spectrotec BT2000-AC User manual

GES_Extension-AC_0323

1

Contents

Page

1 Use 1

1.1 Technical data 2

1.2 Labelling 2

2 Safety information 3

3 Installation 4

4 Repairs 5

1 Use

The extension is designed for use with a BT2000-AC or BU13-AC pressure control panel. It

allows the connection of further gas cylinders to an existing supply system.

All stipulations valid for the pressure control panel BT2000-AC and BU13-AC must also be

observed during operation and use of the extensions.

The extensions may only be used for the gas type acetylene.

Note

The materials and production processes used are tailored to the intended use.

All components represent the technical state of the art, comply with the recognised

engineering standards and meet the requirements of the standards and regulations applicable

in this field, in particular the acetylene regulations.

The components are manufactured with the utmost care and under clean conditions in special

workshops, where they are subject to continuous quality controls throughout the production

process.

Each complete system and its individual components are tested for correct functioning and

leak-tightness, thus ensuring compliance with the exacting Spectron quality standards.

Compliance with this instruction manual, and in particular

the safety instructions, is mandatory when handling the articles listed above.

Instruction manual

Extension for

BT2000-AC / BU13-AC

GES_Extension-AC_0323

2

1.1 Technical data

SPECTROTEC

Extensions for acetylene

Max. permissible pressure PV:

max.25 bar

Materials:

Distributor:

brass

Screw fittings and pipe:

zinc-plated steel

Mounting plate:

stainless steel

Weight:

Extension DN5

1.0 kg

Extension DN10

1.9 kg

Connections:

Shut-off unit DN5

Inlet: M16x1,5 / M24x1.5

Outlet: ¼ “ NPT

Shut-off unit DN10

Inlet: G ¾“-LH / M24x1.5

Outlet: ½“ NPT

1.2 Labelling

On the baseplate of the extension, there is a type plate with information on the gas type.

Inspection sticker

Prior to delivery, all extensions undergo a 100% leak and function test. To document this, an

inspection sticker is attached on the mounting plate on the back of each panel.

GES_Extension-AC_0323

3

2 Safety information

2.1 Handling combustible gases

Specialist knowledge is required when handling acetylene, and the instructions in this manual

and existing regulations must be complied with.

Training and regular safety training for operating personnel on the correct procedures for

handling this system, combustible gases and pressurised gas vessels is mandatory and must

be repeated annually. Incorrect handling and/or use of the system can endanger operating

personnel and other persons, and can lead to damage to the system and the surrounding area.

This instruction manual must be available to operating personnel at all times.

2.2 Manifold size and output

The withdrawal rate per acetylene cylinder should not exceed 500 l/h in continuous operation.

This prevents solvent being withdrawn from the cylinders.

For brief periods, the withdrawal quantity can be increased to 1000 l/h.

2.3 Gas-specific design

The extensions may only be used for acetylene. Alternating use for other gases is not permitted.

It is also prohibited to attach adapters to the cylinder connection. The materials and seals have

been selected for gas type "acetylene."

2.4 Resistance of the materials

The resistance of the materials can only be guaranteed with the use of dry gas and if lines and

fittings are dry-purged. Incorrect installation and leaking screw fittings can reduce the service life

of the equipment.

2.5 Regulations, directives, technical specifications

A series of regulations must be observed when installing and operating acetylene cylinder

manifolds. For example, the systems created must comply with the following regulations and

rules.

2.5.1 Accident prevention regulations

BGR 500 (Sections 2.26, 2.31.2.33)

2.5.2 Laws,ordinances,technical regulations

German acetylene ordinance with technical rules for acetylene (TRGS, TRBS,

TRAS) e.g. TRGS 400, 407, 500, 720, 721, 722, 727, etc.

Explosion protection directives Ex RL

Guidelines for the prevention of ignition hazards as a result of electrostatic

charging.

The installation of electrical equipment in potentially explosive atmospheres.

VDE 0170/DIN 57 165

Employers' liability insurance association leaflet on preventing the explosion of

acetylene cylinders.

GES_Extension-AC_0323

4

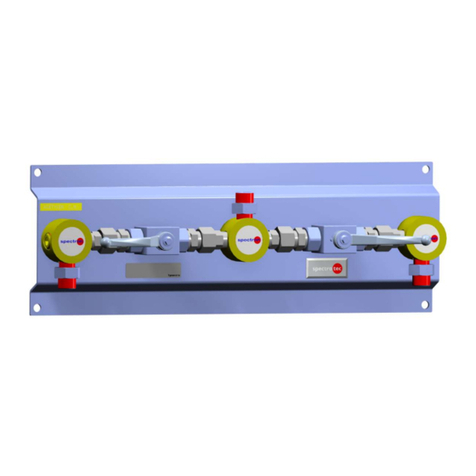

Abb.2

Einseitige Erweiterung DN 10

(Maße für Erweiterung DN 5 in Klammern)

Abb.4

Entspannungsstation BT 2000-AC mit Absperreinheit und beidseitiger Erweiterung DN 5

Abb.3

Entspannungsstation BT 2000-AC mit beidseitiger Erweiterung DN 5

5

6

1

2

3

4

G 3/4"- LH (M16x1,5)

GES_Extension-AC_0323

5

3 Installation

3.1 Installation must be performed by personnel with the requisite expertise and who have

received the appropriate training and instruction on safety engineering.

3.2 All components of the shut-off unit are tested for correct functioning and leak-tightness

prior to delivery. All apertures are closed off.

3.3 Before commencing installation, check that connections and threads are undamaged

(possibly by briefly blowing them out). If damage is ascertained, the extension must not

be connected.

3.4 Remove the sealing plug (not shown here) of the distributor block (2) and screw in the

NPT fitting (3) of the connection pipe (4) in its place. To do this, wrap PTFE tape (Teflon

tape, Part No. 0321422) with 7 times in anti-clockwise direction, leaving the first thread

turn free and pressing the end of the tape down tightly. Screw the parts together so that

the connection is gastight.

3.5 Connect the extension (5) to the pre-assembled connection pipe (4). Here, to ensure

adequate stability of the Ermeto screwed connection, it is essential to tighten the pre-

assembled union nut (6) in a professional procedure.

3.6 Attach the baseplate of the extension (5) and cylinder brackets (not shown here) to the

wall using the screws provided.

3.7 Place the cylinders in front of the bracket and secure with safety chain or strap.

3.8 When all screws, screw fittings and connections have been tightened, slowly supply the

system with gas and carry out leakage testing on all newly installed, gas-bearing

connections.

4 Repairs

4.1 For safety reasons, repairs must be carried out in authorised workshops, by the

manufacturer or suitably qualified personnel.

4.2 Only original spare parts may be used.

4.3 After every repair, the panel must be checked for correct functioning and leak-tightness.

4.4 The manufacturer accepts no liability for repairs not effected in authorised workshops, if

the panels are modified or if non-original spare parts are used, and in such cases, the

warranty is rendered null and void with immediate effect.

4.5 The system should be tested for correct functioning and operational safety once per year

by the manufacturer.

4.6 Annual inspection of the flashback arrestors and other safety devices attached to the

tapping points downstream of the pressure control panel is prescribed by law. The

operator must provide verification of this.

GES_Extension-AC Edition 0323

Subject to change without notice

© Spectron Gas Control Systems GmbH

This manual suits for next models

1

Table of contents

Other spectrotec Control Panel manuals

Popular Control Panel manuals by other brands

Digital Electronics

Digital Electronics GP-377 Series user guide

Siemens

Siemens SIMATIC PP7 Equipment manual

Crystal Vision

Crystal Vision REM1U user manual

Trane

Trane TCONT602AF22MA installation instructions

TyloHelo

TyloHelo PURE 2.0 quick start guide

Cobalt Digital Inc

Cobalt Digital Inc OGCP-9000 product manual