Spectronik PROTIUM-1000 User manual

PROTIUM-1000

FUEL CELL SYSTEM

USER GUIDE

VERSION 2.2 DECEMBER 2021

© 2021 Spectronik Pte. Ltd., All Rights Reserved.

Spectronik, the ‘S’ logo, and PROTIUM are registered trademarks of Spectronik Pte. Ltd.

SAFETY, HANDLING & SUPPORT

WARNING:Failure to follow these safety instructions could result in fire, electric shock, or

other injuries, or damage to PROTIUM-1000 Fuel Cell System (PROTIUM-1000)or other property.

Read all the safety information below before using PROTIUM-1000.

Handling Handle PROTIUM-1000 with care.Itis made of thin sheet metal, graphite, and plastic and has sensitive

electrochemical membrane and components inside.PROTIUM-1000 is not designed for extreme conditions,

rough handling, vibration, shock or drop.Keep PROTIUM-1000 away from heat, flame, strong sunlight, water,

dust, soil or mud.Do not use adamaged PROTIUM-1000.

Repairing PROTIUM-1000 is assembled under high compression.Do not disassemble or tamper with PROTIUM-

1000.Do not troubleshoot, repair or replace any component by yourself.

Hydrogen Use only high purity (99.999%) dry Hydrogen gas with PROTIUM-1000.Hydrogen is acolorless,

odorless and highly flammable gas. It is non-toxic but can cause asphyxiation.Follow all local rules and regulations

for safe handling, storage and usage of Hydrogen gas.Do not smoke when operating PROTIUM-1000.

Ventilation Operate PROTIUM-1000 in awell ventilated environment.Fresh air intake for the fuel cell oxidant

blower, cooling air entry from the front of the protective mask, and hot air exit from the cooling fans shall not be

obstructed or restricted.

Purging PROTIUM-1000 periodically flushes its anode during operation, releasing Hydrogen gas and water from

the Hydrogen gas outlet.Do not block the Hydrogen gas outlet.Do not bring flame or electric spark close to the

Hydrogen gas outlet. It is advisable to attach alonger gas tubing to the Hydrogen gas outlet connector and safely

guide the purge exhaust far away from the fuel cell.

CAUTION:

Always put the Hydrogen gas outlet tubing behind the cooling fan and never in front of

the fuel cell stack or oxidant blower inlet.Purged Hydrogen mixed with air intake into the fuel cell’s

cathode channels may cause fire and irreversible damage to the fuel cell.

Connectors, ports and buttons Never force aconnector into aport or apply excessive pressure to abutton.If

the connector and port do not join with reasonable ease, they probably do not match.Check for obstructions and

ensure that the connector matches the correct port.

Disposal and recycling As PROTIUM-1000 contains electronic components, it must be disposed of separately

from household waste.When PROTIUM-1000 reaches its end of life, follow local laws and regulations for proper

disposal and recycling options.

High-consequence activities PROTIUM-1000 is acustomized system with pending safety tests and certifications.

It is not intended for use where the failure of the system could lead to death, personal injury or severe

environmental damage.

Disclaimer Every effort has been made to ensure that the information in this manual is accurate.This manual

serves to adequately recommend safe operating procedures, but shall not be treated as comprehensive.Do not

use PROTIUM-1000 in any other way than the one recommended in this manual.Spectronik reserves the right to

change system specifications, appearance or discontinue the product at any time.

Warranty Spectronik warrants the included hardware product and accessories against defects in materials and

workmanship for the first 30 days after delivery.Spectronik does not warrant against normal wear and tear, nor

damage caused by accident or abuse.

To obtain service, contact support@spectronik.com

1

2

3

5

4

6

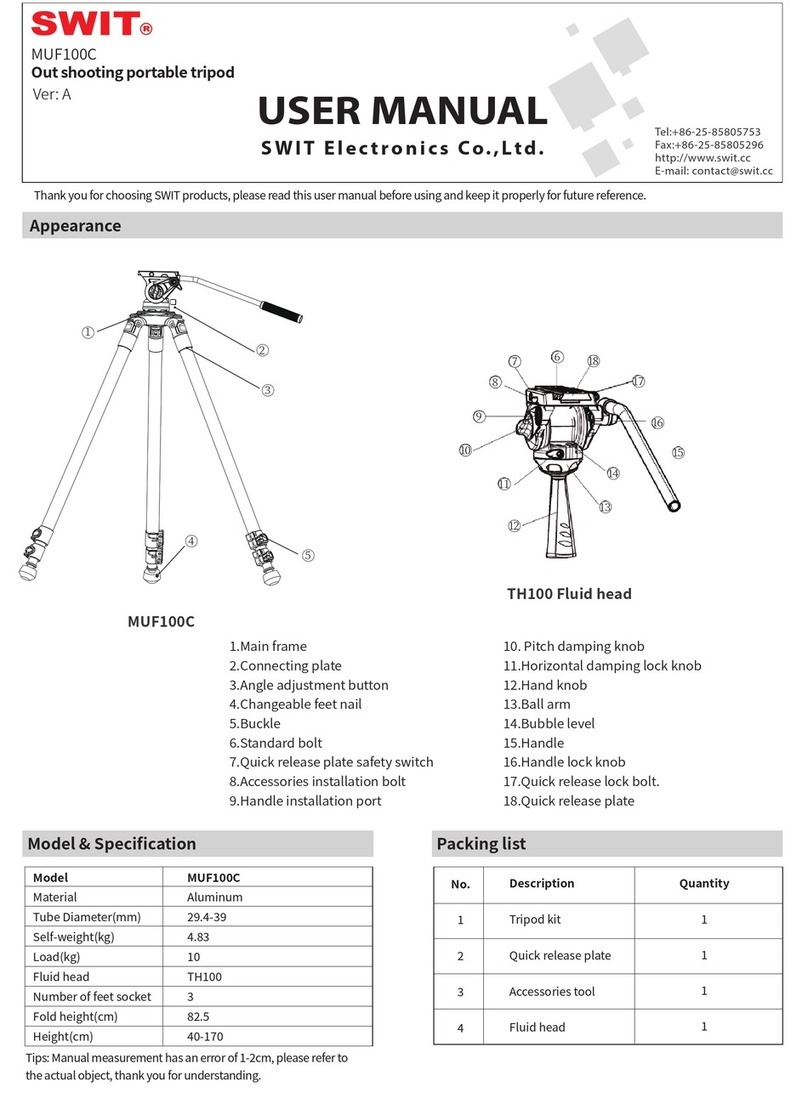

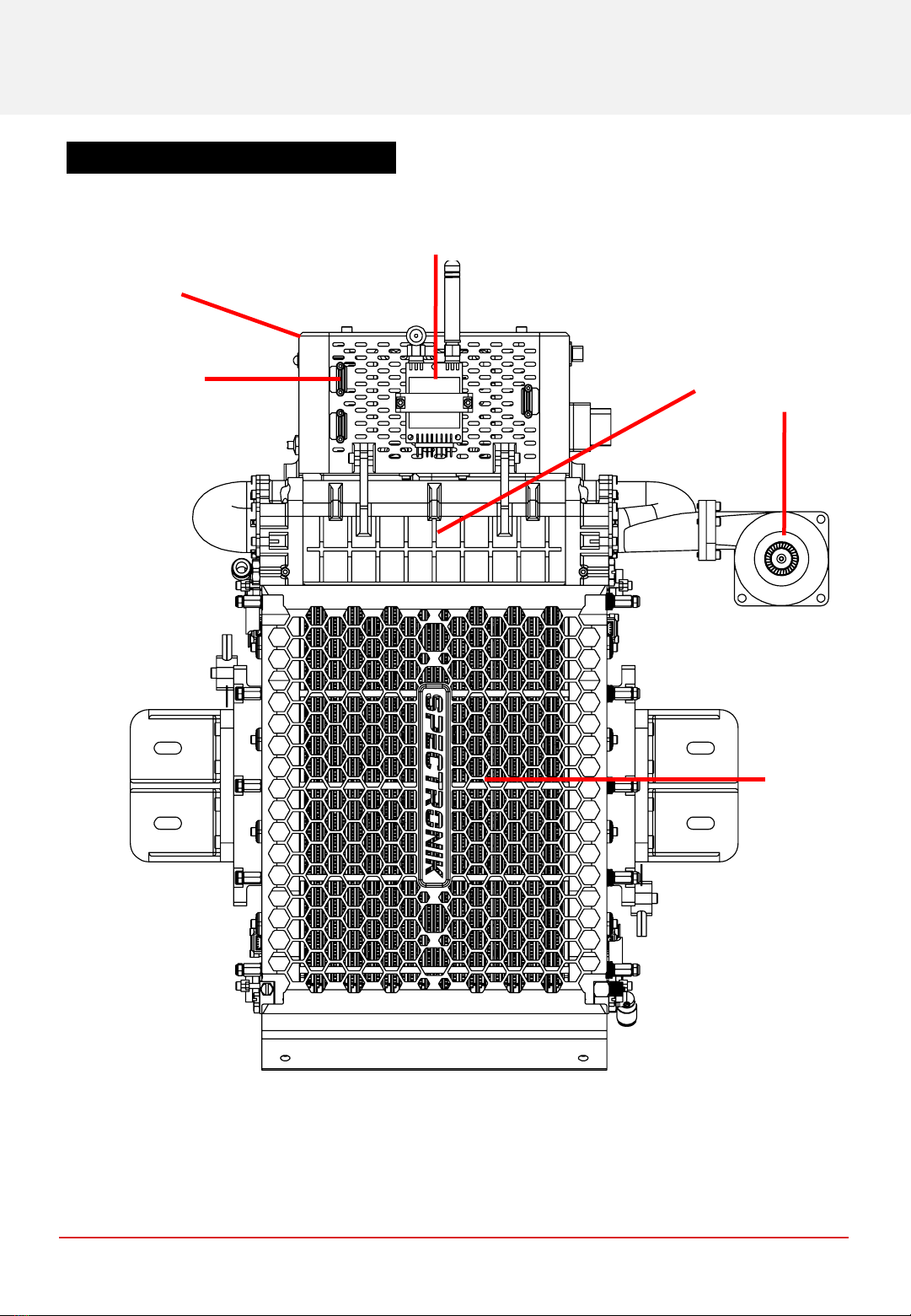

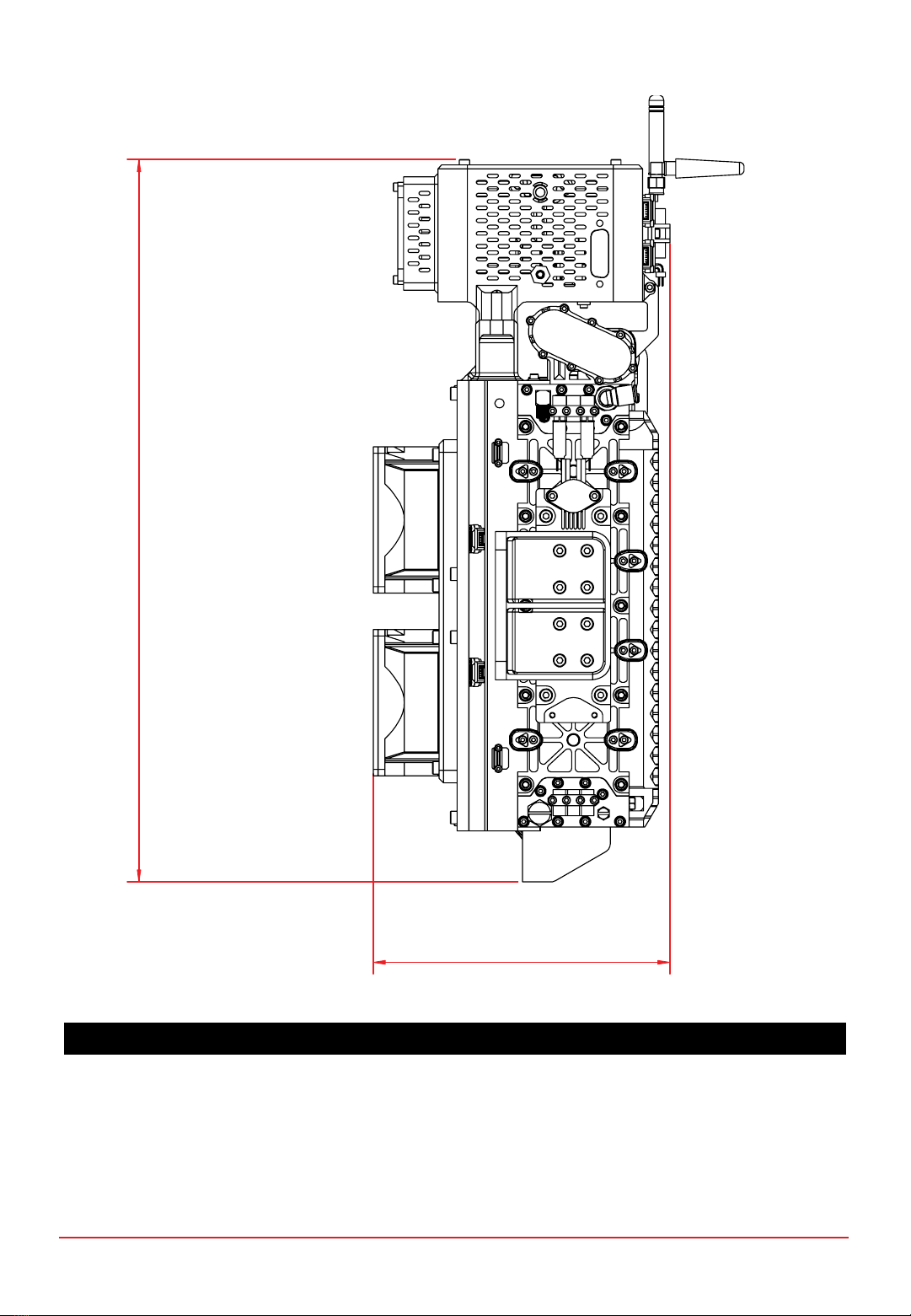

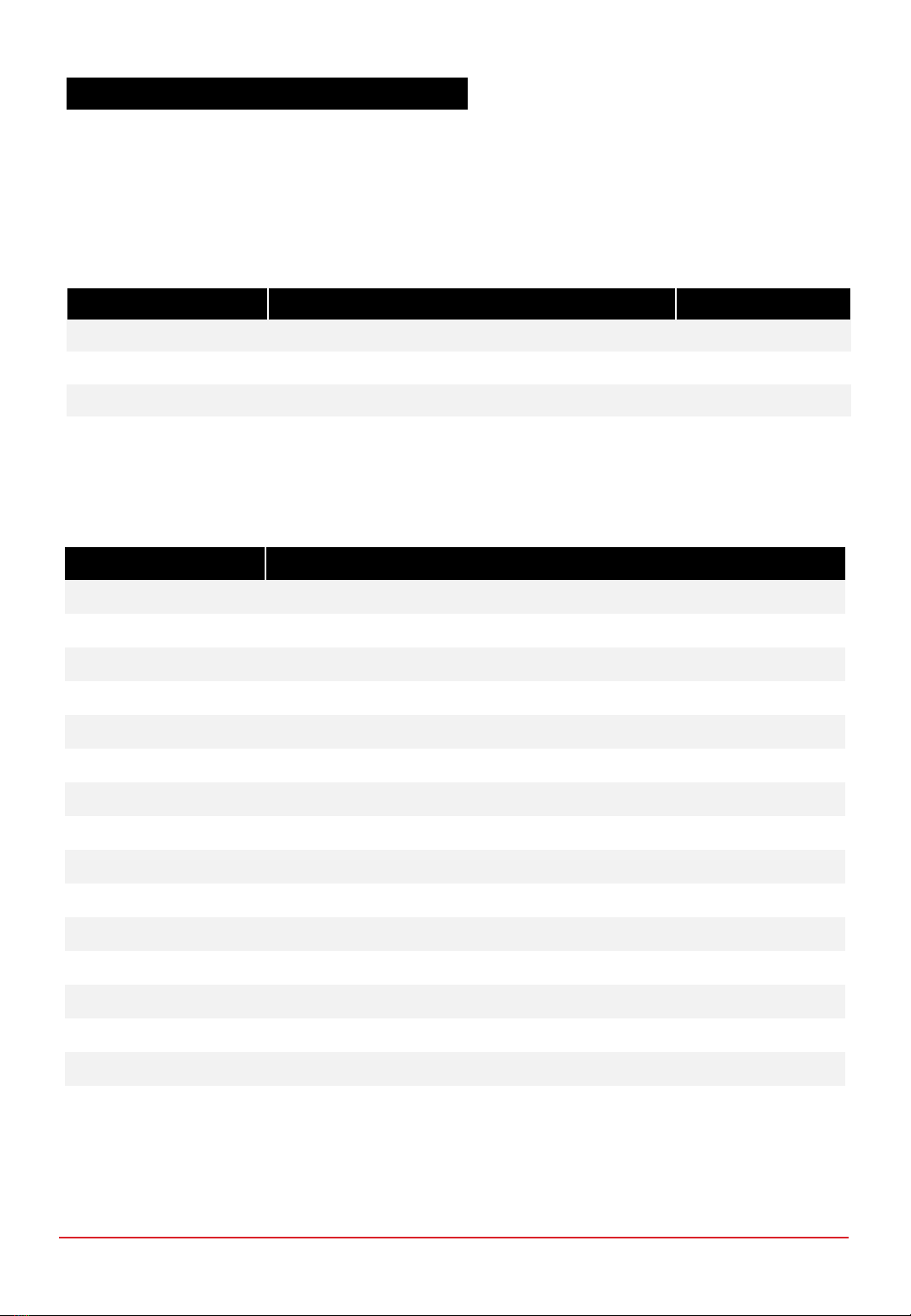

Figure 1.1.1 Front view of PROTIUM-1000

CHAPTER 1 | OVERVIEW

1OVERVIEW

1.1 PROTIUM-1000 SYSTEM OVERVIEW

ITEM DESCRIPTION

1. Programming port 9. H2gas outlet connector

2. Fuel cell electronic controller 10. Cooling fan x2

3. Radio telemetry transmitter 11. User mounting plate (Bottom)

4. Oxidant flow manifold 12. Load power connector (XT-90 female)

5. Oxidant blower 13. External power supply receptacle

6. Protective mask 14. Balance-of-plant (BOP) switch

7. Status LED 15. User mounting plate (Top)

8. ON/OFF push button 16. H2gas inlet connector

7

8

9

10

11

12 13

14

15

16

Figure 1.1.2 Bottom and Top views of PROTIUM-1000

CHAPTER 1 | OVERVIEW

CHAPTER 1 | OVERVIEW

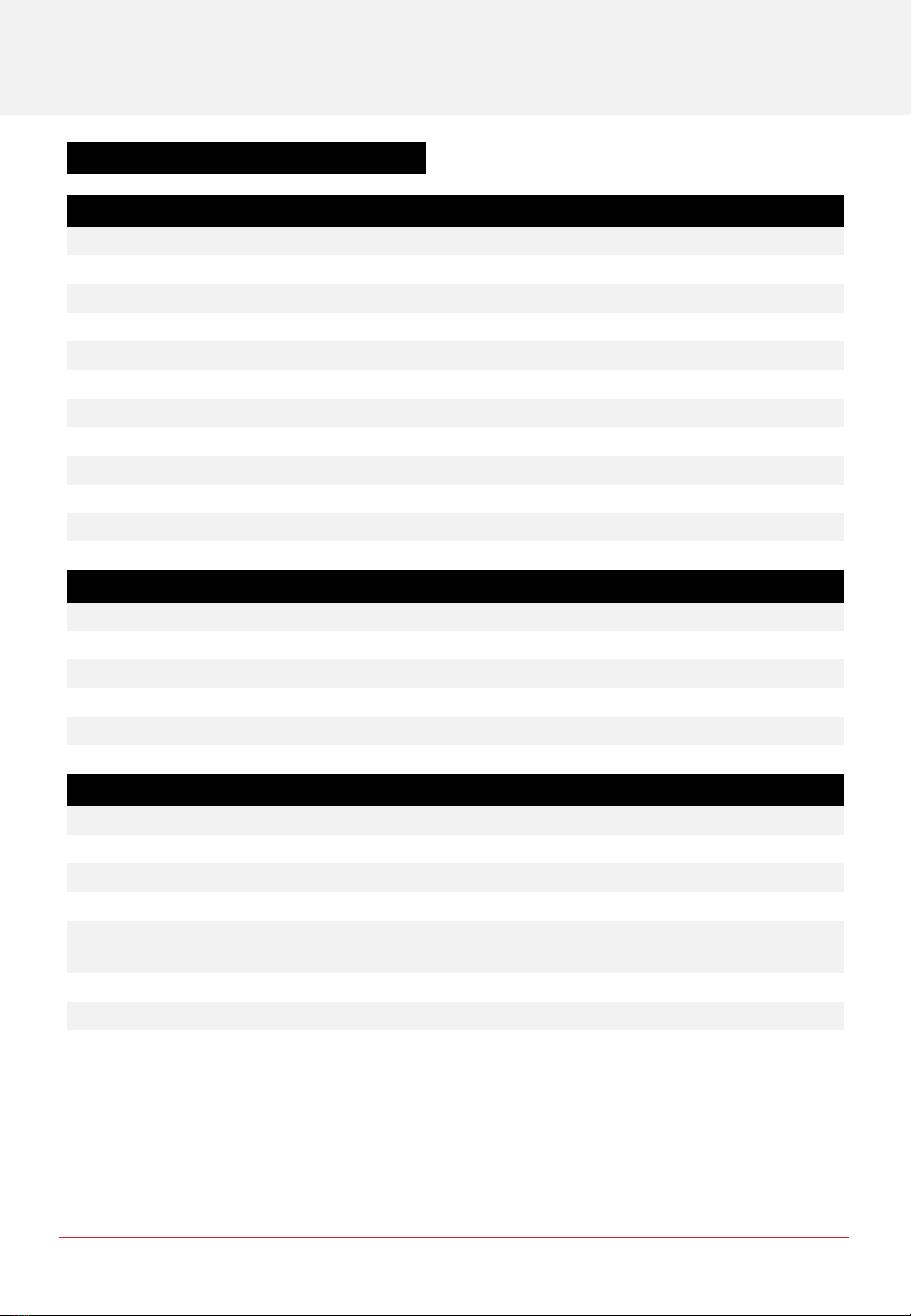

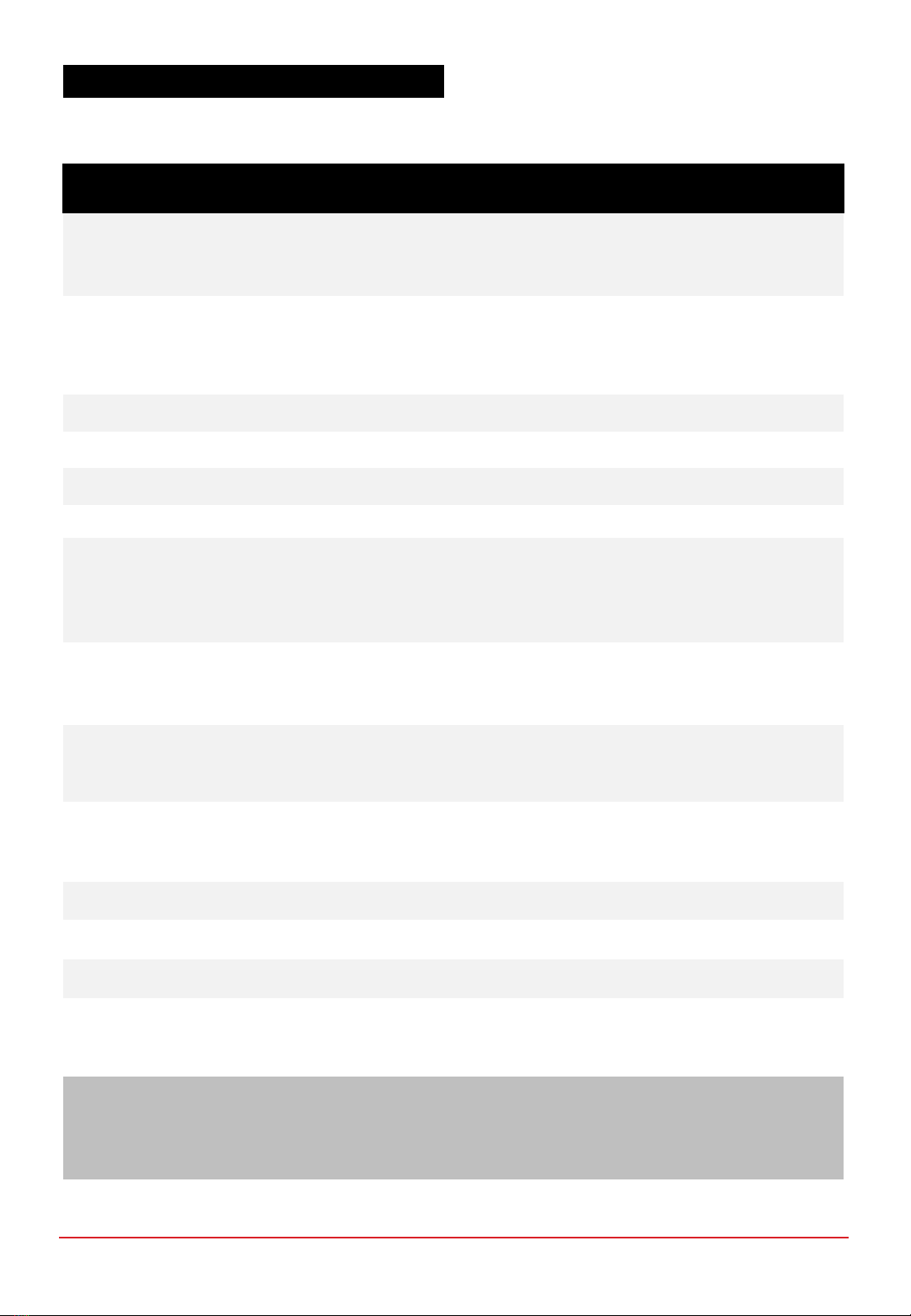

1.2 MECHANICAL DIMENSION

D

8

R3.25

E

C

B (Centre to Centre)

A

All dimensions in mm

A323.60 E40.00

B283.60 F395.50

C215.00 G164.50

D100.50

CHAPTER 1 | OVERVIEW

F

G

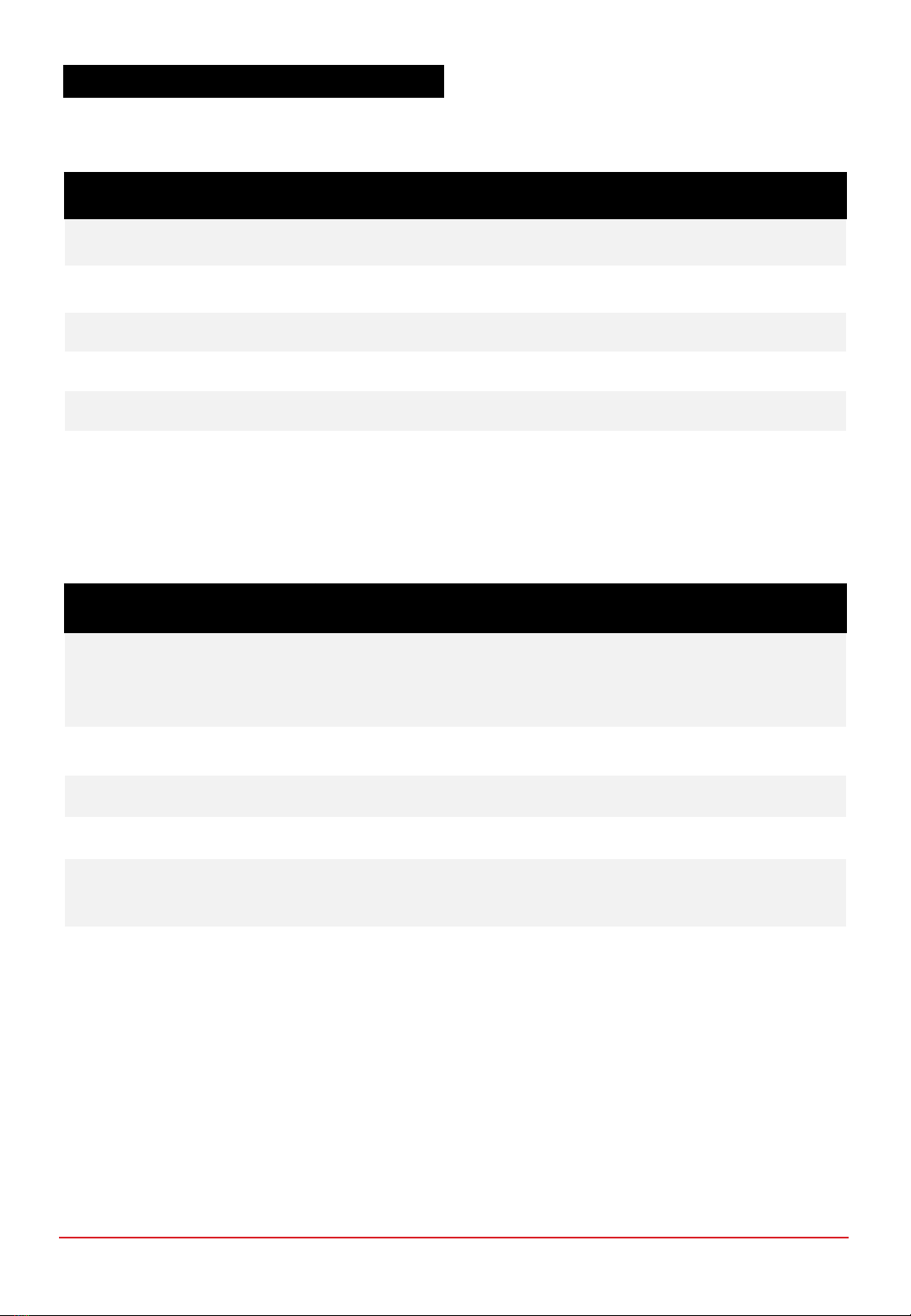

PROTIUM-1000

cannot

be mounted in any orientation due to internal routings of the gas streams within the fuel

cell stack.

The fuel inlet must always be higher than the fuel outlet.The stack should also be level to ensure water does not

get trapped in the Cathode channels, obstructing the oxidant flow and causing potential performance drop and

cell damage.

Mount PROTIUM-1000 in one of the two recommended configurations above.

For optimal oxidant and cooling airflows, it is also recommended that there is at least 15cm unobstructed

clearance in front of the protective mask and oxidant blower inlet, and 30cm unobstructed clearance behind the

cooling fans’ outlet.

Figure 1.3.1 Recommended configuration #1 (Top) and #2 (Bottom)

1.3 Mounting orientation and air clearance

CHAPTER 1 | OVERVIEW

Fuel Cell PROTIUM-1000

Type PEM

No. of cells 30

Architecture Closed cathode

Coolant Air cooled

Rated/gross power 1000/1200W

Rated/gross current 55.5/66.6A

Voltage output 18-27VDC

Start-up time 30s

Operating ambient temperature [-10,45]oC

Operating altitude without power derating 1500m AGL

System weight 4,800g

Max dimension 396 x 165 x 324mm

Fuel Supply

Hydrogen gas Dry, 99.999% purity

Delivery pressure 0.7bar (10 psig)

Fuel consumption @ rated power 12.5L/min

Gas tubing PU, 8 x 5.5

Supply & purge control Solenoid valves with integrated pressure sensor

Stack leakage checks Automated via integrated pressure sensors

Electronic Controller

Processor board FEATHER V1.2

External power supply requirement 15-90V, 150W max

Weight (including casing) 680g

Output connector XT-90

Warning & protections Low voltage, high/low temperature, high/low

pressure, low battery, stack leakage

Communication 868MHz ultra long range radio modem

Data acquisition (DAQ) software GUI PC/Android app

Remote control Fan speed, blower speed, manual purge, remote on-

off

CHAPTER 2 | SPECIFICATIONS

2SPECIFICATIONS

2.1 PROTIUM-1000 TECHNICAL DATA SHEET

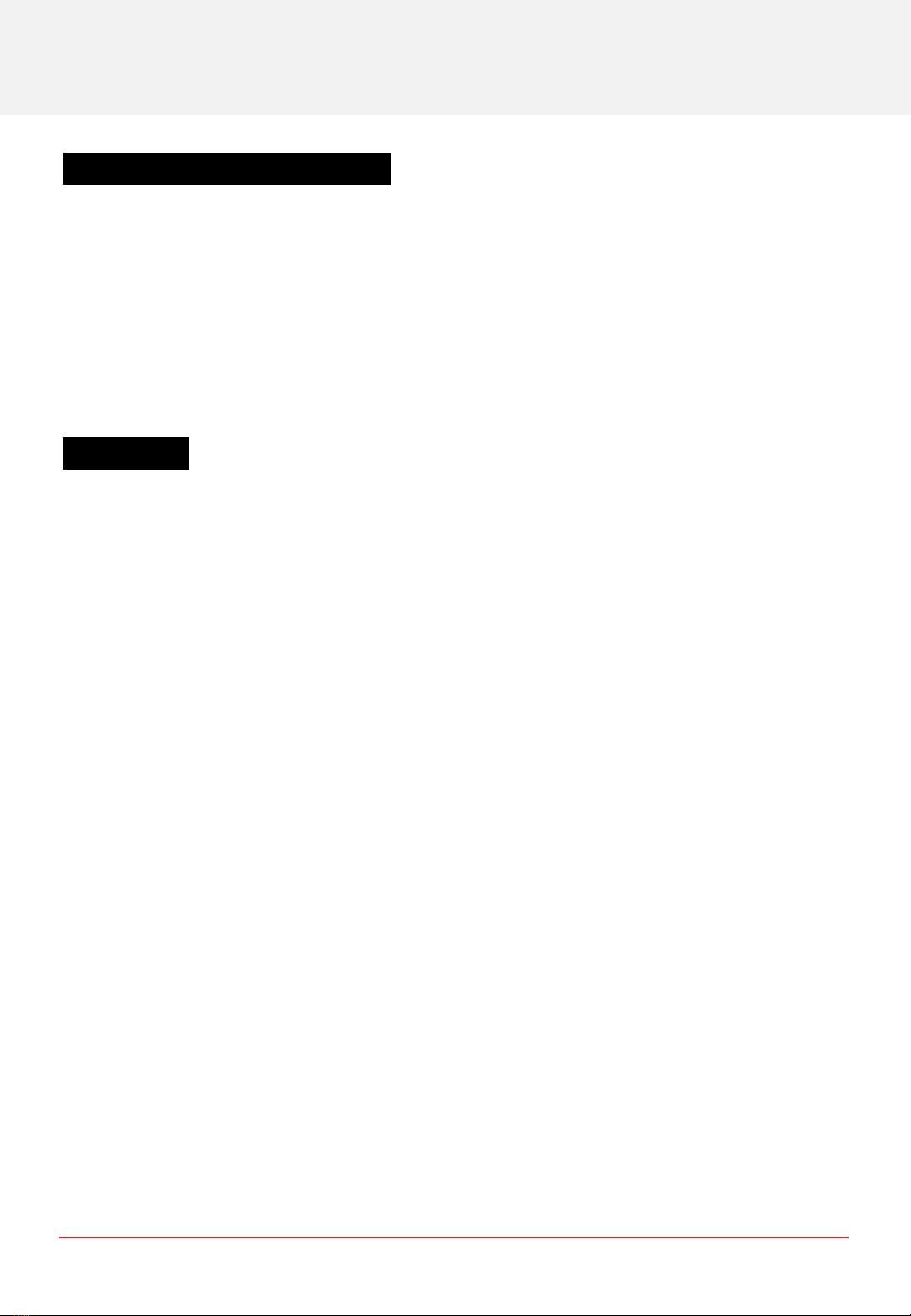

Figure 2.2.1 Nominal polarization curve for a fully conditioned PROTIUM-1000 at its Beginning-of-Life (BOL).

•Ambient temperature: 24oC

•Relative humidity: 60%

•H2supply pressure: 10psig

•Dead-ended operation

•Balance-of-plant (BOP) powered by fuel cell

•Tcell at 1000W: 66oC

CHAPTER 2 | SPECIFICATIONS

2.2 VI CURVE

TEST CONDITIONS

CHAPTER 2 | SPECIFICATIONS

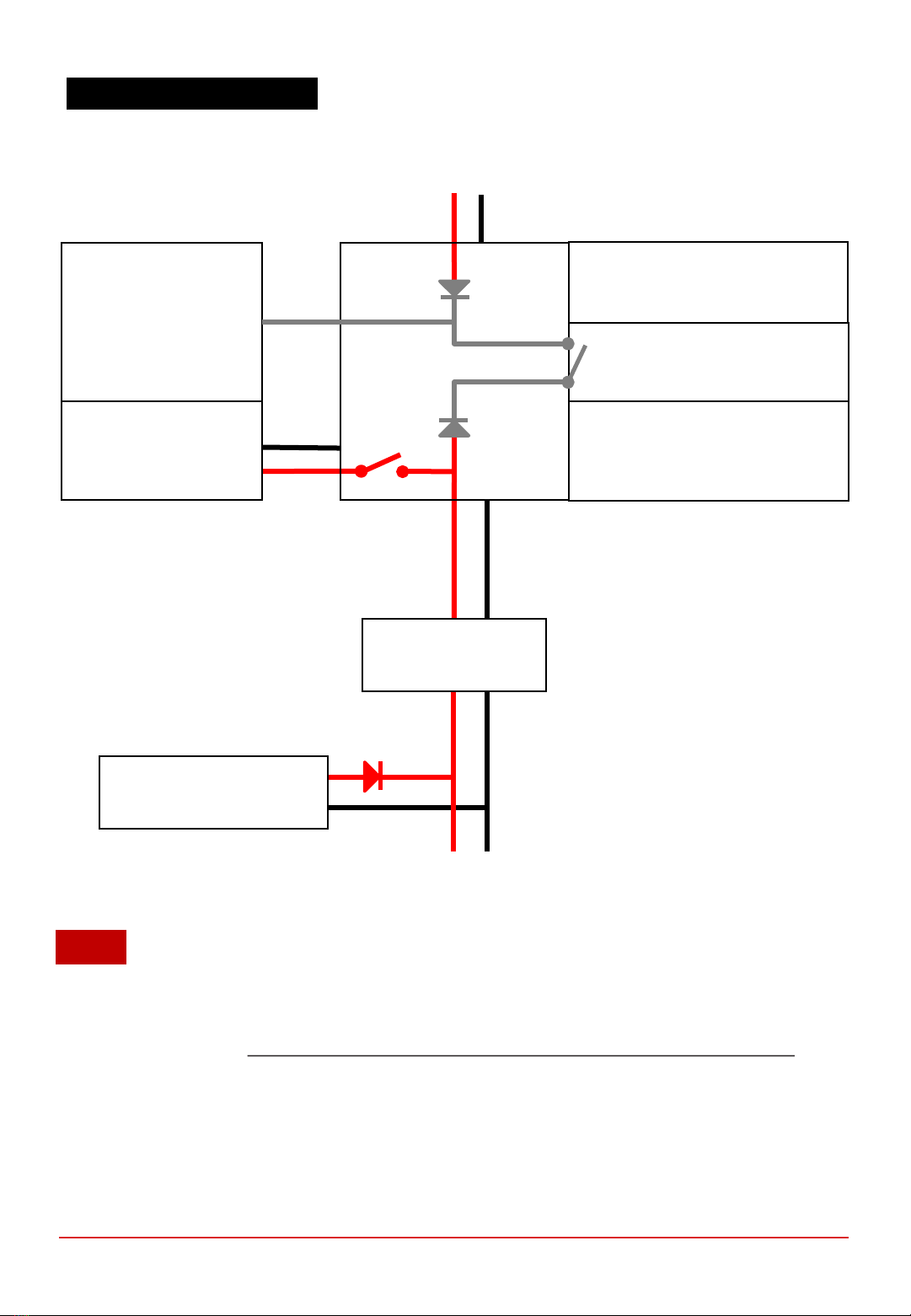

2.3 SYSTEM BLOCK DIAGRAM

1. An external power supply is required to initially turn on the electronic controller.

2. By default, the BOP Switch is set to 1. When the system enters “Running Phase” the fuel cell will be able

to power its own BOP, if Fuel cell power OUT voltage is higher than External Power Supply voltage.

3. By setting the BOP Switch to 0, the External Power Supply will power the BOP at all times including

“Running Phase”.

Fuel cell

power IN

Power output

to LOAD

User Interface

•ON/OFF push button

•Status LED & Buzzer

Communication

•USB or

•Radio telemetry transmitter

External Power Supply

(15 to 90V, 150W)

Fuel cell

power OUT

18-27V

Hybrid Output Source

(optional)

DC-DC converter

(optional)

NOTE

PROTIUM-1000

fuel cell stack

Balance of Plant (BOP)

•Cooling System

•Oxidant System

•Valves

•Sensors

•Communications BOP Switch 1/0

Electronic

Controller

1. Mount Protium-1000 securely in 1of the 2recommended orientations.

2. Connect your Hydrogen gas supply to the H2 gas inlet connector.Make sure that your Hydrogen gas

supply is OFF at this stage.

3. Connect the purge tubing to the H2 gas outlet connector.

Caution:

Channel the purge tubing to

the back of the cooling fans and far away from the oxidant blower inlet.

4. Connect an external power supply to the external power supply receptacle.Make sure that it is

turned OFF at this stage.Set the BOP switch to 0if you want the external power supply to continue

powering PROTIUM-1000 BOP throughout the entire operation.

5. Connect your load to the Load power connector.

Tip

:check that the polarity is correct. It is

also advisable to put an ON/OFF switch at your load and ensure that it is turned OFF at this

time.

6. Turn on your PC and connect the communication USB cable to aUSB port.Download the Spectronik Data

Acquisition (DAQ) GUI PC application from the Protium-1000 product webpage.Install the app and follow

the instructions in its user guide.

Tip:

You can also use any serial data application like Hyperterminal.Set the parameters (57600

baud rate, 8data bit, No parity, 1stop bit).

Reminder:

Ensure that all gas tubing and electrical wire connections are firm and secure.

PROTIUM-1000 is now ready to turn on.

CHAPTER 3 | OPERATING PROCEDURES

3OPERATING PROCEDURES

3.1 SETTING UP PROTIUM-1000

3.2 TURNING ON PROTIUM-1000

1. Turn on the external power supply. Wait for 5s. A welcome header should appear in the GUI. LED will blink

at 10%.

2. In the GUI, click the “start” command or type the word “start” and <enter> using the keyboard function.

Alternatively, press and hold on ON/OFF push button for more than 2s. PROTIUM-1000 will enter its

“Starting Phase” and the message “Low H2 supply” should appear.

3. Turn on your Hydrogen gas supply.

Caution:

Ensure that the gas delivery pressure is 0.5-

0.7barg.

Insufficient delivery pressure may cause cell flooding and drop in performance, while excessive pressure

may rupture the fuel cell membrane, causing dangerous gas leakage and irreversible cell damage. Ensure

that your pressure regulator can provide Hydrogen gas flow rate of more than 15L/min.

4. PROTIUM-1000 will do a series of gas purging and internal diagnostic checks. If everything is normal, the

fuel cell will enter its “Running Phase” –indicated by the message in the GUI and a solid white LED.

PROTIUM-1000 is now ready to power your application.

1. Turn ON your load and draw power as per normal. Caution: never pull the fuel cell voltage below 18V or

draw power beyond 1000W.

If hybrid battery is connected at the load, PROTIUM-1000 will provide up to its maximum rated output and

the rest is augmented by the battery. The total power available depends on the capacity of the battery.

3.3 POWERING YOUR LOAD WITH PROTIUM-1000

CHAPTER 3 | OPERATING PROCEDURES

Mode Range Ramp-rate

Constant Voltage Load Open circuit voltage to 18VDC min or 1000W max -1VDC/second

Constant Current Load 0A to 55A or 1000W max +2A/second

Constant Power Load 0W to 1000W max +100W/second

2. During Running Phase, the following live status of the fuel cell can be monitored from the GUI.

Parameters Description

FCV FC voltage (V)

FCA FC current (A)

FCW FC power (W)

Energy Energy delivered by the fuel cell during this operation (Wh)

FCT1 FC temperature at location 1 (˚C)

FCT2 FC temperature at location 2 (˚C)

FAN Cooling fan duty cycle (%)

BLW Oxidant blower duty cycle (%)

H2P1 H2supply pressure (Barg)

H2P2 H2pressure in FC (Barg)

Tank-P* Gas tank pressure (Barg)

Tank-T* Gas tank temperature (˚C)

DCDCV* Converter voltage (V)

DCDCA* Converter current (A)

DCDCW* Converter power (W)

BattV External power supply voltage (V)

*with purchase of optional Spectronik accessories (gas tank, pressure regulator and DC/DC converter)

CHAPTER 3 | OPERATING PROCEDURES

1. Turn OFF your load. The cooling fans will turn faster to cool down the fuel cell, before returning to their

minimum speed.

2. In the GUI, click “end” command or type “end” and <enter> using the keyboard function. Alternatively, press

and hold the ON/OFF push button for more than 2s.

The message “Shutdown Initiated” will appear in the GUI and PROTIUM-1000 will enter its “Shutdown

Phase”. The system is now OFF. LED will blink at 60% on standby awaiting the next start-up command.

3. If you do not intend to restart the system soon, turn OFF your Hydrogen gas supply and remove the

Hydrogen gas tubing from the H2gas inlet connector. Caution: some remaining gas in the tubing will be

released into the atmosphere.

4. Turn OFF the external power supply.

PROTIUM-1000 is now ready to be kept for storage.

3.4 SHUTTING DOWN PROTIUM-1000

The PROTIUM-1000 comes with in-built firmware control that is optimized to bring out its best performance

over the applicable ambient environment range.In normal use-case scenario, there is no need for user to fine-

tune the parameters.For advanced user who wishes to control the fuel cell manually, the following commands

can be entered via Hyperterminal or the GUI’s keyboard function.

Command PROTIUM-1000 action

start <enter> Starts the system

end <enter> Enters normal shutdown phase

ver <enter> Displays the firmware version

f <enter> Return to automatic cooling fan control

b <enter> Return to automatic oxidant blower control

p <enter> Open the Hydrogen purge valve for 2s. This is useful to remove excess water if

cell flooding is suspected due to decreasing power output.

= (equal) Increase cooling fan speed by 5% (manual control)

-(hyphen) Decrease cooling fan speed by 5% (manual control)

0Increase cooling fan speed by 1% (manual control)

9Decrease cooling fan speed by 1% (manual control)

]Increase oxidant blower speed by 3% (manual control)

[Decrease oxidant blower speed by 3% (manual control)

PROTIUM-1000 has several in-built protections.The LED will flash and error message will appear in the GUI.

Follow the basic troubleshooting guide below.Most errors should be rectified once the suggested corrective

action has been done and the system restarted.

If the error persists, contact support@spectronik.com.

Tip:you may also long press the ON/OFF push button by >2s to turn ON/OFF the system instead of

entering “start” and “end” command via the GUI.

CHAPTER 4 | SYSTEM MONITORING & PROTECTIONS

SYSTEM MONITORING, PROTECTIONS &

MANUAL CONTROL

4

4.1 MANUALLY CONTROLLING THE PROTIUM-1000

4.2 SYSTEM WARNING &PROTECTIONS

Message Meaning/ Corrective Action

"Gas Tank Not Detected"*Either the gas tank communication cable is not

connected or the tank is empty.

"Gas Tank Pressure Low" *There is less than 20 Bar remaining in the gas tank.

"Gas Tank Insufficient Pressure" *◉There is not enough pressure in the gas tank to start.

"Error: Gas Tank at High Temperature" *◉The Gas Tank internal temperature is above 60℃.

Please check for abnormalities.

"Low H2 Supply"

Hydrogen supply pressure is low and the system will wait

up to 1min for correction. Please check and correct the

delivery pressure.

"Error: Low H2 Supply" ◉

Hydrogen is not correctly supplied within the stipulated

time limit. Check and ensure sufficient Hydrogen supply

and correct delivery pressure. Restart the system.

"Over Pressure" Hydrogen supply pressure is too high and the system will

wait for 1min. Reduce the delivery pressure.

"Error: Over Pressure" ◉

Hydrogen is not properly supplied within the stipulated

time limit. Check and ensure sufficient Hydrogen supply

and correct delivery pressure. Restart the system.

"High Temperature" Stack temperature is too high and the system

will wait for 1min.

"Error: High Temperature" ◉

Disconnect everything and wait for system to cool down

and restart after 10min. If the problem persists, internal

temperature sensor might have been compromised.

Contact Spectronik.

"Error: FC Over Cooled" ◉Stack temperature is too low. Wait for ambient

temperature to increase and restart the system.

"FC Sealing Compromised" ◉Possible stack leakage. Check and ensure all gas tubing

and connectors are securely connected.

"Error: Low Voltage" ◉

Stack open circuit voltage is too low. Check and ensure

sufficient hydrogen supply and correct delivery pressure.

Restart after 1 min.

◉Emergency Shutdown = "Abnormal Shutdown" would be activated

*with purchase of optional Spectronik accessories (gas tank and pressure regulator)

Warning messages during “Starting Phase”:

CHAPTER 4 | SYSTEM MONITORING & PROTECTIONS

4.2 SYSTEM WARNING &PROTECTIONS (Cont.)

Message Meaning/ Corrective Action

"High Temperature" ●

Stack temperature is too high. The fuel cell power output

to load will be temporarily disconnected for 5s for system

to recover. LED will blink. Reduce your load.

"Error: High Temperature" ◉

Stack temperature is too high. Disconnect everything and

wait for system to cool down and restart after 10min. If the

problem persists, internal temperature sensor might have

been compromised. Contact Spectronik.

"Low Temperature" ●Stack temperature is low. LED will blink.

"Error: FC Over Cooled" ◉Stack temperature is too low for operation.

"Low Voltage" ●Stack Voltage at minimum threshold of 0.6V/cell.

"Error: Low Voltage" ◉Stack Voltage below safety threshold limit.

"Low H2 Supply" ●

Hydrogen supply pressure is low and the fuel cell power

output to load will be temporarily disconnected.

LED will blink. Check and ensure sufficient

Hydrogen supply and correct delivery pressure.

"Error: Low H2 Supply" ◉

Hydrogen supply pressure is too low. Check and ensure

sufficient Hydrogen supply and correct delivery pressure.

Restart the system.

"High H2 Supply Pressure" ●

Hydrogen supply pressure is too high and the supply valve

will be temporarily shut off. LED will blink at 80%.

Reduce the delivery pressure.

"Error: High H2 Supply Pressure" ◉

Hydrogen supply pressure is too high. Check and ensure

sufficient Hydrogen supply and correct delivery pressure.

Restart the system.

"Low Battery" ●The External Power Supply is at below 15V.

"Gas Tank Running Low" *●The pressure in the gas tank is below 20 Bar.

"Gas Tank Depleting" *●The pressure in the gas tank is below 10 Bar.

"Error: Gas Tank at High Temperature" *◉The Gas Tank internal temperature is above 60℃.

Please check for abnormalities.

◉Emergency Shutdown = "Abnormal Shutdown" would be activated

●LED flashing at 80% to alert warning in the running

* with purchase of optional Spectronik accessories (gas tank and pressure regulator)

Warning messages during “Running Phase”:

CHAPTER 4 | SYSTEM MONITORING & PROTECTIONS

4.2 SYSTEM WARNING &PROTECTIONS (Cont.)

Message Meaning

Fan PWM auto Cooling fans control is in auto mode

Blower auto Oxidant blower control is in auto mode

Mileage Cumulative Watt-Hour of the system

Shutdown initiated Entering “Normal Shutdown Phase”

Abnormal Shutdown initiated Entering “Abnormal Shutdown Phase” due to an error

System off System is turned off and ready to restart at the next command

Other messages:

Phase Blink % (at 1Hz) Meaning

Power ON 10%

5s after start-up power is provided into the fuel

cell controller, LED will blink at 10%, indicating

that the system is ready to receive its “start”

command

Starting Phase 40% Executing “Starting Phase” procedures

Running Phase 100% System in normal “Running Phase”

Running Phase 80% System warning during “Running Phase”

After shutdown 60% System off due to normal shutdown and on

standby for the next “start” command

After shutdown 0% System off due to abnormal shutdown

LED status:

CHAPTER 4 | SYSTEM MONITORING & PROTECTIONS

4.2 SYSTEM WARNING &PROTECTIONS (Cont.)

When not in use, Spectronik recommends that PROTIUM-1000 is reconditioned at least once amonth.

1. Set up PROTIUM-1000 as per instructions in Section 3, using aDC electronic load in lieu of your regular load.

2. After the system enters “Running Phase”, set constant voltage (CV) load of 18Vand run the system for 1h.

The fuel cell should recover to its maximum rated power output.

PROTIUM-1000 is now ready for usual operation or can be stored again for future use.

CHAPTER 5 | MAINTENANCE & STORAGE

5MAINTENANCE AND STORAGE

5.1 MAINTENANCE FOR PROTIUM-1000

5.2 STORAGE

Keep PROTIUM-1000 in an open, cool (standard room temperature of 25oC) and dry place.

Table of contents

Other Spectronik Camera Accessories manuals