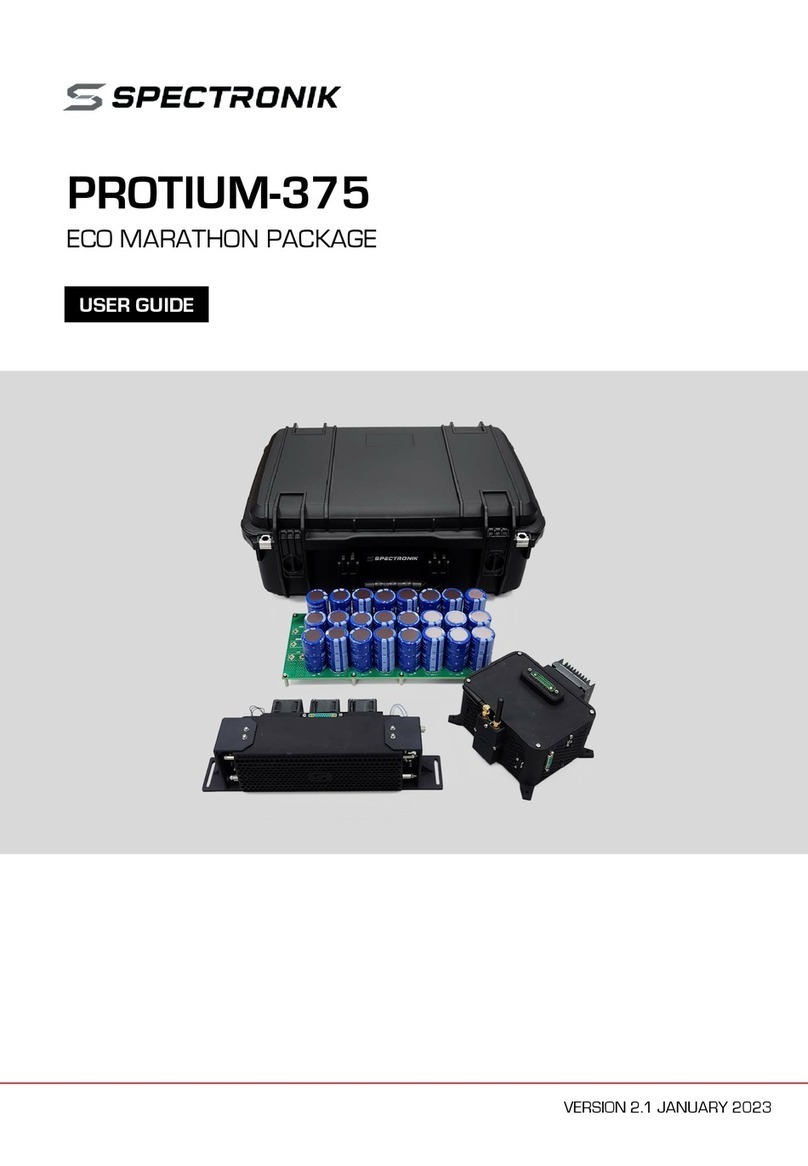

Spectronik Protium-150 User manual

PROTIUM-150 FUEL CELL SYSTEM

USER GUIDE

VERSION 4.1 MAY 2019

WARNING:Failure to follow these safety instructions could result in fire, electric shock, or other injuries, or

damage to PROTIUM-150 Fuel Cell System (PROTIUM-150)or other property.Read all the safety

information below before using PROTIUM-150.

Handling Handle PROTIUM-150 with care.It is made of thin sheet metal, graphite, and plastic and has

sensitive electrochemical membrane and components inside.PROTIUM-150 is not designed for extreme

conditions, rough handling, vibration, shock or drop. Keep PROTIUM-150 away from heat, flame, strong

sunlight, water, dust, soil or mud.Do not use adamaged PROTIUM-150.

Repairing Do not troubleshoot, disassemble or tamper with PROTIUM-150.Do not attempt to repair or

replace any component by yourself.

Hydrogen Use only high purity (99.999%) dry Hydrogen gas with PROTIUM-150.Follow all local rules and

regulations for safe handling, storage and usage of Hydrogen gas.Do not smoke when operating

PROTIUM-150.

Connectors, ports and buttons Never force aconnector into aport or apply excessive pressure to a

button.If the connector and port do not join with reasonable ease, they probably do not match. Check for

obstructions and ensure that the connector matches the correct port.

Disposal and recycling As PROTIUM-150 contains electronic components and abattery, it must be

disposed of separately from household waste. When PROTIUM-150 reaches its end of life, follow local

laws and regulations for proper disposal and recycling options.

High-consequence activities PROTIUM-150 is acustomized system with pending safety tests and

certifications.It is not intended for use where the failure of the system could lead to death, personal injury

or severe environmental damage.

Disclaimer Every effort has been made to ensure that the information in this manual is accurate.This

manual serves to adequately recommend safe operating procedures, but shall not be treated as

comprehensive.Do not use PROTIUM-150 in any other way than the one recommended in this manual.

Spectronik reserves the right to change system specifications, appearance or discontinue the product at

any time.

© 2019 Spectronik Pte. Ltd., All Rights Reserved.

Spectronik, the ‘S’ logo, and PROTIUM are trademarks of Spectronik Pte. Ltd.

SAFETY, HANDLING & SUPPORT

CHAPTER 1 | OVERVIEW

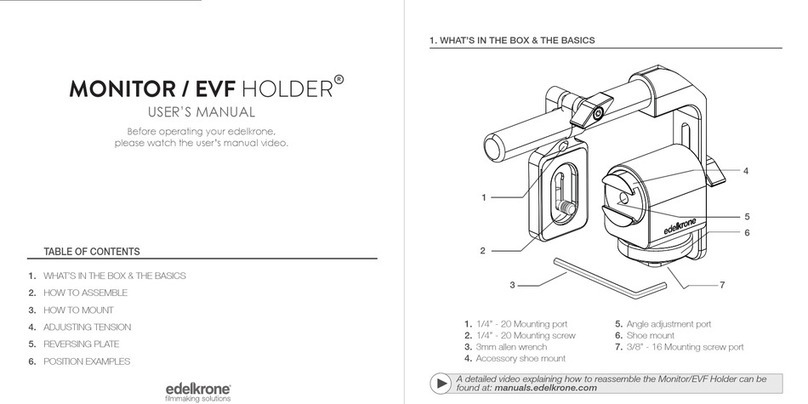

OVERVIEW 1

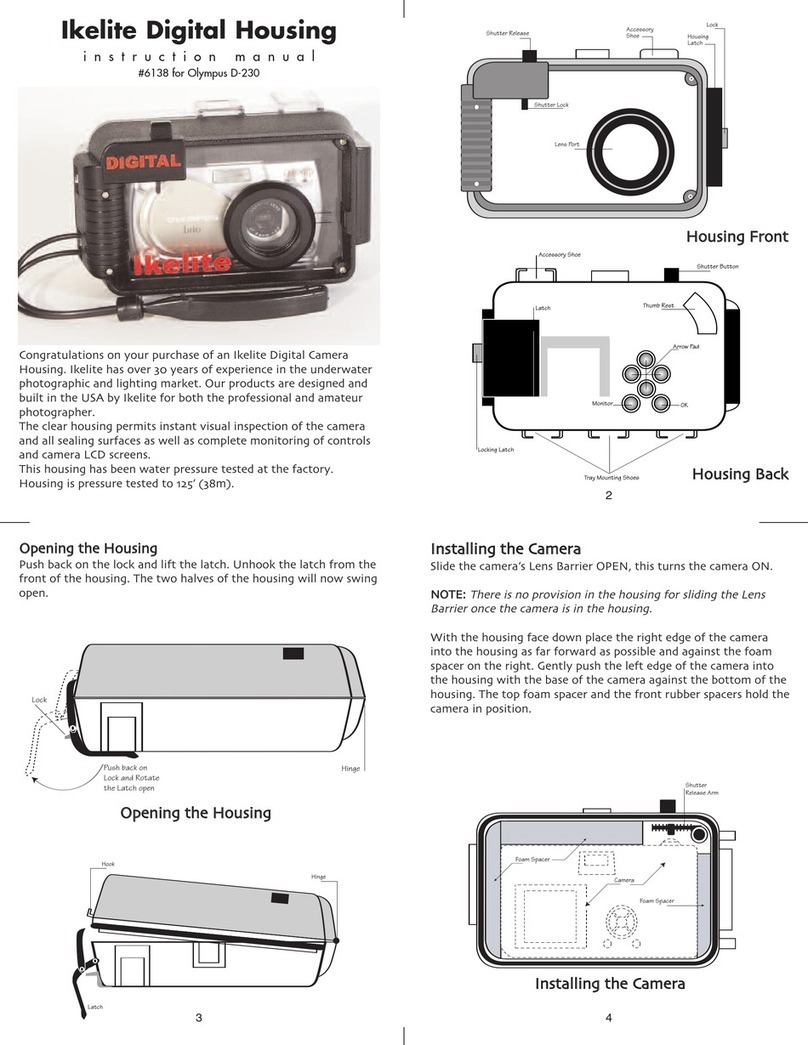

Cooling fan

PROTIUM-150

fuel cell stack

FC power/signal socket

Hydrogen gas

supply port

Fuel cell electronic controller

XT60 female socket

(to FC power/signal plug)

On/Off switch &

RS-232 header

Interface header

Load terminal block

H2supply pressure

sensor header

ICSP header

What’s in the Box

Gas pressure

sensor

Gas supply &

purge valves

Cell voltage monitoring

wires (optional add-on)

CHAPTER 1 | OVERVIEW

Power Manager

Hybrid Battery

Load terminal block

XT60 male plug

(to Hybrid Battery)

XT60 female socket

(to Power Manager)

On/Off switch

FC power/

signal plug

RS-232 connector

Gas tubing

XT60 male plug

(to fuel cell

electronic controller)

Optional Accessories

CHAPTER 2 | SPECIFICATIONS

SPECIFICATIONS 2

Fuel Cell System

Type PEM, 20 cells

Flow Field S-flow technology

Cooling 1x 12V fan, pwm controlled

Operating Ambient Temperature 1-40oC

Power Interface Terminal block, max 40A

Fuel Cell Dimension 109 x 101 x 84 mm

Fuel Cell Weight 470g

Electronic Controller FLY driver board version 3.1

Electronic Controller Dimension 80 x 55 x 25 mm

Electronic Controller Weight 105g

Nett Performance

Rated Power 150W (12.5A @ 12V)

Peak Power (only with Hybrid Battery) Dependent on capacity

Voltage Range 12-18V

Start-up Time 5s

Efficiency 48% (based on LHV of H2)

Fuel Supply

Hydrogen Gas Dry, 99.999% purity

Delivery Pressure 0.4-0.7bar (6-10psig)

Max Consumption 1.9L/min @ 150W

Gas Tubing Requirement PU, 4mm OD

Supply & Purge Control Solenoid valves

Protections & System Monitoring

Low Voltage Shutdown 10V

High Temperature Shutdown 65oC

Low Battery Warning <10.5V

Low Hydrogen Shutdown <0.2bar

Data Acquisition, Graphic User Interface RS232/USB

Hybrid Battery & Power Manager

(optional)

Hybrid Battery Type Lithium Polymer 3S

Hybrid Battery Capacity User specified

Hybrid Battery Dimension Dependent on capacity

Hybrid Battery Weight Dependent on capacity

Power Manager Settings 0-60V, 0-5A

Power Manager Dimension 61 x 37 x 22 mm

Power Manager Weight 120g

CHAPTER 3 | OPERATING PROCEDURES

OPERATING PROCEDURES 3

Preparing the Hybrid Battery

1. The Hybrid Battery is not charged when you receive them.Follow the safety instructions provided with

the Hybrid Battery for charging.Tip:Spectronik recommends using Thunder Power LiPo battery in

conjunction with Thunder Power charger and balancer.

2. You can also charge the Hybrid Battery using the Power Manager.Caution:the Power Manager is

factory set to 12Vand 1A, use only 3S LiPo battery above 2000mAh.

3. Connect the load terminal block of the Power Manager to an external DC power supply and the XT60

male plug into its female socket at the Hybrid Battery.

4. Set the DC power supply to (13V, 2A) and turn it on.The Hybrid Battery will start charging.

5. When the Hybrid Battery is full, the Current reading on the DC power supply will be close to 0A. Turn

off the DC power supply and disconnect the Hybrid Battery.

The Hybrid Battery is now ready.

Setting up PROTIUM-150

1. Connect the FC power/signal plug into the socket on the PROTIUM-150 fuel cell stack.Connect the

receptacles and XT60 male plug into their respective headers and XT60 female socket on the fuel cell

electronic controller.Tip:the receptacles are designed to have different number of pins and can only

fit into their mating headers on the electronic controller.Only the ICSP header should be free.

2. Plug in your load into the load terminal block of the electronic controller. Check that the polarity is

correct.Tip:for safety, ensure that your load has aswitch and is switched off at this stage.

3. Connect your hydrogen gas supply tubing into the gas supply port.

4. Connect the load terminal block of the Power Manager in parallel to the same load in step #2.

5. Connect the XT60 male plug of the Power Manager into the XT60 female socket of the Hybrid Battery.

Caution:the load terminal is now live.

PROTIUM-150 fuel cell &Hybrid Battery systems are now ready.

CHAPTER 3 | OPERATING PROCEDURES

Turning ON

1. Turn on the hydrogen gas supply.Tip:check that gas supply is regulated to 6-10psi (0.4-0.7bar).Do

not exceed 10psi.

2. Press the On/Off button.The LED will light up, followed by gas purging and cooling fans turning.The

system is now live.

3. Switch on your load and draw power as per normal.

Note

•Do not draw power (Constant Power mode) in excess of the fuel cell rated power (150W).If the Hybrid

Battery is connected, you can draw amaximum of 1000Wfor 3mins if the Hybrid Battery is fully charged.

The peak power is dependent on the capacity of Hybrid Battery used.

•If the fuel cell has excess power beyond powering your load, it will also automatically be charging the

Hybrid Battery, unless the Hybrid Battery is full.

•If you did not purchase the Hybrid Battery and Power Manager, you can connect an external DC power

supply in lieu of the Hybrid Battery.Set the DC power supply voltage to 12V. The maximum power you can

draw is now limited to the maximum Current of your power supply.

•Alternatively, asmall power supply (12V,1A) is sufficient if you are drawing load in Constant Voltage

mode.Do not set the load below 12V.

Reminder

•Ensure all gas tubing and electrical wire connections are firm and secure.

•Do not block the purge outlet. Keep the outlet pointed to open space.Do not bring flame or electric spark

close to it.

•Check the delivery pressure of the hydrogen gas supply.Insufficient pressure will affect PROTIUM-150’s

performance while excessive pressure might rupture its membrane electrode assembly and cause

permanent damage.

CHAPTER 4 | PROTECTIONS & WARNING MESSAGES

PROTECTIONS & WARNING MESSAGES 4

PROTIUM-150 has in-built system protections.During normal running phase, the LED will be solid white

and acontinuous buzzer sound can be heard.When an error is detected, the LED will flash, the buzzer

sound will become intermittent, and amessage will appear.The message can be viewed on aPC using

Spectronik’s Graphic User Interface (GUI) data acquisition software.Link up aPC via the RS232

connector.

Note:instruction on how to use the GUI is separately listed in the GUI user guide.

Follow the basic troubleshooting guide below.Most errors should be rectified once the suggested action

has been done and the system restarted.

If the error persists, contact support@spectronik.com.

During start-up

In Operation

Message Corrective Action

Low H2supply Check and ensure sufficient hydrogen supply and correct delivery pressure.

High temperature Disconnect everything and wait for system to cool down. Restart after 10 min.

Error: Temperature Internal temperature sensor might have been compromised. Contact Spectronik.

Error: Low voltage Check and ensure sufficient hydrogen supply and correct delivery pressure.

Restart after 1 min.

Message Corrective Action

High temperature Fuel cell temperature has reached 60oC, load is temporarily auto-disconnected.

Reduce load.

Error: High

temperature

Disconnect everything and wait for system to cool down. Restart after 10 min. If

system fails to restart, internal temperature sensor might have been

compromised. Contact Spectronik.

Low voltage Fuel cell is overloaded and the load is temporarily auto-disconnected. Reduce

load.

Error: Low voltage User has drawn power way beyond the fuel cell capacity. Restart the system and

reduce load.

Low H2supply Hydrogen gas supply is depleted, reduce load or prepare to end operation.

Error: Low H2

supply

Hydrogen gas supply is way too low to support operation. Refill the supply and

restart the system.

Low battery Hybrid Battery voltage is low. Reduce load or prepare to end operation.

CHAPTER 5 | MAINTENANCE & STORAGE

MAINTENANCE & STORAGE 5

Maintenance for PROTIUM-150

When not in use, Spectronik recommends that PROTIUM-150 is reconditioned at least once amonth.

1. Follow the steps in Chapter 3, using aDC electronic load in lieu of your regular load and an external

DC power supply (12V,1A) instead of the Hybrid Battery.

2. Set aconstant voltage (CV) load of 12Vand run the system for 1hour.

3. PROTIUM-150 is now ready for usual operation or can be stored again for future use.

Storage

Keep PROTIUM-150 in an open, cool (standard room temperature of 25oC) and dry place.

Table of contents

Other Spectronik Camera Accessories manuals