Safety instructions

8A03452_15_X00_00 HBM: public T40B

conditioning the measurement signal should be designed so that measurement

signal failure does not subsequently cause damage.

The scope of supply and performance of the transducer covers only a small

area of torque measurement technology. In addition, equipment planners,

installers and operators should plan, implement and respond to safety engi

neering considerations in such a way as to minimize residual dangers. Perti

nent national and local regulations must be complied with.

General dangers of failing to follow the safety instructions

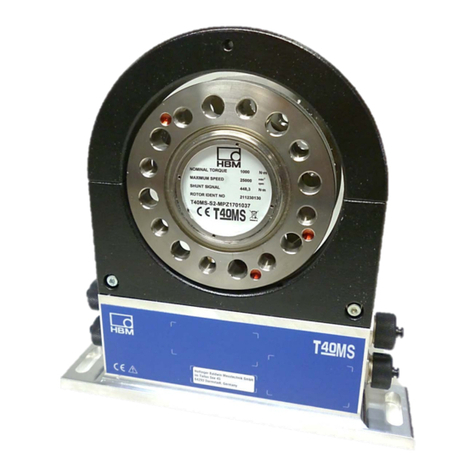

The torque flange corresponds to the state of the art and is reliable. Transduc

ers can give rise to residual dangers if they are incorrectly operated or inappro

priately mounted, installed and operated by untrained personnel. Every person

involved with siting, starting‐up, operating or repairing a torque flange must

have read and understood the mounting instructions and in particular the tech

nical safety instructions. The transducers can be damaged or destroyed by

non‐designated use of the transducer or by non‐compliance with the mounting

and operating instructions, these safety instructions or any other applicable

safety regulations (BG safety and accident prevention regulations), when using

the transducers. Transducers can break, particularly in the case of overloading.

The breakage of a transducer can also cause damage to property or injury to

persons in the vicinity of the transducer.

If the torque flange is not used according to the designated use, or if the safety

instructions or specifications in the mounting and operating instructions are

ignored, it is also possible that the transducer may fail or malfunction, with the

result that persons or property may be adversely affected (due to the torques

acting on or being monitored by the torque flange).

Conversions and modifications

The transducer must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall

exclude all liability on our part for any damage resulting therefrom.

Selling on

If the torque flange is sold on, these mounting instructions must be included

with the torque flange.