-- 2 --

TOCe

Rights reserved to alter specifications without notice.

1SAFETY 5...........................................................

2 INTRODUCTION 6...................................................

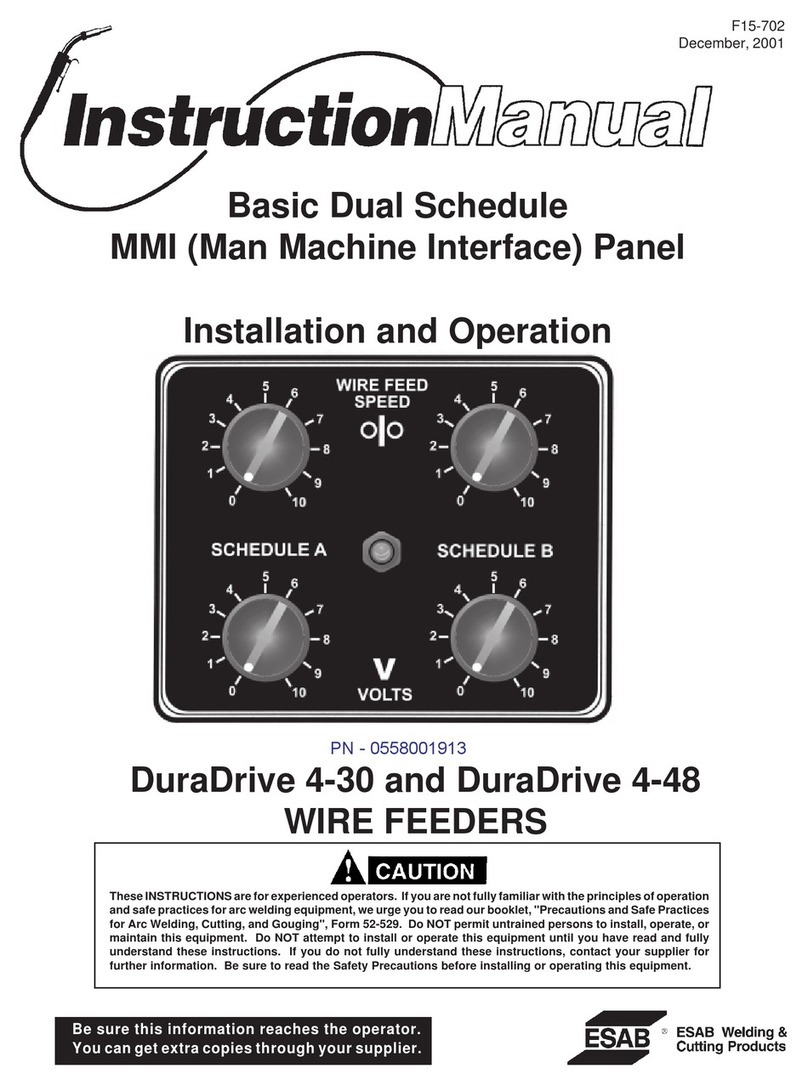

2.1 Control panel Aristo U82 6....................................................

2.1.1 Keys and knobs 6......................................................

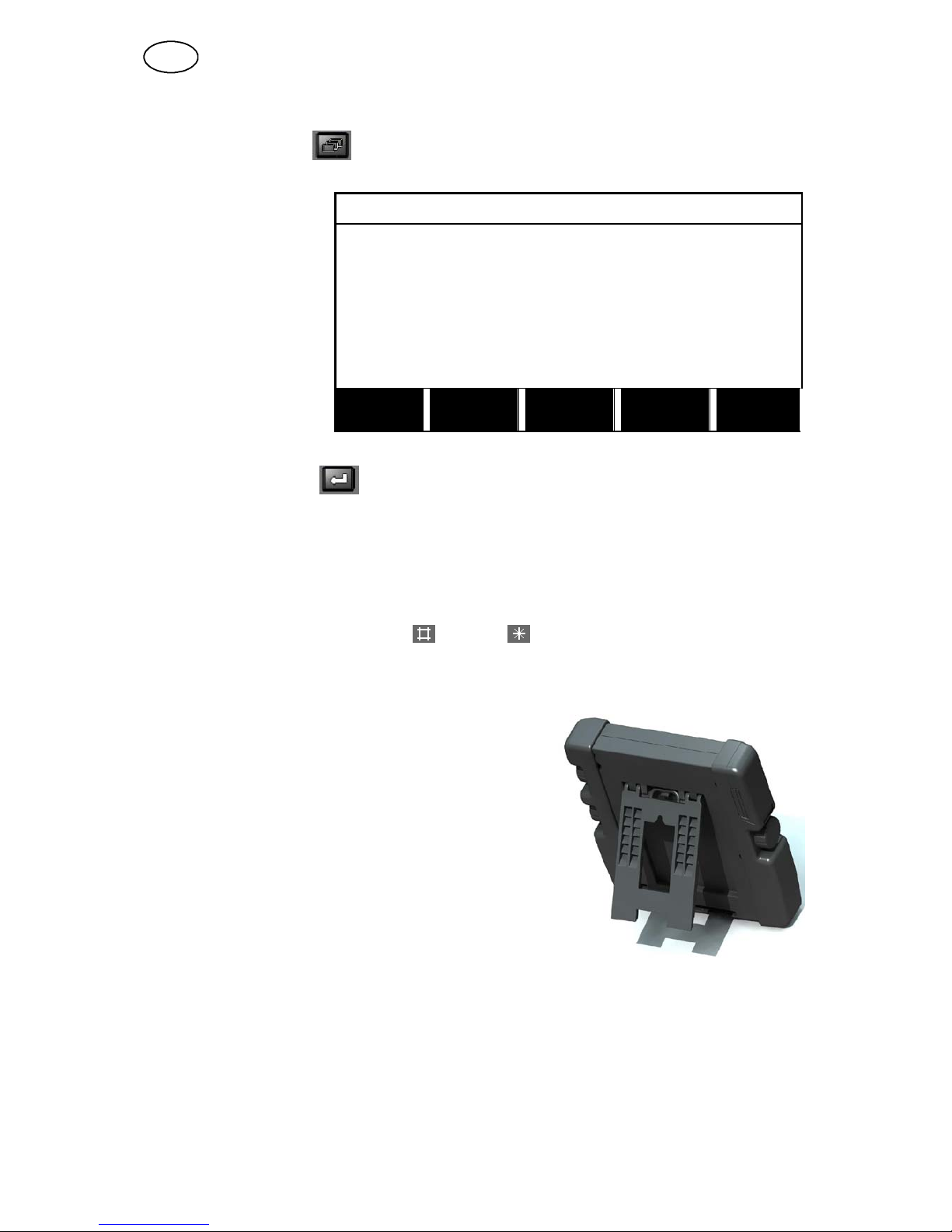

2.2 Location 7..................................................................

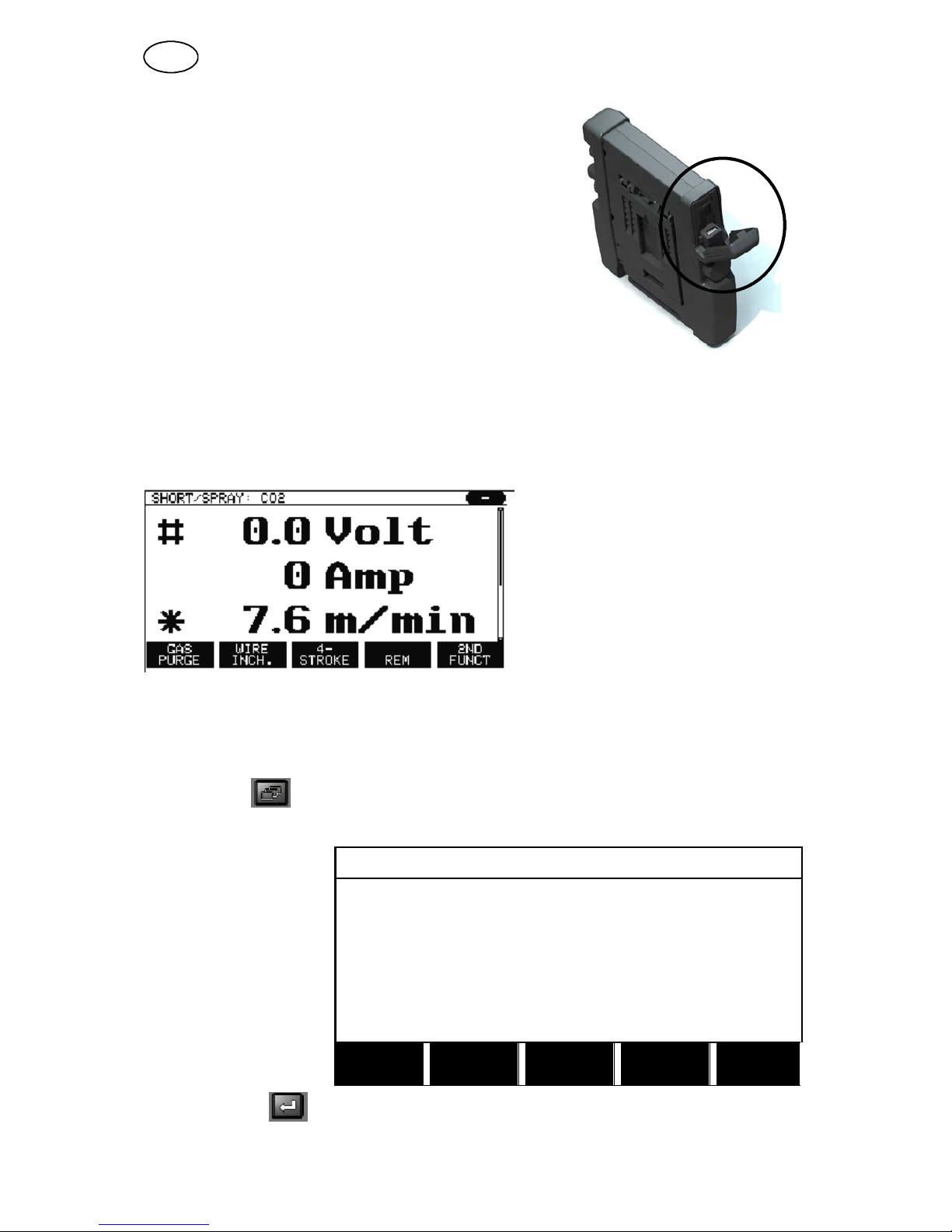

2.3 USB connection 7...........................................................

2.3.1 Insert USB memory 8...................................................

2.4 First step – choice of language 8..............................................

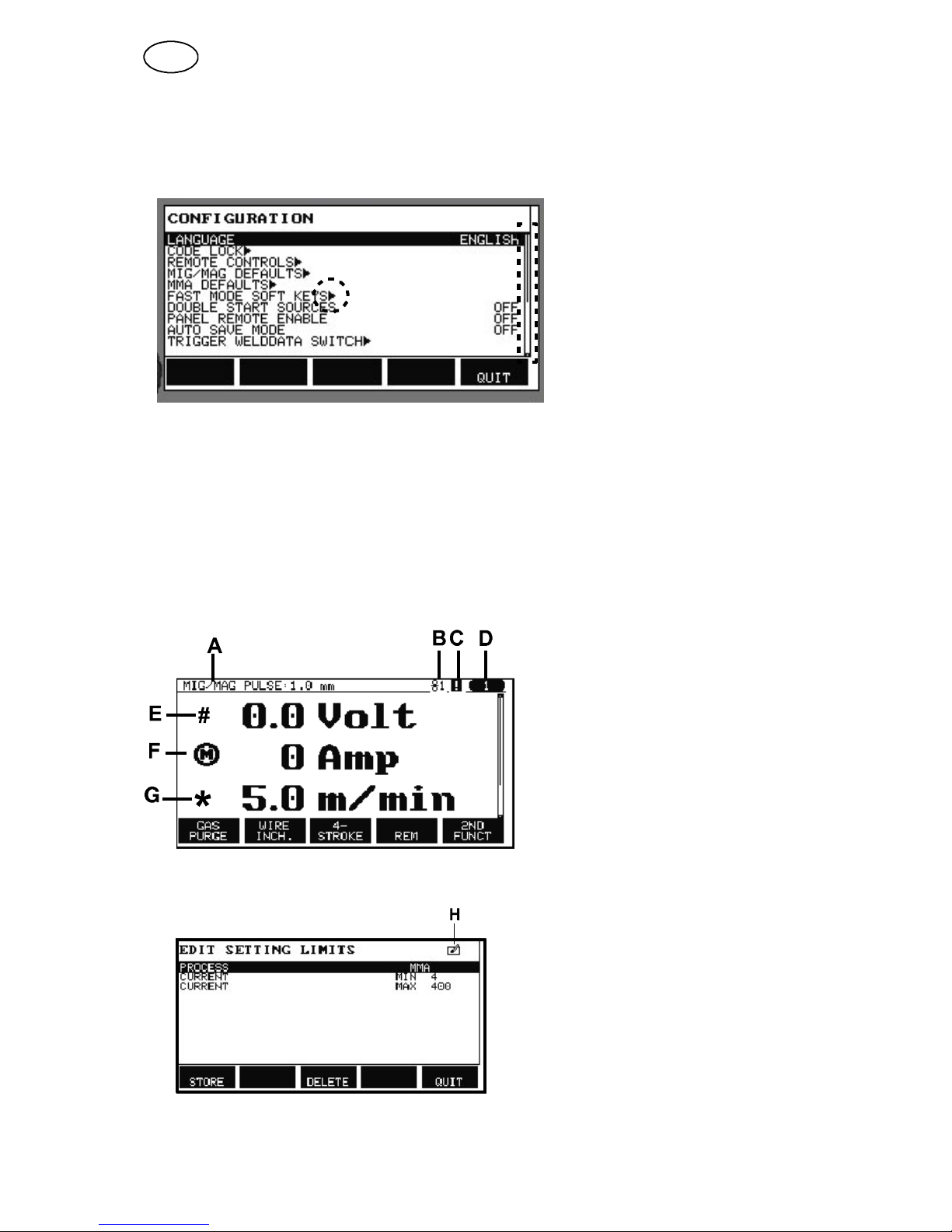

2.5 Display 9...................................................................

2.5.1 Symbols in the display 10.................................................

2.6 General information about settings 11...........................................

2.6.1 Setting of numerical values 11.............................................

2.6.2 Setting with given alternatives 11..........................................

2.6.3 Settings ON/OFF 11.....................................................

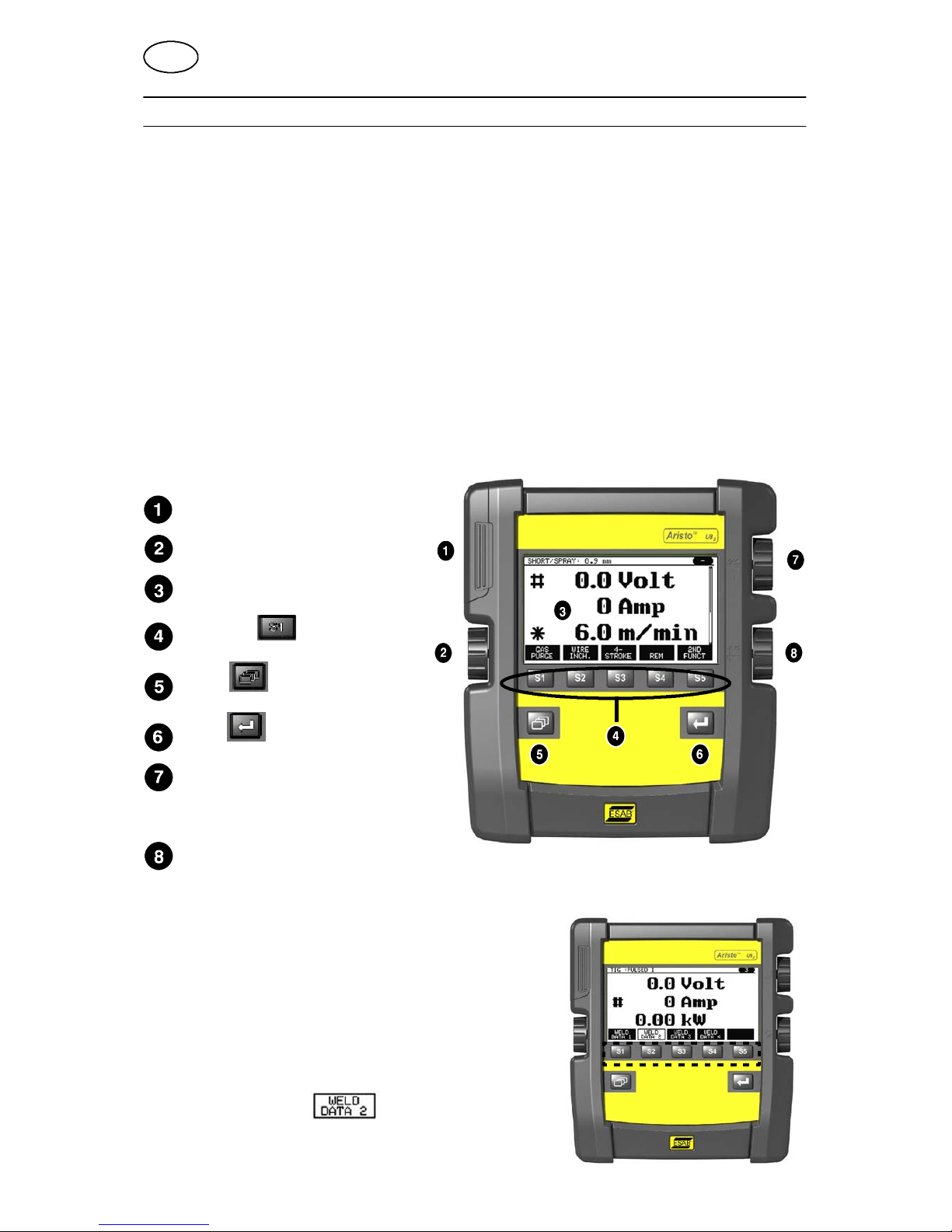

2.6.4 QUIT and ENTER 11.....................................................

3 MENUS 12...........................................................

3.1 Main menu 12...............................................................

3.1.1 Configuration menu 12...................................................

3.1.2 Tools menu 13..........................................................

3.1.3 Weld data setting menu 13................................................

3.1.4 Measure 14.............................................................

3.1.5 Weld data memory meny 14..............................................

3.1.6 Fast mode menu 15......................................................

4 MIG/MAG WELDING 15................................................

4.1 Settings in the weld data setting menu 16........................................

4.1.1 MIG/MAG welding with short--/sprayarc. 16.................................

4.1.2 MIG/MAG welding with pulsing 17.........................................

4.1.3 MIG/MAG welding with SuperPulseä, primary/secondary, short--/sprayarc/pulsing .

18

4.1.4 MIG/MAG welding with QSet 19...........................................

4.2 Function explanations for settings 19............................................

4.3 SuperPulse 24...............................................................

4.3.1 Wire and gas combinations 25.............................................

4.3.2 Different pulsing methods 25..............................................

4.3.3 Wire feed unit 25........................................................

4.4 QSet 27.....................................................................

5 MMA WELDING 27....................................................

5.1 MMA welding DC 27..........................................................

6 TIG WELDING 28.....................................................

6.1 Settings in the weld data setting menu 28........................................

6.1.1 TIG welding without pulsing DC 28.........................................

6.1.2 TIG welding with pulsing DC 29............................................

6.2 Function explanations for settings 29............................................

6.3 Other function explanations 32.................................................

7 ARC AIR GOUGING 33................................................

7.1 Settings in the weld data setting menu 33........................................

7.2 Function explanations 33......................................................