Spectris HBM U2B User manual

Force Transducers

U2B

Mounting instructions

B 20.U2B.20 en

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

3

U2B

HBM 24.5.2000

Contents page

Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Instructionsfor use 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Structure and operating mode 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Measuring device 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Housing 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Measurementprocess, output signal 7. . . . . . . . . . . . . . . . . . . . . . . .

2.4 Compensatingfor disturbance variables 8. . . . . . . . . . . . . . . . . . . . .

3 Operation on site 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Ambient temperature 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Humidity 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Ambient pressure 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Chemical influences 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Contamination 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanicalinstallation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Important precautions during installation 10. . . . . . . . . . . . . . . . . . . . .

4.2 General installation guidelines 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 U2B installation for tensile loading 11. . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 U2B installation for tensile and compressive loading 12. . . . . . . . . .

5 Electrical connection 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Notes on cabling 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Six-wire connection 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Four-wire connection 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Technical Data 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

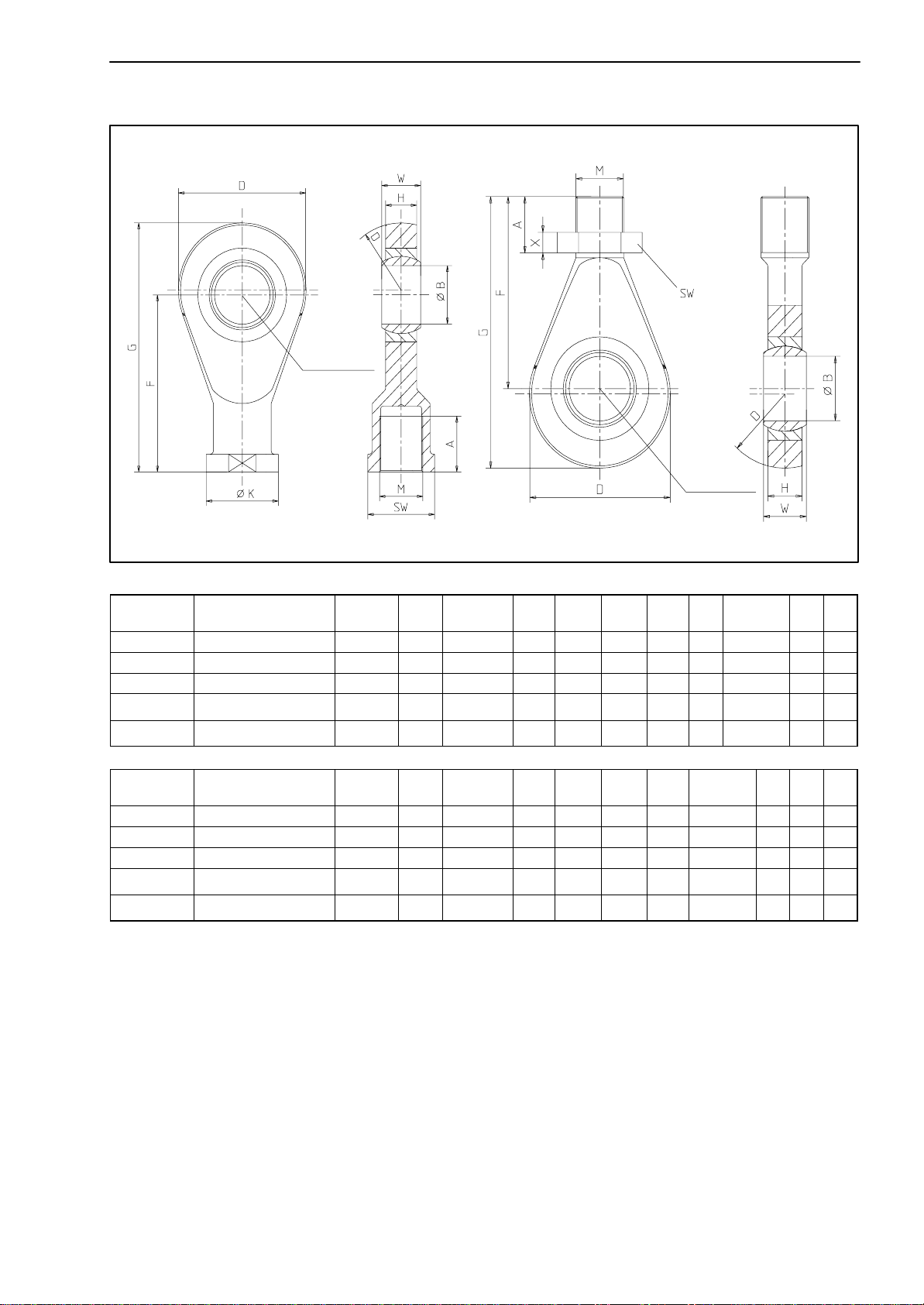

7 Dimensions 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Copy of Declaration of Conformity 20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

4U2B

HBM 24.5.2000

Safety instructions

Use in accordance with the regulations

The U2B force transducer is to be used

exclusively for force measurement

tasks and directly related control tasks

. Use for any additional purpose shall

be deemed to be not in accordance with the regulations.

In the interests of safety, the transducer should only be operated as described

in the Mounting Instructions. It is also essential to observe the appropriate

legal and safety regulations for the application concerned during use. The

same applies to the use of accessories.

The transducer is not a safety element within the meaning of its use as

intended. Proper and safe operation of this transducer requires proper

transportation, correct storage, assembly and mounting and careful operation

and maintenance.

General dangers of failing to follow the safety instructions

The U2B force transducer corresponds to the state of the art and is fail-safe.

The transducers can give rise to remaining dangers if they are inappropriately

installed and operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair

of a force transducer must have read and understood the Mounting

Instructions and in particular the technical safety instructions.

Remaining dangers

The scope of supply and performance of the transducer covers only a small

area of force measurement technique. In addition, equipment planners,

installers and operators should plan, implement and respond to the safety

engineering considerations of force measurement technique in such a way as

to minimise remaining dangers. Prevailing regulations must be complied with

at all times. There must be reference to the remaining dangers connected with

force measurement technique.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

5

U2B

HBM 24.5.2000

In these mounting instructions remaining dangers are pointed out using the

following symbols:

Symbol: DANGER

Meaning:

Maximum danger level

Warns of an imminently dangerous situation in which failure to comply with

safety requirements will result in death or serious physical injury.

Symbol: WARNING

Meaning:

Potencially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious physical injury.

Symbol: CAUTION

Meaning:

Possibly dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could result in damage to property or some form of

physical injury.

Symbol: NOTE

Means that important information about the product or its handling is being

given.

Symbol:

Meaning:

CE mark

The CE mark enables the manufacturer to guarantee that the product

complies with the requirements of the relevant EC directives (see Declaration

of Conformity at the end of this document).

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

6U2B

HBM 24.5.2000

Unauthorised conversions and modifications are prohibited

The transducer must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall

exclude all liability on our part for any damage resulting therefrom.

Qualified personnel

These transducers are only to be installed and used by qualified personnel,

strictly in accordance with the technical data and the safety requirements and

regulations listed below. It is also essential to observe the appropriate legal

and safety regulations for the application concerned. The same applies to the

use of accessories.

Qualified personnel means persons entrusted with the installation, fitting,

commissioning and operation of the product who possess the appropriate

qualifications for their function.

Conditions on site

Protect the transducer from damp and weather influences such as rain, snow,

etc.

Maintenance

The U2B force transducer is maintenance free.

Accident prevention

Although the specified nominal force in the destructive range is several times

the full scale value, the relevant accident prevention regulations from the

trade associations must be taken into consideration.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

7

U2B

HBM 24.5.2000

1 Instructions for use

The U2B series of force transducers is suitable for measuring tensile forces

and pressures. They measure static and dynamic forces with great accuracy

and therefore require careful handling. Transport and installation of the de-

vices require special attention for the same reason. Transducers can be per-

manently damaged if knocked or dropped.

These force transducers are manufactured from stainless steel and are suit-

able for use under harsh environmental conditions and severe operating

constraints. They are maintenance free and can even be installed in places

that are hard to reach. Their measuring signals can be transmitted to remote

measuring equipment.

The perfect seal that protects the sensitive strain gauge applications has to be

maintained by the housing in all conditions. The base of the housing must

therefore be treated with special care, since it is very thin.

The permitted limits for mechanical, thermal and electrical loadings are given

in the Technical Data. Please take these points into account whenever plan-

ning for measurement arrangements and when installing or operating the

equipment.

2 Structure and operating mode

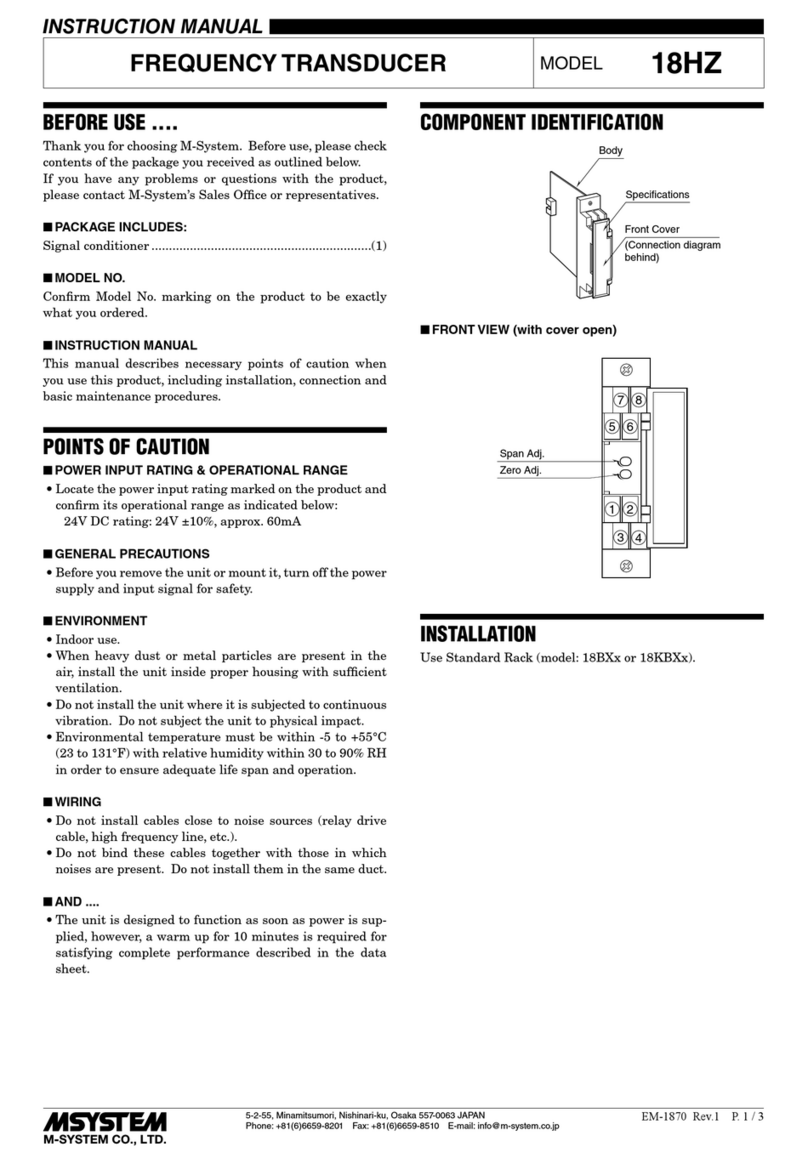

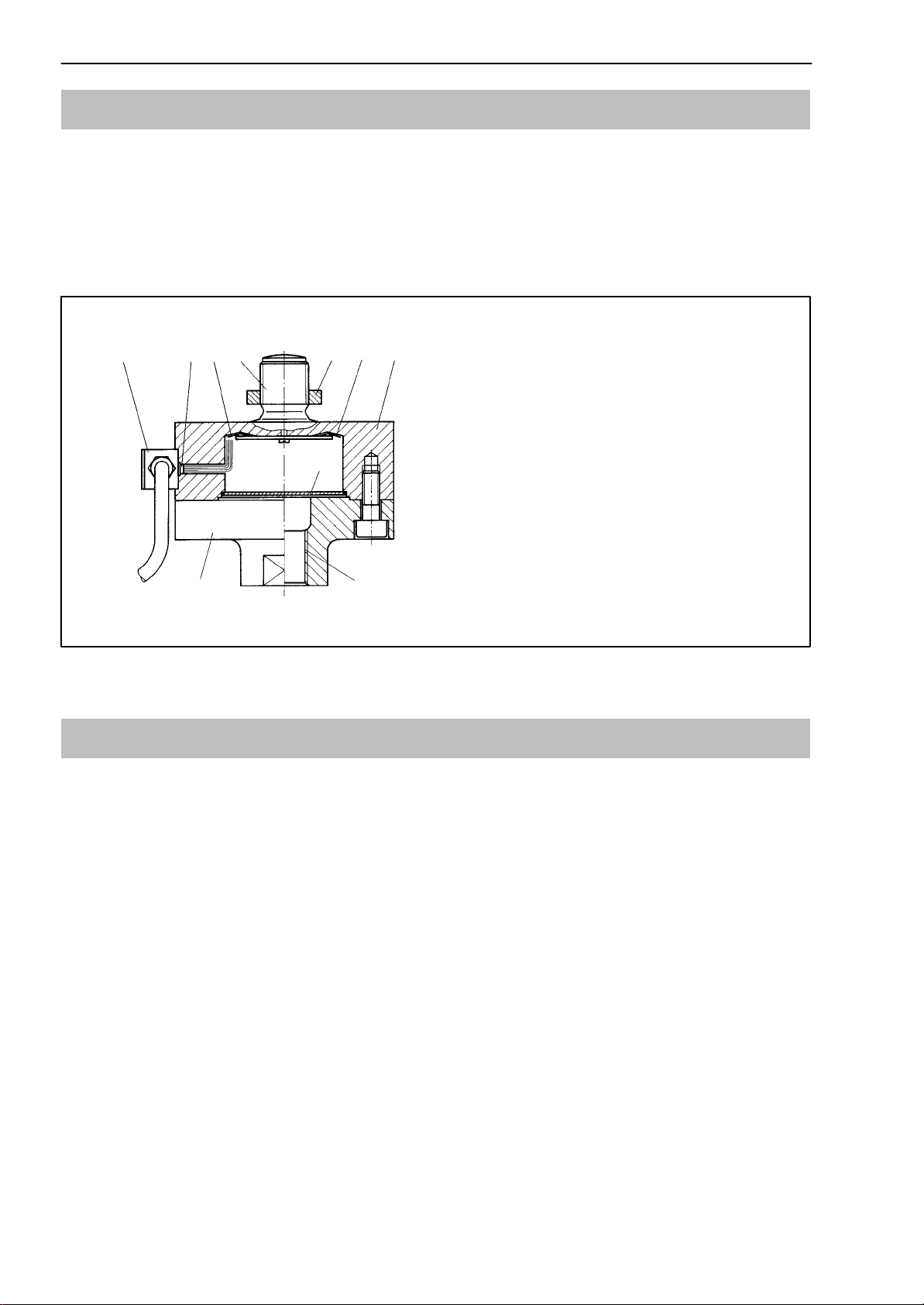

2.1 Measuring device

The measuring device is a stainless steel measuring spring to which strain

gauges (SG) are applied. The measuring device simultaneously forms the up-

per part pf the transducer housing (Fig. 2.1). The SGs are arranged so that

four of them are stretched and the other four are compresses when a force is

applied to the transducer. The transducer circuit contains correcting and com-

pensating resistors, in order to reject undesirable influences on the zero signal

and sensitivity.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

8U2B

HBM 24.5.2000

2.2 Housing

The housing with its integral measuring spring is closed by a floor plate

welded to its underside. The measuring spring on the force transducer has a

threaded pin which acts as a force conductor. A removable adapter is

screwed to the lower part of the housing and acts as a force conductor via

jointed eyelets (see Section 7).

12

3

4

57

8

9

61

1 = Strain gauges

2 = Housing with integral measuring spring

3 = Adapter

4 = Lock nut

5 = Threaded pin for force conductor

6 = Glass bushing

7 = Cable chest

8 = Welded cover

9 = Internal thread

Fig. 2.1: Schematic diagram: U2B

2.3 Measurement process, output signal

A force acting upon the transducer will elastically deform the SGs applied to

the measuring body. Their electrical resistance then changes in proportion to

the change in their length. This disturbs the balancing of the measurement

system wired in the form of a Wheatstone bridge, resulting in an output volt-

age UAat contacts 1 and 4 if a bridge excitation voltage UBis present at

points 2 and 3 on the bridge.

The ratio between the voltages, UA/UB, expressed in mV/V, is a measure of

the sensitivity of the force transducer. The change in output voltage UAis lin-

ear to the acting force. Provided the force transducer is connected in accor-

dance with Fig. 5.1 and as specified in the User Manual for the amplifier con-

cerned, compressive forces are displayed with a positive operating sign and

tensile forces are shown with a negative operating sign. The force transducer

is electrically connected in 6-wire mode (see Section 5.2). To reverse the po-

larity, the white and red wires in the cable should be transposed.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

9

U2B

HBM 24.5.2000

2.4 Compensating for disturbance variables

The geometry of the measuring body and the positioning of the SGs ensure

that the output signal from the transducer suffers only minimal distortion if the

force being measured is affected by superimposed lateral forces and/or tor-

sional and bending moments. The specifications for this can be found in the

Technical Data. In the interests of greater accuracy, however, it is generally

better to try to prevent spurious loadings of this kind altogether. The U2B also

has separate lateral force compensation which reduces lateral force in-

fluences to a minimum (see Technical Data).

The influence of temperature on the zero signal and sensitivity are compen-

sated. Changes in ambient pressure have the same effect as additive (sub-

stractive) forces (see Section 3.3).

3 Operation on site

3.1 Ambient temperature

For optimum measurement results, keep to the rated temperature range. The

best conditions are constant or very slowly changing temperatures. Measure-

ment errors due to temperature are the result of uneven warming (e.g. radiant

heat) or cooling. A radiation shield and all-round heat insulation provide no-

ticeable improvements. However, they should not be allowed to form any kind

of force leakage.

3.2 Humidity

Extremes of humidity or tropical conditions have no effect on the measure-

ment capability of the transducer, provided they are within the specified limit

values (protection system IP67 in accordance with DIN EN 60529).

Note:

Moisture should not be allowed to penetrate the free end of the connector

cable.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

10 U2B

HBM 24.5.2000

3.3 Ambient pressure

Ambient pressure should be between 0 and 5 bar. Please note that changes

of pressure alter the zero point:

Nennlast 20 kN 500 N 1 kN 2 kN 5 kN 10 kN

Zero point modification

[% sensitivity/10 mbar] ≤±0.004 ≤±0.141 ≤±0.071 ≤±0.035 ≤±0.014 ≤±0.007

Nennlast 50 kN 100 kN 200 kN

Zero point modification

[% sensitivity/10 mbar] ≤±0.002

3.4 Chemical influences

Transducer housings are manufactured from stainless steel. They can be

used in a corrosive environment.

3.5 Contamination

Dust, dirt and other foreign bodies should not be allowed to accumulate to

such an extent that part of the measured force is diverted to the housing so as

to falsify the measured value (force leakage).

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

11

U2B

HBM 24.5.2000

4 Mechanical installation

4.1 Important precautions during installation

•Handle the transducer carefully.

•Do not overload the transducer.

•During or directly after installation the transducer should be bridged with a

50 mm2stranded copper wire (a highly flexible earth cable (EEK) obtain-

able from the HBM delivery programme). The cable is screwed to the top

and bottom of the transducer. This prevents welding current from flowing

across the transducer and welding the force triggering point.

•Where there is a risk that the transducer might burst and endanger per-

sonal safety if overloaded, additional safety measures need to be taken.

4.2 General installation guidelines

The forces must as far as possible act on the transducer in precisely the di-

rection of measurement. Torsional and bending moments, eccentric loadings

and lateral forces lead to measurement errors, and if the limit values are ex-

ceeded the transducer can be destroyed. Lateral forces include components

corresponding to process quantities that may be obliquely introduced. As an

aid to installation, HBM supplies jointed eyelets for series U2B transducers as

in Section 7. These aids to installation prevent the introduction of torsional

and bending moments as well as lateral and oblique loadings into the trans-

ducer.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

12 U2B

HBM 24.5.2000

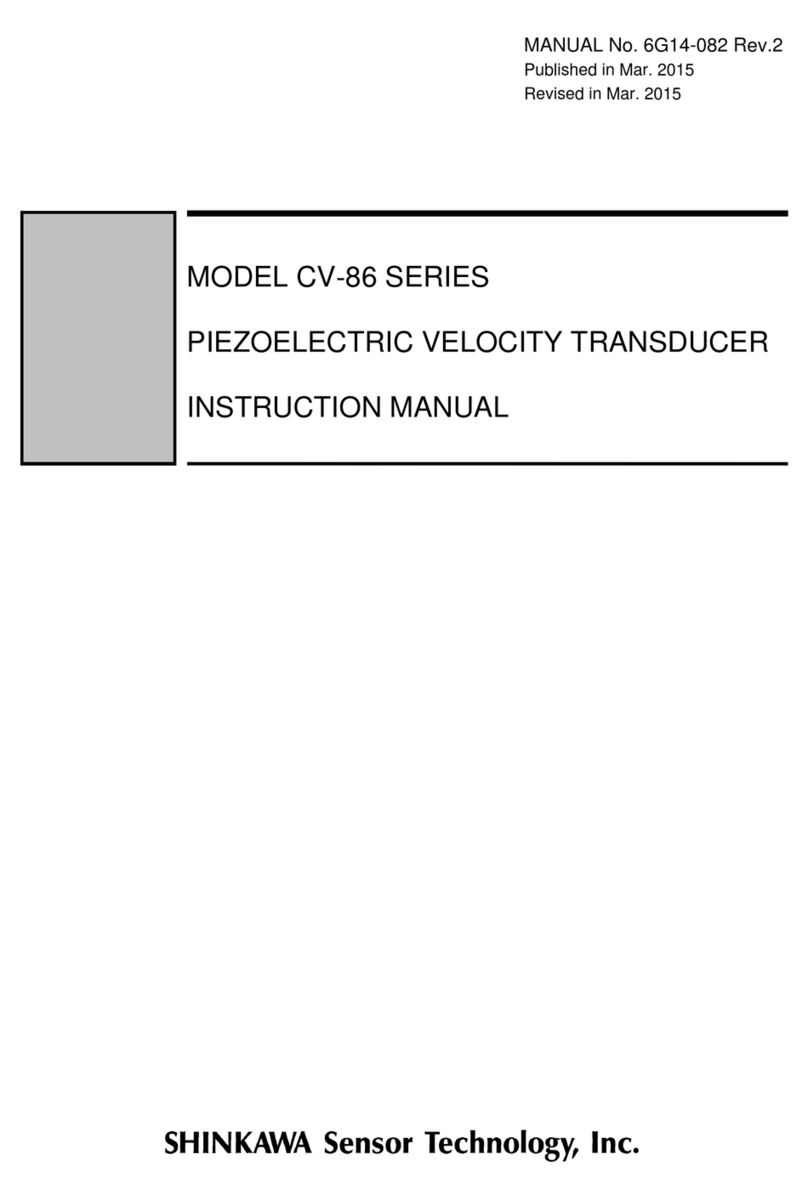

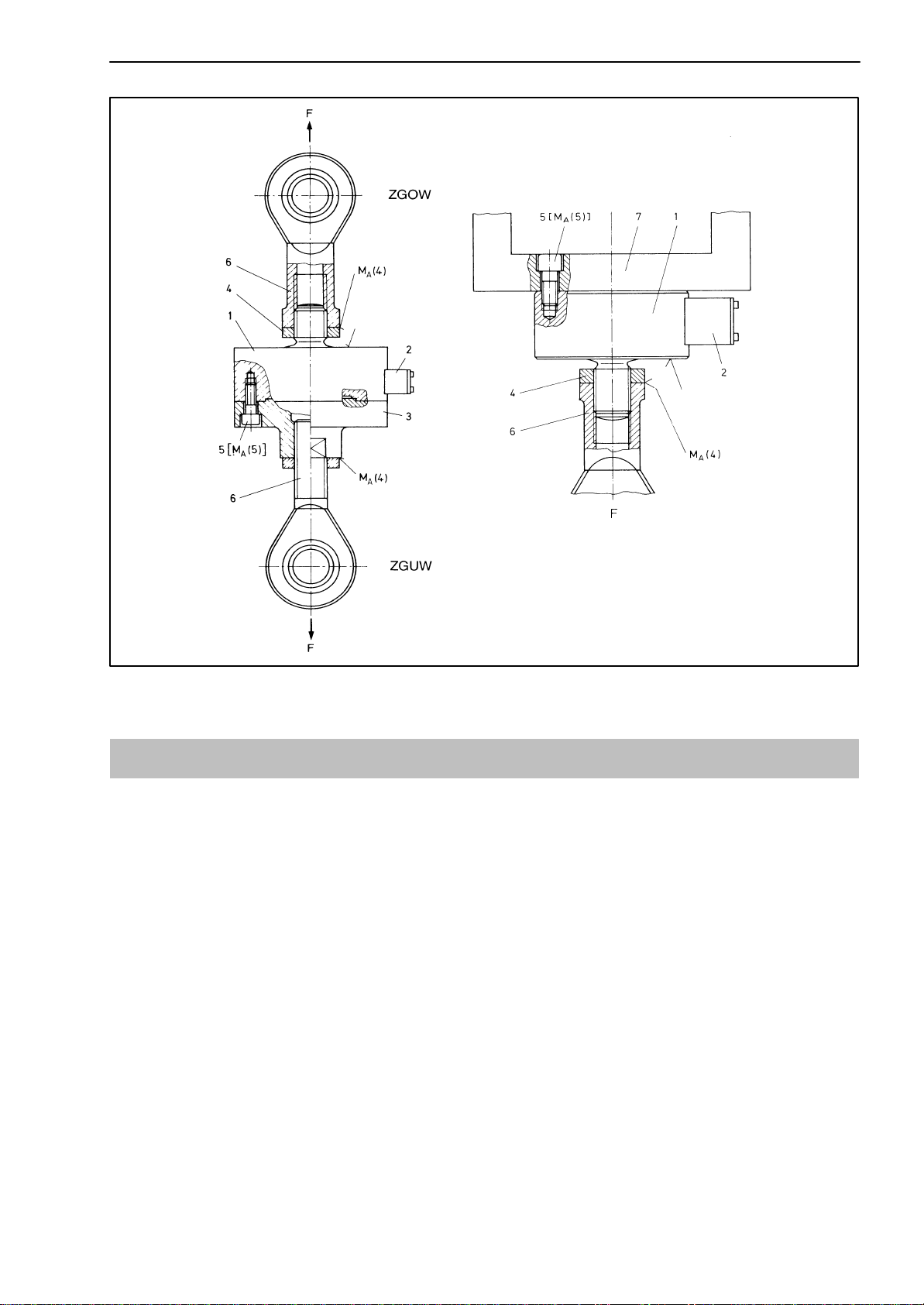

4.3 U2B installation for tensile loading

To introduce tensile loading, there is provision for a threaded pin on top of the

housing and an internal thread on the adapter.

Jointed eyelets are suitable for use in the case of quasi-static loading (stress

reversal 10 Hz). In the case of dynamic loading with a higher frequency,

flexible tension bars should be used.

The adapter (3) can be removed by undoing the screws (5). The transducer

can then be screwed onto the upper part for taking tensile measurements.

Care must be taken to make the bearing surface on the mounting plate flat.

For attachment use screws (5) of at least A2-70 quality (Fig. 4.1). To withdraw

them again use torque MA(5) (see dimension chart). When the adapter is re-

moved the zero signal on the force transducer can change by << 1%. Make

compensating adjustments for this when connecting the electronics. When

measuring dynamic forces, the screw connections to the threaded pin and in-

ternal thread must be properly pretightened when the transducer is free of

load: the tightening torque MA(4) is listed in the dimension chart. It may be ex-

ceeded by not more than 10%. If a lock-nut is used, the torque must on no ac-

count be conducted through the transducer.

U2B Weight Starting torque

Rated force (kN) approx. MA(4) MA(5)

0.5 to 10 0.8kg 60Nm 5Nm

20 2.9kg 300Nm 35Nm

50 4.3kg 500Nm 60Nm

100 10.7kg 2500Nm 60Nm

200 15.9kg 4500Nm 150Nm

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

13

U2B

HBM 24.5.2000

1 = Transducer

2 = Cable chest

3 = Adapter

4 = Lock nut

5 = Fastening screws

6 = Jointed eyelet

7 = Mounting plate

U2B in

normal position Overhead U2B installation

Fig. 4.1: Installing the U2B

4.4 U2B installation for tensile and compressive loading

The transducers can measure axial forces in torsional as well as compressive

directions. Alternating loads are also captured perfectly. For this purpose the

transducer must be installed without axial play. For dynamic sustained loading

the upper and lower threaded connectors must be pretightened with lock nuts

to more than the maximum load. For this purpose tighten the lock nuts fully

under nominal load in the tensile direction. If a lock-nut is used, the torque

must on no account be conducted through the transducer.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

14 U2B

HBM 24.5.2000

5 Electrical connection

5.1 Notes on cabling

Electrical and magnetic fields often cause noise voltage induction in the mea-

suring circuit. This interference arises most commonly from high-power trans-

mission lines running parallel to the measuring circuits, but may also come

from nearby protective contacts or electric motors. Noise voltage induction

can also occur on galvanic paths, especially if the measuring equipment is

earthed at several points.

Please note the following instructions:

•Use only shielded, low-capacitance measuring cable from HBM.

•Lay measuring cable so that it is not parallel to high-tension lines or control

circuits. If this is not possible (e.g. in cable shafts), protect the measuring

cable with e.g. steel conduit and keep it at least 50 cm away from the other

cables. High-tension lines or control circuits should be twisted (15 turns per

metre).

•Stray fields from transformers, motors and protective contacts must be

avoided.

•Do not multi-earth transducers, amplifiers and display devices. All devices

in the measuring system must be connected to the same protection circuit.

•Link the connector cable shield to the transducer housing.

•Connection diagram, earthing scheme (Green-Line)

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

15

U2B

HBM 24.5.2000

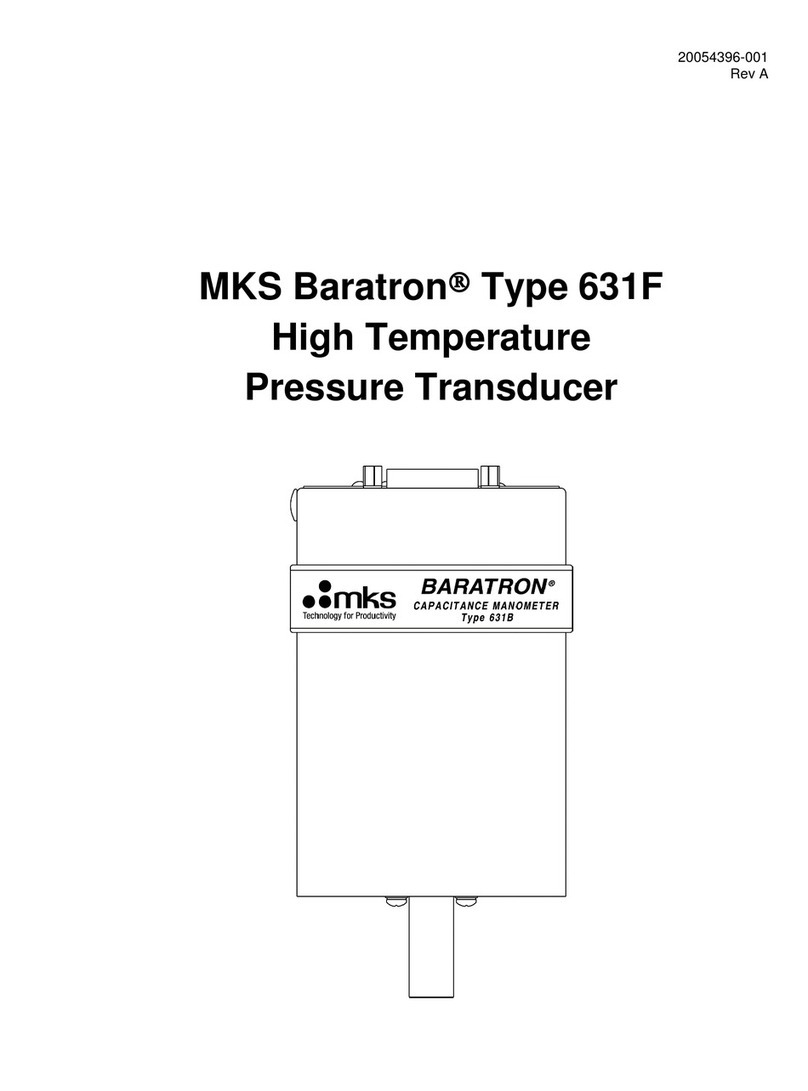

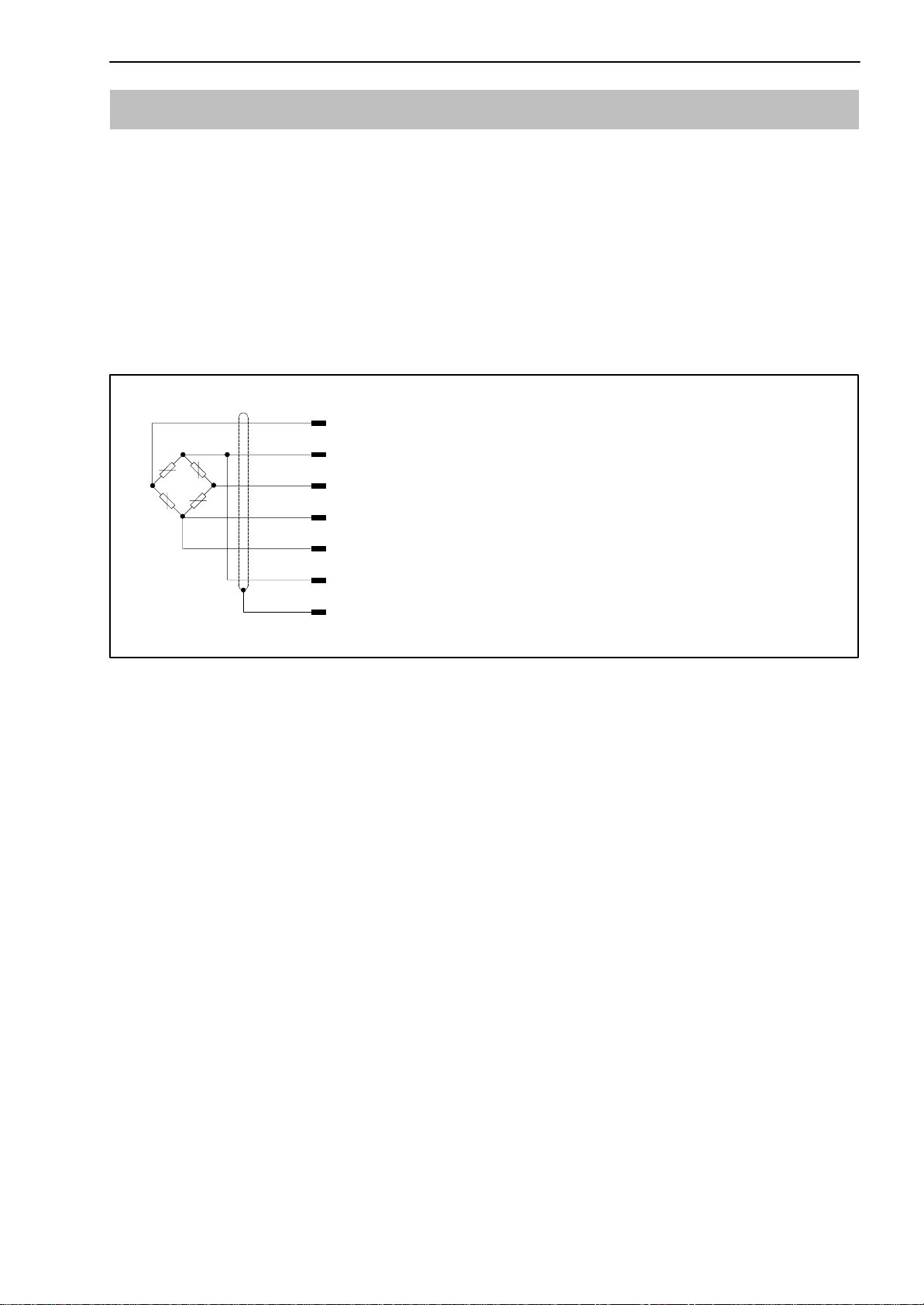

5.2 Six-wire connection

The grey and green wires that are provided in addition to the conventional

four-wire connection pick off the actual value of the bridge excitation voltage

on the transducer and feeds it back to the appropriate measurement electron-

ics. This then corrects the excitation voltage so that the set value is available

to the transducer loss-free. Possible changes in the resistance of the cable

due to temperature or a cable extension are therefore constantly corrected,

even during a measurement. It is therefore possible to extend the cable with-

out any problem.

wh (white)

bk (black)

rd (red)

bu (blue)

gn (green)

gy (grey)

ye (yellow)

Measuring signal (+) UA

Bridge excitation voltage (+) UB

Sensor circuit (–)

Sensor circuit (+)

Bridge excitation voltage (–) UB

Measuring signal (–) UA

Cable shielding, connected to housing

Fig. 5.1: U2B pin assignment

Earthing scheme (Green-Line)

The cable shielding is connected in accordance with the Greenline scheme.

Under this scheme, the measuring system is enclosed in a Faraday cage. In-

side this cage, electromagnetic interference has no effect on the measuring

signal. The transformer section is protected from electromagnetic influences

by special electronic coding procedures.

When there is interference due to potential differences (balance current), the

connections between zero operating voltage and the body of the casing must

be separated on the amplifier and a potential equalisation line must be fitted

between the housing and the amplifier housing (highly flexible stranded wire,

10mm2line cross-section).

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

16 U2B

HBM 24.5.2000

5.3 Four-wire connection

If the force transducers have to be operated with an amplifier in four-wire con-

nection, then connect the black wire with the grey and the green wire with

the blue. This changes transducer sensitivity by -0.022%. The change in the

temperature coefficient of sensitivity (TKC)) is neglible. Changing the cable

length changes the sensitivity. There is no correction for the effects of temper-

ature on the cable. In fact, even with four-wire connection the accuracy ob-

tained is adequate for many measurement technology requirements.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

17

U2B

HBM 24.5.2000

6 Technical Data

Technical Data in accordance with VDI/VDE 2638

Force transducer type U2B

Rated force Fnom kN 0.5 1 2 5 10 20 50 100 200

Accuracy class 0.2 0.1

Rated sensitivity Cnom mV/V 2

Rel. sensitivity variance

Tension/compression dc%<0.2/1.5 <0.2/0.5

Rel. zero signal variance ds,o %<<1

Rel. inversion span

(0.2Fnom to Fnom)u % <0.2 <0.15

Linearity variation dlin %<<0.2 <<0.1

Influence of temperature on

sensitivity/10K

relative to sensitivity TKc% 0.1

Influence of temperature on the

zero signal/10K

relative to sensitivity TK0% 0.05

Influence of eccentricity (1mm) dE% 0.05

Influence of lateral force

(Lateral force 10% Fnom)*dQ% 0.1

Rel. leakage over 30 min dcrF+E %<<± 0.06

Input resistance RiΩ >345

Output resistance RoΩ300...400

Insulation resistance Ris Ω >2⋅109

Reference excitation voltage Uref V 5

Service range of

excitation voltage BU,GT V 0.5...12

Rated temperature range Bt,nom °C –10...+70

Service temperature range Bt,G °C–30...+85 (120***)

Storage temperature range Bt,S °C –50...+85

Reference temperature tref °C +23

Max. operating force (FG) % 130 150

Breaking force (FB) % >300

Static lateral force limit*(FQ) % 25 (100**)

Nominal displacement Snom mm <<0.1 <<0.07 <<0.09

Fundamental resonance fre-

quency fGkHz 4 6 8.7 14 17.5 8 8.5 6 5.6

Weight kg 0.8 2.9 4.3 10.7 15.9

Rel. permissible

vibration loading Frb % 100 160

Protection system in accor-

dance with DIN EN 60529 IP67 (IP68****)

Length of cable, 6-wire connection***** 3m 6m 12m

*relative to a force triggering point 20mm over the membrane

** Mechanical lateral force compensator on request

*** Class 120 version optional

**** IP68 version optional

***** Cable shielding connected to housing

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

18 U2B

HBM 24.5.2000

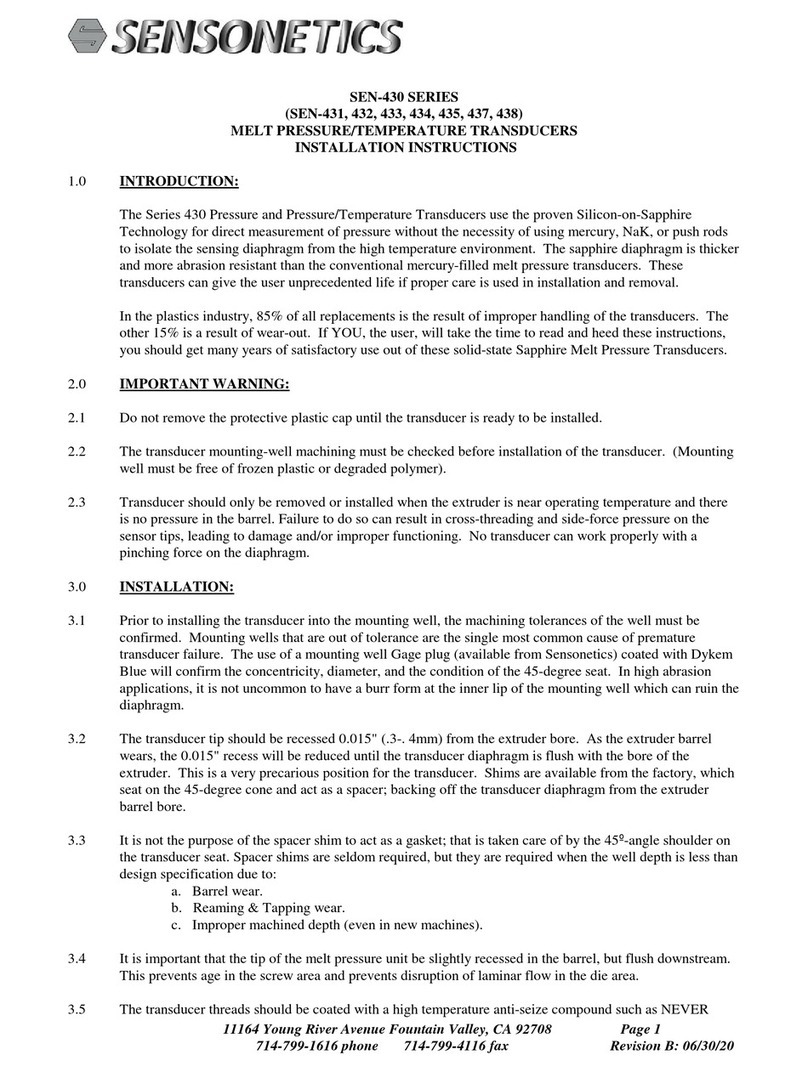

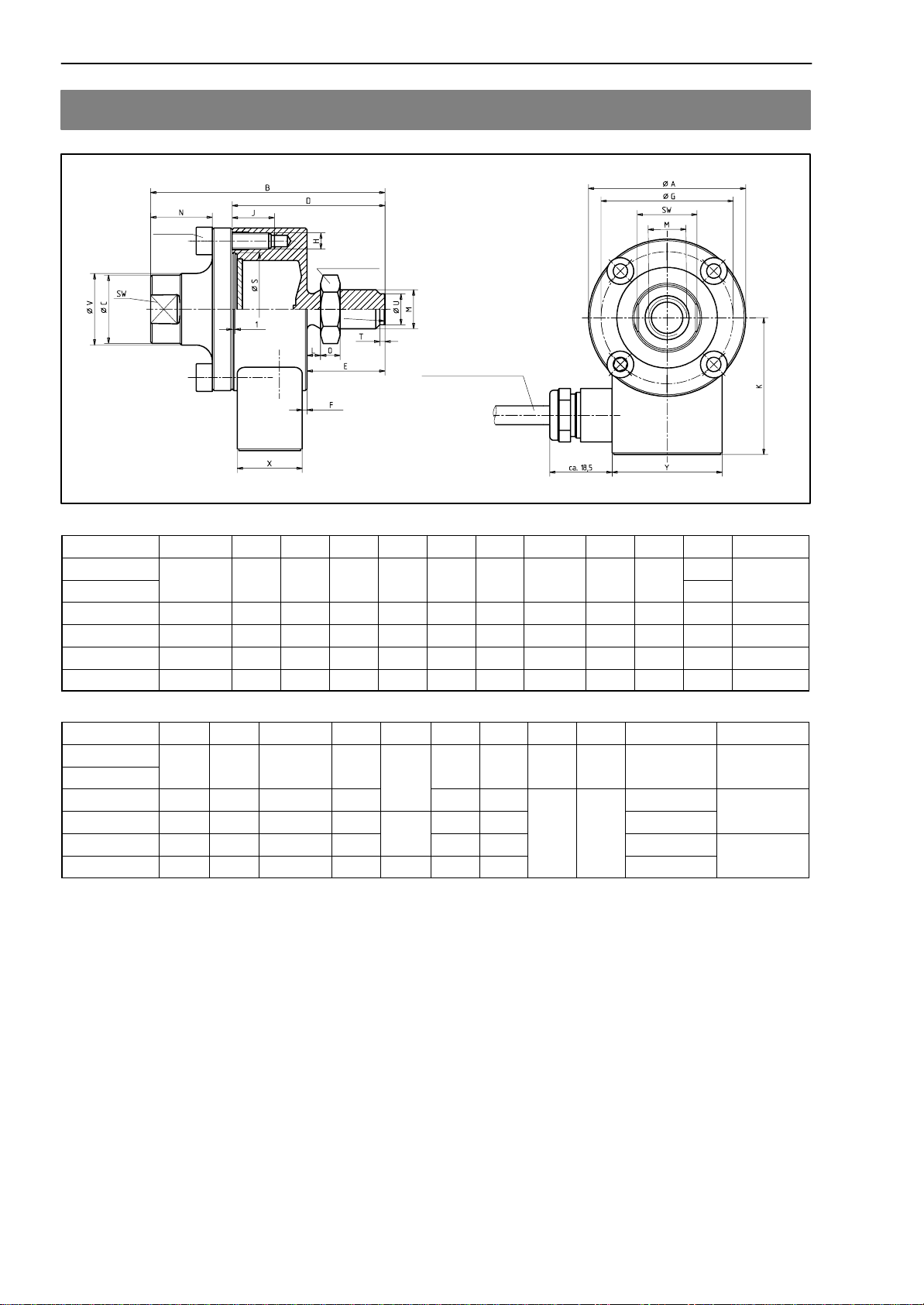

7 Dimensions

drawn off-

sett by 45°

Ball R

Locknut MA

see table

Silicone cable ∅6.5mm

Rated force ∅A–0.2 B∅C D E F ∅G H J K L M

0.5-5kN

50

72

21

47

24

15

42

4xM5

13

43 5

4.2

M12

10kN 50 72 21 47 24 1.5 42 4xM5 13 43.5 7.6 M12

20kN 90 112 33 72 38 2 70 4xM10 20.5 63.5 10.6 M20x1.5

50kN 100 141 40 86 47 6 78 4xM12 19 68 13.2 M24x2

100kN 135 197 68 122 67 17 105 8xM12 16 85.5 19 M39x2

200kN 155 232 82 142 85 19 125 8xM16 26 95.5 24.2 M48x2

Rated force N O ∅Sf8H8 SW T ∅U∅V X Y *MA(Nm) Ball R

0.5-5kN

19

6

34

19

95

22

20

35

60

60

10kN 19 6 34 19 1.6 9.5 22 20 35 60 60

20kN 15 10 55 30

1

.

6

17 34 300

100

50kN 20 12 61 36

2

20 42 30 50 500 100

100kN 29 19 79 60 236 70

30

50

2500

160

200kN 32 22 97 70 2.2 43 84 4500 160

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

19

U2B

HBM 24.5.2000

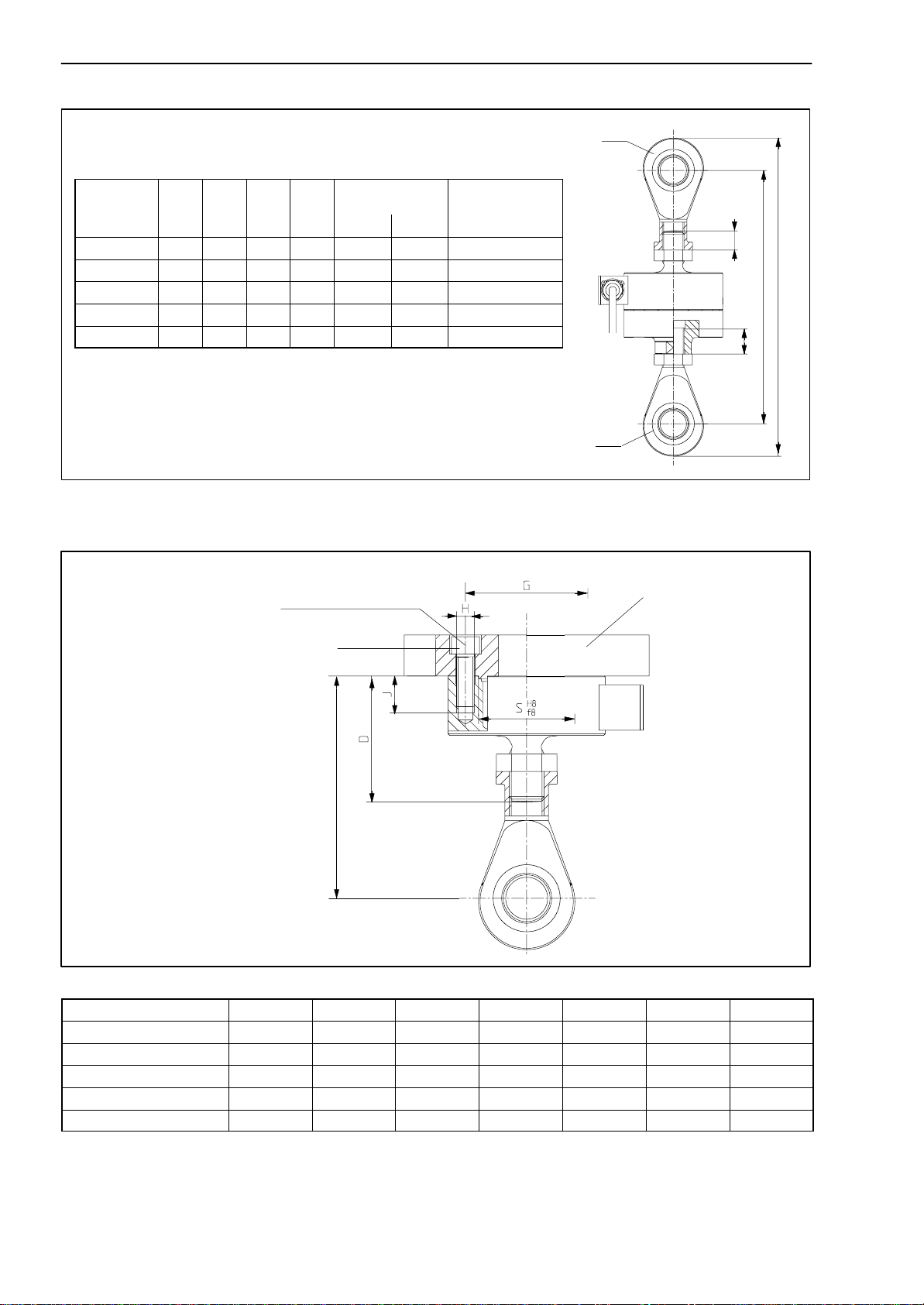

Aid to installation

Jointed eyelet ZGOW Jointed eyelet ZGUW

Material: tempered steel, galvanised; rolled steel and Teflon/bronze fabric foil

Central

bearing ring

Central

bearing ring

Rated force

in kN Order Nr.

Jointed eyelet ZGOW Weight

in kg A∅B D F G H ∅K M SW W

0.5...10 1-U2A/1t/ZGOW 0.2 22 12H7 32 50 66 12 22 M12 19 16

20 1-U2A/2t/ZGOW 0.5 33 20H7 50 77 102 18 34 M20x1.5 32 25

50 1-U2A/5t/ZGOW 0.8 42 25H7 60 94 124 22 42 M24x2 36 31

100 1-U2A/10t/ZGOW 3.2 50 50 +0.002

-0.014 115 151 212.5 28 65 M39x2 60 35

200 1-U2A/20t/ZGOW 4.8 60 60 +0.003

-0.018 126 167 235 36 82 M48x2 70 44

Rated force

in kN Order Nr.

Jointed eyelet ZGUW Weight

in kg A∅B D F G H M SW W X

0.5...10 1-U2A/1t/ZGUW 0.1 33.5 12H7 32 54.5 70.5 12 M12 19 16 7

20 1-U2A/2t/ZGUW 0.2 48.8 20H7 50 79.8 104.8 18 M20x1.5 30 25 9

50 1-U2A/5t/ZGUW 0.4 57.5 25H7 60 94.5 124.5 22 M24x2 36 31 10

100 1-U2A/10t/ZGUW 1.1 65.5 50 +0.002

-0.014 115 148.5 210 28 M39x2 60 35 16

200 1-U2A/20t/ZGUW 3.2 80 60 +0.003

-0.018 126 168 236 36 M48x2 75 44 18

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

ZGOW

ZGUW

B

A

F

C

20 U2B

HBM 24.5.2000

U2B force transducer

complete with jointed eyelets ZGOW, ZGUW

Rated force

in [kN] Amin Amax Fmin Fmax Minimum

screwed-in depth Maximum

screwed-in depth

B C

0.5...10 139 156 171 188 9.6 9.6 25

20 212 234 262 284 16 16 40

50 260 288 320 348 19.2 19.2 55

100 418 436 541 559 27 31.2 75

200 466 489 602 625 36.6 38.4 90

Aid to installation

U2B, with ZGOW, wi-

thout adapter ∅

∅

MA

Base plate,

customer side,

shown

offset 45°or 22.5°

K*

*Recommended mass in relation

to minimum screwed-in depth

Rated force in kN D∅G H J K ∅S MA1) [Nm]

0.5...10 47 42 4xM5 13 84...86.4 34 5

20 72 70 4xM10 20.5 131.6 55 35

50 86 78 4xM12 19 158.2 61 60

100 122 105 8xM12 16 244 79 60

200 142 125 8xM16 26 270.2 97 150

1) Recommended values when using a torque wrench on dry thread

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

Table of contents

Other Spectris Transducer manuals