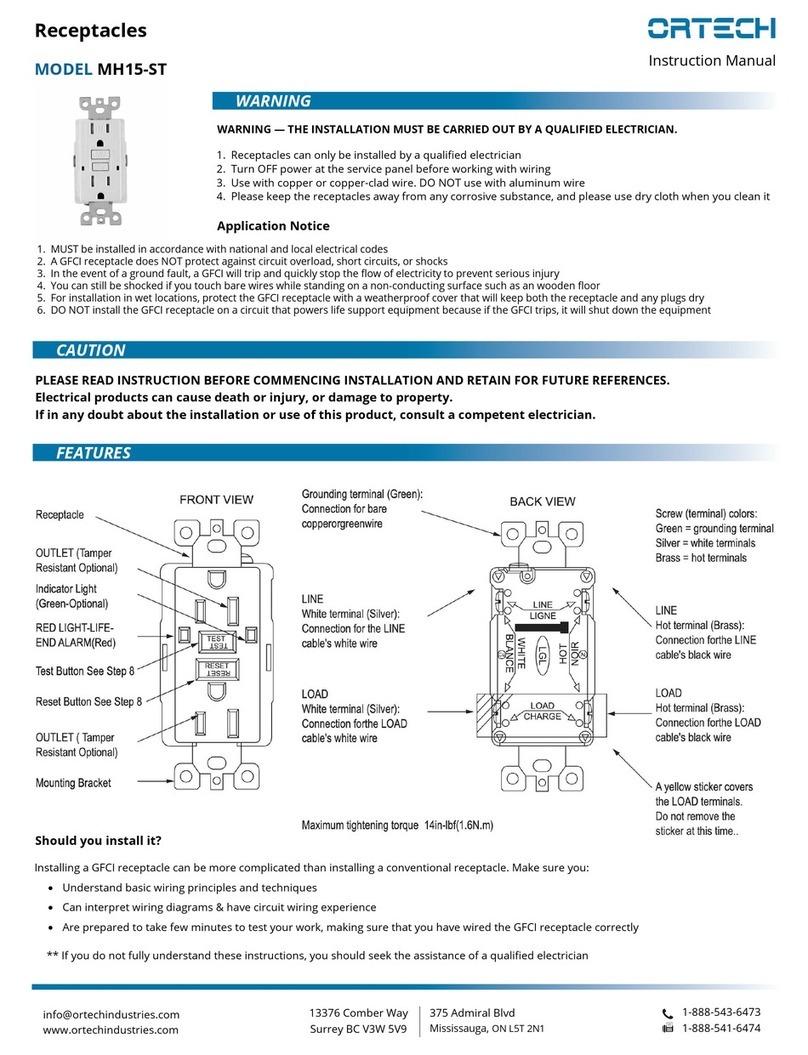

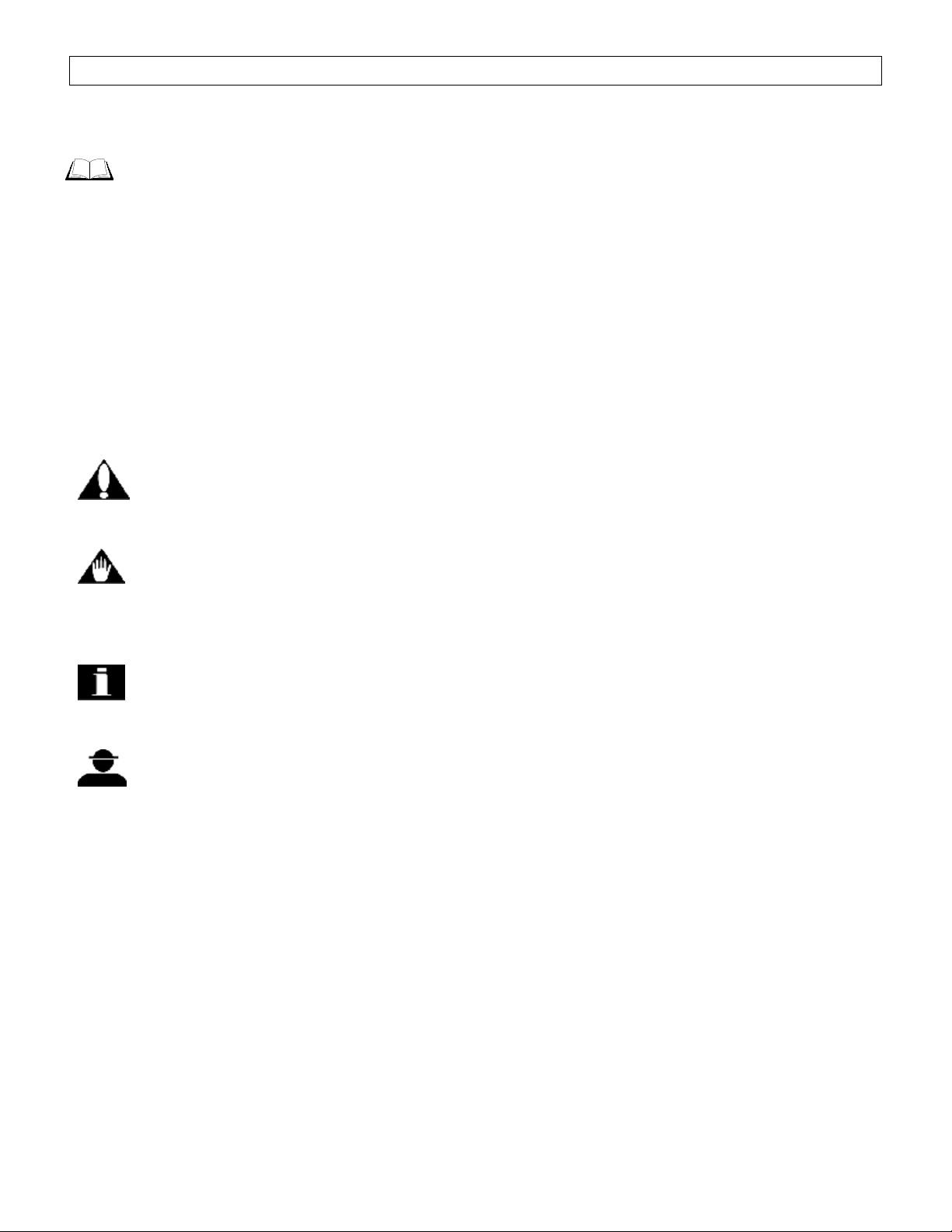

1.2 MachineData Plate

A. Nameofmanufacturer

B. Date of manufacture

C. Type(Model)

D. Serial number

E. Feedingvoltage

F. Frequency

G. Drivingvoltage

H. Control voltage

I. Machine weight

J. Amperage

Importantinformation When inquiringaboutor orderingparts pleasehave the

machine model (type) and serial number onhand.Refer to the machine dataplatefor this

information.

Technical Support

For technical support please contact the Edge Technologies Service Department

byphoneat314-692-8388 or byemail edgeservice@edgetechnologies.com

Importantinformation When calling for technical support please have the

machine model (type) and serial number onhand.Refer to the machine dataplatefor this

information.

G

I

E

C

B

A

DRIVINGVOLTAGE

FEEDINGVOLTAGE

WEIGHT

TYPE NO

11600 AdieRoad

Fax 314.692.5152

Phone 314.692.8388

www.edgetechnologies.com

edgeservice@edgetechnologies.com

Maryland Heights,MO 63043 USA

A DIVISION OF HYDROMATINC

TECHNOLOGIES

DATE

H

J

F

D

2. Technical InformationRebel 80

3

2.Technical Information

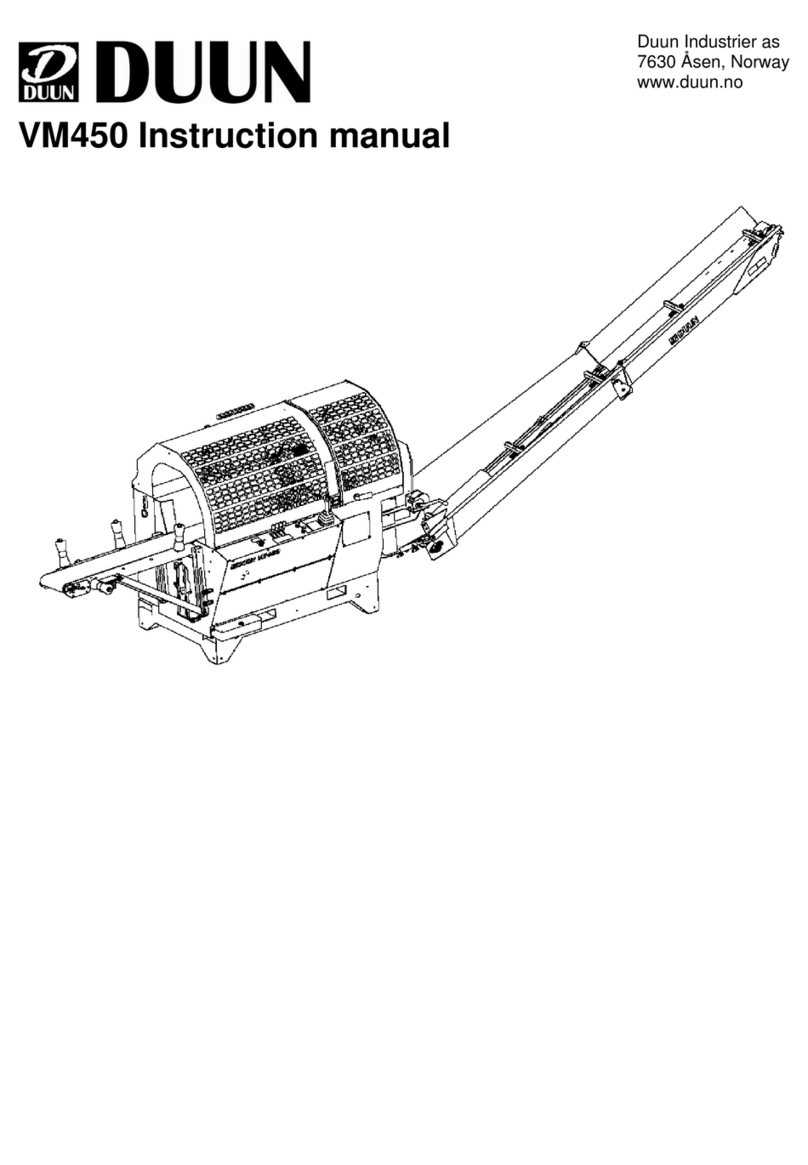

2.1Description of the Machine

The Rebel 80 is aPLC controlled, full servo automatic bar feeder designedto loadand

feedbar stock up to 4 inches in diameter.

FeaturesoftheRebel 80 include:

Mitsubishi PLC controller anddrive system.

All electrical operation, eliminatingthe need for shop air.

Storagefor spindle liners incorporated into the bar feeder base.

An axial shiftingdevice to allowthe bar feeder to be moved awayfromthe lathe spindle for

maintenance or spindle liner changes with no loss of alignment.

Soft load bar presentation to reducethe jarringeffectofheavy barsdroppinginto the channel.

Parameter driven fully automatic bar diameter adjustment andpusher thrust.

Fixed piece feeding,sub-spindle mode and push to a stopmethods ofbar feeding.

Return and wait function toreduce bar change timebyup to30%.

Touch screen controlpanel with memoryfor 36 individual jobs.

Easyto changepushers, diameters 10and19 (optional 8mm pusher available)

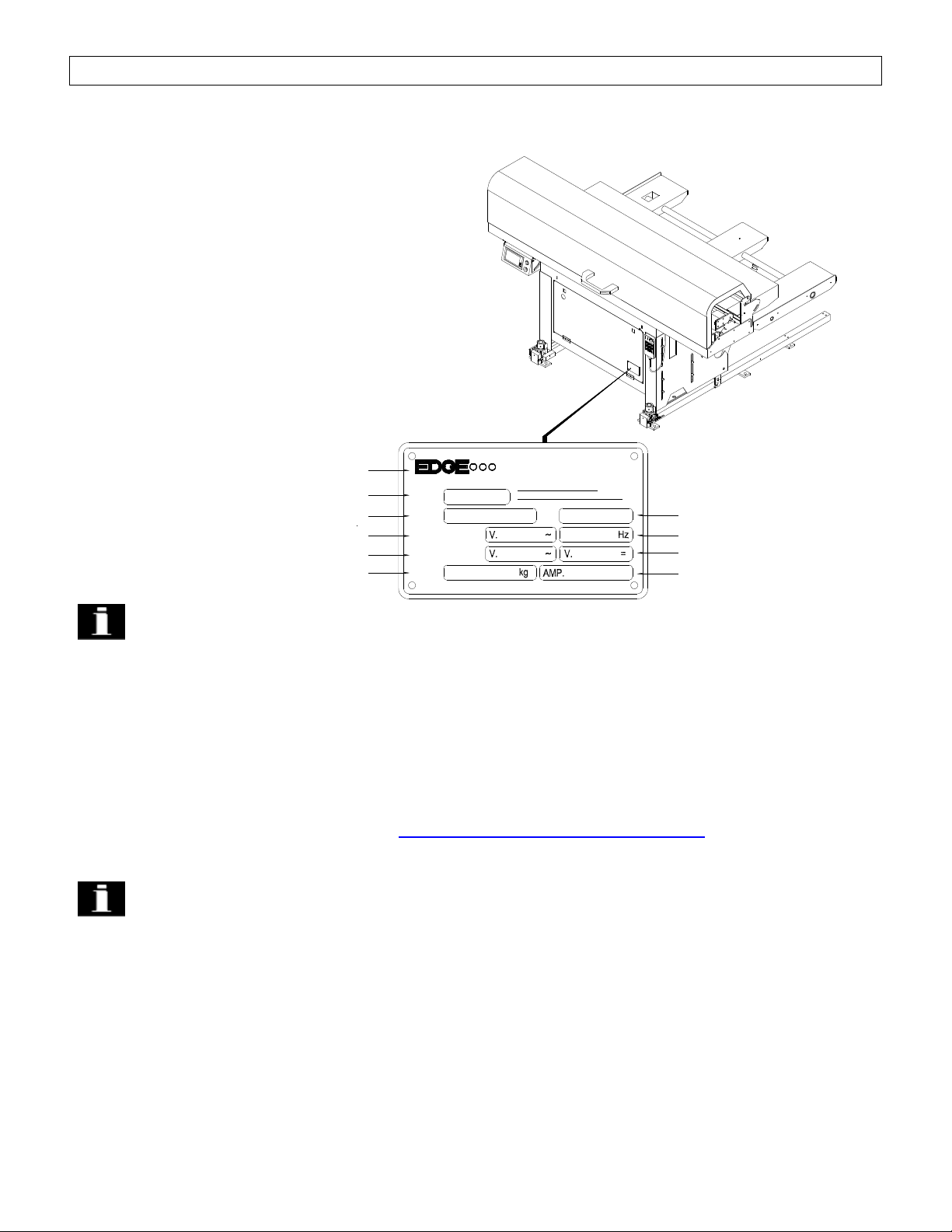

2.2Machine Footprint

2. Technical InformationRebel 80

4

2.3Specifications and Capacities

Bar diameter capacity8mmto 80mm (.315” to 3.150”)

Maximumbar length60” (NOTTO EXCEEDSPINDLE LENGTH)

Magazine rack capacity30” (60 ½” bars, 301.0” bars, 15 2.0” bars)

Bar weight 175 lbs. per bar not to exceed 1500 lbs. total

Power consumption 1 kW

Operatingvoltage 200-230VAC/60Hz– 3phase

Control voltage24VDC

Centerline height950-1350mm(37.4” to53.15”)

Machine footprint84” X48”

Machine weight 1100 lbs.

2.4Bar Stock Requirements

Material should be relativelystraight and clean. While bent stockwill not necessarilycause

problems within thelathe spindle while turning, it mayprevent loadingifbar condition is such

that thebar collides with the back of the lathe spindle or it binds while feedingintothe spindle.

Bars ofsmall diameter maynot pick up properlyfromthe magazine if theyare not straight.

Excessive chips, burrs or dirt maycause bindingwithin the spindle.

The ends ofthe bar should be relativelystraight tothe diameter of the bar to help ensureproper

positioningof the bar as it reaches thefacingpositionand tokeep the bar pusher fromslidingoff

the bar while feedingthe material.

Under no circumstances should a bar be run that extends pastthe end of the lathe

spindle!Failure to complywith this rule mayresult in injuryor death to the operator or

personnel in the vicinityof the machine and /or severe damage to the machinery!

2. Technical InformationRebel 80

5

2.5Safety

The bar feeder is designed to be safeandreliable to operate. However, the machine can be

dangerousifused improperlybyuntrainedpersonnel. Personnel should befamiliar with the

operatinginstructions ofthe equipment before usingandmust follow standard safetypractices.

The bar feeder is equipped with safetydevices to prevent accidental damage to the machine

and injuryto theoperator. These devices must notbebypassedor tamperedwith.

2.5.1 Covers

The bar feeder is supplied with covers to prevent access tomovingparts duringoperation. The

hood of the bar feeder is equippedwith a safetyswitch, S6, to place the machine inalarm ifthe

hood is not closed. The magazine cover prevents access to the material on the rackand the

bar separators.

2.5.2 Axial Shifting Switch

The bar feeder is equipped with an axial shiftingdevice to allowthe machine to bemoved away

fromthe lathe without losingthe alignment. A safetyswitch, S27,onthe axial shiftingdevice

prevents operation of the bar feeder if it is not in the proper position.

2. Technical InformationRebel 80

6

2.5.3 Lathe Door Safety

An input to the bar feeder for monitoringthelathedoor is available. Ifused, this input will

prevent movement of the bar pusher when the lathe door is open.

2.5.4 EmergencyStop Buttons

There aretwo emergencystop buttons on the bar feeder. Button ES1 is the emergencystop

button on the HMI control panel housing. Button ES2 is the emergencystop buttononthe

remote pendantcontrol. Pressingeither emergencystop button disconnects the Emergency

Stop Relay. The emergencystop relayturns offrelays MC1 and MC2 which disconnects power

fromthe servo drive and the outputs fromthe bar feeder to the lathe.

Contacts fromthe emergencystop buttons are incorporated into theinterfacewith the lathe

emergencystopcircuitto enable the lathe to be manuallyplaced into emergencystop condition

fromthe bar feeder control panel.

3. Transportation and Handling Rebel 80

7

3.Transportation and Handling

Warning Theweight ofthe bar feeder without packagingis approximately1100 lbs.

Verifythe equipment to beusedfor movingthe bar feeder is ratedto safelylift the weight ofthe

bar feeder plus the packagingmaterial. Makespecial notethat the bar feeder is top heavy and

take proper precautions.

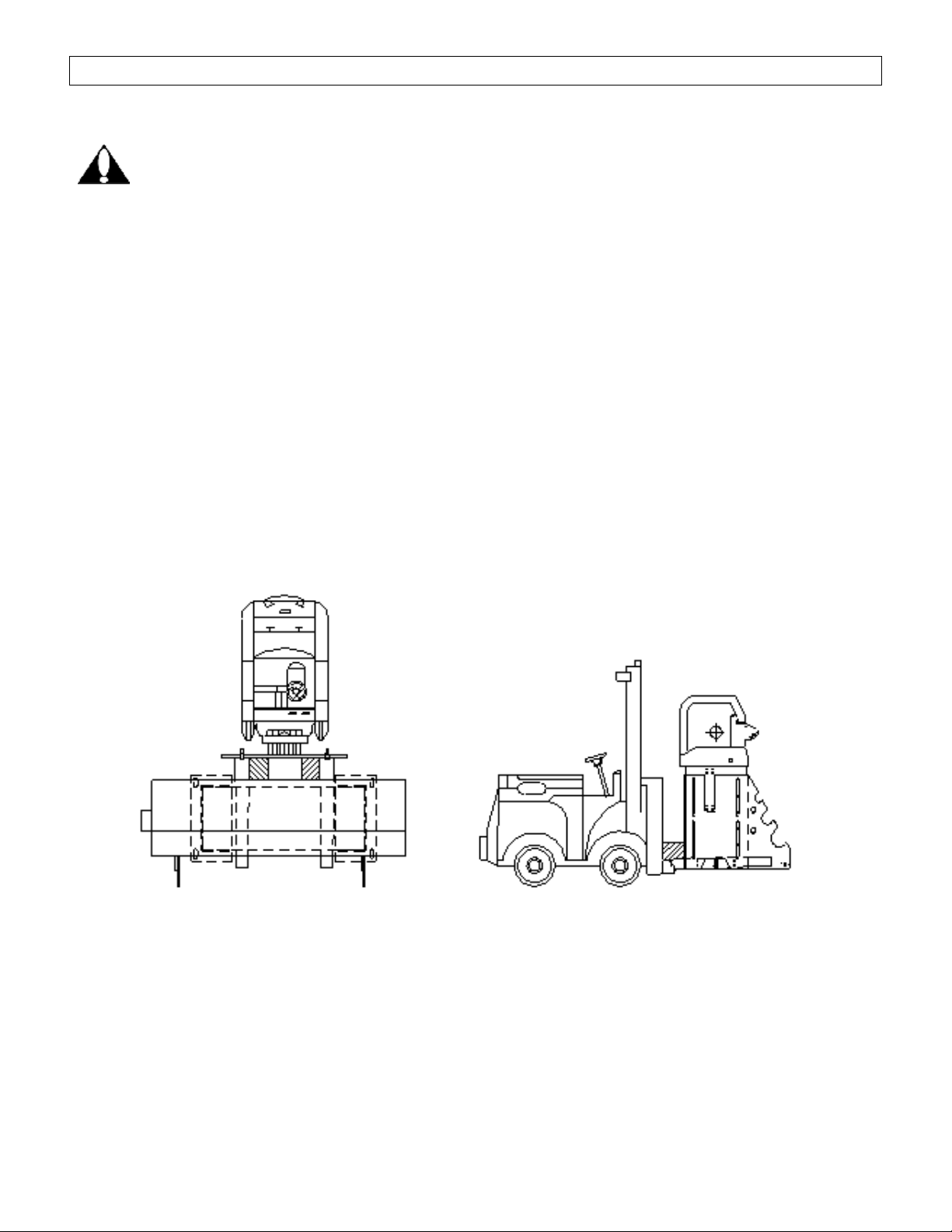

3.1Lifting and Moving byForklift

Liftingandmovingthe bar feeder byforklift is the preferredmethod ofhandlingthemachine.

Themachine shouldbe moved onlybypersonnel qualified in the operation offorklifts. The forks

must extend pastthemachine cabinet, see the drawings below. Lift themachinefromthe side

opposite the magazinemaintainingsufficient clearance fromtheforkliftmasttoavoid contact.

Care should be takento keep the load balanced. Do not lift the machine anyhigher than

necessary.

3. Transportation and Handling Rebel 80

8

3.2Lifting with acrane

Liftingandmovingthe bar feeder with a craneis possible if a forklift is not available. The crane

must be capable ofliftingat least 1,100lbs. Themachine shouldonlybe moved bypersonnel

qualifiedin the operation of the crane. Two padded liftingbars that extend at least 12inches

past the sides ofthe cabinet are required. Ideallythe liftingbars willhave eyebolts attached.

The liftingbars are placed under thepan of the bar feeder next to the electrical cabinet (see

diagram). The liftingstraps or chains should be padded to prevent damage tothe sheet metal

covers. Themachine shouldbe lifted slowlya short distance. The balance should be checked

and adjusted if necessarybefore continuing. Never lift themachinehigher than necessary.

4. Installation Rebel 80

9

4. Installation

Caution Thefollowinginstructions should be carriedoutonlybyskilled, trained

personnel. Proper alignment andinstallation is crucial to achieve optimal performanceofthe

bar feeder.Improper alignment can cause difficultyduringloading, damageto the bar feeder

and damage to the actuator andspindle bearings on the lathe.

4.1Lathe Preparation

Prior to beginningthe bar feeder installation the lathe must be properlyleveled. It is strongly

recommended that thelathebeanchored tothe floor to prevent it fromshifting.

4.2Distance FromLathe

The bar feeder shouldbe placed as closelyas possibleto therear ofthelathe while maintaining

sufficientclearance toallowthe bar feeder to be moved on the axial shiftingdevice. The area to

be occupied bythebarfeeder while shifted awayfrom the lathe should alsobe checked for

sufficientclearance. The maximumpusher extension fromthe front ofthe bar feeder is

1650mm(64.96”).

4. Installation Rebel 80

10

4.3Axial Shifting Device

The axial shiftingdevice canbeconfigured to move the bar feeder awayfrom the lathe either

parallel or perpendicular to the spindleaxis. No additional parts arerequired for changing

direction ofthe axial shift.

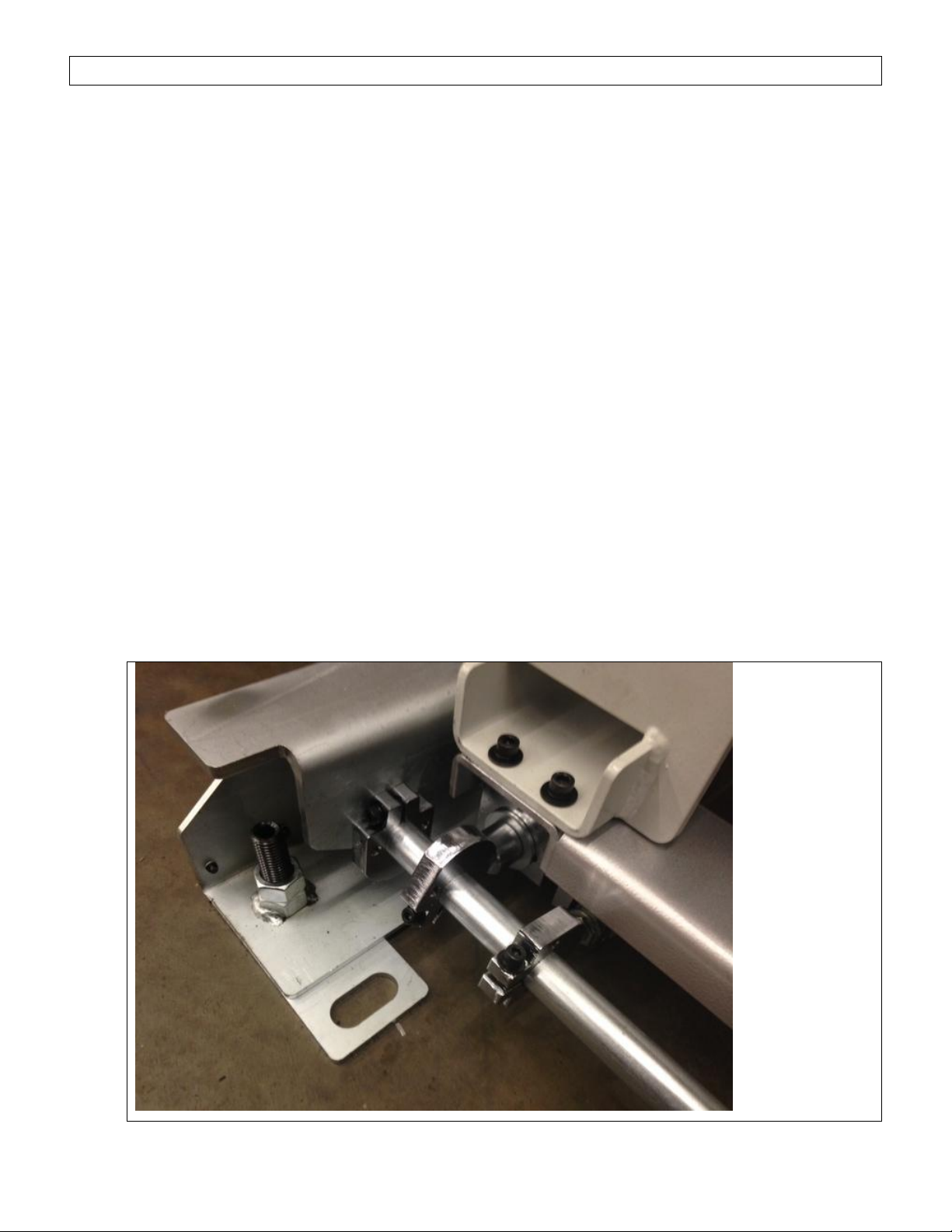

4.3.1 Prepare the axialtrack slide

·Begin byplacingtheaxial track slide rails on the floor.

·Locate and fasten the foot lockcross rail toend oftheaxial track rail sides that would be

the open hoodside ofthe bar feeder.

·Locate and fasten the cross rail rod between the rear ofaxial track slide rails.

·Be sureto loosen the4 axial track jack screws so there is zero preload on the floor.

·Loosen the socket head capscrews that fasten the mountinglock plate to the axial track

slide rail, then press lock plateupso there are nogaps between theaxial track bottom

thentightenscrews.

4. Installation Rebel 80

11

·Raise and supportthebar feeder to install the axial track roller slides to the baseofthe

bar feeder.

·Once axial track roller slides are installed place bar feeder onto axial track slide rails. Be

sure the roller bearings engage the slide track.

·Position bar feeder tothe full forward positionon the axial track andlock into place with

the footlock cross rail.

·It maybe necessarytoadjustlock stops on thefoot lock crossrail sothere is no

movement ofthe bar feeder once locks are engaged. Besure it does not require

excessive force to lockor unlockthe bar feeder with the foot lockrail. There should be

just enoughforce to remove bar feeder movement when locked.

·Attachthe axial track switch to the leftfront, under side of the bar feeder. Adjustswitch

camto contact the switch roller.

·Position the final installposition of the bar feeder and axial track assemble and perform

alignment. See section4.5 for alignment procedure.

4. Installation Rebel 80

12

The axial track in position switch (LS03) is on the inside of one axial track. Thetwo latches are

mounted to the outside ofthe tracks.

The tracks should be leveled in both theXand Z axis. Keep the rails as closeas possible to the

floor.

Caution

Themagazine is heavy and will require a minimumof two people toinstall.

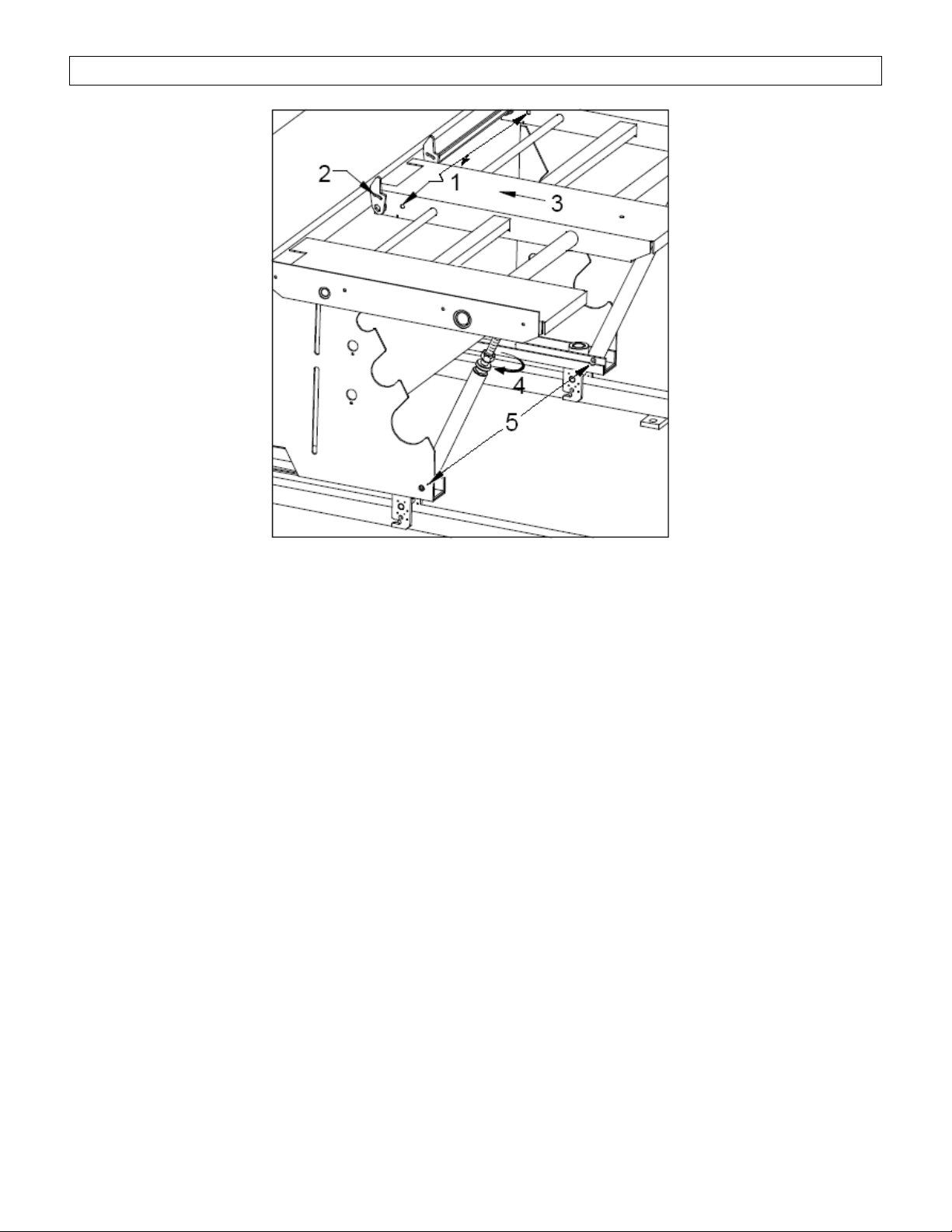

4.4Magazine attachment

Themagazine is notattached duringshipment and must be installedon site. Before liftingthe

magazine, loosen screws 2 (2 places) and remove screws 1 (3 places). Attach thetwo braces

with the bolts(5). Lift the magazine and slideit into the feeder so the center section is between

the bar lifters (2). Thread the screws ofthe braces into the nuts on the underside of the

magazine (4). Secure the magazine with the 3 screws (1). Adjust the magazine to the proper

level for the diameter and profile of the material to be run (See section 5).

Caution Magazine angle adjustment should never exceed 20 degrees or damage to

material fingers will occur.

4. Installation Rebel 80

13

4. Installation Rebel 80

14

Caution

Do notattempt tomove the bar feeder alignment when the bar stock or thebar pusher are

extendedintothe lathespindle. Damage to the bar pusher or lathespindle mayoccur.

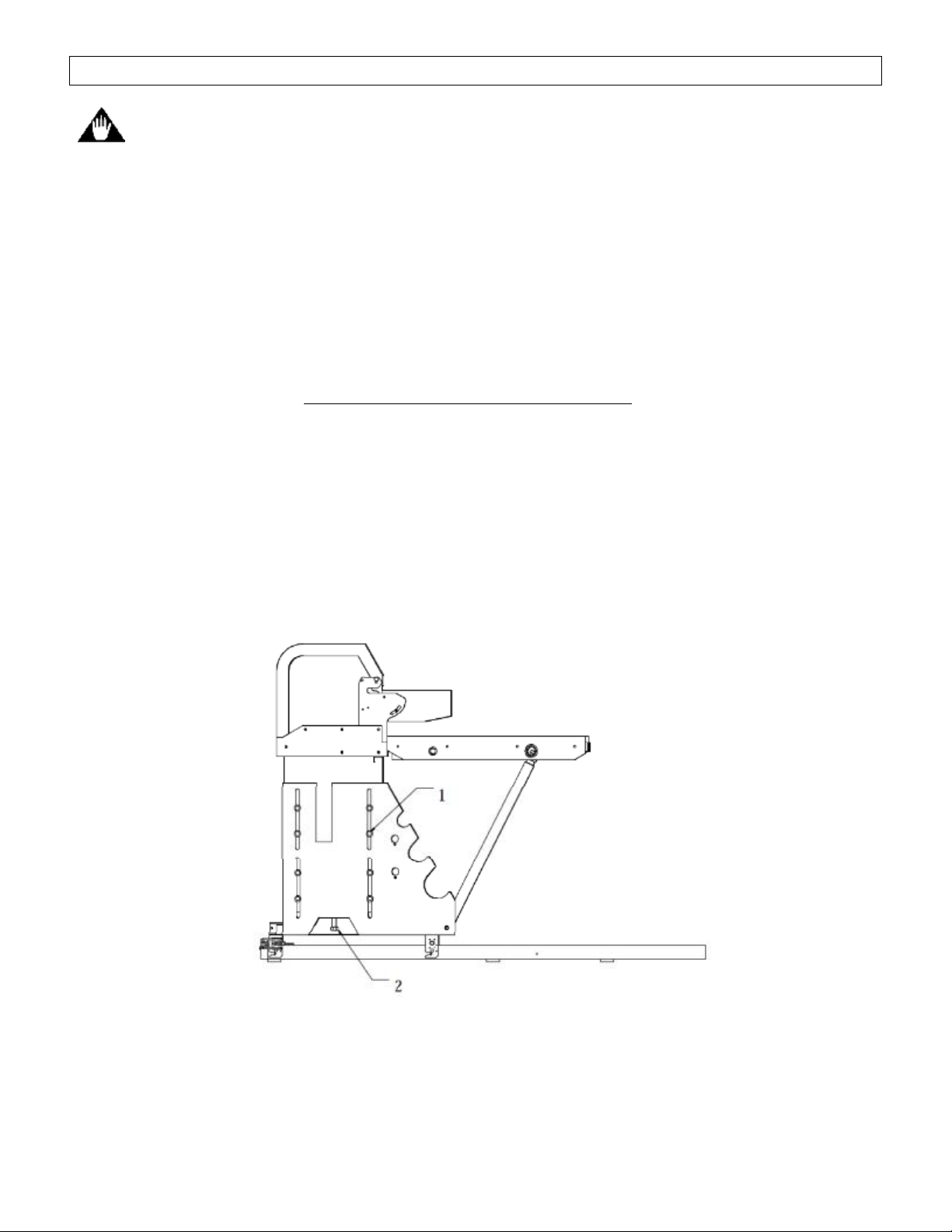

4.5Alignment

The preferred andmost precise method of barfeeder alignment is with the Edge Technologies

Laser Alignment kit, part number EZ90001 bycontactingEdge Technologies Parts department

at (314) 692-8388 or email edgeservice@edgetechnologies.com

4.5.1 Alternate method of alignment

Elevation of the bar feeder is adjusted bythetwo jack screws located at thecenter of each

stand. Loosen the fourbolts securingthelegto the stand(1). Turnthe jack screw(2) to raise

or lower the bar feedercenter height. Theside-to-side alignmentis set byslidingthe bar feeder

on the floor.

·Choosea straight piece ofbar stock with a diameter asclose as possible to theboreof

the lathespindle.

·In the bar feeder parameters enter the bar length.

4. Installation Rebel 80

15

·Place the bar on the V-trayand raise the V-tray to positionusingthe trayup button.

·Slide the stock toward the spindle.

·Look into thespindlefromthe chuck end and observe theringoflight around the bar

stock. Move the bar feeder sothe ringis equal all around thestock.

·Once the bar is centered at the end ofthe spindle push itintothe lathe.

·Lookingthrough the spindle fromthe chuck the goal is tohave the bar equallyspaced

fromthe sides.

·The bar will rest on thebottom of thebore as it moves further into thespindle. This is not

a problem as longas the bar moves freely.

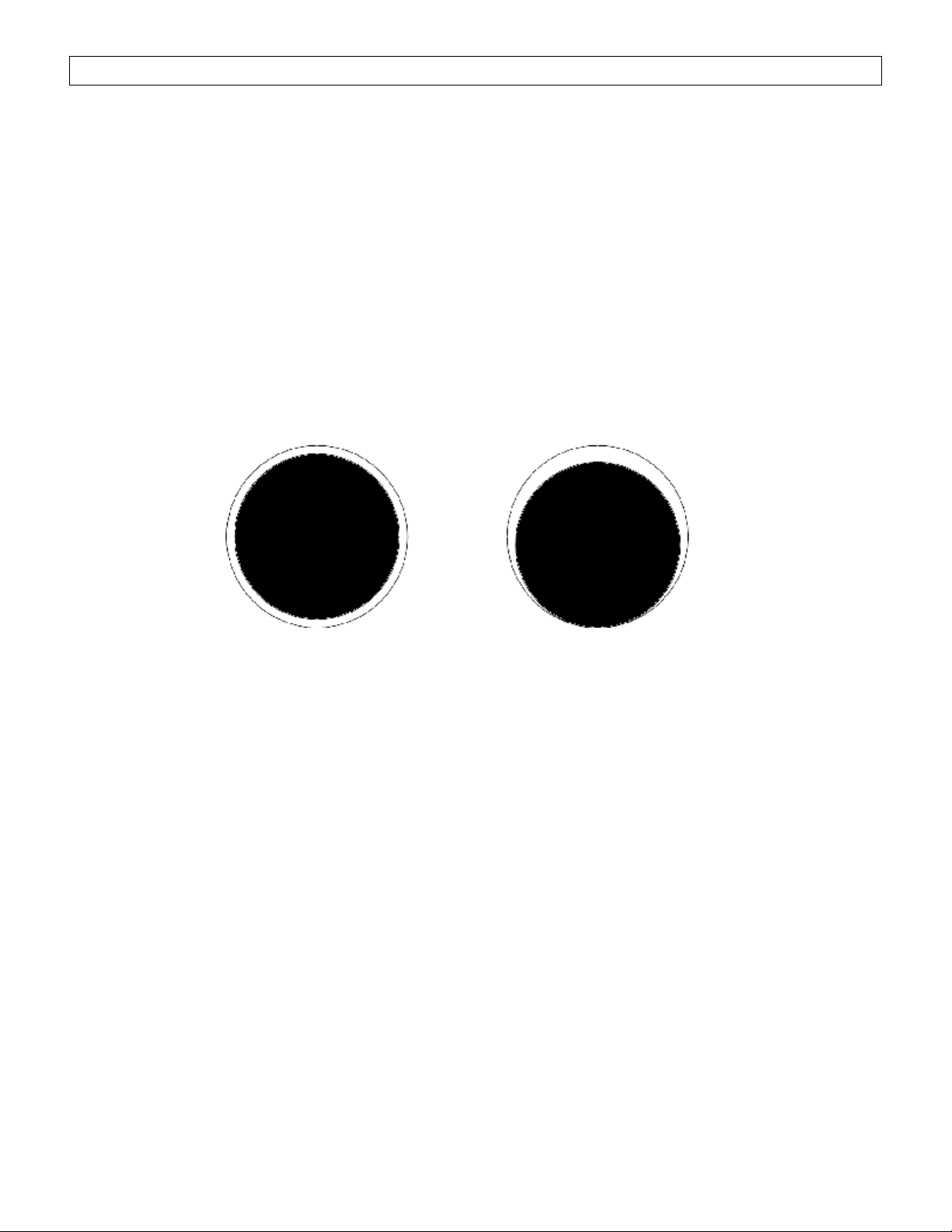

Bar centeredin spindle Restingon bottomofspindle

4.6Anchoring the bar feeder

When the alignment is correct the bar feeder must be anchoredto thefloor to prevent it from

movingout of position.The bar feeder is supplied with ½” diameter anchor bolts to secure the

axial track to thefloor. It is recommended to drill the holes for theanchor bolts through thefloor

ifpossibleor atleastas deep asthe anchor bolt is longso that the bolt maybe driven flushwith

the floor should themachine need tobemoved. Alignmentshould be rechecked after anchoring

the bar feeder to the floor to make sure the alignment has notchanged.

Small adjustments to the alignmentcanbemade bythe levelingnuts on the levelingfeet.

4. Installation Rebel 80

16

4.7Electrical connection

The power for the bar feeder and the input and output signals between the bar feeder and lathe

are supplied throughthe interface cable.The interfacecable is pre-wired for the lathe

application. The installer should verifythe connection to the lathe before applyingvoltage to the

system. If the lathe is not equipped with an interface connection forthe bar feeder a plugand

cables will be supplied.The lathemust support a magazine type bar feeder interface for the

machines to be connected.

Caution Failure to followthe procedure insection 4.8mayresult in damageto the

magazine feed motor and linkage.

This procedure is for the initial setup onlyand shouldnotbeperformed again unlessinstructed

to do so bythe EdgeTechnologies service department.

4.8Initial magazinefinger adjustment

·Remove anystock fromthe magazine.

·Fromthe User Level 1 screen select Maintenance screen,enter password as required.

Table of contents

Other Edge Industrial Equipment manuals